Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

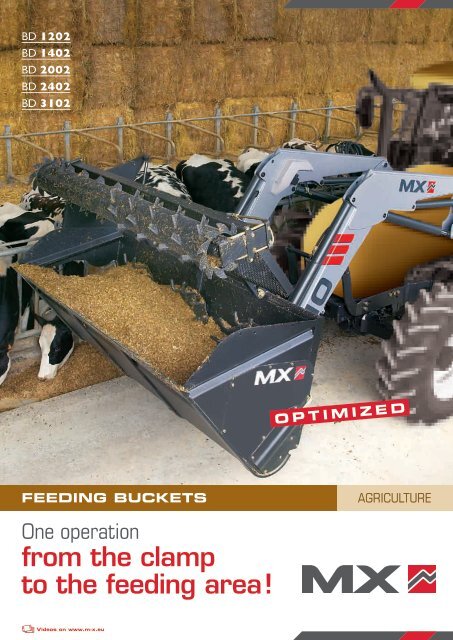

BD 1202<br />

BD 1402<br />

BD 2002<br />

BD 2402<br />

BD 3102<br />

FEEDING BUCKETS Agriculture<br />

One operation<br />

from the clamp<br />

to the <strong>feeding</strong> area !<br />

Videos on www.m-x.eu<br />

Optimized

A g r i c u l t u r e<br />

FEEDING<br />

BUCKETS<br />

MAXIMUM VERSATILITY TO SATISFY<br />

ALL YOUR REQUIREMENTS<br />

Cost effective and easy to use; <strong>MX</strong> BD <strong>feeding</strong> <strong>buckets</strong> handle and distribute a wide variety of<br />

animal feeds. Efficient <strong>feeding</strong> of maize silage, grass silage, roots, grains and concentrates.<br />

Maize Silage Grass Silage Roots<br />

SINGLE<br />

FEED DOOR<br />

DOUBLE FEED<br />

DOOR c/W rotor

Direct<br />

from the clamp<br />

to the <strong>feeding</strong> area !<br />

The concept of the <strong>MX</strong> Feeding Bucket is to simplify the daily process of <strong>feeding</strong> livestock,<br />

hence optimizing your time and reducing costs.<br />

A range of<br />

5 models with a capacity<br />

OF 1 200 l tO 3 100 l<br />

<strong>MX</strong> BD1202<br />

capacity of 1 200 l<br />

<strong>MX</strong> BD1402<br />

capacity of 1 400 l<br />

<strong>MX</strong> BD2002<br />

capacity of 2 000 l<br />

<strong>MX</strong> BD2402*<br />

capacity of 2 400 l<br />

<strong>MX</strong> BD3102*<br />

capacity of 3 100 l<br />

*For material handlers only<br />

SUMMARY<br />

SINGLE FEED DOOR P.4<br />

DOUBLE FEED DOOR P.5<br />

FEED MODES P.6<br />

SPECIFICATION AND OPTIONS P.7

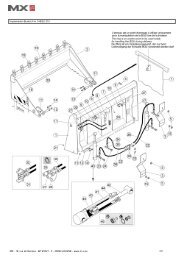

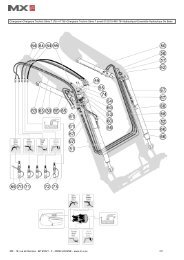

FeeDiNg BucKetS Agriculture<br />

Single Feed Door<br />

An essential attachment to feed<br />

your animals quickly and efficiently.<br />

Strong reliable and easy to use, with large capacities to maximize output.<br />

Additionally the <strong>buckets</strong> outside profile is free from protruding and vulnerable components<br />

which could be damaged against the clamp walls, or <strong>feeding</strong> barriers.<br />

Driven by a powerful hydraulic motor<br />

and gearbox the output to the auger<br />

screw is constant and easily monitored.<br />

A central nylon anti wear bush (maintenance<br />

free) supports the auger screw to ensure<br />

a trouble free life.<br />

The motor inside the<br />

auger is completly<br />

protected, thus<br />

increasing the volume<br />

of the bucket<br />

Optimized<br />

Fast, even distribution.<br />

<strong>MX</strong> Feeding Buckets<br />

are equipped with a powerful<br />

hydraulic motor to ensure<br />

materials are distributed evenly<br />

and quickly.<br />

With the feed door fully closed<br />

the bucket can be easily filled,<br />

then materials are retained for transportation<br />

without spillage.<br />

The feed door and auger screw are sequenced<br />

thus only one hydraulic service is required<br />

Feed door open<br />

Feed door closed<br />

The opening of the feed door<br />

can be adjusted with a stop<br />

to control feed distribution.

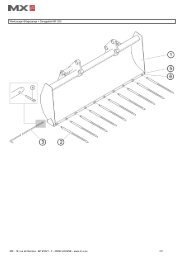

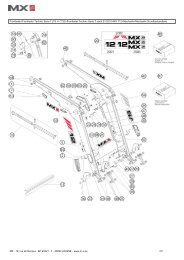

Double feed door<br />

Save time and reduce handler manoeuvres. The “double door” models can distribute materials<br />

from both the left hand side and right hand side, the direction is controlled by the driver in the<br />

cab, via the control joystick of the handler.<br />

Left feed door open Right feed door open<br />

P.04-05<br />

the ideal solution for buildings<br />

with restricted access and “cul-de-sac” feed passages<br />

Adaptable on all types of frame<br />

With their “bolt-on” bracket design <strong>MX</strong><br />

Feeding Buckets can be adapted to fit all makes<br />

of material handlers or front end loaders.<br />

The implement<br />

brackets can be<br />

mounted in an off-set<br />

position to allow<br />

easy distribution<br />

into the feed passage<br />

or over barriers.<br />

FOCUS<br />

Wear blade.<br />

A thick hard<br />

wearing front blade<br />

ensures maximum<br />

rigidity and<br />

durability.<br />

Perfect control of feed doors.<br />

A unique time lag system ensures that one door is fully closed before the<br />

opposite door starts to open. Thus the operator maintains total control<br />

of the <strong>feeding</strong> process. With both doors fully closed materials are retained<br />

inside the bucket without spillage.<br />

Silage kit<br />

A regular distribution of the grass<br />

on both sides<br />

Specifications of the double <strong>feeding</strong> door Feeding<br />

Bucket need an additional kit with specifics forms<br />

to distribute the grass regularly from both sides.<br />

OPTION

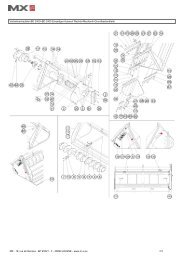

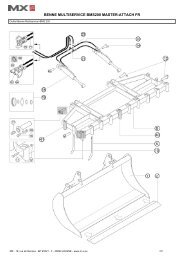

FeeDiNgS BucKetS Agriculture<br />

Handling methods<br />

for clamped silage.<br />

METHOD 1<br />

Fixed<br />

claw tines.<br />

A cost effective and practical solution<br />

for handling both grass or maize silage<br />

without the requirement<br />

of an additional hydraulic service.<br />

The silage is pulled from the clamp<br />

then scooped up with the bucket.<br />

METHOD 2<br />

Hydraulic<br />

grab.<br />

Effective for maize silage, the hydraulic<br />

grab promotes easier and quick loading<br />

of the bucket.<br />

(UK ; not recommended for grass silage<br />

clamps)<br />

METHOD 3<br />

Mobile rotor<br />

Effective for maize silage the self loading rotor<br />

is specifically designed to produce a clean face<br />

on the silage clamp. As the compaction<br />

of the silage becomes more dense towards<br />

the bottom of the clamp the rotor<br />

has a special patented control system that<br />

gives more priority to the rotor; as the clamp<br />

becomes more difficult to penetrate the rotor<br />

is pushed harder and turns faster.<br />

(UK ; not recommended for grass silage clamp)

BD 1202 BD 1402 BD 2002 BD 2402 BD 3102<br />

Feeding door single single double single double single double single double<br />

Width inside (mm) 2 110 2 440 2 440 2 440 2 440 2 440 2 440 2 440 2 440<br />

Width Overall (mm) 2 150 2 480 2 480 2 480 2 480 2 480 2 480 2 480 2 480<br />

Capacity l 900 1 040 1 040 1 500 1 500 1 800 1 800 2 300 2 300<br />

Heaped capacity l 1 200 1 400 1 400 2 000 2 000 2 400 2 400 3 100 3 100<br />

Weight (Kg) 510 565 585 680 700 705 725 800 820<br />

Silage kit :<br />

No. of tines 8 9 9 9 9 9 9 9 9<br />

Hydraulic<br />

silage grab<br />

opening (m) 1,27 1,27 1,27 1,5 1,5 1,95 1,95 1,95 1,95<br />

No.<br />

of tines<br />

size<br />

of tines (mm)<br />

10 12 12 12 12 11 11 11 11<br />

Ø 28<br />

x 560<br />

Ø 28<br />

x 560<br />

Ø 28<br />

x 560<br />

Mobile rotor patented :<br />

No. of cylinders<br />

Agitators :<br />

1 1 1 1 1 2 2 2 2<br />

No. of tines 3 3 3 3 3 3 3 3 3<br />

Root cutter<br />

13 blade<br />

(Fodder beet)<br />

20 blade<br />

(Potatoes)<br />

yes<br />

yes<br />

yes<br />

yes<br />

-<br />

-<br />

yes<br />

yes<br />

-<br />

-<br />

yes<br />

yes<br />

-<br />

-<br />

yes<br />

yes<br />

-<br />

-<br />

Ø 28<br />

x 560<br />

PERFORMANCES P.06-07<br />

Root cutter<br />

The optional root cutter chops the<br />

roots as they are being distributed.<br />

The mechanism is driven by the auger<br />

screw, thus no additional hydraulic<br />

service is required.<br />

A versatile “quick attack” design means<br />

it can be mounted in seconds without<br />

needing any tools.<br />

Distribution<br />

of fodder beet<br />

with a 13 blade<br />

cutter<br />

Agitators<br />

The agitators are driven<br />

by the auger screw. They<br />

break up clods to produce<br />

an even distribution (UK;<br />

not recommended for<br />

grass silage)<br />

MPE 3<br />

The first portable<br />

and wireless<br />

weighing<br />

system for<br />

loaders.<br />

Cost effective, it<br />

allows reliable and<br />

accurate rationing of<br />

materials; i.e. silage stock,<br />

cereals, concentrates, etc.<br />

Ø 28<br />

x 560<br />

Ø 30<br />

x 760<br />

Ø 30<br />

x 760<br />

Ø 30<br />

x 760<br />

Ø 30<br />

x 760<br />

3 point rear linkage<br />

With the 3 point linkage kit you can use<br />

your <strong>feeding</strong> bucket on the front linkage or<br />

rear linkage of your tractor.The bucket can<br />

be easily filled with the aid of an integrated<br />

tipping ram.<br />

Mach 2<br />

Strong, reliable and easy to use, it<br />

enables both couplings of one hydraulic<br />

line to be connected simultaneously in<br />

one simple action, even under pressure.<br />

OPTIONS

www.m-x.eu<br />

19, rue de rennes<br />

BP 83221<br />

F-35690 Acigné<br />

tél :+33 (0)2 99 62 52 60<br />

Fax :+33 (0)2 99 62 50 22<br />

email : contact@m-x.eu<br />

©Mailleux company copyright<br />

10/11- GB - <strong>MX</strong> reserves the right to modify the specification, fittings and prices of the models shown, without notice.<br />

This brochure is not a contractual document. Reproduction of this document is prohibited.