- Page 1 and 2:

0.0 THE BEGINNING INTRODUCTION CAST

- Page 3 and 4:

The contributors: Jason Adams Charl

- Page 5 and 6: TABLE OF CONTENTS 0.0 THE BEGINNING

- Page 7 and 8: WHEELWEIGHTS AND HEAT TREATING CAST

- Page 9 and 10: HOW TO DETERMINE “FIRST SHOT HIT

- Page 11 and 12: ALLOY CYLINDER WEIGHTS BY CALIBER A

- Page 13 and 14: 1.0 SAFETY BULLET CASTING SAFETY Th

- Page 15 and 16: Second, after you pick up each case

- Page 17 and 18: educe the pressures until the effec

- Page 19 and 20: Tapered bullets have bands that are

- Page 21 and 22: last band .315”. Bullet seated in

- Page 23 and 24: These are the hollow base and stand

- Page 25 and 26: The most important thing about slug

- Page 27 and 28: From Ken Mollohan: Joe, Pretty nice

- Page 29 and 30: 2.2 BULLET DESIGN AND FIT How To Sc

- Page 31 and 32: A .257" diameter, 1" long wheelweig

- Page 33 and 34: Here's a table showing the wind def

- Page 35 and 36: Here's the same data as a graph: He

- Page 37 and 38: I just have to study these tables a

- Page 39 and 40: Army. About 40% of the bullet is a

- Page 41 and 42: throat, reducing down at 1 degree a

- Page 43 and 44: to fit the chamber. The 387178 is a

- Page 45 and 46: it drops in of its own weight, it i

- Page 47 and 48: Over stabilization Let's take anoth

- Page 49 and 50: Repeat this several times until you

- Page 51 and 52: Lead bullets weigh (very) approxima

- Page 53 and 54: 1,000-yd line. A faster twist would

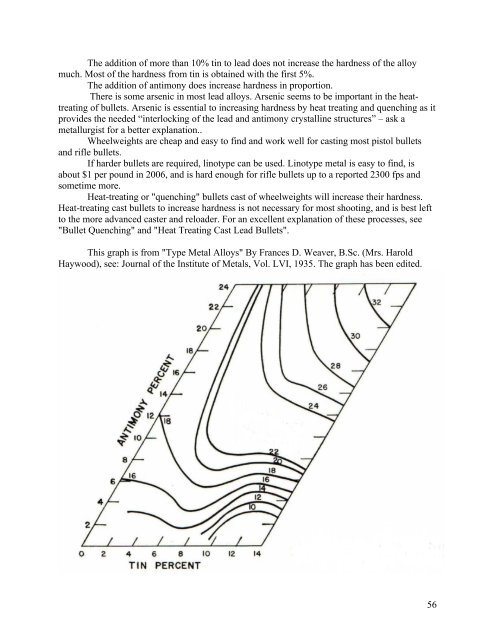

- Page 55: 3.2 BULLET CASTING METALS ACQUIRING

- Page 59 and 60: Based on all of this data, I conclu

- Page 61 and 62: Bill McGraw: "Tin (Sn) has a specif

- Page 63 and 64: difference in percentage of tin or

- Page 65 and 66: So the mystery alloy has about 2% t

- Page 67 and 68: "Quickload" is a computer program t

- Page 69 and 70: These are the prescriptions for the

- Page 71 and 72: 38/55 160-31 Floyd 246 Rel 7 17 WW

- Page 73 and 74: (psi) which simplifies matching the

- Page 75 and 76: achieve some very high velocities w

- Page 77 and 78: 3.4 HOW TO CAST BULLETS Safety Melt

- Page 79 and 80: Bullet molds come in “nose pour

- Page 81 and 82: lasts just under two hours. I inspe

- Page 83 and 84: Here's my setup for weighing bullet

- Page 85 and 86: over and make a mess, but it doesn

- Page 87 and 88: Filing the mold top. Filing chamfer

- Page 89 and 90: Make sure the mold is adjusted acco

- Page 91 and 92: A set of bullets had the bases file

- Page 93 and 94: damaged = filed bases fly wildly to

- Page 95 and 96: More damaged bullets To damage some

- Page 98 and 99: tests: I repeated the tests on 5/23

- Page 100 and 101: 4.0 HOW TO MODIFY CAST BULLETS . Bu

- Page 102 and 103: 4) Even if bullets are slightly ell

- Page 104 and 105: the handle joint trying to get them

- Page 106 and 107:

How many revolutions, or how long d

- Page 108 and 109:

If you want to enlarge a mold more

- Page 110 and 111:

out once on a RCBS 165 gr. Sil. bul

- Page 112 and 113:

ullets to fit his rifles, and set m

- Page 114 and 115:

I use the NUT; it fits inside the S

- Page 116 and 117:

4.2 GAS CHECKS Gas checks are small

- Page 118 and 119:

Tom Gray on CBA "My use of annealed

- Page 120 and 121:

"I use gas checks in my 44 Mags on

- Page 122 and 123:

4.3 Swaging Cast Bullets Norman F.

- Page 124 and 125:

The other meaning; that which Tom G

- Page 126 and 127:

Commercial .38 Caliber SWC Swaged t

- Page 128 and 129:

Swaging Flat Points From 250 Grain

- Page 130 and 131:

Illustration 3230 Grain FMJ Swaged

- Page 132 and 133:

local auto factory to be measured f

- Page 134 and 135:

The Lee Classic press will not swag

- Page 136 and 137:

4.4 PAPER-PATCHED BULLETS Ken Mollo

- Page 138 and 139:

A little digging through my bits ga

- Page 140 and 141:

use a Lyman M -die and Lyman seatin

- Page 142 and 143:

ody at groove diameter or slightly

- Page 144 and 145:

4.5 HEAT TREATING LEAD BULLETS HEAT

- Page 146 and 147:

method, I've produced bullets as ha

- Page 148 and 149:

Attached is a graph that I develope

- Page 150 and 151:

Colander Getting the bullets out of

- Page 152 and 153:

Does this matter? That depends on y

- Page 154 and 155:

There have been articles on heat tr

- Page 156 and 157:

I reviewed the test process several

- Page 158 and 159:

Those 34 bullets were then washed i

- Page 160 and 161:

many years ago. Part of it had 1% T

- Page 162 and 163:

the bullet. It’s limited to low v

- Page 164 and 165:

frying pan. When the lube melts, st

- Page 166 and 167:

Keep the heat as low as possible. T

- Page 168 and 169:

Lyman used to sell a device called

- Page 170 and 171:

50% Pure Natural Beeswax 40% Crisco

- Page 172 and 173:

The rifle is a Savage Tactical rifl

- Page 174 and 175:

etch droplets - and their surface t

- Page 176 and 177:

6.1 CAST BULLET RELOADING HOW TO AS

- Page 178 and 179:

ullet can be oriented with the head

- Page 180 and 181:

with my fingers before putting the

- Page 182 and 183:

olt will let me seat the bullet out

- Page 184 and 185:

.38/55 Winchester and Ballard, 375

- Page 186 and 187:

We are told that the energy and vel

- Page 188 and 189:

4. Use Lee die "O" rings between yo

- Page 190 and 191:

TARGET AND HUNTING AMMO, THE WAY I

- Page 192 and 193:

6.2 CARTRIDGE CASES HOW TO CARE FOR

- Page 194 and 195:

down to a smaller diameter, the way

- Page 196 and 197:

Being chicken, I trimmed the cases

- Page 198 and 199:

Oct. 6, '01 - 311403, - 20:1 - 8.3

- Page 200 and 201:

dropping it in water, will keep you

- Page 202 and 203:

I have checked chamber length in mi

- Page 204 and 205:

I still use plated 357 cases to ide

- Page 206 and 207:

As part of the case inspection proc

- Page 208 and 209:

come by: If you don't have a chemic

- Page 210 and 211:

6.3 PRIMERS AND PRIMING TOOLS Ameri

- Page 212 and 213:

most cases with the Lee Auto Prime,

- Page 214 and 215:

another by the force of the firing

- Page 216 and 217:

1) Fill Cases with Water 3) Lightly

- Page 218 and 219:

6.4 POWDERS AND POWDER MEASURES Use

- Page 220 and 221:

Second, this powder can be hard to

- Page 222 and 223:

THE ASTOUNDING POWDER MEASURE TEST!

- Page 224 and 225:

Dippers and repeatability Hoping th

- Page 226 and 227:

The Lee Perfect measure doesn't cru

- Page 228 and 229:

AA#9 14.5 grains 55 grains IM R4227

- Page 230 and 231:

The Chargemaster must be put on a s

- Page 232 and 233:

Yet other shooters use grease or lu

- Page 234 and 235:

If a person has a less than perfect

- Page 236 and 237:

I rechambered to .50-140, switched

- Page 238 and 239:

Did the chamber of the 30/30 or 30/

- Page 240 and 241:

6.6 HOW TO WORK UP AN ACCURATE RIFL

- Page 242 and 243:

a bullet that is properly fitted to

- Page 244 and 245:

For gas check bullets, the metal sh

- Page 246 and 247:

Powder A Powder B Powder C #1 Prime

- Page 248 and 249:

It seems pretty clear that variatio

- Page 250 and 251:

"I value my Pact I because it gives

- Page 252 and 253:

underlying average and we call it M

- Page 254 and 255:

Another way to look at the relation

- Page 256 and 257:

Here's a table showing the muzzle v

- Page 258 and 259:

no neck. To hold a bullet in the ca

- Page 260 and 261:

Sometimes the bullet will breech se

- Page 262 and 263:

Here are the cases from the side, s

- Page 264 and 265:

This photo shows the rifle barrel w

- Page 266 and 267:

The breech-muzzle loading technique

- Page 268 and 269:

6.6.3 RELOADING CAST LEAD BULLETS F

- Page 270 and 271:

When you slug your barrel, note if

- Page 272 and 273:

MORE ABOUT SHOOTING LEAD BULLETS IN

- Page 274 and 275:

for hand gunners are the semi-wadcu

- Page 276 and 277:

I now use BHN = 10 alloy ( 20:1 Pb:

- Page 278 and 279:

evolver. But, the effects of changi

- Page 280 and 281:

6.6.4 LOADING AND RELOADING WITH BL

- Page 282 and 283:

Cartridge firearms using black powd

- Page 284 and 285:

"I loaded up some loads and shot th

- Page 286 and 287:

Black powder cartridges "In a cartr

- Page 288 and 289:

Many shooters use a “blow tube”

- Page 290 and 291:

Another caveat is that this was all

- Page 292 and 293:

Roll a piece of wrapping paper abou

- Page 294 and 295:

Moisten entire front end of paper a

- Page 296 and 297:

Drop right in a 58 Remington. Colts

- Page 298 and 299:

It is claimed that 22 cast bullets

- Page 300 and 301:

My own experience shooting 22 cast

- Page 302 and 303:

6.7 ON HEADSPACE (Drawings courtesy

- Page 304 and 305:

Other cases headspacing on the shou

- Page 306 and 307:

Thanks to Paul Brasky for asking wh

- Page 308 and 309:

primer protrusion is equal to the e

- Page 310 and 311:

6.8 ON MOLY COATED BULLETS Jesse H.

- Page 312 and 313:

A Note on the Lee Collet Die by Joe

- Page 314 and 315:

In aiming the rifle (N.R.A. standin

- Page 316 and 317:

Good luck be with you." 315

- Page 318 and 319:

The rifle should be free to recoil

- Page 320 and 321:

I used this arrangement for many ye

- Page 322 and 323:

Here's the muzzle clamp with the wo

- Page 324 and 325:

7.3 SIGHTS Sights are either iron s

- Page 326 and 327:

glare on exposed sights. The tube k

- Page 328 and 329:

The Anschutz sight has clicks of .0

- Page 330 and 331:

HOW TO ADJUST A WINDGAUGE FRONT SIG

- Page 332 and 333:

is to file a little bit back on! Or

- Page 334 and 335:

emove parallax. I have a Simmons 4X

- Page 336 and 337:

In the ASSRA matches, I believe tha

- Page 338 and 339:

Test 1 "Effect Of Learning On Dispe

- Page 340 and 341:

7.4 ON ACCURACY Accuracy is the deg

- Page 342 and 343:

I propose the following procedure f

- Page 344 and 345:

Number Upper Lower Upper Lower of g

- Page 346 and 347:

were less than 1:2, most were much

- Page 348 and 349:

7.5 SPOTTING SCOPES Spotting Scopes

- Page 350 and 351:

7.6 SHOOTING IN MIRAGE AND WIND Win

- Page 352 and 353:

7.7 CANT (Cant in a handgun is not

- Page 354 and 355:

ig envelope held on with a rubber b

- Page 356 and 357:

those minimum shot/maximum shot par

- Page 358 and 359:

I have been shooting a CPA 32-40 cl

- Page 360 and 361:

After ten patches, if the next patc

- Page 362 and 363:

juice is turned on. The plan is to

- Page 364 and 365:

8.1 CAST BULLET ASSOCIATION MATCHES

- Page 366 and 367:

CBA PRODUCTION CLASS--John Alexande

- Page 368 and 369:

Barrels: Hart 6 Shilen 3 Lilja 3 St

- Page 370 and 371:

In Cast Bullet competition there is

- Page 372 and 373:

(b) Targets the original issued sto

- Page 374 and 375:

8.2 INTRODUCTION TO SCHUETZEN RIFLE

- Page 376 and 377:

8.3 BUFFALO RIFLE Forrest Asmus I l

- Page 378 and 379:

weight of course and such weight wi

- Page 380 and 381:

8.4 BLACK POWDER SHOOTING We're for

- Page 382 and 383:

in and soften the black powder foul

- Page 384 and 385:

8.5 HUNTING WITH CAST BULLETS HUNTI

- Page 386 and 387:

Boar hog taken with a pure lead .49

- Page 388 and 389:

Hog/deer double taken with a .308 a

- Page 390 and 391:

The wad (beeswax softened with enou

- Page 392 and 393:

further; otherwise, the HT-Q bullet

- Page 394 and 395:

deer's forequarter from this one ti

- Page 396 and 397:

priming charge which lights off the

- Page 398 and 399:

The rifle muzzle showing the alignm

- Page 400 and 401:

produce this size bullet diameter.

- Page 402 and 403:

Hodgdon brand Pyrodex and Triple Se

- Page 404 and 405:

USA 492-450 Bullet greaser for .451

- Page 406 and 407:

Some commonly used muzzleloading pr

- Page 408 and 409:

Full bore conicals should be lubed

- Page 410 and 411:

First is the single shot pistol wit

- Page 412 and 413:

military configuration. "F" grade i

- Page 414 and 415:

This is a photo of a Peabody Creedm

- Page 416 and 417:

many shooters share this opinion. M

- Page 418 and 419:

This action is similar to the 1885

- Page 420 and 421:

the time and money to have a rifle

- Page 422 and 423:

The earlier Mausers are legion. The

- Page 424 and 425:

configuration, available from Colt,