Wing Kam Liu* and Wei Chen, Northwestern University ... - SAMSI

Wing Kam Liu* and Wei Chen, Northwestern University ... - SAMSI

Wing Kam Liu* and Wei Chen, Northwestern University ... - SAMSI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

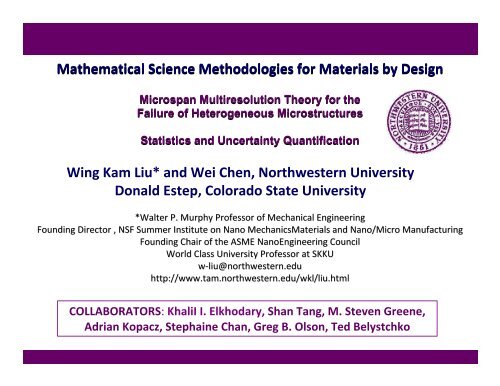

Mathematical Science Methodologies for Materials by Design<br />

Microspan Multiresolution Theory for the<br />

Failure of Heterogeneous Microstructures<br />

Statistics <strong>and</strong> Uncertainty Quantification<br />

<strong>Wing</strong> <strong>Kam</strong> <strong>Liu*</strong> <strong>and</strong> <strong>Wei</strong> <strong>Chen</strong>, <strong>Northwestern</strong> <strong>University</strong><br />

Donald Estep, Colorado State <strong>University</strong><br />

*Walter P. Murphy Professor of Mechanical Engineering<br />

Founding Director , NSF Summer Institute on Nano MechanicsMaterials <strong>and</strong> Nano/Micro Nano/Micro<br />

Manufacturing<br />

Founding Chair of the ASME NanoEngineering Council<br />

World Class <strong>University</strong> Professor at SKKU<br />

w‐liu@northwestern.edu<br />

liu@northwestern.edu<br />

http://www.tam.northwestern.edu/wkl/liu.html<br />

http:// www.tam.northwestern.edu/wkl/liu.html<br />

COLLABORATORS: KhaliI I. Elkhodary, Shan Tang, M. Steven Greene,<br />

Adrian Kopacz, Stephaine Chan, Greg B. Olson, Ted Belystchko

Objectives<br />

Mathematical Science (Multiresolution Mesoscale<br />

Continuum) Methodologies for the Analysis <strong>and</strong> Design of<br />

Multiscale/Multirate Microstructured Materials<br />

•Facilitate the extraction of structure/property/performance<br />

metrics for multiscale/multirate materials design<br />

•Predictive dynamic modeling of fracture nucleation <strong>and</strong><br />

propagation due to contributions from all COUPLED scales<br />

•Set up an approach that is valid across materials systems,<br />

that is MATERIALS GENERIC field equations, <strong>and</strong> MATERIALS SPECIFIC<br />

coupled multiscale constitutive laws<br />

•Uncertainty Sources <strong>and</strong> Quantification<br />

•Wish List for Multiscale Methodologies <strong>and</strong> UQ Discussions Topics

Multiresolution Modeling Scope: Processing/Structure/Property

Mathematical Science Foundation<br />

Mathematically link spatial <strong>and</strong> temporal scales for continuous resolution of a<br />

microstructure<br />

Separate Data by Scales<br />

with Help from<br />

Materials Science<br />

Quantification &<br />

Variability of Data<br />

Sets<br />

Scale 1<br />

Data<br />

Refined<br />

Scale 1<br />

Data<br />

Large Stochastic,<br />

Multi-Scale Data Set<br />

Scale 2<br />

Data<br />

Refined<br />

Scale 2<br />

Data<br />

…<br />

…<br />

…<br />

Scale n<br />

Data<br />

Refined<br />

Scale n<br />

Data

Mathematical Science Foundation, Continued<br />

Reconstruction<br />

of Data Set<br />

Scale linking via testing <strong>and</strong> characterization of samples.<br />

Refined<br />

Scale 1<br />

Data<br />

Scale<br />

Link<br />

Refined<br />

Scale 2<br />

Data<br />

Refined Data in Order of Scale<br />

Refined<br />

Scale n<br />

Data<br />

Keep in mind that the data is in 4D, (x,y,z,t), so the spatial <strong>and</strong> temporal<br />

resolution axes are the 5 th <strong>and</strong> 6 th dimensions. Now the microstructure is<br />

shown in continuous resolution.<br />

To represent the stochastic nature of the data, another dimension will be<br />

added for each parameter with an axis as the variance of that parameter.<br />

…<br />

Scale<br />

Link<br />

Resolution<br />

Axes

Multiresolution Concept<br />

t0<br />

t<br />

f<br />

Macroscale Demonstration<br />

Ice “Reinforced” Ice<br />

Dropped Dropped<br />

Newspaper<br />

Fine resolution<br />

material morphology<br />

Structure dictates the bulk<br />

properties<br />

Properties dictate the bulk<br />

performance

Multiresolution Concept: zoom into a microstructure in the same way that<br />

modern satellite technology allows us to zoom into an image of the earth<br />

a.<br />

Small Number of pixels<br />

per km 2 – suitable for a<br />

global image<br />

TiC<br />

~5 um<br />

0<br />

u<br />

Small Number of<br />

degrees of freedom –<br />

suitable for average<br />

behavior<br />

b.<br />

Increasing Image Resolution<br />

More resolution – cities<br />

can be observed<br />

1<br />

u<br />

Discrete behavior of TiN<br />

primary inclusions<br />

begins to be observed<br />

Increasing Constitutive Resolution<br />

c. d.<br />

Increasing resolution –<br />

buildings can be observed<br />

~1 um ~0.1 um 10 nm<br />

u<br />

Discrete behavior of<br />

TiC secondary<br />

particles is observed<br />

2<br />

<strong>Northwestern</strong> <strong>University</strong><br />

- a fine institution<br />

Macro Micro TiN Sub-Micro TiC Nano<br />

3<br />

u<br />

Very fine resolution – material<br />

interface is observed

Polymer Nanocomposite Material Design<br />

Goals.<br />

(1) Increase transportation materials performance,<br />

(2) ballistic protection, <strong>and</strong><br />

(3) fracture toughness<br />

Atomic bonds visible Aggregated structure,<br />

interface morphology<br />

clear<br />

R<strong>and</strong>om atomic<br />

phase-space<br />

R<strong>and</strong>om secondary<br />

microstructure,<br />

interface morphology<br />

Filler network visible,<br />

detailed shape<br />

information lost<br />

R<strong>and</strong>om aggregation,<br />

mesostructure<br />

Design materials: multiple monomers, fillers, interphase, interface<br />

Filler shape invisible,<br />

statistical homogeneity<br />

R<strong>and</strong>om primary<br />

substructure, statistic<br />

homogeneity<br />

Increasing resolution, decreasing spatial scale, increasing uncertainty<br />

Experiments at various spatial <strong>and</strong> temporal scales <strong>and</strong> its statistical analysis are important<br />

Homogeneous medium<br />

R<strong>and</strong>om operating<br />

conditions<br />

Co-polymer design, interface <strong>and</strong> interphase design, experimental imaging at various scales (V2, V1)<br />

The above is for matrix materials, now we need to add in structural materials to become polymer<br />

matrix composites

High Strength Alloy Analysis & Uncertainty<br />

Goal. Deliver high strength alloys for transportation applications<br />

Primary ( microns) <strong>and</strong> Secondary (tens of nanometers) particles design to control strength & toughness<br />

Quantum-scale design of interfacial strengths between particles <strong>and</strong> matrix<br />

R<strong>and</strong>om operating<br />

(boundary) conditions<br />

TiC<br />

Small Number of degrees<br />

of freedom – suitable for<br />

average behavior<br />

Primary microstructure<br />

r<strong>and</strong>om<br />

~5 μm ~1 μm ~0.1 μm 10 nm<br />

Discrete behavior of TiN<br />

primary inclusions begins<br />

to be observed<br />

Secondary microstructure<br />

r<strong>and</strong>om<br />

Macro Micro TiN Sub-Micro TiC Sub-Nano<br />

Increasing resolution, decreasing spatial scale, increasing uncertainty<br />

Discrete behavior of TiC<br />

secondary particles is<br />

observed<br />

True system size: modeling only 1,000 primary particles, (about 2,500,000) secondary<br />

particles > billions DOFs<br />

Feasible system size: 120 primary particles, >30 million DOF<br />

Destructive evaluation testing dictates the importance of statistical analysis<br />

R<strong>and</strong>om atomic phasespace<br />

Very fine resolution – material<br />

interface is observed

Multiscale Modeling & Simulations<br />

Multiscale Continuum Strata<br />

Computational<br />

Theories<br />

Scale-Bridging Theory<br />

KEY<br />

Control Flow<br />

Information Flow<br />

Atomic<br />

Level<br />

Free<br />

Particle<br />

Dislocation<br />

Walls<br />

Free<br />

Atom<br />

Space‐Time<br />

Discretization<br />

Specimen<br />

Level<br />

interface<br />

Point<br />

Defect<br />

Void<br />

Coalescence<br />

Shear<br />

B<strong>and</strong><br />

interphase Secondary<br />

Phase<br />

Dislocation Ensemble<br />

of Defects<br />

Collective<br />

of Excitation<br />

High Performance<br />

Computing<br />

Uncertainty<br />

Multiresolution Theory<br />

Fields<br />

Rings<br />

Groups

Equations of Archetype Multiresolution Theory<br />

Sets of Equations<br />

(1) Kinematics<br />

(2) Kinetics<br />

(3) Constitutive<br />

(4) Compatibility<br />

(5) Fracture<br />

(6) Uncertainty<br />

materials generic<br />

Multiscale:<br />

Lagrangian,<br />

Computational Theory<br />

materials specific<br />

To be derived for all “building<br />

blocks” as modules in<br />

multiscale framework<br />

Balance<br />

Laws<br />

Reference<br />

Configuration<br />

Constitutive<br />

Laws<br />

Compatibility<br />

Laws<br />

Final<br />

Configuration<br />

Deformation<br />

Crack tip

Microstructural Hierarchy <strong>and</strong> Behavioral Complexity

More on the Theory: Motion Assumptions<br />

Microstructural Kinematics<br />

l*<br />

*<br />

( ( ), , Φ) ≡ ( ( ),0, Φ ) + ∫ ∂α ( ( ), , Φ)<br />

0<br />

x� p ξ l x� p ξ x� p ξ α dα<br />

Beginning from the fundamental theorem of calculus on the second argument…<br />

Meaning of the first term<br />

�x(p(ξ),0,Φ)<br />

Local (intrinsic) point behavior<br />

Meaning of the second term<br />

l*<br />

∫ ∂ x� α ( p( ξ), α, Φ)<br />

dα<br />

0<br />

Corrected influence at p due to<br />

the inhomogeneous neighborhood<br />

x<br />

p

More on Kinematics…<br />

Elemental Kinematics<br />

The effective microstructural rate can be broken down as…<br />

L eff 0 ( p(ξ),x(α ))<br />

( p(ξ)) = Lij + Lij<br />

ij<br />

x(a 1 )<br />

Each term representing<br />

a relative rate for its span<br />

or length scale, hence the<br />

multiscale‐multirate double decomposition<br />

x(0)<br />

( p(ξ),x(α ))<br />

+ Lij x(a 2 )<br />

x(a 1 )<br />

x<br />

( p(ξ),x(α ))<br />

+ ...+ Lij x(a n )<br />

x(a n−1 )<br />

p

More on the Theory: Variational Statement<br />

E� ≡ S L + s L∇ dΩ<br />

∫<br />

1 M M<br />

E� kin =∂ ∫ t ρv<br />

⋅v dΩ<br />

2 Ω<br />

E�= ∫ f ⋅v dΩ<br />

V M<br />

imp i i<br />

Ω<br />

E�= ∫ t ⋅v dΓ<br />

S M<br />

imp i i t<br />

Γ<br />

t<br />

Elemental Kinetics<br />

( M M )<br />

def ij ij ijk ijk<br />

Ω<br />

δE� − δE� = δE�<br />

imp def kin<br />

Elemental Domain ξ<br />

Exp<strong>and</strong>ing V M <strong>and</strong> L M will express all elemental<br />

Fields in terms of microstructural quantities …

More on the Theory: Strong Form<br />

Euler‐Lagrange<br />

Equations<br />

σ −Σ + f = � γ<br />

ij, j ijk , kj i i<br />

Boundary Conditions<br />

Σ ijk n k<br />

= 0<br />

σ ij n j −Σ ijk ,k n j = t i<br />

Discretized Strong Form<br />

δE� − δE� = δE�<br />

imp def kin<br />

[ ]<br />

ρ ρ ρ<br />

S ijk , k − s + B =Γ�ij , for ∀ρ∈ 1,..., n<br />

ij ij<br />

ρ<br />

S ijknk = T ij<br />

for ∀ρ ∈ 1,...,n ⎡⎣ ⎤⎦ Stress conjugate to relative deformation rates<br />

Constitutive laws are needed for all archetypes…<br />

x<br />

p

Three Invariants (Strain rates, Inhomogeneity Length Scales,<br />

Deformation Length Scales) Fracture Space in the Multiscale Context<br />

Maximal stressed zone (m)<br />

Strain rates (s ‐1 )<br />

Materials-Generic Multiresolution Fracture Criterion<br />

10 −2<br />

10 −3<br />

10 −4<br />

10 −5<br />

10 −6<br />

10 −7<br />

10 −8<br />

10 −9<br />

10 −10<br />

10 2<br />

10 3<br />

10 4<br />

10 5<br />

10 6<br />

10 7<br />

10 8<br />

10 1<br />

Local Plastic<br />

Deformation<br />

10 9<br />

Crack tip<br />

Statistical Description<br />

of Structural Inhomogeneity<br />

Structure<br />

Fragmentation<br />

1 st Order Differential Form<br />

Integral Form<br />

(a) (b)<br />

Essential Description<br />

of Structural Inhomogeneity<br />

10<br />

Structural inhomogeneity (m)<br />

−8<br />

10 −7<br />

10 −6<br />

10 −5<br />

10 −4<br />

10 −2 10 −9<br />

10 −3 10 −10<br />

Dimension<br />

(m)<br />

Objects Realizing<br />

Stressed Zone Size<br />

Objects of Structural<br />

Inhomogeneity<br />

10 ‐2 Testing Sample Reinforcement<br />

10 ‐3<br />

10 ‐4<br />

10 ‐5<br />

10 ‐6<br />

Zone at<br />

Impact test<br />

Zone at Fatigue<br />

Fracture Samples<br />

Zone at Cavitation.<br />

Macrocrack<br />

Mechanical Activation<br />

by Processing<br />

10 ‐7 Zone near Crack tip<br />

Coarse Lamellar<br />

Structures. Explosion<br />

Fragments<br />

Coarse Grains<br />

Inclusions<br />

Mn‐Dispersoids in<br />

Aluminum<br />

Al 2 Cu Precipitates<br />

in Aluminum<br />

10 ‐8 Zone at Irradiation Carbides in Steel<br />

10 ‐9<br />

Strain Rate<br />

(s ‐1 )<br />

Crystal Defects.<br />

Nano particles.<br />

Physical<br />

Mechanisms<br />

10 ‐3 Diffusion<br />

10 3 ‐10 6 Wave interactions<br />

10 9<br />

Curl(F M ) = κ<br />

M e p p<br />

*<br />

∫� ( F − R R U ) dx= δ<br />

Shock Waves &<br />

EOS<br />

Atomic lattice<br />

Deformations<br />

Phenomenological<br />

Inhomogeneity<br />

Isothermal shear b<strong>and</strong><br />

Void nucleation & growth<br />

Adiabatic Localization of<br />

shear, Spalling<br />

Fragmentation, Pulverization<br />

(c)

Multiscale Constitutive Physics of Microstructures<br />

Schematic: Complex<br />

Microstructure<br />

(Al - 2139)<br />

Volume Fractions<br />

Phase Spacings<br />

Phase Clusters<br />

Variant Multiplicity<br />

Residual Stresses<br />

Interfaces <strong>and</strong> GBs<br />

Porosities & Defects<br />

Mass Densities<br />

V1<br />

V2<br />

Structure <strong>and</strong> Property Metrics<br />

Edge Crack<br />

Model<br />

Crystallography<br />

� t<br />

� n<br />

� s<br />

Slip System Multiplicity<br />

Habit Planes, Orientations<br />

Deformations<br />

Grain Texture<br />

Elastic/ Plastic Anisotropy<br />

Lattice Curvature<br />

Lattice Stretch, Rotation<br />

Dislocation Densities

Illustrative Example: Two-Scale Elasticity<br />

Dominant Edge Crack<br />

Aluminum Matrix (Usual DOFs)<br />

20% precipitates (Additional DOFs)<br />

Stationary Crack, 5μm× 5 μm,<br />

� ε ε<br />

−1<br />

nom = 20,000 s , nom = 14%<br />

20% Volume fraction of precipitates<br />

Illustration of Design of Materials<br />

Strengthening Mechanisms<br />

(a)Spatial Patterns (Normal Stress)<br />

(b)Magnitudes & Signs (Shear stress)<br />

(c)Curvatures, Nonlocality (Stress couples)<br />

Nanosized<br />

Ω Precipitate<br />

Aluminum<br />

Matrix

Illustrative Example: Two-Scale Elasticity, Continued<br />

S 122(Imbedded Crystal) Σ 122(Matrix Crystal)<br />

[ S, Σ]/<br />

Eb<br />

Stationary Crack, 5μm× 5 μm,<br />

� ε ε<br />

−1<br />

nom = 20,000 s , nom = 14%<br />

Materials Design Implications:<br />

Matrix gradient term (curvature, nonlocality) is important for local fracture processes…<br />

accounts for lattice curvature <strong>and</strong> accommodation processes

Two-Scale Concurrent Multiresolution Model for TiC (Secondary Particles) - Matrix<br />

<strong>and</strong> Direct Numerical Simulation (DNS) of TiN (Primary Particles)<br />

crack<br />

Mod4330 Crack tip specimen #1:<br />

Primary particles (yellow) near crack tip<br />

Reconstruction area: 633x516x259 μm 3<br />

Averaged: 2.857 μm<br />

Spacing: 16 μm<br />

Volume fraction: 1.756%<br />

Ultra High Strength Alloys<br />

Primary Inclusions<br />

Primary Voids<br />

Oxides<br />

Submicron Carbides<br />

Microvoids<br />

Shearing<br />

Mod4330 shear specimen:<br />

Secondary particles (white dots) inside shear b<strong>and</strong><br />

Reconstruction area: 70x15x28μm3 Averaged: 0.117035 μm<br />

Spacing: 2 μm<br />

Volume fraction: 0.0384%<br />

Courtesy of Stephanie Chan (Olson’s group), <strong>and</strong> HJ Jou (QuesTek)<br />

McVeigh & Liu, Linking microstructure & properties through a predictive multiresolution continuum, CMAME, 2008.<br />

McVeigh & Liu, Multiresolution modeling of ductile reinforced brittle composites. J. Mech. Phys. Solids, 2009.<br />

Liu et. al., Complexity science of multiscale materials via stochastic computations, IJNME, 2009.<br />

Tian & Liu et al., “A Multiresolution Continuum Simulation of the Ductile Fracture Process,” JMPS (2010)

Multiscale Materials Modeling, High Performance Alloy<br />

crack<br />

Fracture test<br />

Tomography<br />

Fatigue<br />

crack tip<br />

Mod4330 crack tip specimen #1:<br />

Primary particles (yellow) near crack tip<br />

Reconstruction area: 633x516x259 μm 3<br />

Averaged: 4.857 μm<br />

Spacing: 16 μm<br />

Volume fraction: 1.756%<br />

Fracture Process Model<br />

to be Validated<br />

3μm<br />

Large scale simulations even when blending TiC particles<br />

Degrees of Freedom:<br />

30 million<br />

(132 particles)

Summary:<br />

comparison with experiments<br />

Experiments<br />

Simulation<br />

Pre‐crack<br />

Shear b<strong>and</strong>s<br />

Mixed mode I/II fracture<br />

Primary voids<br />

Crack opening distance along fracture path<br />

Experiments<br />

Simulation<br />

Crack Opening Displacment (μm)<br />

Fracture path<br />

20<br />

15<br />

10<br />

5<br />

0<br />

-5<br />

Fracture path<br />

Experiments<br />

Simulation<br />

0 50 100 150 200 250 300 350<br />

X μm<br />

Experiments<br />

Simulation<br />

Contour plot of crack opening distance<br />

Experiments<br />

Void growth<br />

Simulation<br />

Final void radius (μm)<br />

25<br />

20<br />

15<br />

10<br />

5<br />

Δa<br />

PZ<br />

0<br />

0 1 2 3 4 5 6 7 8 9 10<br />

R0 inclusion radius(μm)

Formation of Multiscale <strong>and</strong> Multistage Fracture Process<br />

Macro deformation (contour of macro effective strain)<br />

(a) Void growth<br />

(primary voids)<br />

Micro deformation (contour of micro effective strain)<br />

(a) Development of<br />

micro deformation<br />

(b) Intense deformation at<br />

ligament between voids<br />

(b) Microvoid sheeting (c) Microvoid shear<br />

coalescence<br />

(c) Initial macro crack (d) Macro crack propagation<br />

Arising from the Strong Interaction between Micro <strong>and</strong> Macro Deformations<br />

(d) Further Microvoid shear<br />

coalescence<br />

I. Multiresolution modeling across multi‐scale of microstructures (voids)<br />

II. Concurrent modeling considering interaction across microstructures has been achieved<br />

(Though there are many primary <strong>and</strong> secondary particles involved)

Animation of the Fracture Process<br />

Initial Fatigue Crack Opening is about 3 microns, a load is<br />

applied gradually until the material reaches the initial <strong>and</strong> then<br />

final fracture toughness strengths followed by unloading to the<br />

final state of deformation<br />

Total experimental time is one minute<br />

The below MOVIE shows the CONCURRENT interaction of macro <strong>and</strong> micro effective<br />

strains due to submicron <strong>and</strong> micron voids growth, interaction, coalescence to form<br />

Micro <strong>and</strong> macro defects (mini-cracks) that eventually define the fracture process zone

Examples of Archetypes <strong>and</strong> their Conformations<br />

ALLOYS POLYMERS CERAMICS<br />

PMC<br />

Multiscale Phenomenology<br />

Shear b<strong>and</strong>ing Pulverization<br />

Cavitation Fragmentation<br />

Conformation of archetypes (sub‐mesoscale)<br />

Sub‐granular structures CNT through Epoxy Resin Polycrystalline Structure Layered Structure<br />

Cortical Bone Lamellae<br />

Archetypes (Space‐filling units)<br />

Crystals<br />

Polymer Chains AlON<br />

CNT MicroCrack<br />

Polymer<br />

Nanocomposite<br />

Fibers<br />

BONES<br />

Collagen Fibrils<br />

Fracture<br />

Path

<strong>Northwestern</strong> <strong>University</strong> Materials Design Loop<br />

METRICS<br />

Structural<br />

Behavioral<br />

Validation<br />

Validation<br />

Concurrent Mesoscale Physics<br />

Multiscale Experiments & Characterization<br />

Multiscale Modeling & Simulation<br />

Scale‐<br />

Bridging<br />

Multiresolution Constitutive Coupling<br />

Direct Numerical Modeling & Simulation<br />

QM<br />

MD<br />

Computational<br />

Theories<br />

Dislocation<br />

Dynamics<br />

Advanced Experiments & Characterization<br />

Sub - mesoscale Physics<br />

High Performance<br />

Computing<br />

Phase<br />

Fields<br />

27

Multiphyics Extensions<br />

Multiresolution<br />

Mesoscale Manifold<br />

Nonlocal<br />

Conformation<br />

Nanomorphic<br />

Archetypes<br />

Blending<br />

Implanting<br />

Cmcm I 4 / mcm I 4m2<br />

Classical Forms Multiresolution<br />

�<br />

( q−p) i∇+<br />

Q = μθ�<br />

� �<br />

pi∇− p+ R= � θ∇iI<br />

Mechanical Balance<br />

Thermal Balance<br />

Electrodynamic Balance<br />

Mass Diffusion Balance<br />

N ⎛ n ⎞ �<br />

⎜q−∑p ⎟i∇+<br />

Q = μθ�<br />

⎝ ⎠<br />

p i∇− p + R = � θ ∇iI<br />

n=<br />

1<br />

� �<br />

n n n n n

Uncertainty Sources <strong>and</strong> Quantification<br />

Inherent structural variation (batch to batch r<strong>and</strong>omness, r<strong>and</strong>om field)<br />

Uncertain multiscale boundary <strong>and</strong> initial conditions<br />

R<strong>and</strong>om parameters determined by experiment or behavior at other scales<br />

Lack of knowledge, lack of information<br />

Low fidelity physical descriptions<br />

Sparse <strong>and</strong> limited experimental data<br />

Missing models <strong>and</strong>/or data for sub-processes<br />

Simulation <strong>and</strong> approximation errors<br />

Discretization <strong>and</strong> finite sampling errors<br />

Solver errors<br />

Statistical modeling <strong>and</strong> representations<br />

Model Complexity<br />

STOCHASTIC PDE’s<br />

Interactions between different sources of errors <strong>and</strong> uncertainty<br />

Uncertainty feedback in coupled processes

General Stochastic Formulation<br />

Write general partial differential equation governing evolution of some<br />

system<br />

( Ωℑ , ,P)<br />

Ω<br />

[ ] ( ,, t ω) [ ] ( ,, t ω)<br />

Tvx + S+ S vx = 0<br />

Temporal operator<br />

( t ω)<br />

[ B+ B ] v x, , = 0<br />

ω<br />

Probability space<br />

Could be infinite dimensional<br />

Governing System of Equations<br />

Boundary condition<br />

( , t = 0, ω) = ( , ω)<br />

v x v x<br />

RANDOM SOLUTION<br />

0<br />

ω<br />

Nominal spatial operator<br />

Initial condition<br />

R<strong>and</strong>om spatial operator<br />

Representations<br />

CDF <strong>and</strong> PDF<br />

Finite collection of samples<br />

Polynomial <strong>and</strong> spectral approximations<br />

Equation Domain<br />

in D( ω ) × (0, T ] ×Ω<br />

Spatial domain<br />

Time domain<br />

R<strong>and</strong>om domain<br />

in ∂ D( ω)<br />

× [0, T]<br />

×Ω<br />

Spatial boundary<br />

in D( ω ) × { t = 0} ×Ω<br />

Uncertainty<br />

(1)<br />

Stochastic differential operators.<br />

R<strong>and</strong>om coefficients<br />

Material properties<br />

Stochastic modeling of<br />

complexity, chaos, fine<br />

(2)<br />

Uncertain environment, i.e. r<strong>and</strong>om<br />

boundary or initial conditions.<br />

Mechanical loads unknown<br />

Temperature field unknown<br />

Current state of system uncertain<br />

(3)<br />

Uncertain domain.<br />

Rough edges from processing<br />

Micro/tele scope finite resolution<br />

Domain manifold subject to stress

Stochastic Mathematical Formulation<br />

General<br />

⎣ Z ⎦<br />

( ,, t )<br />

⎡T+S+ S ⎤v<br />

x Z = 0<br />

in D( ω ) × (0, T ] ×Ω<br />

Solid Mechanics<br />

Uncertainty parameterization technique required<br />

Approximate representations are used<br />

. e.g. KL, PC, finite collection of samples<br />

Dimension reduction methodology<br />

Composition operation<br />

( v) = [ � � � ]( v)<br />

⎡⎣T + S⎤⎦ −T<br />

+ N f g h<br />

[ T ]( • ) = � ∂ ( •)<br />

acceleration t<br />

• = balance law � ∇ ⋅ •<br />

�<br />

[ N ]( ) ( )<br />

[ f ]( •) � constitutive law<br />

[ g](<br />

• ) = objectivity � sym ( •)<br />

[ h](<br />

• ) = compatibility ∇ ( •)<br />

� �<br />

Solution (vector) space<br />

Tensor space<br />

( ,, t )<br />

v x Z<br />

( ,, t )<br />

∇v x Z<br />

Symmetric tensor space<br />

( t )<br />

sym ⎡⎣ ∇v<br />

x, , Z ⎤⎦<br />

Stress tensor space<br />

{ sym ⎡∇ ( , t,<br />

) ⎤}<br />

σ ⎣ v x Z ⎦<br />

Balance Law<br />

acts on stress space<br />

Compatibility<br />

conditions<br />

Objectivity<br />

requirements<br />

Constitutive<br />

law

Stochastic Formulation for Multiresolution Continua<br />

Solid Mechanics<br />

( v) ⎡ + �( ) � � ⎤(<br />

v)<br />

⎡T + S + S ⎤ = −T<br />

N f + f g h<br />

⎣ Z⎦ ⎣ Z ⎦<br />

Intrinsic stress<br />

( )<br />

σ · ∇−Σ: ∇⊗∇ + f = � γ<br />

ρ ρ ρ<br />

S · ∇−s + B = Γ � , ρ = 1, 2, …,<br />

N<br />

Σ · n = 0<br />

σ · n−Σ: ∇⊗n<br />

S<br />

ρ<br />

Macro double stress<br />

Spatial operator<br />

Boundary conditions<br />

( )<br />

body force<br />

= t<br />

· n = T, ρ = 1,2, …,<br />

N<br />

acceleration<br />

Temporal operator<br />

( ( t ) ( t ) ( t ) )<br />

n n n n<br />

σβ , , β = f , f , f sym ∇v x, , Z , L x, , Z −L, ∇L<br />

x, , Z<br />

σ<br />

Z(<br />

s)<br />

x1<br />

β β<br />

R<strong>and</strong>om dimension<br />

Z<br />

x3<br />

Z()<br />

i<br />

t1<br />

x1<br />

VELOCITY<br />

x2<br />

x3<br />

(1)<br />

t1<br />

x2<br />

x1<br />

t2<br />

x3<br />

RANDOM SOLUTIONS<br />

t1<br />

x2<br />

t2<br />

MICRO-VELOCITY GRADIENT<br />

t2<br />

In stochastic collocation, Galerkin<br />

projection, r<strong>and</strong>om dimension<br />

discretized like space <strong>and</strong> time<br />

Constitutive law an implicit function of a denumerable set of r<strong>and</strong>om<br />

variables

Stochastic Constitutive Theory<br />

Denumerable set of r<strong>and</strong>om<br />

variables are structural<br />

descriptors of microstructure<br />

Unique stress distributions<br />

averaged to provide<br />

constitutive behavior<br />

MACRO-SCALE SIMULATION<br />

Greene, M.S., Y. Liu, et al. (2011).<br />

SVE<br />

l<br />

δ =

Stochastic Constitutive Theory<br />

Macroscale, e.g. Fine resolution statistical volume element realizations<br />

d<br />

( , , , T , t, , SA)<br />

〈〉 S = f κ 〈〉〈〉〈 ε ε� 〉 …<br />

( , 〈〉〈〉 , , T , t, , SA,<br />

ω)<br />

S = f κ ε ε� 〈 〉 …<br />

ω<br />

consider statistics of constitutive<br />

behavior other than mean<br />

For multiscale analysis, fine scale simulations create r<strong>and</strong>omness<br />

S<br />

ε<br />

l Realization 1 Realization 2<br />

Deterministic homogenization<br />

(st<strong>and</strong>ard constitutive modeling)<br />

Transfer uncertainty from general<br />

constitutive law to<br />

phenomenological parameters<br />

S<br />

strain<br />

strain rate<br />

temperature<br />

time<br />

structural approx.<br />

ε<br />

General form of stochastic<br />

constitutive theory<br />

Specific form of<br />

S<br />

ε<br />

Realization 3<br />

Fit set of phenomenological<br />

constitutive law parameters to SVE<br />

simulation results<br />

Treat parameters as multivariate<br />

statistical distribution whose data<br />

are each realization<br />

stochastic constitutive theory<br />

Sω = f ⎡⎣Κ( ω),<br />

〈〉〈〉〈 ε , ε� , T〉 , t, …,<br />

SA⎤⎦<br />

Κ( θ ) ~ fK<br />

( κ,<br />

θ )

Desired Features Multiresolution Microspan Theory<br />

• Unifies the three field effects: Nanomorphism, Conformation Complexity, Nonlocality.<br />

• No need for cell modeling, or intermediate models of any kind.<br />

• Strong coupling between length scales <strong>and</strong> 1st <strong>and</strong> 2nd order deformations.<br />

• All archetype formulations are rate-dependent for dynamic applications.<br />

• Conjugate stress measures have clear physical associations (archetype based).<br />

• Asymmetric strain-rate matrices used: Micropolar effects, Interface effect captured<br />

• No requirement on infinitesimality as was in micromorphic theory.<br />

• Nonlocal sweeping permits holonomic velocity fields, simple compatibility conditions<br />

• Derivation of a topologically three-invariant based multiscale fracture theory.<br />

• Higher Order Boundary conditions are easier to interpret (as they are relative)<br />

• No “relative densities” need be defined, so equations are more meaningful.<br />

• No risk of double counting energies<br />

• Continuous formulation, also accepts non-linear spatial fields

Research Challenges/Questions – UQ for Materials<br />

• Materials specific UQ issues<br />

– UQ of Microstructure<br />

– Impact of uncertainty across multiple scales<br />

– Relative role of microstructure <strong>and</strong> property uncertainties<br />

– Life time prediction/extreme events<br />

• General UQ methodologies<br />

– Lack of data/Is extrapolation possible?<br />

– Quantification of material model uncertainty<br />

– Error analysis<br />

• Tradeoffs<br />

– Physics based vs. data-driven model refinement<br />

– Concurrency of material, product, <strong>and</strong> process modeling for design<br />

– When will UQ become intractable?