Laser Drilling Enables Advanced Drug Delivery Systems - Coherent

Laser Drilling Enables Advanced Drug Delivery Systems - Coherent

Laser Drilling Enables Advanced Drug Delivery Systems - Coherent

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

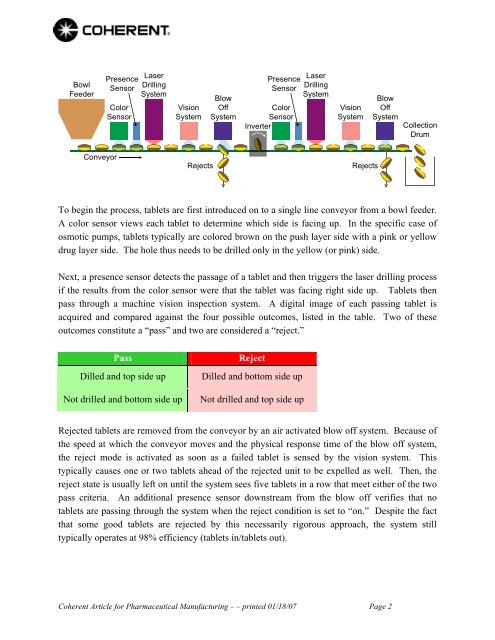

Bowl<br />

Feeder<br />

Conveyor<br />

Presence<br />

Sensor<br />

Color<br />

Sensor<br />

<strong>Laser</strong><br />

<strong>Drilling</strong><br />

System<br />

Vision<br />

System<br />

Rejects<br />

Blow<br />

Off<br />

System<br />

Presence<br />

Sensor<br />

Color<br />

Sensor<br />

Inverter<br />

<strong>Laser</strong><br />

<strong>Drilling</strong><br />

System<br />

Vision<br />

System<br />

Rejects<br />

Blow<br />

Off<br />

System<br />

Collection<br />

Drum<br />

To begin the process, tablets are first introduced on to a single line conveyor from a bowl feeder.<br />

A color sensor views each tablet to determine which side is facing up. In the specific case of<br />

osmotic pumps, tablets typically are colored brown on the push layer side with a pink or yellow<br />

drug layer side. The hole thus needs to be drilled only in the yellow (or pink) side.<br />

Next, a presence sensor detects the passage of a tablet and then triggers the laser drilling process<br />

if the results from the color sensor were that the tablet was facing right side up. Tablets then<br />

pass through a machine vision inspection system. A digital image of each passing tablet is<br />

acquired and compared against the four possible outcomes, listed in the table. Two of these<br />

outcomes constitute a “pass” and two are considered a “reject.”<br />

Pass Reject<br />

Dilled and top side up Dilled and bottom side up<br />

Not drilled and bottom side up Not drilled and top side up<br />

Rejected tablets are removed from the conveyor by an air activated blow off system. Because of<br />

the speed at which the conveyor moves and the physical response time of the blow off system,<br />

the reject mode is activated as soon as a failed tablet is sensed by the vision system. This<br />

typically causes one or two tablets ahead of the rejected unit to be expelled as well. Then, the<br />

reject state is usually left on until the system sees five tablets in a row that meet either of the two<br />

pass criteria. An additional presence sensor downstream from the blow off verifies that no<br />

tablets are passing through the system when the reject condition is set to “on.” Despite the fact<br />

that some good tablets are rejected by this necessarily rigorous approach, the system still<br />

typically operates at 98% efficiency (tablets in/tablets out).<br />

<strong>Coherent</strong> Article for Pharmaceutical Manufacturing – – printed 01/18/07 Page 2