- Page 1 and 2:

1th International Congres on Engine

- Page 4 and 5:

FOOD PROCESS ENGINEERING IN A CHANG

- Page 6:

ICEF11 ORGANIZERS Organizer: Nation

- Page 9 and 10:

Rao, Anandha (Andy) Raspor, Peter R

- Page 12 and 13:

ACKNOWLEDGEMENTS The 11 th Internat

- Page 14 and 15:

PREFACE The present book is part of

- Page 16 and 17:

Emerging technologies CONTENTS-VOLU

- Page 18 and 19:

Effect of ultra high pressure homog

- Page 20 and 21:

Bioprocessing engineering Character

- Page 22 and 23:

Rapid HPTLC-based method for qualit

- Page 24 and 25:

Effect of contamination stage and i

- Page 26 and 27:

Furan derivatives dynamic in rye br

- Page 28 and 29:

Manufacture of gelatin-based films

- Page 30 and 31:

Mechanical processing of foods Stud

- Page 32 and 33:

11th International Congress on Engi

- Page 34 and 35:

Production of Turkish delight (loku

- Page 36 and 37:

Effect of different ratios of malto

- Page 38 and 39:

HIGHTECH EUROPE PROJECT WORKSHOP OP

- Page 40:

The potential for superchilling to

- Page 43 and 44:

Table 1. mass transfer results for

- Page 45 and 46:

as 37% at 40g/l, 2.0MPa TMP and 30

- Page 47 and 48:

and OAA of the bun decreased with i

- Page 49 and 50:

temperature profile when applying a

- Page 51 and 52:

Figure 1 compared the PSD patterns

- Page 53 and 54:

Table 1. Results of the EF treatmen

- Page 55 and 56:

VI solution in combination with the

- Page 57 and 58:

RESULTS & DISCUSSION Fig. 1 present

- Page 59 and 60:

RESULTS & DISCUSSION The impact of

- Page 61 and 62:

seemed to be less effective on TVC

- Page 63 and 64:

presence of colored compounds and p

- Page 65 and 66:

PCA model to identify fresh and fro

- Page 67 and 68:

The concentration of vitamin C was

- Page 69 and 70:

denoting that these tissues became

- Page 71 and 72:

egime, presents a concave curve sha

- Page 73 and 74:

encapsulation by Spray Gun was 2.40

- Page 75 and 76:

studying the squid protein concentr

- Page 77 and 78:

Since treatment at maximum voltage

- Page 79 and 80:

educed to 22,5% in comparison to un

- Page 81 and 82:

material (unprocessed carrot). None

- Page 83 and 84:

them barely visible at the optical

- Page 85 and 86:

peak viscosity over control was obs

- Page 87 and 88:

model of enzymes inactivation. The

- Page 89 and 90:

values than controls. A significant

- Page 91 and 92:

G'(Pa) 100 90 80 70 60 50 40 30 20

- Page 93 and 94:

Viscosity (mPa.s) 7 6 5 2 0 10 20 3

- Page 95 and 96:

The previous thermal germination of

- Page 97 and 98:

activity. Recent results have been

- Page 99 and 100:

Jam preparation and methods for the

- Page 101 and 102:

The size of the ice crystals in gel

- Page 103 and 104:

volatile constituents are the sesqu

- Page 105 and 106:

at 300 and 400 MPa (D = 1.99 and 0.

- Page 107 and 108:

of the fact that some enzymes canno

- Page 109 and 110:

Table 1: Effect of high pressure hy

- Page 111 and 112:

contrast, in samples treated at 300

- Page 113 and 114:

It was found that HP-tofu, using th

- Page 115 and 116:

amount of quercetin that was infuse

- Page 117 and 118:

[]*10 -3 (deg.cm 2 .dmol -1 ) 10 0

- Page 119 and 120:

which no culture management is nece

- Page 121 and 122:

Rheological measurements were carri

- Page 123 and 124:

1690

- Page 125 and 126:

Yield (%) 80 70 60 50 40 30 20 10 0

- Page 127 and 128:

corresponding to antagonism (the ef

- Page 129 and 130:

Also the separation efficiency has

- Page 131 and 132:

as an in vitro study on the colon c

- Page 133 and 134:

BSA, trypsin, and pepsin were selec

- Page 135 and 136:

proposed by Apelblat can describe t

- Page 137 and 138:

potassium phosphate salts confer di

- Page 139 and 140:

Figure 1. Effect of pH and NaPA con

- Page 141 and 142:

subsequently temperature maintained

- Page 143 and 144:

could increase the viscosity of the

- Page 145 and 146:

eductions. Taking availability and

- Page 147 and 148:

Liquid Chromatography Coupled to Is

- Page 149 and 150:

and a 5.2-fold improvement (average

- Page 151 and 152:

Regarding the solubility of astaxan

- Page 153 and 154:

Figure 1. Cumulative oil yield vers

- Page 155 and 156:

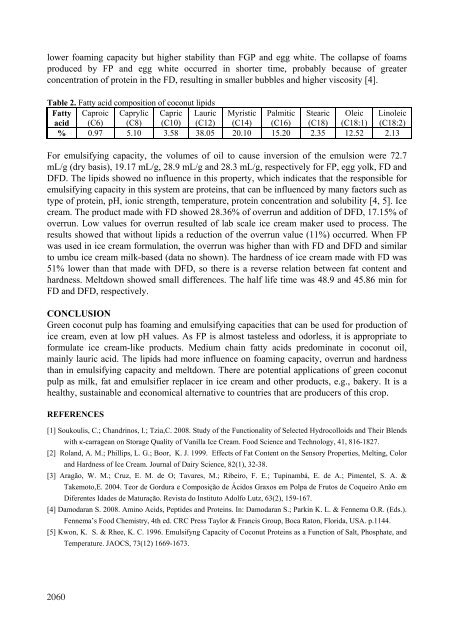

This indicates that all the medium-

- Page 157 and 158:

RESULTS & DISCUSSION In the KCl1 co

- Page 159 and 160:

Furthermore, it was observed that t

- Page 161 and 162:

production of the intermediate limo

- Page 163 and 164:

Table 1. Microbial counts of total

- Page 165 and 166:

Total viable counts remained about

- Page 167 and 168:

Table 1. Mean values of the notes a

- Page 169 and 170:

RESULTS & DISCUSSION The general tr

- Page 171 and 172:

a) b) meq oxígeno/Kg 6 5 4 3 2 1 0

- Page 173 and 174:

According to Figure 1, in glucose m

- Page 175 and 176:

Figure 1. a) Surface plots with eff

- Page 177 and 178:

expressed by the molecular diffusio

- Page 179 and 180:

Effect of dispersed phase volume fr

- Page 181 and 182:

RESULTS & DISCUSSION Figure 1. Expe

- Page 183 and 184:

Oxygen rate transmission (OTR) was

- Page 185 and 186:

outputs and experimental values. It

- Page 187 and 188:

Figure 1: Gallery of corn tortilla

- Page 189 and 190:

esistance to mass transfer takes pl

- Page 191 and 192:

Table 1-Levels of protein fractions

- Page 193 and 194:

Figure 1. Minimum Noise Fraction Tr

- Page 195 and 196:

for 28.6 and 12.6% of the total sam

- Page 197 and 198:

Phenomena related to the movement o

- Page 199 and 200:

order/genus level. In one year appl

- Page 201 and 202:

RESULTS & DISCUSSION No differences

- Page 203 and 204:

RESULTS & DISCUSSION The shelf-life

- Page 205 and 206:

RESULTS & DISCUSSION The spectra of

- Page 207 and 208:

RESULTS & DISCUSSION The results fo

- Page 209 and 210:

factors for the development of shap

- Page 211 and 212:

plates were dipped into a 0.05% DPP

- Page 213 and 214:

esponse of the samples and measurin

- Page 215 and 216:

and median of 0.25 mg/L) in the raw

- Page 217 and 218:

inadequate/poor information about e

- Page 219 and 220:

The joint analysis of these results

- Page 221 and 222:

A study on germination time and myc

- Page 223 and 224:

for decreasing temperature. An incr

- Page 225 and 226:

Table 1. Weibull distribution param

- Page 227 and 228:

Figure 1 shows the contour plots of

- Page 229 and 230:

minute [2]; therefore attached E. c

- Page 231 and 232:

the presence of L-carnitine. At 14

- Page 233 and 234:

The results were obtained over time

- Page 235 and 236:

depends on the temperature. Rather

- Page 237 and 238:

* da * * ka a (1) dt * * 15.08 aa0

- Page 239 and 240:

RESULTS & DISCUSSION Simultaneous c

- Page 241 and 242:

Figure 1. Change of HMF concentrati

- Page 243 and 244:

RESULTS & DISCUSSION Data on remain

- Page 245 and 246:

under sub-optimal conditions, were:

- Page 247 and 248:

Figure 1. Scores Plot for 3 storage

- Page 249 and 250:

modulates thermal inactivation of e

- Page 251 and 252:

conditions, this procedure was isol

- Page 253 and 254:

150-400 CFU/cm 2 ) may still pass t

- Page 255 and 256:

1822

- Page 257 and 258:

theirs hands and arms before milkin

- Page 259 and 260:

Figure 1. HMF reduction of styrene-

- Page 261 and 262:

high respiration rates could be exp

- Page 263 and 264:

6.4-5.5 and aw 0.98 to

- Page 265 and 266:

in Graviera cheese due to reheating

- Page 267 and 268:

RESULTS & DISCUSSION IMF items are

- Page 269 and 270:

implementation in the hospitals. Wi

- Page 271 and 272:

Finally, concerning the water-bottl

- Page 273 and 274:

a high amount of data, enough to es

- Page 275 and 276:

a-T room = 20°C b-T room = 25°C c

- Page 277 and 278:

Table 1. Fillet pH drip loss and le

- Page 279 and 280:

oth temperatures. The rates of putr

- Page 281 and 282:

RESULTS & DISCUSSION The population

- Page 283 and 284:

Until now the declaration has been

- Page 285 and 286:

For the selection of the appropriat

- Page 287 and 288:

RESULTS AND DISCUSSION Volatile com

- Page 289 and 290:

3. Characterisation of protein phys

- Page 291 and 292:

High CA contents were usually accom

- Page 293 and 294:

electric transformer in order to gi

- Page 295 and 296:

icher in compounds from all chemica

- Page 297 and 298:

the pH and temperature changes are

- Page 299 and 300:

may cause 100 times greater risk of

- Page 301 and 302:

RESULTS & DISCUSSION Concerning the

- Page 303 and 304:

Food-serving businesses that wish t

- Page 305 and 306:

CONCLUSION Meat texture and fat con

- Page 307 and 308:

RESULTS & DISCUSSION Irrespective o

- Page 309 and 310:

Table 1. Furan levels in roasted co

- Page 311 and 312:

was verified that furan levels sign

- Page 313 and 314:

The parameter of form (n) varied pr

- Page 315 and 316:

antioxidant capacity of spices extr

- Page 317 and 318:

RESULTS & DISCUSSION DON concentrat

- Page 319 and 320:

Figure 1. Fitted curves of polynomi

- Page 321 and 322:

The equations describing the system

- Page 323 and 324:

RESULTS & DISCUSSION Nine furan der

- Page 325 and 326:

RESULTS & DISCUSSION The mycelia gr

- Page 327 and 328:

REFERENCES [1]. Leung AY. 1978. Enc

- Page 329 and 330:

1896

- Page 331 and 332:

ACKNOWLEDGMENTS These results are p

- Page 333 and 334:

evaporated. It is assumed that the

- Page 335 and 336:

onion tissue was not observed becau

- Page 337 and 338:

temperature. During the first 5 min

- Page 339 and 340:

Pre cooling Filleting Baader 184/18

- Page 341 and 342:

1908

- Page 343 and 344:

700 mm and predominantly Western wi

- Page 345 and 346:

In the beginning of heating, there

- Page 347 and 348:

To investigate the damage of cooked

- Page 349 and 350:

The water activity of the pistachio

- Page 351 and 352:

done. Figure 1 shows the comparison

- Page 353 and 354:

The first results show a variation

- Page 355 and 356:

contrast, the nature of the pan has

- Page 357 and 358:

with 12 sec process holding times y

- Page 359 and 360:

Figure 1. Temperature history of wh

- Page 361 and 362:

heat transfer characteristics. Two

- Page 363 and 364:

espondents of the five (5) schools

- Page 365 and 366:

it was 62.73 (±4.68) ppb for force

- Page 367 and 368:

treatment time and therefore an ene

- Page 369 and 370:

Figure 1 shows the effect of tannin

- Page 371 and 372:

influenced significantly by osmodeh

- Page 373 and 374:

intracellular product extraction. A

- Page 375 and 376:

The textural analysis did not diffe

- Page 377 and 378:

powder. Kumar et al. [1] reported t

- Page 379 and 380:

In all the position of MW3 cases, t

- Page 381 and 382:

ventilation led to significant savi

- Page 383 and 384:

correlation was found between the t

- Page 385 and 386:

tested in this work (0-37 kW/m 3 ).

- Page 387 and 388:

Comparing trials 9 and 10, it is po

- Page 389 and 390:

To study the effect of pH and added

- Page 391 and 392:

Spectronic). Bovine serum albumin w

- Page 393 and 394:

temperature up to 50 °C or even hi

- Page 395 and 396:

(1547 cm -1 ) and amide-III (1239 c

- Page 397 and 398:

The respiration pattern at 0 day fo

- Page 399 and 400:

In the whole grains of wheat and oa

- Page 401 and 402:

eduction verified by Reddy et. al.

- Page 403 and 404:

most flavours, except esters, were

- Page 405 and 406:

anisotropic shrinkage since shrinki

- Page 407 and 408:

Analysis of water activity (a w) Ta

- Page 409 and 410:

year on colour was more important t

- Page 411 and 412:

texture analyzer CT3 (BROOKFIELD, E

- Page 413 and 414:

1980

- Page 415 and 416:

1982

- Page 417 and 418:

was obvious that the higher levels

- Page 419 and 420:

t test not shown)The fitted results

- Page 421 and 422:

RESULTS & DISCUSSION Each fruit pre

- Page 423 and 424:

powder, indicates that during the d

- Page 425 and 426:

(a) (b) Figure 1. Relationship betw

- Page 427 and 428:

RESULTS & DISCUSSION The results sh

- Page 429 and 430:

TA/XT/PLUS-Texture Analyser and the

- Page 431 and 432:

RESULTS & DISCUSSION The results of

- Page 433 and 434:

RESULTS & DISCUSSION The final mois

- Page 435 and 436:

model was their average relative er

- Page 437 and 438:

indicated that the moisture diffusi

- Page 439 and 440:

Figure 1. Vitamin C content for the

- Page 441 and 442: ehydration with a fast initial wate

- Page 443 and 444: At this condition, the moisture con

- Page 445 and 446: RESULTS & DISCUSSION The ENCF treat

- Page 447 and 448: Table 1. Experiments were scheduled

- Page 449 and 450: RESULTS & DISCUSSION All volatile c

- Page 451 and 452: generated by cavitation injured str

- Page 453 and 454: PA, PB and PC, respectively. The DE

- Page 455 and 456: Table 1. Resume of results of the d

- Page 457 and 458: passes without change of phase, and

- Page 459 and 460: vegetable coagulant alone or a blen

- Page 461 and 462: esults in a cheese with higher scor

- Page 463 and 464: RESULTS & DISCUSSION Concerning the

- Page 465 and 466: chemical properties evaluated. It w

- Page 467 and 468: Substitution with pea protein isola

- Page 469 and 470: the fact that aleurone oat layer an

- Page 471 and 472: RESULTS & DISCUSSION Function of Cr

- Page 473 and 474: plants. Only freeze-dried lemon bal

- Page 475 and 476: at promoting homemade preparation o

- Page 477 and 478: From 200 isolates, 60 isolates rema

- Page 479 and 480: acid (AA). The juice of San Martin

- Page 481 and 482: organisation of the thylakoids at t

- Page 483 and 484: Cáhuil from the Center showed the

- Page 485 and 486: RESULTS & DISCUSSION Composition of

- Page 487 and 488: 65% Figure 1. Stress-strain curves

- Page 489 and 490: unique for each sugar. The volume (

- Page 491: 2058

- Page 495 and 496: obtained in the flowering period, u

- Page 497 and 498: The results of physicochemical char

- Page 499 and 500: Drolet et al. [2] and Løvaas [3],

- Page 501 and 502: In order to obtain an absorbance va

- Page 503 and 504: decrease in the water ability due t

- Page 505 and 506: Table 1. Global yield (X0 % w/w) of

- Page 507 and 508: Figure 1. Effect of mixing time wit

- Page 509 and 510: chain. Liquid-holding capacity was

- Page 511 and 512: Where, is the porosity of the extr

- Page 513 and 514: RESULTS & DISCUSSION The results sh

- Page 515 and 516: that showed a higher intensity of t

- Page 517 and 518: fermented sausages was detected by

- Page 519 and 520: interval, four aliquots stored in m

- Page 521 and 522: 2.26 ppm) that can be considered as

- Page 523 and 524: The three controlled factors (VI, p

- Page 525 and 526: presenting differences in color. Ca

- Page 527 and 528: The mean composition of ice creams

- Page 529 and 530: particles, increasing the diameter

- Page 531 and 532: Table 1 Initial values of analysis

- Page 533 and 534: at DH 1%. This limitation can be ex

- Page 535 and 536: the less effective inhibitors, whil

- Page 537 and 538: Figure 1. Data adjusted to Michaeli

- Page 539 and 540: Low water content Water Enzyme and

- Page 541 and 542: Table 1. Experiments results in Pla

- Page 543 and 544:

Table 1. Physicochemical analysis o

- Page 545 and 546:

of curcumin, which followed changes

- Page 547 and 548:

RESULTS & DISCUSSION Figure 1 shows

- Page 549 and 550:

Variable Table 1. Physicochemical c

- Page 551 and 552:

THE RAW MATERIALS Sugar: Sugar is t

- Page 553 and 554:

severity scores, while the scores c

- Page 555 and 556:

phase. L. acidophilus had logarithm

- Page 557 and 558:

where M is the property, M 0 is the

- Page 559 and 560:

Table 1. pH values, titratable acid

- Page 561 and 562:

the compositions of the microemulsi

- Page 563 and 564:

The breakfast cereal of broken rice

- Page 565 and 566:

sensory parameters analyzed. In mos

- Page 567 and 568:

77.1% carbohydrates. After process,

- Page 569 and 570:

egarding the browning is that this

- Page 571 and 572:

fermentation at 42°C until pH 4.6

- Page 573 and 574:

form. Concentration of TP in commin

- Page 575 and 576:

2142

- Page 577 and 578:

Phenolic compounds are generally co

- Page 579 and 580:

RESULTS & DISCUSSION Plastic viscos

- Page 581 and 582:

difference (P>0.05) in shear strain

- Page 583 and 584:

honey biscuits has higher level of

- Page 585 and 586:

probably due to their less fat cont

- Page 587 and 588:

RESULTS & DISCUSSION The results (T

- Page 589 and 590:

RESULTS AND DISCUSSION Samples The

- Page 591 and 592:

200 190 180 170 0.68 0.68 0.67 0.66

- Page 593 and 594:

7 6 5 4 pH 3 2 1 0 Fig.1. Variation

- Page 595 and 596:

Table 1. Full factorial central com

- Page 597 and 598:

Biomass(g/L) 4,0 3,5 3,0 2,5 2,0 1,

- Page 599 and 600:

evaluated. The results from the pH

- Page 601 and 602:

RESULTS & DISCUSSION The increase i

- Page 603 and 604:

RESULTS & DISCUSSION Particle yield

- Page 605 and 606:

sample (dia. 10 mm, height 10 mm) w

- Page 607 and 608:

improve encapsulation efficiency wa

- Page 609 and 610:

that constituents of lemon balm are

- Page 611 and 612:

A B C extraction of flavanols requi

- Page 613 and 614:

The data obtained were analyzed usi

- Page 615 and 616:

Table 1. Phenolic compounds in juic

- Page 617 and 618:

compounds were detected in ‘Auksi

- Page 619 and 620:

RESULTS AND DISCUSSION Km value for

- Page 621 and 622:

Table 1. Flavonoids, phenolic compo

- Page 623 and 624:

demonstrates that a higher recovery

- Page 625 and 626:

territorial taxes, engineering, etc

- Page 627 and 628:

RESULTS & DISCUSSION Spectra of new

- Page 629 and 630:

RESULTS & DISCUSSION Variation of p

- Page 631 and 632:

exothermic peak could be attributed

- Page 633 and 634:

Table 1. Content of essential amino

- Page 635 and 636:

extracts extracted below 180 o C, t

- Page 637 and 638:

1 Mean ± Standard Deviation Table

- Page 639 and 640:

\ Figure 1. Hardness of spaghetti f

- Page 641 and 642:

(a) g oligosaccharides/ 100g of oat

- Page 643 and 644:

investigation a non-commercial Celi

- Page 645 and 646:

MATERIALS & METHODS The work plan o

- Page 647 and 648:

Table 1. Antioxidant activity and c

- Page 649 and 650:

RESULTS & DISCUSSION The main metab

- Page 651 and 652:

time (Fig 1). Even though there wer

- Page 653 and 654:

whereas HIPEF-1400 s and heat proce

- Page 655 and 656:

pursuing innovation, enhancing coll

- Page 657 and 658:

Innovation sharing by cooperative R

- Page 659 and 660:

B) The HTE consortium considers in

- Page 661 and 662:

segmented by defining a threshold v

- Page 663 and 664:

performed OCT imaging sessions on B

- Page 665 and 666:

Conversely, adding fibres increases

- Page 667 and 668:

2234

- Page 669 and 670:

with whipping time. The porous stru

- Page 671 and 672:

incidence of browning (90%) and cav

- Page 673 and 674:

(Hamamatsu, Louvain-La-Neuve, Belgi

- Page 675 and 676:

degradation kinetics. By recording

- Page 677 and 678:

Add Cold Chain Data 0 Stage/step of

- Page 679 and 680:

Table 1. Safety and quality indicat

- Page 681 and 682:

a-Troom = 20°C b-Troom = 25°C c-T

- Page 683 and 684:

RESULTS & DISCUSSION Household refr

- Page 685 and 686:

A short overview of each technology

- Page 687 and 688:

RESULTS & DISCUSSION The shelf life

- Page 689 and 690:

The integration concept of CAFÉ Th

- Page 691 and 692:

Within these groups, the most relev

- Page 693 and 694:

Optimal conditions of biodiesel pro

- Page 695 and 696:

REFERENCES [1] Arvanitoyannis I.S.

- Page 697 and 698:

2264

- Page 699 and 700:

AbKadir,M.O. 213,259,1697 Abakarov

- Page 701 and 702:

Benkhelifa,H. 55,523,1531 Benning,

- Page 703 and 704:

CordeiroMancini,M. 2001 Córdova,A

- Page 705 and 706:

Eshraghi,E. 1497,1499 Esmaiili,M.

- Page 707 and 708:

Grinde,M. 511 Grob,F. 569 Groen

- Page 709 and 710:

Karbowiak,T. 373 Kargar,M. 61 Ka

- Page 711 and 712:

Lucas,T. 125,199,227,1435,1443, 147

- Page 713 and 714:

Mytilinaki,E. 1629 N’guessanGeor

- Page 715 and 716:

Polovka,M. 1171 Polychniatou,V. 9

- Page 717 and 718:

Saraiva,J. 1879 Sarghini,F. 263

- Page 719 and 720:

Tjahjohutomo,R. 547 To,N. 201 To

- Page 721 and 722:

Youssef,K. 1089,1091,1979,1981 Yufe

- Page 723 and 724:

1.PASTIAEFPRESIDENTS(Retired) JeanJ

- Page 725 and 726:

SouthAfrica SouthAfricanAssociation