English - Putzmeister Mörtelmaschinen

English - Putzmeister Mörtelmaschinen

English - Putzmeister Mörtelmaschinen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Pressemitteilung Nr. 0001-05<br />

A view to France - The "wet in wet - laying" is on the rise<br />

Screed, in its various forms, has been one of the<br />

most established construction materials for<br />

centuries. It was used to secure the supporting<br />

ground in the palace of King Minos in Crete, which,<br />

incidentally, is the oldest use of screed known to<br />

us. Even the builders of the Egyptian pyramids<br />

used an early form of spreadable gypsum screed.<br />

A look “over the fence” to our neighbours in France<br />

reveals that the wet-on-wet laying of bonded<br />

screeds is being used increasingly there to save<br />

time.<br />

<strong>Putzmeister</strong> Mörtelmaschinen GmbH, one of the<br />

leading manufacturers of screed pumps, was able<br />

to observe this process being used in the<br />

construction of a nursing home in Proisy (Aisne<br />

region). On this construction site, which was<br />

equipped with <strong>Putzmeister</strong> screed pumps (e.g.<br />

M740DB), the tiling was laid immediately after the<br />

bonded screed was laid and levelled.<br />

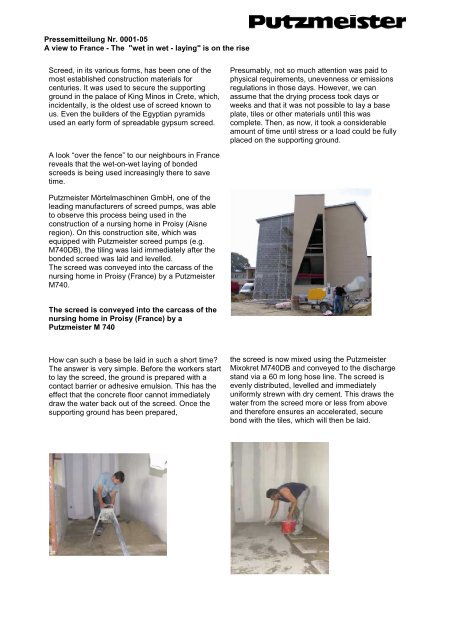

The screed was conveyed into the carcass of the<br />

nursing home in Proisy (France) by a <strong>Putzmeister</strong><br />

M740.<br />

The screed is conveyed into the carcass of the<br />

nursing home in Proisy (France) by a<br />

<strong>Putzmeister</strong> M 740<br />

How can such a base be laid in such a short time?<br />

The answer is very simple. Before the workers start<br />

to lay the screed, the ground is prepared with a<br />

contact barrier or adhesive emulsion. This has the<br />

effect that the concrete floor cannot immediately<br />

draw the water back out of the screed. Once the<br />

supporting ground has been prepared,<br />

Presumably, not so much attention was paid to<br />

physical requirements, unevenness or emissions<br />

regulations in those days. However, we can<br />

assume that the drying process took days or<br />

weeks and that it was not possible to lay a base<br />

plate, tiles or other materials until this was<br />

complete. Then, as now, it took a considerable<br />

amount of time until stress or a load could be fully<br />

placed on the supporting ground.<br />

the screed is now mixed using the <strong>Putzmeister</strong><br />

Mixokret M740DB and conveyed to the discharge<br />

stand via a 60 m long hose line. The screed is<br />

evenly distributed, levelled and immediately<br />

uniformly strewn with dry cement. This draws the<br />

water from the screed more or less from above<br />

and therefore ensures an accelerated, secure<br />

bond with the tiles, which will then be laid.

Once completed, there is a delay of only 24 hours<br />

before the floor can be walked on without causing<br />

damage.<br />

The tiles are laid immediately. The floor can be<br />

walked on again after only 24 hours. The only limit<br />

is that, because the heat is generated "from below",<br />

the system does not work with underfloor heating.<br />

Contact:<br />

<strong>Putzmeister</strong>Mörtelmaschinen GmbH<br />

Frank Kretzschmar<br />

Max-Eyth-Str. 10<br />

72631 Aichtal<br />

mm@pmw.de<br />

http://www.moertelmaschinen.de/<br />

The <strong>Putzmeister</strong> experts observed that 4 workers<br />

were able to use this process to complete a fully<br />

tiled floor of approximately 100 m2 in only one<br />

day. Considering that the usual drying time for<br />

screed can be up to 3 weeks, the wet-on-wet<br />

laying process represents an enormous saving in<br />

both time and money.<br />

2<br />

2