Download this publication as PDF - Sodick

Download this publication as PDF - Sodick

Download this publication as PDF - Sodick

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

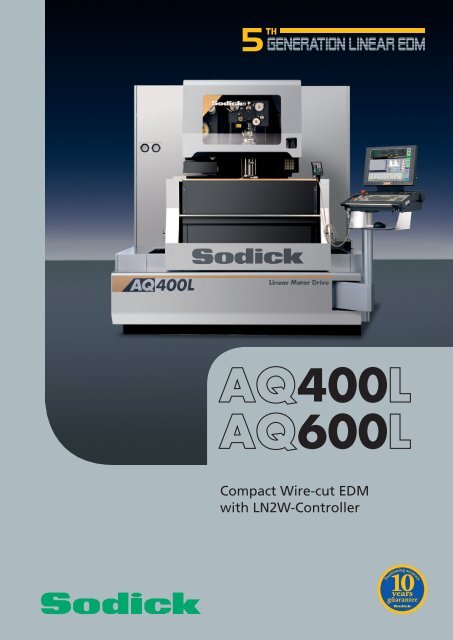

AQ400L<br />

AQ600L<br />

Compact Wire-cut EDM<br />

with LN2W-Controller

The 5th Generation Linear EDM H<strong>as</strong> Arrived<br />

Since the launch of the world’s first linear EDM machines in 1999, <strong>Sodick</strong> h<strong>as</strong> constantly improved and further<br />

developed <strong>this</strong> unique technology. With over 27,000 machines installed around the world, <strong>this</strong> latest series of EDM<br />

machines represents the 5th generation of <strong>Sodick</strong> linear technologies.<br />

10 years of linear EDM experience and know-how at your finger tips.<br />

2

Employing the linear motor drive system, <strong>Sodick</strong> die-sinker EDMs and wire-cut EDMs have enabled difficult<br />

machining operations that were not possible with conventional ball screw-type EDMs.<br />

The linear motor-driven EDMs, eliminate the need for ball screws and the <strong>as</strong>sociated disadvantages. Use of<br />

the Linear Motor removes the deterioration in machining accuracy caused by worn ball screws throughout the<br />

machine life (more than 10 years). <strong>Sodick</strong> is so confident of the performance and accuracy of their machines<br />

over a 10 year period, that they are the only Manufacturer to offer a 10 year positioning accuracy guarantee<br />

on all Linear EDM Machines.<br />

3

Best-Seller 9,000 Units since 2003<br />

4<br />

Since the introduction of the AQ360L/AQ560L <strong>this</strong> machine range w<strong>as</strong> developed from the beginning using<br />

<strong>Sodick</strong>'s in-house made technologies such <strong>as</strong> linear motors, ceramics, c<strong>as</strong>t machine structures and own NC control.<br />

Since 2003 <strong>this</strong> compact range h<strong>as</strong> evolved into today's AQ400L/AQ600L range with over 9,000 machines produced<br />

supporting world manufacturing needs.<br />

2003 2006 2008 2012<br />

Standard Features<br />

High Rigidity<br />

Tech 2<br />

Tech 1<br />

<strong>Sodick</strong>’s expertise in EDM innovation using 3D design systems, the latest CAE technologies<br />

and numerous simulations have made it possible to create an improved b<strong>as</strong>ic machine<br />

structure of optimised rib arrangements which incre<strong>as</strong>e rigidity by approximately 70%.<br />

Deformation is minimised, allowing optimum performance of high-speed and rapid<br />

acceleration linear motors. Furthermore the original design of an independent X<br />

and Y-axis plus an efficient machine layout lead to a longer stroke, smaller footprint<br />

and highly accurate machining capability.<br />

Compact<br />

The rigid c<strong>as</strong>t construction is<br />

mounted on a frame-type platform<br />

allowing the complete machine<br />

and all it's peripherals (Generator,<br />

dielectric system* and chiller Unit)<br />

to moved <strong>as</strong> a complete unit<br />

therefore reducing floor space<br />

and facilitating a simplified<br />

machine installation.<br />

*AQ600L h<strong>as</strong> a seperate dielectric system

Standard Features<br />

Linear Motor Drive<br />

Tech 3<br />

<strong>Sodick</strong>’s linear motor is a direct drive, vibration free device which h<strong>as</strong><br />

unrivalled acceleration and positioning accuracy with no backl<strong>as</strong>h. Its<br />

high dynamic responsiveness, stability for precision machining, and<br />

performance do not diminish over time and remain maintenance free.<br />

The linear motor achieves even better performance thanks to the<br />

Motion Controller (K-SMC) which <strong>Sodick</strong> h<strong>as</strong> perfected over the years.<br />

Absolute Linear Scales<br />

Ceramic Components<br />

Gap Detection<br />

Tech 6<br />

<strong>Sodick</strong><br />

Motion<br />

Controller<br />

NC Unit<br />

Wire<br />

Workpiece<br />

Linear Scale<br />

Motor<br />

Linear Motor<br />

Ball-screw<br />

<strong>Sodick</strong> Motion Controller Conventional Ball Screw Drive<br />

Tech 4<br />

The AQ400L and AQ600L wire EDMs are constructed using ceramic components for the<br />

work stand table and critical parts, all of which are built in-house to ensure high precision<br />

machining with better electrical insulation, abr<strong>as</strong>ion resistance and rigidity. Ceramics are<br />

ideal for high precision machining due to their very low thermal expansion co-efficient<br />

(less than one third than that of c<strong>as</strong>t iron), high rigidity and resistance to ageing.<br />

<strong>Sodick</strong>’s New Efficient Power Supply Unit<br />

Tech 5<br />

The AQ wire EDM series profits from <strong>Sodick</strong>’s latest generation of power supply unit, which<br />

is capable of high-speed, high precision and high-efficiency machining. An NC control system<br />

b<strong>as</strong>ed on modern operating system used in conjunction with the power supply delivers<br />

outstanding results. The user interface benefits from a 15” colour touch screen for e<strong>as</strong>e<br />

of use and operation.<br />

Gap Detection<br />

Motor<br />

Driver<br />

NC Unit<br />

Wire<br />

Workpiece<br />

With the introduction of new advanced absolute linear gl<strong>as</strong>s scales the need for referencing h<strong>as</strong> been removed.<br />

Therefore, ensuring total positional control at all times and reduced setting up time.<br />

Electrolysis Free Machining<br />

<strong>Sodick</strong> created the electrolysis-free circuit to prevent oxidation, deterioration<br />

and pitting corrosion of the workpiece. A high frequency bipolar pulse p<strong>as</strong>ses<br />

between the electrode and workpiece eliminating bi<strong>as</strong> and allowing ultra<br />

high speed machining without electrolysis.<br />

5<br />

Encoder

Standard Features<br />

Options<br />

6<br />

"FJ AWT" Automatic Wire<br />

Threading<br />

Low Maintenance Tank Seal<br />

Tech 7<br />

This new AWT system allows submerged and non-submerged threading.<br />

Combining thermal wire cut for a straighter wire and a new waterjet function<br />

the reliability of the <strong>Sodick</strong> AWT system h<strong>as</strong> been further improved.<br />

The exclusive use of closed guides on the compact AQ range in combination<br />

with "FJ AWT" further incre<strong>as</strong>es productivity.<br />

2D Form Design and Integrated<br />

Cutting Conditions<br />

Tech 8<br />

Heart NC on-board programming software with CAD file (DXF) import capability<br />

is standard on AQ series. Varying top & bottom contours, involute gears, coreless<br />

forms (pocket machining) and free-form curves can be designed e<strong>as</strong>ily.<br />

Furthermore an integrated datab<strong>as</strong>e of cutting conditions allows the geometry<br />

to be automatically integrated with the cutting conditions. This data is available<br />

for many materials allowing <strong>Sodick</strong>'s expertise to be available to all.<br />

Tech 9<br />

The tank seal flushing function h<strong>as</strong> been introduced to support the machines<br />

capability for high precision stable machining. This also provides for e<strong>as</strong>ier<br />

maintenance and extends the life of the seal.<br />

Taper Flex<br />

Taper Flex is available <strong>as</strong> an option for further advanced high angle taper cutting up to<br />

45°. Taper Flex is e<strong>as</strong>y to use and requires no special training. The function consists of three<br />

parts, high angle guides, and compensation jig and specialised software.<br />

L-Cut (Wire Chopper)<br />

Jumbo Feeder<br />

The wire supply device allows up to 50 kg wire bobbin<br />

<strong>as</strong> standard and supports continuous machining.<br />

Part of the ejected wire is chopped into small pieces for e<strong>as</strong>y disposal.<br />

WS-4P/5P<br />

<strong>Sodick</strong>’s own Rotary Table developed In-house is available <strong>as</strong> an<br />

additional A or B axis for indexing or simultaneous contouring.

Specification AQ400L/AQ600L<br />

Specification Of Machine AQ400L AQ600L<br />

X x Y x Z-axis Stroke (mm) 400 x 300 x 250 600 x 400 x 300<br />

U axis x V axis Stroke (mm) 80 x 80 80 x 80<br />

Taper angle (height of 80mm) ±20° ±20°<br />

Max. workpiece dimensions (mm) 590 x 450 x 250 790 x 550 x 300<br />

Max. workpiece weight (kg) 550 930<br />

Worktank dimensions (mm) 935 x 770 1,135 x 890<br />

Wire diameter (mm) 0.10~0.30* 0.10~0.30*<br />

Machine dimensions (mm) 1,920 x 2,600 x 2,095 2,400 x 2,930 x 2,185<br />

Installation Space (mm) 2,980 x 3,675 3,350 x 4,005<br />

Machine Weight (kg) 4,300 4,830<br />

Features AQ400L AQ600L<br />

Linear Motor Driver l l<br />

Absolute Linear Scale l l<br />

<strong>Sodick</strong> Motion Control l l<br />

Ceramic Components l l<br />

FJ AWT l l<br />

Wire Tension Servo l l<br />

Electrolysis Free Circuit l l<br />

Dielectric Chiller l l<br />

Touch Panel l l<br />

High-rigid C<strong>as</strong>t Machine Constructions l l<br />

LAN Connection l l<br />

UPS l l<br />

S-PIKA-W s s<br />

LN20W 8-axis s s<br />

Taper Flex o o<br />

Jumbo Feeder o o<br />

L-Cut (Wire Chopper) o o<br />

Indexing Table o o<br />

HTP high voltage circuit o o<br />

l Standard s Factory Option o Option<br />

CNC Power Supply LN2W<br />

Pl<strong>as</strong>tic Mould Component<br />

Workpiece: ELMAX,<br />

Height of 20mm<br />

Surface Finish: 0.14µmRa<br />

Wire Diameter: 0.20mm<br />

Thin Ribs<br />

Workpiece: STAVAX,<br />

Height of 20mm<br />

Tooth Length: 7.0mm<br />

Tooth Width: 0.1mm<br />

Tooth Pitch: 0.6mm<br />

Wire Diameter: 0.20mm<br />

* 1 HTP is required for 0.10 mm wire cutting<br />

Max. machining current 40A Display type 15.1” TFT-LCD Touch Screen (XGA)<br />

Power requirement 380-440V 50Hz Character set Alphanumeric and symbols<br />

CNC unit Multi-t<strong>as</strong>k OS, <strong>Sodick</strong> Motion Controller Simultaneously controlled axes Max. 4 axes (LN20W Max 8 axes)<br />

User memory capacity Edit: 100,000 blocks / saving: 30MB Min. input command 0.01µm<br />

Memory device CF Card, External Memory Min. drive unit 0.01µm<br />

Input format USB port, LAN, Touch Screen, Keyboard Drive mechanism Linear motor<br />

7

0<br />

2600<br />

114<br />

200<br />

460<br />

250<br />

335<br />

20<br />

2125<br />

400<br />

475<br />

884<br />

475<br />

481<br />

1235<br />

500<br />

1405<br />

1025<br />

600<br />

2600<br />

600<br />

2930<br />

475<br />

3675<br />

AQ600L AQ400L<br />

4005<br />

1000<br />

Min.5/Max.305<br />

350<br />

Min.5/Max.250<br />

980<br />

138.5 125 5 330 157<br />

40<br />

600<br />

55<br />

200 200<br />

2600<br />

200<br />

2125<br />

475<br />

884<br />

1235<br />

481<br />

550 940 550 430 940 430<br />

6001920<br />

1920 460<br />

2980<br />

2980<br />

600<br />

1920<br />

23-M8 Tap depth 16<br />

(for clump to work) 132.5 125 125 132.5<br />

40 10 400 (X-Stroke) 10 40<br />

32-M8 Tap depth 16<br />

(for clump to work)<br />

134 125 5 460 127<br />

<strong>Sodick</strong> Europe Ltd.<br />

Rowley Drive, Baginton<br />

Coventry, CV3 4FG<br />

United Kingdom<br />

40<br />

55<br />

50<br />

2930<br />

300 (Y-Stroke)<br />

114<br />

250<br />

2095<br />

20 20<br />

114<br />

114<br />

10<br />

50 50 50 50 50 50 50 50<br />

475<br />

2600<br />

3675<br />

215 30<br />

30 215<br />

237.5<br />

460<br />

237.5<br />

1980<br />

2400<br />

20 400<br />

600<br />

2185<br />

132.5 125 125 132.5<br />

40 10 600 (X-Stroke) 10 40<br />

250 250<br />

30<br />

400 (Y-Stroke)<br />

10<br />

2930<br />

50<br />

1025<br />

475<br />

2930<br />

1405<br />

25 50505050505050505050505050<br />

25<br />

40<br />

40<br />

205 330 20 330 205<br />

227.5 680 227.5<br />

30<br />

2600<br />

200<br />

460<br />

114<br />

250<br />

500<br />

395 395 1250 335 1250 335<br />

1980 20 1980 400 20<br />

600 2400 2400 350<br />

3350 3350<br />

2125<br />

600<br />

475<br />

884<br />

1235<br />

481<br />

400530<br />

400<br />

Min.5/Max.250<br />

980<br />

138.5 125 5 330 157<br />

40<br />

200 200 200<br />

200<br />

1920<br />

23-M8 Tap depth 1623-M8<br />

Tap depth 16<br />

(for clump to work) (for clump 132.5to work) 125 132.5 125 125 132.5 125 132.5<br />

40 10 400 (X-Stroke) 40 10 10 400 40 (X-Stroke) 10 40<br />

Min.5/Max.305<br />

1000<br />

475<br />

50 50 50 50 50 50 15<br />

60<br />

15<br />

2600<br />

3675<br />

600<br />

50<br />

300 (Y-Stroke)<br />

215 30 215 30 30 215 30 215<br />

237.5<br />

237.5 460<br />

460 237.5<br />

237.5<br />

2095<br />

20 20 20<br />

20<br />

10<br />

50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50<br />

2185<br />

1980 1980 20 400 20 400<br />

2400 2400<br />

30<br />

10<br />

600<br />

50 50 50 50 50 15<br />

50<br />

60<br />

15<br />

32-M8 Tap depth 32-M8 16 Tap depth 16<br />

(for clump to work) (for clump 132.5 to work) 125 132.5 125 125 132.5 125 132.5<br />

40 10 600 (X-Stroke) 40 10 600 (X-Stroke) 10 40 10 40<br />

30<br />

475<br />

500<br />

140575<br />

5050505050505050<br />

1025<br />

2930<br />

4005<br />

134 125 5 460 127<br />

350<br />

600<br />

Min.5/Max.305<br />

1000<br />

Min.5/Max.250<br />

980<br />

40<br />

138.5 125 5 330 157<br />

40<br />

134 125 5 460 127<br />

600<br />

55<br />

40<br />

250<br />

1920<br />

550 940<br />

1920<br />

2980<br />

430<br />

2930<br />

400 (Y-Stroke)<br />

30<br />

114<br />

250<br />

395 1250 335<br />

1980 20 400<br />

600 25 505050505050505050505050<br />

2400 25 505050505050505050505050<br />

50350<br />

25 50 25<br />

40 335040<br />

40<br />

40<br />

205 330 205 20 330 33020 205 330 205<br />

227.5 227.5 680 680 227.5 227.5<br />

114<br />

400 (Y-Stroke)<br />

10<br />

300 (Y-Stroke)<br />

10<br />

30<br />

2600<br />

200<br />

460<br />

1025<br />

2125<br />

475<br />

1405<br />

2930<br />

500<br />

600<br />

2095<br />

475<br />

884<br />

1235<br />

481<br />

4005<br />

Min.5/Max.305<br />

1000<br />

30<br />

475<br />

2600<br />

3675<br />

2185<br />

50<br />

30<br />

30<br />

75 5050505050505050<br />

Min.5/Max.250<br />

980<br />

32-M8 Tap depth 16<br />

(for clump to work)<br />

134 125 5 460 127<br />

40<br />

30<br />

138.5 125 5 330 157<br />

40<br />

create your future<br />

200<br />

23-M8 Tap depth 16<br />

(for clump to work) 132.5<br />

50 50 50 50 50 50 15<br />

60<br />

15<br />

30<br />

75 5050505050505050<br />

<strong>Sodick</strong> Contact<br />

Phone +44 (0) 24 7621 4314<br />

email europe@sodick.eu.com<br />

online www.sodick.org<br />

1980<br />

2400<br />

132.5 125<br />

40 10<br />

30<br />

23<br />

600 (X<br />

25 50505050505<br />

40<br />

205<br />

227.5<br />

330 20