RZ eta-engl Kopie - HOWATHERM

RZ eta-engl Kopie - HOWATHERM

RZ eta-engl Kopie - HOWATHERM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4<br />

Optimized design<br />

The ETA fan system is one of the most<br />

technologically advanced members of our<br />

central AHU range with energy-optimized<br />

drive systems.<br />

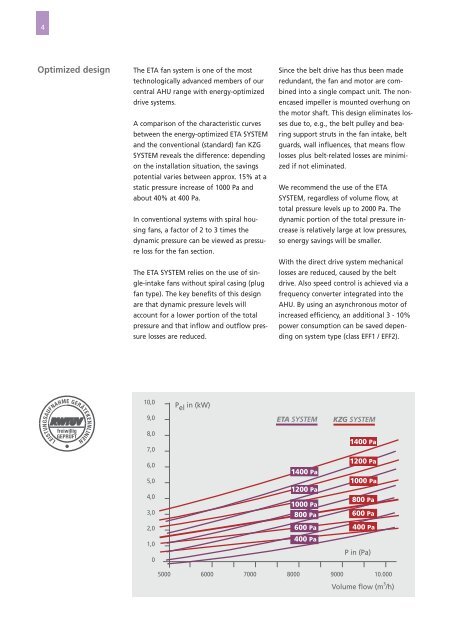

A comparison of the characteristic curves<br />

between the energy-optimized ETA SYSTEM<br />

and the conventional (standard) fan KZG<br />

SYSTEM reveals the difference: depending<br />

on the installation situation, the savings<br />

potential varies between approx. 15% at a<br />

static pressure increase of 1000 Pa and<br />

about 40% at 400 Pa.<br />

In conventional systems with spiral housing<br />

fans, a factor of 2 to 3 times the<br />

dynamic pressure can be viewed as pressure<br />

loss for the fan section.<br />

The ETA SYSTEM relies on the use of single-intake<br />

fans without spiral casing (plug<br />

fan type). The key benefits of this design<br />

are that dynamic pressure levels will<br />

account for a lower portion of the total<br />

pressure and that inflow and outflow pressure<br />

losses are reduced.<br />

Since the belt drive has thus been made<br />

redundant, the fan and motor are combined<br />

into a single compact unit. The nonencased<br />

impeller is mounted overhung on<br />

the motor shaft. This design eliminates losses<br />

due to, e.g., the belt pulley and bearing<br />

support struts in the fan intake, belt<br />

guards, wall influences, that means flow<br />

losses plus belt-related losses are minimized<br />

if not eliminated.<br />

We recommend the use of the ETA<br />

SYSTEM, regardless of volume flow, at<br />

total pressure levels up to 2000 Pa. The<br />

dynamic portion of the total pressure increase<br />

is relatively large at low pressures,<br />

so energy savings will be smaller.<br />

With the direct drive system mechanical<br />

losses are reduced, caused by the belt<br />

drive. Also speed control is achieved via a<br />

frequency converter integrated into the<br />

AHU. By using an asynchronous motor of<br />

increased efficiency, an additional 3 - 10%<br />

power consumption can be saved depending<br />

on system type (class EFF1 / EFF2).