Knee Type Milling Machines - Manfred Fedler jun. MF ...

Knee Type Milling Machines - Manfred Fedler jun. MF ...

Knee Type Milling Machines - Manfred Fedler jun. MF ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

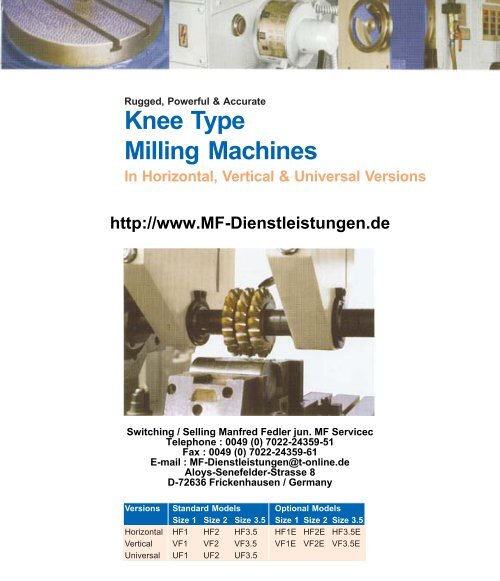

Rugged, Powerful & Accurate<br />

<strong>Knee</strong> <strong>Type</strong><br />

<strong>Milling</strong> <strong>Machines</strong><br />

In Horizontal, Vertical & Universal Versions<br />

http://www.<strong>MF</strong>-Dienstleistungen.de<br />

Switching / Selling <strong>Manfred</strong> <strong>Fedler</strong> <strong>jun</strong>. <strong>MF</strong> Servicec<br />

Telephone : 0049 (0) 7022-24359-51<br />

Fax : 0049 (0) 7022-24359-61<br />

E-mail : <strong>MF</strong>-Dienstleistungen@t-online.de<br />

Aloys-Senefelder-Strasse 8<br />

D-72636 Frickenhausen / Germany<br />

Versions Standard Models Optional Models<br />

Size 1 Size 2 Size 3.5 Size 1 Size 2 Size 3.5<br />

Horizontal HF1 HF2 HF3.5 HF1E HF2E HF3.5E<br />

Vertical VF1 VF2 VF3.5 VF1E VF2E VF3.5E<br />

Universal UF1 UF2 UF3.5

<strong>Knee</strong> <strong>Type</strong> <strong>Milling</strong> <strong>Machines</strong><br />

Standard Models : HF1, VF1, UF1, HF2, VF2, UF2, HF3.5, VF3.5, UF3.5<br />

Rugged, powerful and precision knee type milling mahines are offered in Horizontal, Vertical<br />

and Universal versions in size 1, size 2 and size 3.5 models to suit the varied requirements of<br />

the customer. Electrical cycle controlled models in horizontal and vertical versions are offered<br />

for series and mass production of components.<br />

Features<br />

Rigid Structure<br />

The rigid spindle housing, cross ribbed box type column structure, closed box<br />

type knee design ensure optimum chip removal capacity and surface finish. The<br />

rigid structure ensures vibration free and smooth machining.<br />

Work spindle<br />

Optimum spacing of precision taper roller bearings ensure vibration free cutting.<br />

The bearing preload is adjusted by a common nut.<br />

Vertical milling head can<br />

be swivelled either side of<br />

vertical by 45deg.<br />

Vertical <strong>Milling</strong> Machine VF1<br />

Power operated feedin longitudinal & cross<br />

directions for standard Size 1 machine. Rapid<br />

feed in longitudinal direction as option.<br />

Guides<br />

Table, cross slide and the knee slide in dovetail guide ways.<br />

The dovetail guide ways are amply dimensioned to resist<br />

extreme machining loads. The guide ways are protected<br />

constantly from the ingress of swarf and coolant.<br />

Three lever control for spindle<br />

speed selection<br />

Three lever control for<br />

feed selection<br />

Column mounted<br />

electrical cabinet<br />

<strong>Milling</strong> head can be moved<br />

away from work position<br />

quickly with ease and<br />

parked on the side of the<br />

column<br />

Table drive<br />

Lead screw with 2 nuts for backlash free setting. Feed<br />

selection by sliding gear drive. Reversal of movement<br />

direction by motor reversal, dead accurate stop by brake<br />

clutch. Change over and rapid traverse feed by multi disc<br />

clutch.

Power operated feed and rapid<br />

traverse in longitudinal, cross and<br />

vertical directions for Size 2 & 3.5<br />

models.<br />

Differential thread<br />

clamping system for knee<br />

ensures higher clamping<br />

force.<br />

Large tray on the base<br />

plate to collect chip and<br />

coolant<br />

Universal <strong>Milling</strong> Machine UF2<br />

„<br />

Motorised Over Arm (MOA)<br />

An added advantage of vertical spindle on horizontal and universal<br />

machines on size 2 and size 3.5 models.<br />

MOA is supplied with a vertical milling head. A manual quill stroke<br />

of 70 mm is available on milling head. MOA comes with<br />

independent drive motor of 3kW (4HP) power. Spindle is provided<br />

with 12 speeds in the range 45 - 2000 rpm and ISO 40 taper.<br />

Since MOA itself is used as over arm for mounting arbor support<br />

bracket, the machine doesn’t require normal over arm.<br />

Horizontal <strong>Milling</strong> Machine HF 3.5<br />

Rigid over-arm makes overarm<br />

brace superfluous<br />

Lubrication<br />

Central lubrication for guide ways and<br />

leadscrews. Splash lubrication for speed and feed<br />

gearing.<br />

Coolant<br />

An electric pump mounted at the rear of the<br />

machine base ensures copious flow of coolant<br />

to the work zone. The coolant is discharged in to<br />

the built - in coolant tank in the machine base.<br />

Chip collection and<br />

coolant diversion with<br />

large tray below the table<br />

Built-in coolant tank<br />

in machine base

Electrical cycle controlled<br />

<strong>Machines</strong> as option<br />

Models :HF1E, VF1E, HF2E, VF2E,<br />

HF3.5E, VF3.5E<br />

These special version machines are provided<br />

with highly reliable Programmable Logic<br />

Controller (PLC) which enables programming of<br />

table movement in longitudinal direction.<br />

Extremely useful for series and mass production<br />

of components with consistent accuracy, these<br />

machines ensure minimum idle time and<br />

optimum efficiency.<br />

Attachments and Accessories for Increased Flexibility<br />

VMH can be swiveled 45 deg. on either side<br />

and clamped. The quill carrying the cutter<br />

spindle can be moved manually along its axis<br />

up or down and clamped in the desired<br />

position. Four position turret stop and rapid<br />

quill movement facility (for size 1 & size 2<br />

machines only) are provided as optional<br />

features on vertical milling head.<br />

UDH allows simple, differential and<br />

compound dividing. With universal milling<br />

machine it can also be used for spiral<br />

milling. Spindle axis can be tilted in the<br />

vertical plane.<br />

RMA permits manufacturing of racks with all<br />

modules normally required. Suitable for<br />

horizontal and universal versions, it consists of<br />

a milling unit, a fixture and a manually operated<br />

dividing attachment connected to the table drive<br />

lead screw.<br />

This equipment can be used for<br />

milling and drilling operations<br />

whenever direct indexing up to<br />

12 or 24 divisions is required.<br />

Machine vices are offered with a solid base and<br />

also a swivel base. They are supplied with jaw<br />

width 100 – 250mm and clamping capacity up<br />

to 150mm.<br />

Ideal for circular dividing, these are used for<br />

accurate rotary movements. They are offered<br />

in 250mm dia. and 400mm dia. Motorized<br />

version is supplied for 400 mm table.<br />

Used for milling of accurate radial grooves &<br />

slots and drilling radial holes in round<br />

components. It can be used for vertical or<br />

horizontal positions.<br />

Consists of a fixed base over which a swivel base<br />

and slotting ram are mounted. The drive from the<br />

machine spindle is transmitted as a reciprocating<br />

motion to the ram for machining of slots.

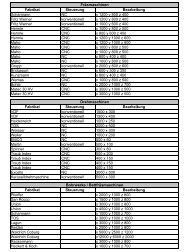

MACHINE DIMENSIONS<br />

Horizontal Vertical Universal<br />

Details HF1 HF2 HF3.5 VF1 VF2 VF3.5 UF1 UF2 UF3.5<br />

HF1E HF2E HF3.5E VF1E VF2E VF3.5E<br />

A1 1960 2450 3600 1960 2450 3600 1975 2730 3410<br />

A2 500 500 700 500 500 700 500 500 700<br />

A3 940 1155 1800 940 1155 1800 1045 1280 1681<br />

A4* 1105 1350 1630 1105 1350 1630 1090 1350 1630<br />

A5* Min 245 335 180 245 335 180 265 335 380<br />

Max 805 1135 1380 805 1135 1380 825 1135 1380<br />

B1 1480 1730 2120 - - - 1480 1730 2120<br />

B2 1407 1657 2047 1691 1890 2345 1407 1657 2047<br />

B3 1100 1295 1565 1167 1367 1626 1100 1295 1565<br />

B4 Min -10 90 70 57 162 131 -10 50 70<br />

Max 380 490 520 447 562 581 330 450 470<br />

B5 115 145 185 - - - 115 145 185<br />

B6 - - - 70 70 100 - - -<br />

C1 1591 1900 2550 1591 1900 2550 1591 1900 2550<br />

C2 1050 1060 1500 1050 1060 1500 1050 1060 1500<br />

C3 230 315 355 230 315 355 230 315 315<br />

C4 465 465 589 - - - 465 465 589<br />

C5 43 43 55 - - - 43 43 55<br />

C6 - - - 250 300 360 - - -<br />

C7 Min 40.5 27.5 21.5 40.5 27.5 21.5 40.5 17.5 54<br />

Max 290.5 257.5 341.5 290.5 257.5 341.5 290.5 247.5 347<br />

*Dimensions given for left end of clamping table clamping area

TECHNICAL DATA Horizontal Vertical Universal<br />

Unit HF1 HF2 HF3.5 VF1 VF2 VF3.5 UF1 UF2 UF3.5<br />

HF1E HF2E HF3.5E VF1E VF2E VF3.5E<br />

Table overall size (L x W) mm 1245 x 230 1555 x 315 2055 x 355 1245 x 230 1555 x 315 2055 x 355 1175 x 230 1555 x 315 2055 x 315<br />

Clamping area mm 1000 x 230 1350 x 315 1630 x 355 1000 x 230 1350 x 315 1630 x 355 1000 x 230 1350 x 315 1630 x 315<br />

T-slots No./Width/CD mm 3/14/45 3/14/63 3/18/100 3/14/45 3/14/63 3/18/100 3/14/45 3/14/63 3/18/100<br />

Swivel range of table<br />

to both sides<br />

Longitudinal movement<br />

degrees - - - - - - 45 45 45<br />

Automatic mm 560 800 1200 560 800 1200 560 800 1000<br />

Manual<br />

Traverse movement<br />

mm 590 830 1230 590 830 1230 590 830 1030<br />

Automatic mm 250 230 320 250 230 320 250 230 320<br />

Manual<br />

Vertical movement<br />

mm 270 260 350 270 260 350 270 260 350<br />

Automatic mm - 400 450 - 400 450 - 400 400<br />

Manual mm 390 420 470 390 420 470 340 420 420<br />

Quill stroke, manual mm - - - 70 70 100 - - -<br />

<strong>Milling</strong> spindle front bearing Ø mm 70 85 95 70 85 95 70 85 95<br />

Spindle taper ISO 40 40 50 40 40 50 40 40 50<br />

Vertical milling head<br />

swivelling to both side<br />

(Graduated upto 50 deg.)<br />

degrees - - - 45 45 45 - - -<br />

Speed Range rpm 45-2000 45-2000 35.5-1800 45-2000 45-2000 35.5-1800 45-2000 35.5-1800 35.5-1800<br />

No./progression 12/1.4 12/1.4 18/12.25 12/1.4 12/1.4 18/1.25 12/1.4 12/1.4 18/1.25<br />

No. of Feeds<br />

Feed range (Prog. 1.25)<br />

Nos. 18 18 21 18 18 21 18 18 21<br />

Longitudinal mm/min 16-800 16-800 16-1600 16-800 16-800 16-1600 16-800 16-800 16-1600<br />

Transverse mm/min 16-800 16-800 16-1600 16-800 16-800 16-1600 16-800 16-800 16-1600<br />

Vertical<br />

Rapid traverse<br />

mm/min - 4-200 4-400 - 4-200 4-400 - 4-200 6.6-630<br />

Longitudinal mm/min 2500** 4000 4000 2500** 4000 4000 - 2500 2000<br />

Transverse mm/min - 4000 4000 - 4000 4000 - 2500 2000<br />

Vertical mm/min - 1000 1000 - 1000 1000 - 630 800<br />

<strong>Milling</strong> spindle motor kW 3 5.5 11 3 5.5 11 3 5.5 11<br />

Feed motor kW 0.75 1.5 1.3/2.2* 0.75 1.5 1.3/2.2* 0.75 1.5 1.3/2.2*<br />

Max. safe Weight<br />

on the table<br />

Kg 170 400 600 170 400 600 170 400 400<br />

Weight/Nett (approx.)<br />

*2 Speed Motors<br />

Kg 1700 2200 3650 1800 2250 3760 1700 2300 3850<br />

**Only for HF1E & VF1E machines