Laser Drilling Enables Advanced Drug Delivery Systems - Coherent

Laser Drilling Enables Advanced Drug Delivery Systems - Coherent

Laser Drilling Enables Advanced Drug Delivery Systems - Coherent

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Laser</strong> Power<br />

Usable<br />

Cutting<br />

Energy<br />

Cutting<br />

Threshold<br />

Power<br />

0 100 200 300 400<br />

Time (microseconds)<br />

Flowing Gas <strong>Laser</strong><br />

<strong>Laser</strong> Power<br />

Usable<br />

Cutting<br />

Energy<br />

Cutting<br />

Threshold<br />

Power<br />

0 100 200 300 400<br />

Time (microseconds)<br />

Slab Discharge <strong>Laser</strong><br />

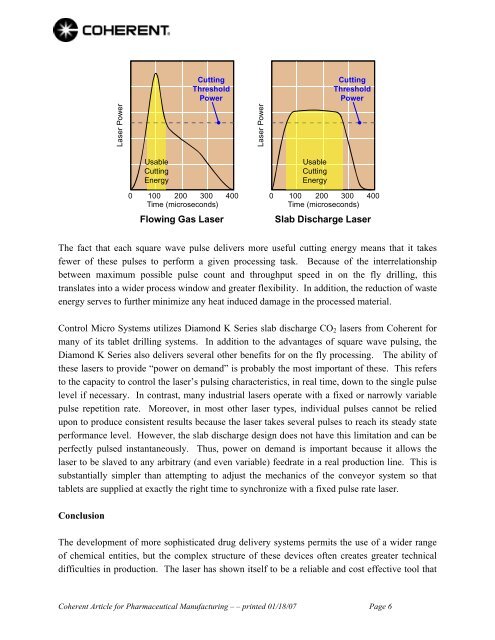

The fact that each square wave pulse delivers more useful cutting energy means that it takes<br />

fewer of these pulses to perform a given processing task. Because of the interrelationship<br />

between maximum possible pulse count and throughput speed in on the fly drilling, this<br />

translates into a wider process window and greater flexibility. In addition, the reduction of waste<br />

energy serves to further minimize any heat induced damage in the processed material.<br />

Control Micro <strong>Systems</strong> utilizes Diamond K Series slab discharge CO2 lasers from <strong>Coherent</strong> for<br />

many of its tablet drilling systems. In addition to the advantages of square wave pulsing, the<br />

Diamond K Series also delivers several other benefits for on the fly processing. The ability of<br />

these lasers to provide “power on demand” is probably the most important of these. This refers<br />

to the capacity to control the laser’s pulsing characteristics, in real time, down to the single pulse<br />

level if necessary. In contrast, many industrial lasers operate with a fixed or narrowly variable<br />

pulse repetition rate. Moreover, in most other laser types, individual pulses cannot be relied<br />

upon to produce consistent results because the laser takes several pulses to reach its steady state<br />

performance level. However, the slab discharge design does not have this limitation and can be<br />

perfectly pulsed instantaneously. Thus, power on demand is important because it allows the<br />

laser to be slaved to any arbitrary (and even variable) feedrate in a real production line. This is<br />

substantially simpler than attempting to adjust the mechanics of the conveyor system so that<br />

tablets are supplied at exactly the right time to synchronize with a fixed pulse rate laser.<br />

Conclusion<br />

The development of more sophisticated drug delivery systems permits the use of a wider range<br />

of chemical entities, but the complex structure of these devices often creates greater technical<br />

difficulties in production. The laser has shown itself to be a reliable and cost effective tool that<br />

<strong>Coherent</strong> Article for Pharmaceutical Manufacturing – – printed 01/18/07 Page 6