You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CYLINDER HEAD & COMPONENTS . VALVES . GUIDES . ROCKER GEAR<br />

22<br />

Performance<br />

& TUNING<br />

Cylinder Head & Components<br />

On all Triumph engines, the cylinder head must be gas flowed properly to<br />

maximise the performance & efficiency from the engine.<br />

Special note for 948/1147 Cylinder Heads:<br />

The cylinder head on the (948/1147) 6 port engines has been fitted with a<br />

number of different size valves during the production run. The Herald<br />

models were always fitted with a larger valve than the Spitfire models,<br />

although these were also of the ‘slide in’ type of valve cap (not<br />

recommended). All the modifications are based using the largest valves<br />

and to the ‘flow rig designed’ chamber/ports profile. Our heads are<br />

supplied ready assembled with new valves, TT springs and new guides.<br />

Work on the cylinder head centres around making the best diameter of the<br />

inlet port to suit and give maximum power potential. We have found that<br />

increasing the size of the Inlet Valve to 1.475" and very careful flowing of<br />

chamber/valve throat area will produce good torque and allow top-end<br />

breathing for sprint/racing use. The increase in exhaust valve size<br />

(competition use only) improves the flow of the port for maximum power.<br />

All heads are supplied ready assembled with new valve springs & guides.<br />

The cylinder head modifications have been designed using a flow-rig to<br />

obtain the maximum from the head casting.<br />

Valve springs fitted to all our cylinder heads are the best uprated road<br />

specification. They are designed to allow the maximum lift from our<br />

performance camshaft profiles without excessive loads on the cam-lobes.<br />

Spring retainers must be checked - especially the two part version for<br />

cracks. Alloy types are available to save weight whilst still being strong<br />

enough for all applications.<br />

Valves, these are recommended to be gas flowed in the slim design, as<br />

this will improve the efficiency of the modified cylinder head<br />

substantially.<br />

Rocker Gear (General)<br />

For a road car the standard rocker gear only requires minor alterations.<br />

For competition use or maximum power then the use of the roller rockers<br />

will be a major benefit.<br />

By reducing the weight of the moving components in the rocker gear,<br />

followers, valves, caps etc. and also the 'resistance of the rockers', the<br />

rev range can be improved without increasing the loading on the<br />

camshaft.<br />

Valves<br />

TriumphTune reshaped valves are manufactured in the very hard wearing<br />

stainless steel EN214 material.<br />

Valve Guides (Bronze)<br />

Our 'bronze alloy' valve guides are for improved reliability and longer life,<br />

especially when being used under duress. Highly recommended for all<br />

heads and especially for any competition engine. Specially reshaped for<br />

'improved' flow.<br />

Valve Springs<br />

It is essential to check the springs for 'coil binding' or being solid at<br />

maximum lift. Our TriumphTune valve springs are specially made for our<br />

high-lift cams. Remove lower spring collars if TriumphTune springs are<br />

used, as they are no longer required.<br />

Valve Spring Caps (Alloy)<br />

Standard caps are adequate in strength for all applications, but our<br />

TriumphTune 'Light alloy' caps reduce valve loading and therefore wear<br />

on cam lobes. Weight saving is approximately 25%.<br />

Rocker Arm Action<br />

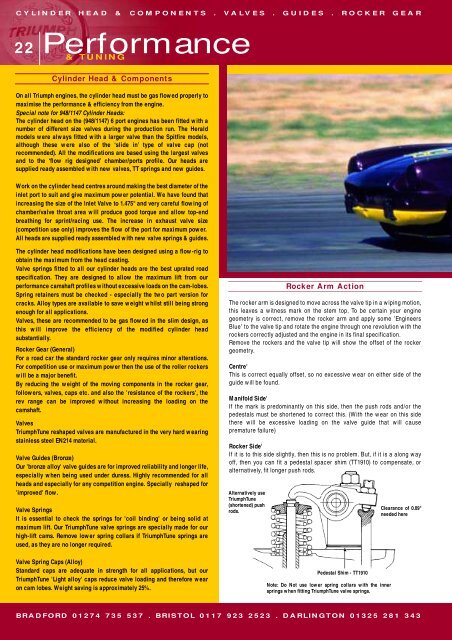

The rocker arm is designed to move across the valve tip in a wiping motion,<br />

this leaves a witness mark on the stem top. To be certain your engine<br />

geometry is correct, remove the rocker arm and apply some 'Engineers<br />

Blue' to the valve tip and rotate the engine through one revolution with the<br />

rockers correctly adjusted and the engine in its final specification.<br />

Remove the rockers and the valve tip will show the offset of the rocker<br />

geometry.<br />

Centre'<br />

This is correct equally offset, so no excessive wear on either side of the<br />

guide will be found.<br />

Manifold Side'<br />

If the mark is predominantly on this side, then the push rods and/or the<br />

pedestals must be shortened to correct this. (With the wear on this side<br />

there will be excessive loading on the valve guide that will cause<br />

premature failure)<br />

Rocker Side'<br />

If it is to this side slightly, then this is no problem. But, if it is a along way<br />

off, then you can fit a pedestal spacer shim (TT1910) to compensate, or<br />

alternatively, fit longer push rods.<br />

Alternatively use<br />

TriumphTune<br />

(shortened) push<br />

rods.<br />

Pedestal Shim - TT1910<br />

Note: Do Not use lower spring collars with the inner<br />

springs when fitting TriumphTune valve springs.<br />

Clearance of 0.09"<br />

needed here<br />

BRADFORD 01274 735 537 . BRISTOL 0117 923 2523 . DARLINGTON 01325 281 343