Keep your Elastomers flexible

Keep your Elastomers flexible

Keep your Elastomers flexible

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Flame Retardants<br />

Due to the chemical constitution TPU’s<br />

are easy to ignite and are therefore<br />

difficult to flame retard. By adding a<br />

metal phosphinate (Exolit OP 1230) in<br />

combination with additional flame<br />

retardants the desired classification<br />

UL 94 V-0 is achieved. But only with<br />

the addition of a further ingredient<br />

(antidrip, e.g. talc) the dripping of the<br />

specimen in the UL 94 test could be<br />

prevented, which is required for some<br />

test in the cable industry (Chart 1).<br />

Graph 2 shows, that the mechanical<br />

properties in this case elongation at<br />

break are maintained on an acceptable<br />

value.<br />

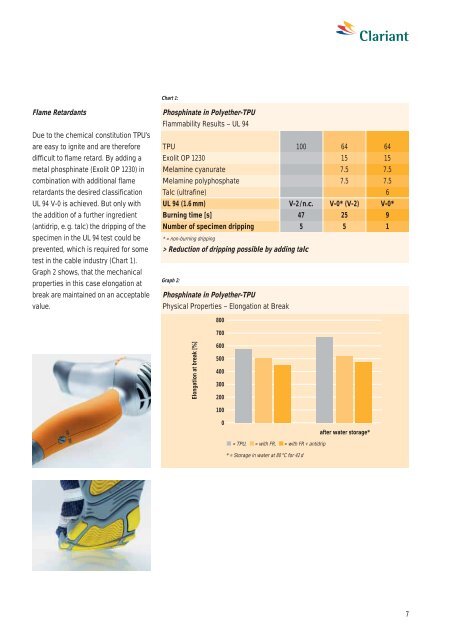

Chart 1:<br />

Phosphinate in Polyether-TPU<br />

Flammability Results – UL 94<br />

TPU 100 64 64<br />

Exolit OP 1230 15 15<br />

Melamine cyanurate 7.5 7.5<br />

Melamine polyphosphate 7.5 7.5<br />

Talc (ultrafine) 6<br />

UL 94 (1.6 mm) V-2/n.c. V-0* (V-2) V-0*<br />

Burning time [s] 47 25 9<br />

Number of specimen dripping 5 5 1<br />

* = non-burning dripping<br />

> Reduction of dripping possible by adding talc<br />

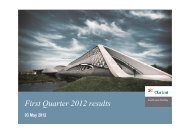

Graph 2:<br />

Phosphinate in Polyether-TPU<br />

Physical Properties – Elongation at Break<br />

Elongation at break [%]<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

= TPU, = with FR, = with FR + antidrip<br />

* = Storage in water at 80 °C for 42 d<br />

after water storage*<br />

7