Ohio Exposed Wall Mounted Thermostatic Shower - Jacuzzi

Ohio Exposed Wall Mounted Thermostatic Shower - Jacuzzi

Ohio Exposed Wall Mounted Thermostatic Shower - Jacuzzi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

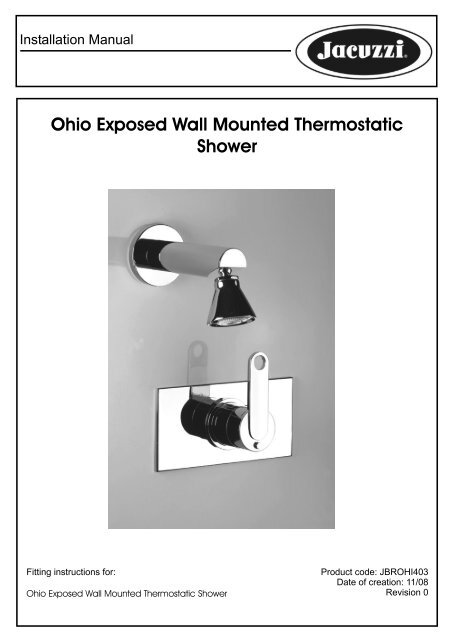

Installation Manual<br />

<strong>Ohio</strong> <strong>Exposed</strong> <strong>Wall</strong> <strong>Mounted</strong> <strong>Thermostatic</strong><br />

<strong>Shower</strong><br />

Fitting instructions for:<br />

<strong>Ohio</strong> <strong>Exposed</strong> <strong>Wall</strong> <strong>Mounted</strong> <strong>Thermostatic</strong> <strong>Shower</strong><br />

Product code: JBROHI403<br />

Date of creation: 11/08<br />

Revision 0

Installation Manual<br />

Water Regulations Requirements :<br />

It is important to ensure that the water supplies to your taps and mixers are connected in<br />

accordance with the water regulation (WRAS) requirements and good plumbing practice.<br />

It is good plumbing practice that the supplies of hot and cold water to the Bathroom fitting should<br />

be equal (balanced) pressure in order to provide a consistent flow. Supplies should be from a<br />

common source, either mains or tank fed. If supplies are not equal pressures then a Non Return<br />

Valve ( Check Valve ) should be fitted on the hot inlet.<br />

It is our recommendation and good plumbing practice that a service valve should be installed in the<br />

inlet supply lines to allow isolation of the Bathroom fitting.<br />

1. Make sure both Hot and Cold supplies have been isolated and drained.<br />

2. Rotate the spout and body so the tap is facing forwards. The spout screw on the tap indicates<br />

the rear of the body. Typically the hot water should be on the left-hand side of the tap.<br />

Before proceeding the assmbly and installation, prepare a smooth surface where you can lay all the<br />

particulars being sure not to damage them.<br />

SYSTEM REQUIREMENTS<br />

To ensure the optimum performance and customer satisfaction please adhere to the following:<br />

• Flush out all pipe work prior to installation.<br />

• Minimum flow pressure for satisfactory operation: (Hot and Cold) 0.2 Bar 20kPa<br />

• Maximum static water pressure 10 Bar 1,000kPa<br />

• If the water pressure exceeds or is likely to exceed 10 Bar 1,000kPa, an approved pressure<br />

limiting valve must be fitted.<br />

• Maximum hot water temperature 80ºC<br />

• If the water temperature exceeds 80ºC an approved tempering valve must be fitted.<br />

• Installation should comply with relevant local authority requirements.<br />

Failure to comply with the above will void all warranties.<br />

Tools required.

Installation Instructions<br />

Please note these instructions are for the hot and cold inlet pipes to enter the mixer from below the<br />

mixer and the outlet to the shower at the top.<br />

If the inlet pipes are located above the mixer rotate the mixer 180 degrees and fasten as indicated<br />

below.<br />

To ensure correct operation of the valve the installer will need to remove the chrome cover sleeve from<br />

the mixer by unscrewing the two grub screws holding the sleeve in place and undoing the large brass<br />

nut holding the thermo cartridge in place, remove the cartridge and rotate the cartridge 180 degrees and<br />

re-install, ensuring a water tight seal is maintained. Re-position the cover sleeve with the temperature<br />

indication mark facing upwards and then retighten the grub screws to fasten the cover sleeve to the<br />

thermomixer body.<br />

1) Fit plug (not supplied) to shut off bottom outlet<br />

2) Position the thermostatic mixer against a mounting board within a maximum (100mm) and a<br />

minimum (70mm) depth allowed from the back of the mixer and the face of the wall lining and fix.<br />

3) Connect the hot and cold water supplies to the mixer, matching the ot and cold inlet pipes to the<br />

correct hot and cold inlets on the thermo mixer.<br />

4) Connect the pipe work and the volume control valve to the top outlet of the thermostatic mixer, and<br />

the shower rose-slide shower set pipe work to the outlet of the volume control valve.<br />

5) Pressure test by plugging outlet pipes: turn on the water supply and the volume control valve. Once<br />

all joints are proved pressure tight turn off the volume control valve and break the seal on the temporary<br />

outlet plug.<br />

6) Cut an access hole 140mm x 70mm in the wall lining for the mixer; fit wall lining.<br />

7) Apply a thin bead of silicone sealant to the back of the faceplate ensuring a continuous seal is<br />

maintained around the edge of the faceplate.<br />

8) Slide the faceplate over the mixer ensuring the faceplate is correctly positioned on the wall and<br />

covering the access hole.<br />

To fit the handle:<br />

Please note the thermostatic valve has been factory set at approximately 38° C when the handle is<br />

positioned on the mixer at the safety button position. (This will be dependant on the hot and cold water<br />

inlet temperatures).<br />

1) Fit the handle to the valve with the blade of the handle facing in a downward (6 o clock) position and<br />

ensuring the lug on the underside of the handle is just touching the safety button stop on the mixer.<br />

2) Turn on the water supply and test the temperature being delivered from the thermostatic mixer.<br />

To increase the temperature being delivered at the safety button position, remove the handle and turn<br />

the spindle of the thermostatic mixer anticlockwise a few degrees and retest the temperature.<br />

Likewise to decrease the temperature turn the spindle clockwise a few degrees and retest te<br />

temperature.<br />

When the appropriate temperature has been achieved align the handle with the handle facing in a<br />

downward (6 o clock) position and ensuring the lug on the underside of the handle is just touching the<br />

safety button stop on the mixer, tighten the grub screw under the handle.

Installation Manual<br />

Care and Maintenance<br />

Important: When joining any screw connections always use PTFE tape and ensure the joints are<br />

fully tightened. Once the product is installed always check the entire installation for leaks.<br />

Your product may require non-return valves to suit your water system or to conform to local water<br />

Bylaws.<br />

Once the product has been installed turn both the hot and cold water on, thoroughly flush any small<br />

particles that may have been dislodged during the installation of the product.<br />

Only clean the product with a soft cloth, warm water and a mild detergent solution, rinse the product<br />

clean thoroughly afterwards with water. Do not use any abrasive or harsh chemical products,<br />

otherwise this will invalidate your guarantee.<br />

These instructions are only intended as a guide, if there is any doubt then<br />

contact a certified plumber.<br />

Please ensure you register your product with <strong>Jacuzzi</strong> UK using the Warranty<br />

Card enclosed in this box.<br />

<strong>Jacuzzi</strong> UK<br />

For further information please contact:<br />

Customer service<br />

<strong>Jacuzzi</strong> UK<br />

Woodlands, Roydsdale Way<br />

Euroway Trading Estate<br />

Bradford, West Yorkshire<br />

Telephone: 01274 475 178<br />

Fax: 01274 654 771<br />

e-mail: aftersales@jacuzziuk.com<br />

www.jacuzzi.co.uk