Mastering High-End Simulated Process Printing - Impressions

Mastering High-End Simulated Process Printing - Impressions

Mastering High-End Simulated Process Printing - Impressions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

step<br />

4<br />

step<br />

7<br />

step<br />

10<br />

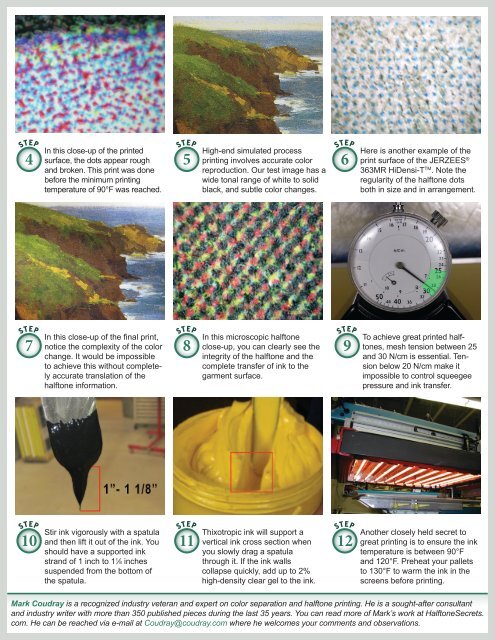

In this close-up of the printed<br />

surface, the dots appear rough<br />

and broken. This print was done<br />

before the minimum printing<br />

temperature of 90°F was reached.<br />

In this close-up of the final print,<br />

notice the complexity of the color<br />

change. It would be impossible<br />

to achieve this without completely<br />

accurate translation of the<br />

halftone information.<br />

Stir ink vigorously with a spatula<br />

and then lift it out of the ink. You<br />

should have a supported ink<br />

strand of 1 inch to 1 1 ⁄8 inches<br />

suspended from the bottom of<br />

the spatula.<br />

step<br />

5<br />

step<br />

8<br />

step<br />

11<br />

<strong>High</strong>-end simulated process<br />

printing involves accurate color<br />

reproduction. Our test image has a<br />

wide tonal range of white to solid<br />

black, and subtle color changes.<br />

In this microscopic halftone<br />

close-up, you can clearly see the<br />

integrity of the halftone and the<br />

complete transfer of ink to the<br />

garment surface.<br />

Thixotropic ink will support a<br />

vertical ink cross section when<br />

you slowly drag a spatula<br />

through it. If the ink walls<br />

collapse quickly, add up to 2%<br />

high-density clear gel to the ink.<br />

step<br />

6<br />

step<br />

12<br />

Here is another example of the<br />

print surface of the JERZEES ®<br />

363MR HiDensi-T TM . Note the<br />

regularity of the halftone dots<br />

both in size and in arrangement.<br />

Another closely held secret to<br />

great printing is to ensure the ink<br />

temperature is between 90°F<br />

and 120°F. Preheat your pallets<br />

to 130°F to warm the ink in the<br />

screens before printing.<br />

Mark Coudray is a recognized industry veteran and expert on color separation and halftone printing. He is a sought-after consultant<br />

and industry writer with more than 350 published pieces during the last 35 years. You can read more of Mark’s work at HalftoneSecrets.<br />

com. He can be reached via e-mail at Coudray@coudray.com where he welcomes your comments and observations.<br />

step<br />

9<br />

To achieve great printed halftones,<br />

mesh tension between 25<br />

and 30 N/cm is essential. Tension<br />

below 20 N/cm make it<br />

impossible to control squeegee<br />

pressure and ink transfer.