EPU DEVELOPMENT

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GDF SUEZ E&P Deutschland GmbH<br />

Waldstraße 39 – D-49808 Lingen<br />

(Ems)<br />

Telefon +49 (0) 591 / 612 – 0<br />

www.gdfsuezep.de<br />

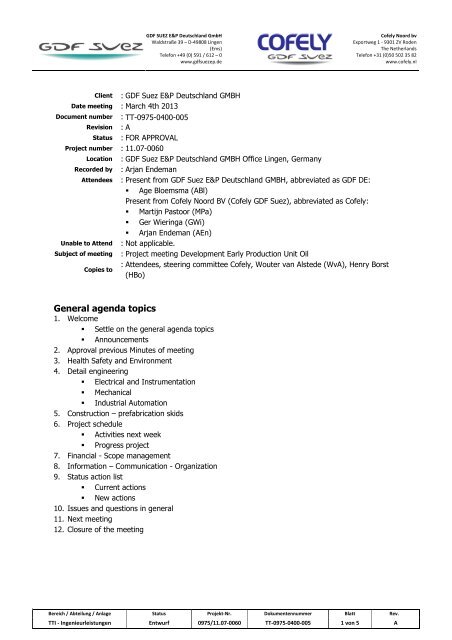

Client : GDF Suez E&P Deutschland GMBH<br />

Date meeting : March 4th 2013<br />

Document number : TT-0975-0400-005<br />

Revision : A<br />

Status : FOR APPROVAL<br />

Project number : 11.07-0060<br />

Location : GDF Suez E&P Deutschland GMBH Office Lingen, Germany<br />

Recorded by : Arjan Endeman<br />

Cofely Noord bv<br />

Exportweg 1 - 9301 ZV Roden<br />

The Netherlands<br />

Telefon +31 (0)50 502 35 82<br />

www.cofely.nl<br />

Attendees : Present from GDF Suez E&P Deutschland GMBH, abbreviated as GDF DE:<br />

Age Bloemsma (ABl)<br />

Present from Cofely Noord BV (Cofely GDF Suez), abbreviated as Cofely:<br />

Martijn Pastoor (MPa)<br />

Ger Wieringa (GWi)<br />

Arjan Endeman (AEn)<br />

Unable to Attend : Not applicable.<br />

Subject of meeting : Project meeting Development Early Production Unit Oil<br />

: Attendees, steering committee Cofely, Wouter van Alstede (WvA), Henry Borst<br />

Copies to<br />

(HBo)<br />

General agenda topics<br />

1. Welcome<br />

Settle on the general agenda topics<br />

Announcements<br />

2. Approval previous Minutes of meeting<br />

3. Health Safety and Environment<br />

4. Detail engineering<br />

Electrical and Instrumentation<br />

Mechanical<br />

Industrial Automation<br />

5. Construction – prefabrication skids<br />

6. Project schedule<br />

Activities next week<br />

Progress project<br />

7. Financial - Scope management<br />

8. Information – Communication - Organization<br />

9. Status action list<br />

Current actions<br />

New actions<br />

10. Issues and questions in general<br />

11. Next meeting<br />

12. Closure of the meeting<br />

Bereich / Abteilung / Anlage Status Projekt-Nr. Dokumentennummer Blatt Rev.<br />

TTI - Ingenieurleistungen Entwurf 0975/11.07-0060 TT-0975-0400-005 1 von 5 A

GDF SUEZ E&P Deutschland GmbH<br />

Waldstraße 39 – D-49808 Lingen<br />

(Ems)<br />

Telefon +49 (0) 591 / 612 – 0<br />

www.gdfsuezep.de<br />

Cofely Noord bv<br />

Exportweg 1 - 9301 ZV Roden<br />

The Netherlands<br />

Telefon +31 (0)50 502 35 82<br />

www.cofely.nl<br />

MoM# Item# Subject Action Due date<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

1.<br />

1-1<br />

2.<br />

2-1<br />

3.<br />

3-1<br />

4.<br />

4-1<br />

WELCOME<br />

AEn provides the attendees the agenda topics. These general topics<br />

will be discussed during the project meetings required for this project.<br />

At the start of the meeting the discussion points will be settled by the<br />

attendees. In this meeting we decided to discuss mainly about the<br />

question list which was been sent by ABl on February 26 th 2013 with<br />

respect to the scope of supply document.<br />

APPROVAL PREVIOUS MINUTES OF MEETING<br />

This is not applicable because of the fact that this concerns the first<br />

official project meeting.<br />

HEALTH SAFETY AND ENVIRONMENT<br />

Note March 5 th 2013: Within our project team we asked our HSE<br />

coordinator to draw up a HSE document which will be used during the<br />

detailed engineering phase. In this document we will describe the HSE<br />

aspects concerning the early production unit.<br />

DETAIL ENGINEERING<br />

Electrical and Instrumentation<br />

In the morning on March 4 th 2013 MPa and GWi discussed with GDF<br />

team members about the Electrical and Instrumentation part of this<br />

project. For this meeting we will draw up separate minutes. MPa<br />

mentioned briefly the highlights of this E&I meeting. The project<br />

location is changed from Römerberg in Börger 7a. The new location<br />

differs from the location in the South part of Germany, namely:<br />

there is an additional pump in the well required for getting out the<br />

crude oil<br />

the crude oil requires heating instead of cooling<br />

well pressure is considerably lower<br />

it is expected that the parameters of both wells show large<br />

differences.<br />

4-2 Question list ABl regarding the scope of supply document<br />

Paragraph 2.2.1 Meteorology and Environment: GDF request a socalled<br />

presence button when the truck is loading. The operator should<br />

every minute press the mentioned button for not interrupting the<br />

loading process. This change should be included during the detail<br />

engineering phase.<br />

4-3 Paragraph 2.2.2 Process data:<br />

The design temperature of the unit of 90 °C is correct stated in the<br />

document. The maximum well head temperature for the location<br />

Börger is however 35 °C.<br />

4-4 Paragraph 8.2 Choke and shutdown valves:<br />

If possible the choke valve should be implemented with a hand wheel<br />

for manual operation (if possible). This adjustment should after<br />

approval be included during the detail engineering phase.<br />

Contact valve supplier about the possibilities and potential additional<br />

cost.<br />

4-5 GDF will provide a template for a datasheet with respect to the choke<br />

MOM-5<br />

4-3-13<br />

valve.<br />

MOM-5 4-6 The choke and shut down valve are nitrogen or instrument dry air<br />

4-3-13<br />

operated. Cofely recommends GDF to do the regular operation of these<br />

valves with the existing hydraulic unit (HWCU). ABl will investigate the<br />

possibilities and will inform Cofely about GDF’s point of view regarding this<br />

topic.<br />

MOM-5 4-7 Paragraph 8.3 Heat Exchanger<br />

Bereich / Abteilung / Anlage Status Projekt-Nr. Dokumentennummer Blatt Rev.<br />

TTI - Ingenieurleistungen Entwurf 0975/11.07-0060 TT-0975-0400-005 2 von 5 A<br />

WvA<br />

Detail<br />

ENG.<br />

Detail<br />

ENG.<br />

AEn<br />

Week 12<br />

3-11-13<br />

ABl Week 10<br />

ABl<br />

3-11-13

GDF SUEZ E&P Deutschland GmbH<br />

Waldstraße 39 – D-49808 Lingen<br />

(Ems)<br />

Telefon +49 (0) 591 / 612 – 0<br />

www.gdfsuezep.de<br />

Cofely Noord bv<br />

Exportweg 1 - 9301 ZV Roden<br />

The Netherlands<br />

Telefon +31 (0)50 502 35 82<br />

www.cofely.nl<br />

MoM# Item# Subject Action Due date<br />

4-3-13 For the location Börger are instead of cooling down the oil heating<br />

facilities required, as mentioned before the crude oil has now of<br />

temperature of 35 °C. Cofely will investigate heating and cooling<br />

facilities combined on one skid. With this approach the <strong>EPU</strong> will be<br />

suitable for a wider variety of wells. This change should after approval<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

be included during the detail engineering phase.<br />

4-8 Paragraph 8.4 Seperator<br />

GDF requires a so-called sight glass for phase visibility. This sight glass<br />

gives an operator immediately information about the separation<br />

process in the tank. The glass should be installed with double flanges.<br />

This change should after approval be included during the detail<br />

engineering phase.<br />

4-9 GDF wants to equip the seperator with sample points for oil, gas and<br />

water. This change should after approval be included during the detail<br />

engineering phase.<br />

4-10 The seperator should be prepared for roof extension. This change<br />

should after approval be included during the detail engineering phase.<br />

4-11 Cofely request ABl to provide GDF’s specifications about protective<br />

coating. Our scope of supply includes to accommodate several<br />

mechanical parts of the <strong>EPU</strong> with a protective coating. Stainless steel<br />

parts will of course not be painted. Galvanizing elements is not<br />

included in our scope.<br />

4-12 Paragraph 8.5 Knock out drum: The High/high and Low/low alarms<br />

are not shown in the P&ID. During the meeting we concluded together<br />

that these signals are not required.<br />

4-13 Paragraph 8.6 Storage tanks: GDF wants to know the specifications of<br />

internal coating in the square storage tanks.<br />

Cofely will provide on short notice the specifications of this storage<br />

tank. Furthermore we mention that the datasheets will also contain<br />

the required information. GDF normally uses a coating called<br />

Permatex. What are the possibilities if GDF demands this coating in<br />

the storage tanks?<br />

4-14 GDF mentioned during the meeting that with respect to the storage<br />

tanks we need to keep in our mind the pour point. The pour point of<br />

crude oil is in fact the lowest temperature at which it becomes semi<br />

solid and loses its flow characteristics. During the meeting we<br />

concluded that we need to measure the temperature in the tanks and<br />

also it was suggested to measure the temperature of the water from<br />

the gasoline fuel heated boiler. In the detail engineering phase Cofely<br />

will give this item the necessary attention.<br />

4-15 Low and high pressure protection storage tanks. The storage tanks are<br />

atmospheric. High pressure in the tank will be controlled by the flame<br />

arrestor. For the location Börger is it not allowed to let the gas escape<br />

into the atmosphere. This gas should for instance be lead back to the<br />

knock out drum. This change should after approval be included during<br />

the detail engineering phase.<br />

4-16 Paragraph 8.7 Closed Gas Flare: Cofely confirms that until the flare<br />

the process piping is accommodate with trace heating and insulation.<br />

GDF request a closed gas flare with a so-called optimized burner head.<br />

This item will be processed in the datasheet of the closed gas flare.<br />

4-17 The flare drum should be equipped with a high level indication for the<br />

water in this tank. In other words a water lock will stop the gas from<br />

flowing to the gas flare which is not a desirable situation. This change<br />

Bereich / Abteilung / Anlage Status Projekt-Nr. Dokumentennummer Blatt Rev.<br />

TTI - Ingenieurleistungen Entwurf 0975/11.07-0060 TT-0975-0400-005 3 von 5 A<br />

MPa<br />

Detail<br />

ENG.<br />

3-11-13<br />

Detail<br />

ENG.<br />

Detail<br />

ENG.<br />

ABl 3-11-13<br />

MPa<br />

MPa<br />

Detail<br />

ENG.<br />

Detail<br />

ENG.<br />

Detail<br />

3-11-13<br />

3-11-13

GDF SUEZ E&P Deutschland GmbH<br />

Waldstraße 39 – D-49808 Lingen<br />

(Ems)<br />

Telefon +49 (0) 591 / 612 – 0<br />

www.gdfsuezep.de<br />

Cofely Noord bv<br />

Exportweg 1 - 9301 ZV Roden<br />

The Netherlands<br />

Telefon +31 (0)50 502 35 82<br />

www.cofely.nl<br />

MoM# Item# Subject Action Due date<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

should after approval be included during the detail engineering phase. ENG.<br />

4-18 8.8 Spoolpieces interconnecting pipelines. The connections of the<br />

pipelines should be flanged with compensators. The compensators will<br />

take care of the possible height differences which could occur during<br />

the site erection. During the detail engineering one and another will be<br />

embedded.<br />

4-19 8.8 HG Adsorber: Cofely confirms that the HG filter is equipped with a<br />

with active coal adsorption.<br />

8.9 Sand Cather: Cofely confirms that for filtering sand out of the oil a<br />

double sand catcher will be installed.<br />

4-20 8.10 Evacuation pumping system:<br />

4-21 GDF request to install on the suction side of the pumps a so-called run<br />

drain dry safety. Furthermore a so-called presence button when the<br />

truck is loading is required. The operator should every minute press<br />

the button for not interrupting the loading process.<br />

4-22 Truck loading. Only on truck can be loaded in the same time.<br />

Detail<br />

ENG.<br />

4-23 Connection. The connection on the loading truck is 3” or 4”. ABl will<br />

provide Cofely with the details of this connection.<br />

ABl Week 11<br />

4-24 The loading capacity of one truck is 30m 3 . The loading rate of 90 m3/h Detail<br />

gives a flow velocities of 5 m/sec. This flow velocity is to high and<br />

should be kept, if possible below, 2,5m/sec. For double walled loading<br />

hoses, DN80 inner hose, the flow velocity shall not exceed 4 m/s. Flow<br />

rate: The design flow rate must not exceed 4m/s.<br />

ENG.<br />

4-25 The loading truck has also pump facilities. We discussed to implement<br />

a by-pass connection for having the ability to load the truck without<br />

the use of the unloading skid. During the detail engineering one and Detail<br />

another will be embedded.<br />

ENG.<br />

4-26 GDF request Cofely to give more information of the pumps which are<br />

selected during the tender phase.<br />

MPa 3-11-13<br />

4-27 Loading arm. Loading arms are chosen as connection between the Detail<br />

pumps and loading truck. We have to clarify with TÜV if we need an<br />

impermeable surface for the loading facility. Otherwise it is perhaps<br />

better and cheaper to go for double walled hoses with leak detection.<br />

ENG.<br />

4-28 The unloading skid the should be provided with a drip pan and leak Detail<br />

detection. This change should after approval be included during the<br />

detail engineering phase.<br />

ENG.<br />

4-29 8.11 Oil circulation: GDF wants to have more information how the<br />

required oil circulation is achieved.<br />

MPa 3-11-13<br />

4-30 8.12 Control container: For generation of electricity two diesel<br />

Detail<br />

generator of 20kVA are installed. In the main distribution board an<br />

additional field must be implement in the case of grid voltage on a<br />

certain location is available.<br />

ENG.<br />

4-31 GDF request for more information regarding the air compressor. MPa 3-11-13<br />

4-32 GDF request for more information regarding the fuel heated boiler. MPa 3-11-13<br />

4-32 Connections for future emulsion breaking or chemical injections<br />

facilities should be available. This will be provided in the flow line just<br />

before the choke valve and on the wellhead both outside scope of <strong>EPU</strong><br />

project.<br />

Detail<br />

ENG.<br />

Bereich / Abteilung / Anlage Status Projekt-Nr. Dokumentennummer Blatt Rev.<br />

TTI - Ingenieurleistungen Entwurf 0975/11.07-0060 TT-0975-0400-005 4 von 5 A

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

MOM-5<br />

4-3-13<br />

GDF SUEZ E&P Deutschland GmbH<br />

Waldstraße 39 – D-49808 Lingen<br />

(Ems)<br />

Telefon +49 (0) 591 / 612 – 0<br />

www.gdfsuezep.de<br />

5. CONSTRUCTION – PREFABRICATION SKIDS.<br />

5-1 During the meeting we skipped this agenda topic.<br />

6. PROJECT SCHEDULE<br />

6-1 Short term activities<br />

Provide document libraries E-plan<br />

Finalize organization scheme<br />

Facilitate scope management procedure<br />

Draw up first Concept detail engineering schedule<br />

Facilitate document management system (Sharepoint)<br />

Detail engineering long lead items (Choke and heater)<br />

P&ID 1 drawing according the specification of GDF<br />

Provide standard template document numbers<br />

Finalize document numbers<br />

7. FINANCIAL - SCOPE MANAGEMENT<br />

7-1 During the meeting we skipped this agenda topic. Note: all changes<br />

will be managed in the Sharepoint portal.<br />

8. INFORMATION – COMMUNICATION – ORGANIZATION<br />

8-1 During the meeting we skipped this agenda topic.<br />

9. STATUS ACTION LIST<br />

9-1 This is not applicable because of the fact that this concerns the first<br />

official project meeting. Note: all actions will be managed in the<br />

Sharepoint portal.<br />

10. ISSUES AND QUESTIONS IN GENERAL<br />

10-1 No comments.<br />

11. NEXT MEETING<br />

11-1 Project meeting<br />

Date – time: March 11 th 2013 | 12.30 – 13.30 hour<br />

Location: GDF Suez E&P Deutschland GMBH<br />

Site visit<br />

Date – time: March 11 th 2013 | 14.00 – 16.00 hour<br />

Location: Betriebsplatz 7, 49767 Twist<br />

12. CLOSURE OF THE MEETING<br />

Cofely Noord bv<br />

Exportweg 1 - 9301 ZV Roden<br />

The Netherlands<br />

Telefon +31 (0)50 502 35 82<br />

www.cofely.nl<br />

ABl<br />

AEn<br />

AEn<br />

AEn<br />

AEn-MPa<br />

MPa<br />

MPa<br />

ABl<br />

MPa<br />

Bereich / Abteilung / Anlage Status Projekt-Nr. Dokumentennummer Blatt Rev.<br />

TTI - Ingenieurleistungen Entwurf 0975/11.07-0060 TT-0975-0400-005 5 von 5 A<br />

3-5-13<br />

Week 11<br />

Week 11<br />

Week 11<br />

Week 11<br />

Week 12<br />

Week 11<br />

3-5-13<br />

Week 11