Yacht Design Newsletter 3 - BMT Group

Yacht Design Newsletter 3 - BMT Group

Yacht Design Newsletter 3 - BMT Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Issue 3 | Summer 2008<br />

<strong>Yacht</strong> <strong>Design</strong> <strong>Newsletter</strong><br />

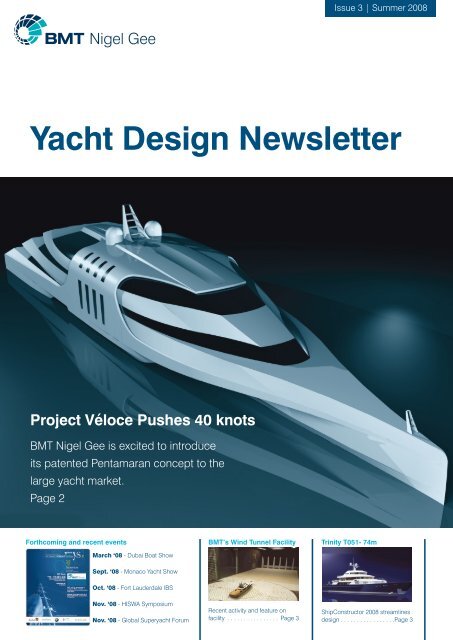

Project Véloce Pushes 40 knots<br />

<strong>BMT</strong> Nigel Gee is excited to introduce<br />

its patented Pentamaran concept to the<br />

large yacht market .<br />

Page 2<br />

Forthcoming and recent events <strong>BMT</strong>’s Wind Tunnel Facility Trinity T051- 74m<br />

March ‘08 - Dubai Boat Show<br />

Sept. ‘08 - Monaco <strong>Yacht</strong> Show<br />

Oct. ‘08 - Fort Lauderdale IBS<br />

Nov. ‘08 - HISWA Symposium<br />

Nov. ‘08 - Global Superyacht Forum<br />

Recent activity and feature on<br />

facility . . . . . . . . . . . . . . . . Page 3<br />

ShipConstructor 2008 streamlines<br />

design . . . . . . . . . . . . . . . . .Page 3

Welcome<br />

The last 12 months has delivered ever more diverse and challenging projects that have seen our<br />

workload grow further. Indeed our offices have expanded further in the last year and now span<br />

four floors at our base in Southampton.<br />

To keep a pace with this growth we continue to seek and employ some of the best engineers the industry has to offer as well as support those<br />

in education via <strong>BMT</strong>’s excellent bursary and recruitment program .Whilst current work load is our main point of focus we maintain our look to<br />

the future with internal research and development studies which have resulted in some new and innovative concepts . Our patented Pentamaran<br />

concept is one such example .<br />

However design is not our only skill and <strong>BMT</strong>’s consultancy continues to provide a broad range of services to the industry . Our wind tunnel facility<br />

at Teddington in the UK has been busy testing a number of yacht projects in the last 12 months and a full feature on the facility can be found in<br />

this edition . Additionally <strong>BMT</strong>’s SMARTPOWER system is featured, which is helping maximize the fuel efficiency of numerous vessels worldwide .<br />

2<br />

Current Projects<br />

130m Motor <strong>Yacht</strong> Concept <strong>Design</strong><br />

120m Motor <strong>Yacht</strong> Consultancy<br />

95m Diesel Motor <strong>Yacht</strong> Detail <strong>Design</strong><br />

85m Diesel Motor <strong>Yacht</strong> Detail <strong>Design</strong><br />

80m Swath <strong>Yacht</strong> Concept <strong>Design</strong><br />

74m Diesel Motor <strong>Yacht</strong> Full <strong>Design</strong><br />

73m Motor <strong>Yacht</strong> Concept <strong>Design</strong><br />

73m Diesel Motor <strong>Yacht</strong> Plan Approval<br />

70m <strong>Yacht</strong> Support Cat Class <strong>Design</strong><br />

43m Catamaran Class <strong>Design</strong><br />

43m Motor <strong>Yacht</strong> Concept <strong>Design</strong><br />

Open 60 Consultancy<br />

Project Véloce Pushes 40 knots<br />

<strong>BMT</strong> Nigel Gee is excited to introduce its<br />

patented Pentamaran concept to the large<br />

yacht market . Developed for high speed<br />

applications the Pentamaran hull form<br />

is a derivative of the stabilised monohull<br />

concept featuring a long slender central<br />

hull, hydrodynamically optimised without<br />

the constraints of needing to be stable .<br />

Stability is then provided by two pairs of<br />

outriggers or ‘sponsons’ . Conventional<br />

stabilised monohulls typically require<br />

relatively deeply immersed and long<br />

sponsons to meet damaged stability<br />

requirements and these can incur<br />

significant resistance penalties . The<br />

Pentamaran overcomes this by having<br />

two pairs of sponsons; a very short and<br />

shallow pair aft and a forward pair clear<br />

of the static water surface . These forward<br />

sponsons only become immersed as<br />

the vessel heels, consequently stability<br />

characteristics are maintained with no<br />

resistance penalty . The Pentamaran<br />

offers a wide bodied stable platform with<br />

outstanding seakeeping characteristics<br />

whilst retaining minimum speed loss in<br />

higher sea states .<br />

<strong>BMT</strong> Nigel Gee has undertaken some<br />

US$5 million worth of testing on numerous<br />

Pentamaran designs and the technology<br />

is now fully mature .<br />

Project Véloce is based on a 130m<br />

platform capable of over 40 knots . The<br />

beam of 30m offers significantly more<br />

internal area than on an equivalently sized<br />

monohull leading to exceptional internal<br />

spaces with true flexibility in configuration<br />

of the layout .<br />

The propulsion system features a<br />

CODOG (Combined Diesel Or Gas)<br />

plant producing approximately 44MW<br />

of installed propulsive power delivered<br />

via waterjets offering outstanding<br />

manoeuvrability and acceleration . For<br />

low and medium speed operation twin<br />

20V8000 diesels are utilised providing<br />

efficient long range operation whilst for<br />

sprint speeds a single LM2500+ pushes<br />

the speed beyond 40 knots .<br />

Project Véloce represents a truly<br />

innovative application of technology in the<br />

large yacht market . Further development<br />

of this design is currently underway .<br />

Principal Particulars<br />

LOA 130m<br />

Bmax 30m<br />

Draught 5m<br />

Propulsion LM2500+, 2x MTU 20V8000<br />

Speed 40 knots<br />

Range 3500nm at 20 knots

Trinity <strong>Yacht</strong>s Signed to <strong>BMT</strong><br />

When Trinity <strong>Yacht</strong>s signed<br />

their largest project to date<br />

they came to <strong>BMT</strong> Nigel Gee<br />

for the design. This striking<br />

vessel styled by Evan Marshall<br />

is at an advanced stage<br />

of construction at Trinity’s<br />

Gulfport shipyard.<br />

<strong>Design</strong> Work on the 74m T051 (M/Y New Horizon) started in May of 2007 and<br />

<strong>BMT</strong> Nigel Gee immediately undertook the design and optimisation of the hull<br />

lines . Extensive model testing undertaken at Oceanic in Newfoundland verified<br />

the excellent resistance and seakeeping characteristics that had been predicted .<br />

<strong>BMT</strong>’s scope included the enhancement of the initial concept, class level and<br />

detailed production design utilising ShipConstructor software . A unit build<br />

philosophy has been adopted specifically tailored to enable Trinity to begin<br />

construction at the earliest stage .<br />

Having operated with ShipConstructor since 1998, <strong>BMT</strong> has extensive<br />

experience in getting the best results from the software . Recent implementation<br />

of the latest release (2008) has enabled <strong>BMT</strong> to further streamline its detail<br />

production design process and reduce delivery times by taking advantage of<br />

the software’s latest features . Together with the 3D pipe work and duct routing<br />

package, also from ShipConstructor, <strong>BMT</strong> are supplying another complete and<br />

fully integrated detailed production design project .<br />

<strong>BMT</strong> Wind Tunnel<br />

<strong>BMT</strong>’s wind tunnel facility, located in<br />

Teddington, has undertaken a number of large<br />

yacht projects in the last few months including<br />

assessment and optimisation studies for an<br />

85m and 76m design.<br />

<strong>BMT</strong> Fluid Mechanics operates 3 major test facilities which<br />

consist of a very large boundary layer wind tunnel suitable for<br />

testing complete designs, a short test section wind tunnel with a<br />

relatively high test speed used for model tests of 2-D structures<br />

such as aerofoil sections, and a racecar/automotive wind tunnel<br />

which has been responsible for 110 Grand Prix Wins and 7<br />

Constructor Championships for McLaren between 1982 and<br />

2002 .<br />

Utilising its very broad experience in the aerodynamics of<br />

marine vessels, <strong>BMT</strong> can offer cost effective investigation and<br />

optimisation studies including;<br />

• Wind and current forces<br />

• Deck level wind environment<br />

• Helideck wind environment (wind gradients and turbulence)<br />

• Funnel emissions and exhaust plume dispersion<br />

• Assessment of temperature profiles<br />

• Ventilation in enclosed/open areas to verify ventilation strategies<br />

The key facility for undertaking these studies is the boundary<br />

layer tunnel which is of a closed return type with a 4 .8m x<br />

2 .4m working section . Capable of simulating full atmospheric<br />

boundary layer conditions a wind speed range between 0 .2<br />

80m Engine Room ShipConstructor model<br />

to 45 m/s can be achieved . These facilities are supported by<br />

comprehensive data acquisition and instrumentation systems .<br />

Additionally the company utilises Computational Fluid Dynamics<br />

(CFD) for modeling internal and external flows that are not<br />

reliably modeled at reduced scale in a physical model test . In<br />

these cases the wind tunnel is used to provide reliable boundary<br />

conditions for the CFD simulations .<br />

With the recent amendments to the LY2 requirements for<br />

helicopter decks on yachts there is an increasing need for more<br />

fundamental aerodynamic studies to be undertaken and <strong>BMT</strong><br />

has significant experience and capability in the assessment of<br />

marine helidecks for operability and compliance with national<br />

and international guidelines . Importantly <strong>BMT</strong> has played a key<br />

role in recent Civil Aviation Authority research to enhance the<br />

safety of marine helicopter operations and has also played a<br />

key role in the framing of certification requirements and design<br />

guidance .<br />

3

Smart <strong>Yacht</strong>s Use SMART POWER<br />

A yacht’s operating efficiency is the sum of the engine, propeller and hull efficiencies. For a<br />

yacht to operate at its most economic the prudent and environmentally conscious owner will<br />

wish to be able to quantify the effects of negative parameters on the performance, such as hull<br />

fouling, in order to optimise the period between hull or propeller cleaning.<br />

SMART POWER is an advanced real time yacht performance monitoring and analysis tool. Utilising<br />

touch-screen technology, the system continuously records the yacht’s speed, fuel consumption,<br />

shaft rpm and torque together with navigational and environmental parameters in order to<br />

present performance trends over time and help to identify remedial measures.<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>BMT</strong> Regatta<br />

In early June <strong>BMT</strong> Nigel Gee held a company regatta racing<br />

off the Bramble Bank in the Solent. Chartering a fleet of nine<br />

Hunter Sonar’s from the Island Sailing Club in Cowes the<br />

event was blessed with champagne conditions. Entries from<br />

<strong>BMT</strong> SeaTech and <strong>BMT</strong> Isis were also in the fleet and spring<br />

tides demanded that consistent results and sound tactics were<br />

essential to win the six race regatta.<br />

The day started with a moderate northerly breeze and a series of windward leeward’s<br />

were set by the race committee . Mischief, helmed by <strong>BMT</strong> Nigel Gee Project Manager<br />

Matt Curthoys, sailed a consistent opening<br />

half taking three firsts . After lunch the<br />

south westerly sea breeze kicked in and<br />

the results became more evenly spread<br />

but Mischief held on to her lead to win the<br />

regatta by a narrow margin .<br />

A similar regatta will be run in 2009 and will<br />

include entries from our customers .<br />

4<br />

By providing the information to assess<br />

the yacht’s performance trends over time,<br />

SMARTPOWER can help improve overall<br />

operating efficiency by assisting the yacht’s<br />

master and engineers in:<br />

Reducing fuel consumption<br />

Increasing operating speed<br />

Educating crew in the factors affecting speed/fuel<br />

consumption<br />

Timely main engine repair /operation<br />

Optimising periods between hull and propeller cleaning<br />

Assessing alternative paint strategies<br />

If you think you have<br />

what it takes to mount<br />

a challenge for the<br />

“Mainsail Cup” please<br />

get in touch!<br />

SMARTPOWER features include…<br />

• Continuous readings of the instantaneous;<br />

• Shaft powers<br />

• RPM<br />

• <strong>Yacht</strong> speed<br />

• Wind speed and direction<br />

• Ship’s heading<br />

• Fuel flow rates<br />

• Graphical comparison of instantaneous and historical data<br />

(ship’s speed, shaft power, fuel consumption etc .)<br />

• Graphical trends of ship speed v .s power over time<br />

(highlighting fluctuations in draught, trim and possible hull<br />

fouling or propeller degradation) .<br />

Plan<br />

Approval<br />

Services<br />

<strong>BMT</strong> have recently been<br />

appointed to undertake<br />

plan approval on a series<br />

of large (>70m) twin screw<br />

motor yachts.<br />

The diverse skills of the group allow a<br />

comprehensive service to be offered,<br />

all coordinated through <strong>BMT</strong> Nigel<br />

Gee . Detailed plan approval for<br />

structural, mechanical and electrical<br />

systems are being undertaken within<br />

a demanding time frame and cover<br />

specification<br />

compliance,<br />

class and flag<br />

requirements<br />

and best<br />

practice .<br />

<strong>BMT</strong> Nigel Gee Ltd<br />

Tel: +44 (0)23 8022 6655<br />

Fax: +44 (0)23 8022 8855<br />

email: enquiries@bmtyachts .com<br />

www .bmtyachts .com