Ultrasonic Shot Peening - MTU Aero Engines

Ultrasonic Shot Peening - MTU Aero Engines

Ultrasonic Shot Peening - MTU Aero Engines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

R-18114 0901A00907<br />

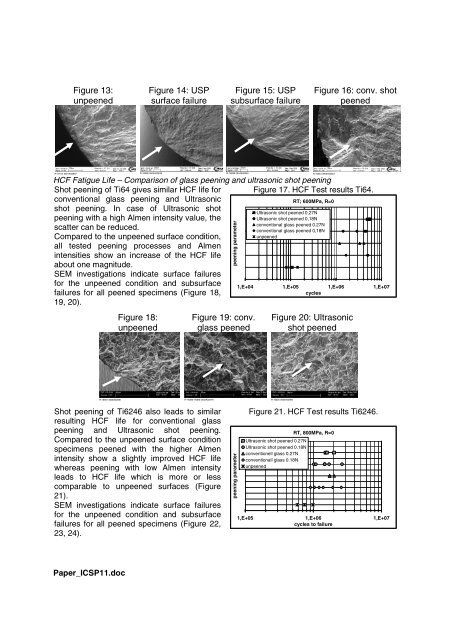

Figure 13:<br />

unpeened<br />

Paper_ICSP11.doc<br />

Figure 14: USP<br />

surface failure<br />

R-18288 0904A00636<br />

Figure 15: USP<br />

subsurface failure<br />

R-18288 0904A00646<br />

Figure 16: conv. shot<br />

peened<br />

R-18244 0903A02651<br />

HCF Fatigue Life – Comparison of glass peening and ultrasonic shot peening<br />

<strong>Shot</strong> peening of Ti64 gives similar HCF life for Figure 17. HCF Test results Ti64.<br />

conventional glass peening and <strong>Ultrasonic</strong><br />

RT; 600MPa, R=0<br />

shot peening. In case of <strong>Ultrasonic</strong> shot<br />

<strong>Ultrasonic</strong> shot peened 0,27N<br />

peening with a high Almen intensity value, the<br />

<strong>Ultrasonic</strong> shot peened 0,18N<br />

conventional glass peened 0.27N<br />

scatter can be reduced.<br />

conventional glass peened 0,18N<br />

Compared to the unpeened surface condition,<br />

unpeened<br />

all tested peening processes and Almen<br />

intensities show an increase of the HCF life<br />

about one magnitude.<br />

SEM investigations indicate surface failures<br />

for the unpeened condition and subsurface<br />

failures for all peened specimens (Figure 18,<br />

19, 20).<br />

R-16691 0608A02861<br />

Figure 18:<br />

unpeened<br />

peening parameter<br />

Figure 19: conv.<br />

glass peened<br />

R-16383-16385 0603A02279<br />

<strong>Shot</strong> peening of Ti6246 also leads to similar<br />

resulting HCF life for conventional glass<br />

peening and <strong>Ultrasonic</strong> shot peening.<br />

Compared to the unpeened surface condition<br />

specimens peened with the higher Almen<br />

intensity show a slightly improved HCF life<br />

whereas peening with low Almen intensity<br />

leads to HCF life which is more or less<br />

comparable to unpeened surfaces (Figure<br />

21).<br />

SEM investigations indicate surface failures<br />

for the unpeened condition and subsurface<br />

failures for all peened specimens (Figure 22,<br />

23, 24).<br />

peening parameter<br />

1,E+04 1,E+05 1,E+06 1,E+07<br />

cycles<br />

Figure 20: <strong>Ultrasonic</strong><br />

shot peened<br />

R-16525 0605A02960<br />

Figure 21. HCF Test results Ti6246.<br />

<strong>Ultrasonic</strong> shot peened 0.27N<br />

<strong>Ultrasonic</strong> shot peened 0.18N<br />

conventionell glass 0.27N<br />

conventionall glass 0.18N<br />

unpeened<br />

RT, 800MPa, R=0<br />

1,E+05 1,E+06 1,E+07<br />

cycles to failure

![Download PDF [5,37 MB] - MTU Aero Engines](https://img.yumpu.com/21945461/1/190x125/download-pdf-537-mb-mtu-aero-engines.jpg?quality=85)