You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Reheater Isolating Device<br />

Sizes 16”– 36”<br />

ASME B16.34<br />

The Dewrance Reheat Isolating Device was developed to<br />

provide the simplest means of isolating a reheater for<br />

hydrostatic test. This test may be to prove the reheater<br />

during a planned shut-down which will prevent an<br />

unplanned shut-down later, or to carry out test after<br />

repair. The isolator is permanently welded into the<br />

pipelines on both sides of the reheater.<br />

The cast steel body has two parallel faces inside the<br />

centre chamber. One of these faces at the turbine end of<br />

the fitting is a sealing face which is deposited with<br />

austenitic stainless steel to prevent corrosion. Access to<br />

the centre chamber is provided by a proven pressure seal<br />

closure which has sufficient preloading to seal against<br />

the vacuum conditions experienced during start-up.<br />

Under normal working conditions the pressure is held by<br />

a stainless steel segmental ring through a forged steel<br />

bonnet and the sealing is effected by an asbestos sealing<br />

ring which is stainless steel reinforced. This sealing ring<br />

does not require a lapped surface or expensive metal<br />

inlay.<br />

During normal plant operation only the external<br />

pressure seal closure is used and the isolator body<br />

effectively becomes a part of the pipe with unobstructed<br />

passage. The Dewrance Reheat Isolating Device is simple<br />

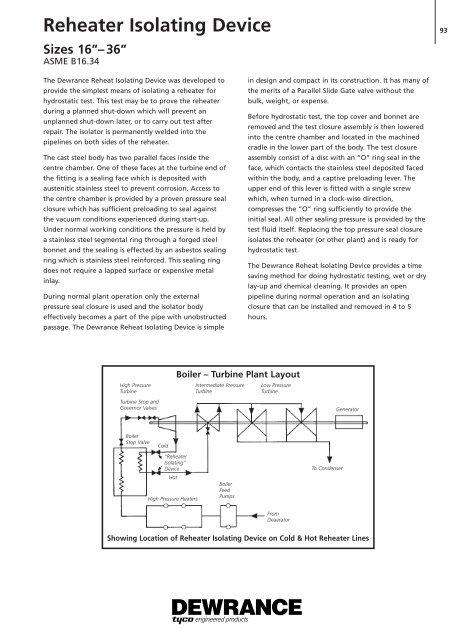

High Pressure<br />

Turbine<br />

Turbine Stop and<br />

Governor Valves<br />

Boiler<br />

Stop Valve<br />

Cold<br />

“Reheater<br />

Isolating”<br />

Device<br />

Hot<br />

High Pressure Heaters<br />

Boiler – Turbine Plant Layout<br />

Intermediate Pressure<br />

Turbine<br />

Boiler<br />

Feed<br />

Pumps<br />

in design and compact in its construction. It has many of<br />

the merits of a Parallel Slide Gate valve without the<br />

bulk, weight, or expense.<br />

Before hydrostatic test, the top cover and bonnet are<br />

removed and the test closure assembly is then lowered<br />

into the centre chamber and located in the machined<br />

cradle in the lower part of the body. The test closure<br />

assembly consist of a disc with an “O” ring seal in the<br />

face, which contacts the stainless steel deposited faced<br />

within the body, and a captive preloading lever. The<br />

upper end of this lever is fitted with a single screw<br />

which, when turned in a clock-wise direction,<br />

compresses the “O” ring sufficiently to provide the<br />

initial seal. All other sealing pressure is provided by the<br />

test fluid itself. Replacing the top pressure seal closure<br />

isolates the reheater (or other plant) and is ready for<br />

hydrostatic test.<br />

The Dewrance Reheat Isolating Device provides a time<br />

saving method for doing hydrostatic testing, wet or dry<br />

lay-up and chemical cleaning. It provides an open<br />

pipeline during normal operation and an isolating<br />

closure that can be installed and removed in 4 to 5<br />

hours.<br />

Low Pressure<br />

Turbine<br />

From<br />

Deaerator<br />

To Condenser<br />

Generator<br />

Showing Location of Reheater Isolating Device on Cold & Hot Reheater Lines<br />

93