8.4: Distinguished Paper: A Full Color Eyewear Display using ... - Sony

8.4: Distinguished Paper: A Full Color Eyewear Display using ... - Sony

8.4: Distinguished Paper: A Full Color Eyewear Display using ... - Sony

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>8.4</strong> / H. Mukawa<br />

<strong>8.4</strong>: <strong>Distinguished</strong> <strong>Paper</strong>: A <strong>Full</strong> <strong>Color</strong> <strong>Eyewear</strong> <strong>Display</strong> <strong>using</strong> Holographic<br />

Planar Waveguides<br />

Hiroshi Mukawa, Katsuyuki Akutsu, Ikuo Matsumura, Satoshi Nakano,<br />

Takuji Yoshida, Mieko Kuwahara, Kazuma Aiki, Masataka Ogawa<br />

Information Technology Laboratories, <strong>Sony</strong> Corporation, Tokyo, Japan<br />

Abstract<br />

A full color eyewear display with over 85% see-through<br />

transmittance and 2500cd/m 2 brightness was developed. Very low<br />

color crosstalk, less than 0.008 Δu’v’ uniformity and 120% NTSC<br />

color gamut were achieved. Waveguides with two in- and outcoupling<br />

hologram elements enabled simple configuration with<br />

side-mounted microdisplays.<br />

1. Introduction<br />

An eyewear display comes to be an important device along with<br />

two technological environment changes, i.e. (1) widespread use of<br />

mobile video contents such as digital broadcasts and video<br />

download services via a cellular phone network or wireless<br />

internet, (2) miniaturization of mobile video devices such as MP4<br />

players and mobile TV devices whose weights and sizes are<br />

essentially determined by the size of those displays. An eyewear<br />

display has mainly three advantages beyond a direct-viewing<br />

mobile display; (1) hands-free, (2) high privacy nature and (3)<br />

larger screen size. Among several proposed eyewear displays [1,<br />

2], those with see-through capability [3] are especially important<br />

for mobile uses since they are safer and also easier to be accepted<br />

in public. It was, however, challenging to configure compact and<br />

high quality image viewing eyewear displays with clear seethrough<br />

capabilities.<br />

Using a volume hologram or grating as an optical combiner in<br />

front of the eyes on a waveguide is a possible approach [4, 5, 6],<br />

since it could also minimize the size of optics. On the other hand,<br />

it shows a significant color dispersion and Bragg wavelength<br />

dependency on an incident angle from a light source, and, in<br />

general, causes color crosstalks and uniformity degradation when<br />

transmitting full-color images through the waveguide. In the<br />

paper, we propose a double-waveguide structure <strong>using</strong> reflection<br />

volume holograms to eliminate the color crosstalks. To achieve<br />

adequate color uniformity for displaying full color images, we<br />

designed an optimum incident angle of image rays on the<br />

hologram. Further, to fine tune the uniformity, a drive signal<br />

management scheme was employed on a microdisplay.<br />

2. Image quality improvement<br />

2.1 Elimination of color crosstalk<br />

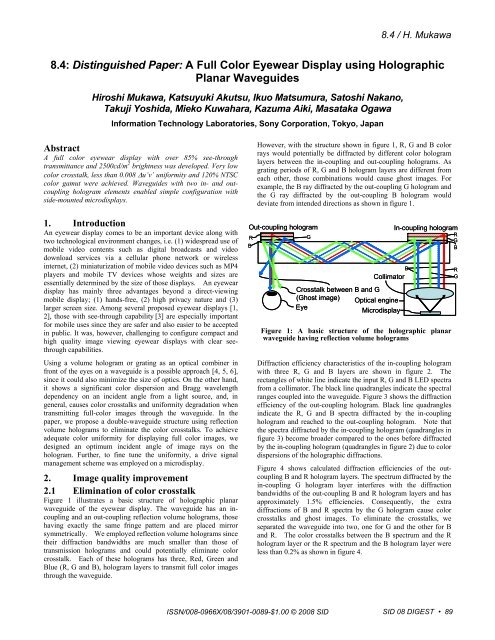

Figure 1 illustrates a basic structure of holographic planar<br />

waveguide of the eyewear display. The waveguide has an incoupling<br />

and an out-coupling reflection volume holograms, those<br />

having exactly the same fringe pattern and are placed mirror<br />

symmetrically. We employed reflection volume holograms since<br />

their diffraction bandwidths are much smaller than those of<br />

transmission holograms and could potentially eliminate color<br />

crosstalk. Each of these holograms has three, Red, Green and<br />

Blue (R, G and B), hologram layers to transmit full color images<br />

through the waveguide.<br />

However, with the structure shown in figure 1, R, G and B color<br />

rays would potentially be diffracted by different color hologram<br />

layers between the in-coupling and out-coupling holograms. As<br />

grating periods of R, G and B hologram layers are different from<br />

each other, those combinations would cause ghost images. For<br />

example, the B ray diffracted by the out-coupling G hologram and<br />

the G ray diffracted by the out-coupling B hologram would<br />

deviate from intended directions as shown in figure 1.<br />

Out-coupling hologram<br />

R<br />

B<br />

ISSN/008-0966X/08/3901-0089-$1.00 © 2008 SID<br />

G<br />

Collimator<br />

Crosstalk between B and G<br />

(Ghost image) Optical engine<br />

Eye<br />

Microdisplay<br />

In-coupling hologram<br />

Figure 1: A basic structure of the holographic planar<br />

waveguide having reflection volume holograms<br />

Diffraction efficiency characteristics of the in-coupling hologram<br />

with three R, G and B layers are shown in figure 2. The<br />

rectangles of white line indicate the input R, G and B LED spectra<br />

from a collimator. The black line quadrangles indicate the spectral<br />

ranges coupled into the waveguide. Figure 3 shows the diffraction<br />

efficiency of the out-coupling hologram. Black line quadrangles<br />

indicate the R, G and B spectra diffracted by the in-coupling<br />

hologram and reached to the out-coupling hologram. Note that<br />

the spectra diffracted by the in-coupling hologram (quadrangles in<br />

figure 3) become broader compared to the ones before diffracted<br />

by the in-coupling hologram (quadrangles in figure 2) due to color<br />

dispersions of the holographic diffractions.<br />

Figure 4 shows calculated diffraction efficiencies of the outcoupling<br />

B and R hologram layers. The spectrum diffracted by the<br />

in-coupling G hologram layer interferes with the diffraction<br />

bandwidths of the out-coupling B and R hologram layers and has<br />

approximately 1.5% efficiencies. Consequently, the extra<br />

diffractions of B and R spectra by the G hologram cause color<br />

crosstalks and ghost images. To eliminate the crosstalks, we<br />

separated the waveguide into two, one for G and the other for B<br />

and R. The color crosstalks between the B spectrum and the R<br />

hologram layer or the R spectrum and the B hologram layer were<br />

less than 0.2% as shown in figure 4.<br />

B<br />

SID 08 DIGEST • 89<br />

R<br />

G<br />

B<br />

R<br />

G

<strong>8.4</strong> / H. Mukawa<br />

Wavelength (μm)<br />

Figure 2: Diffraction efficiencies of R, G and B hologram<br />

layers of the in-coupling hologram. The thicknesses and index<br />

modulations of each hologram layer were approximately 5μm<br />

and 0. 04 respectively.<br />

Wavelength Wavelength (μm) (μm)<br />

Input blue spectrum<br />

A<br />

Coupled in red spectrum<br />

Input green spectrum<br />

Coupled in blue spectrum<br />

Coupled in green spectrum<br />

A<br />

Input red spectrum<br />

Incident angle to the in-coupling hologram (degree)<br />

Incident angle to the out-coupling hologram (degree)<br />

Figure 3: Diffraction efficiencies of R, G and B hologram<br />

layers of the out-coupling hologram. The thicknesses and<br />

index modulations of each hologram layer were<br />

approximately 2μm and 0.035 respectively.<br />

2.2 Improvement of color uniformity<br />

Another issue to achieve high color image quality is the<br />

uniformity through out the field of view (FOV). A Bragg<br />

diffraction wavelength (Bragg λ) varies by an incident angle of a<br />

ray to a hologram. Therefore, each R, G and B color spectrum<br />

profile changes depending on the specific angle (the field viewing<br />

angle) within the FOV. The peak wavelengths of R, G and B<br />

spectra become shorter at the in-coupling hologram side of the<br />

field. To reduce the spectrum shift within the entire FOV, we<br />

employed two approaches. One is to have oblique in and out<br />

optical axes layout on the waveguide and the other is to employ a<br />

drive signal management of the microdisplay.<br />

90 • SID 08 DIGEST<br />

Diffraction efficiency (%)<br />

Diffraction efficiency (%)<br />

Diffraction efficiency (%)<br />

0.2%<br />

Blue diffraction<br />

efficiency<br />

Blue spectrum Green spectrum Red spectrum<br />

Wavelength (μm)<br />

Red diffraction<br />

efficiency<br />

B spectrum diffracted<br />

by the R hologram<br />

G spectrum diffracted<br />

by the B hologram<br />

G spectrum diffracted<br />

by the R hologram<br />

R spectrum diffracted<br />

by the B hologram<br />

Figure 4: Diffraction efficiencies of the out-coupling B and R<br />

hologram layers at an incident angle of -50°. (A cross section<br />

A-A in Figure. 3) The incident R, G and B spectral ranges<br />

on the out-coupling hologram are also shown.<br />

2.2.1 Oblique optical axis layout on the incoupling<br />

hologram<br />

Amount of a Bragg λ shift (the difference between the Bragg<br />

wavelengths at both ends of a given FOV) depends on a designed<br />

light incident angle on a hologram. When a ray C enters the<br />

hologram, a Bragg wavelength λc is given by the Bragg condition,<br />

λc = 2 n Λ Sin θB (1)<br />

θB is an angle between the ray C and a fringe of the hologram,<br />

Λ is a fringe period and n is an index of the hologram as shown in<br />

figure 5. A λc change by θB could be obtained by differentiating<br />

the equation (1) to derive equation (2).<br />

δλc/δθB = 2 n Λ Cos θB (2)<br />

Bragg condition also satisfies the following equation (3).<br />

θB = (θs –θr)/2 (3)<br />

θr is an incident angle on a hologram and θs is a diffraction angle<br />

of the ray C.<br />

λC<br />

C<br />

λRGB<br />

θB<br />

Λ<br />

θr<br />

θs<br />

n<br />

Figure 5: A geometry of the Bragg condition

From the equation (2) and (3), the δλc/δθ B could be minimized<br />

when θs –θr was close to 180°. It indicates that the Bragg λ shift<br />

could be reduced if the incident ray on the in-coupling hologram<br />

was slanted towards diffracted rays. Consequently, we slanted<br />

the optical axis of the microdisplay and collimator (the optical<br />

engine) by 10° against the in-coupling hologram, as shown in<br />

figure 6.<br />

Out-coupling hologram<br />

R<br />

B<br />

G<br />

R<br />

B<br />

G<br />

Collimator<br />

Optical engine<br />

Eye Microdisplay<br />

Figure 6: An oblique layout between the waveguide and<br />

the optical engine<br />

As a result, the Bragg λ disparity between both ends of the FOV<br />

reduced from 45nm to 37nm and the color gamut improved from<br />

76% to 120% compared to the NTSC standard as shown in figure<br />

7. The improved color gamut was confirmed within the common<br />

area of color reproduction areas for -8° through +8° field viewing<br />

angle in an u’v’ diagram. We used R, G and B LEDs to illuminate<br />

the microdisplay and each of the peak wavelengths was 640nm,<br />

525nm and 450nm respectively.<br />

v´<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

(1) 0˚ incident angle<br />

In-coupling hologram<br />

10°<br />

Common area=76 % of NTSC gamut<br />

0<br />

0 0.1 0.2 0.3 0.4 0.5 0.6<br />

u´<br />

NTSC<br />

sRGB<br />

R<br />

B<br />

G<br />

v´<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

(2) 10˚ incident angle<br />

<strong>8.4</strong> / H. Mukawa<br />

Figure 7: <strong>Color</strong> gamut at two different incident angles<br />

on the in-coupling hologram<br />

2.2.2 Drive signal management of microdisplay<br />

The final approach to improve color uniformity is controlling a<br />

drive signal of the microdisplay. If there is no color signal<br />

management, a white position in the diagram moves more than<br />

0.045 Δu’v’, depending on a field viewing angle from -8° through<br />

+8 ° as shown in figure 8. The scheme is similar to that of<br />

projection displays. Our system requires only one-dimensional<br />

control along the diffraction direction, while projection displays<br />

usually require two-dimensional control. The basic signal process<br />

is to multiply compensation matrices by original drive signals (Ri,<br />

G i, B i) to obtain new signals (R’ i, G’ i, B’ i) which could display<br />

uniform chromaticity at any field viewing angle as expressed by<br />

the equation (4) .<br />

⎛ R'<br />

i ⎞<br />

⎜ ⎟<br />

⎜G'<br />

i⎟<br />

⎜ ⎟<br />

⎝ B'<br />

i ⎠<br />

=<br />

⎛αR<br />

⎜<br />

⎜ βR<br />

⎜<br />

⎝ γR<br />

− i<br />

− i<br />

− i<br />

α<br />

β<br />

γ<br />

G − i<br />

G − i<br />

G − i<br />

α<br />

β<br />

γ<br />

B − i<br />

B − i<br />

B − i<br />

⎞<br />

⎟<br />

⎟<br />

⎟<br />

⎠<br />

⎛ Ri<br />

⎞<br />

⎜ ⎟<br />

⎜Gi<br />

⎟<br />

⎜ ⎟<br />

⎝ Bi<br />

⎠<br />

αR − i is a compensation coefficient which is multiplied by<br />

original drive signal Ri to obtain compensated red drive signal R’ i<br />

β is one which is multiplied by original drive signal R i<br />

and R − i<br />

Common area =120% of NTSC gamut<br />

0<br />

0 0.1 0.2 0.3 0.4 0.5 0.6<br />

u´<br />

to obtain compensated green drive signal G’ i, for example. The “i”<br />

means the specific position in the displayed image along the<br />

diffraction direction.<br />

(4)<br />

NTSC<br />

sRGB<br />

SID 08 DIGEST • 91

<strong>8.4</strong> / H. Mukawa<br />

The experimental data of how the color uniformity was improved<br />

by our drive signal management is also shown in figure 8. Δu’v’<br />

decreased from over 0.045 to less than 0.008 which was sufficient<br />

for eyewear displays.<br />

Δu'v'<br />

0.05<br />

0.04<br />

0.03<br />

0.02<br />

0.01<br />

0<br />

-8 -6 -4 -2 0 2 4 6 8<br />

Field angle (deg ree)<br />

Figure 8: <strong>Color</strong> differences before and after the drive<br />

signal management<br />

3. Conclusion<br />

We have developed a see-through full color eyewear display <strong>using</strong><br />

holographic elements on planar waveguides (Figure 9). 120%<br />

NTSC color gamut, less than 0.008 Δu’v’ color uniformity and<br />

over 2500cd/m 2 brightness were achieved with a 20° diagonal<br />

FOV. The advantages of the display are over 85% see-through<br />

transmittance and simply-structured waveguides suitable for<br />

eyewearable devices. The waveguide was a 1.4mm thick glass<br />

substrate with volume reflection holograms placed in mirror<br />

symmetry. In the future, glass substrates could be replaced with<br />

plastic substrates to make them lighter and more robust to expand<br />

applicable fields.<br />

92 • SID 08 DIGEST<br />

before compensation<br />

after compensation<br />

Figure 9: A photograph of the prototype<br />

4. References<br />

[1] J. E. Melzer and K. Moffit, “Head Mounted <strong>Display</strong>s”,<br />

(McGraw Hill, 1997), ISBN 0070418195<br />

[2] H. Mukawa et al., “Novel Virtual Image Optics for<br />

Reflective Microdisplays”, 2000 IDRC Digest, pp96-99,<br />

2000<br />

[3] Y. Amitai, “A Two-Dimensional Aperture Expander for<br />

Ultra-Compact, High-Performance Head-Worn <strong>Display</strong>s”,<br />

2005 SID International Symposium Digest, pp360-363, 2005<br />

[4] Y. Amitai, S. Reinhom and A.A.Friesem, “Visor-display<br />

design based on planar holographic optics”, Appl. Opt. 34,<br />

1352-6, 1995<br />

[5] I. Kasai et al., “Actually wearable see-through display <strong>using</strong><br />

HOE”, ODF 2000, pp117-120, 2000<br />

[6] T. Levola, “Diffractive optical components for near to<br />

eye displays”, 2006 SID International Symposium<br />

Digest, pp64-67, 2006