IBH-093 - Bohamet

IBH-093 - Bohamet

IBH-093 - Bohamet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

SPRAY-TIGHT SHIP DOORS<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

Page: 1/10<br />

Notes:<br />

The shipyard usually follows its own instructions with regard to the division and sequence of<br />

installation procedures. The purpose of this document is to provide the necessary reference material.<br />

BOHAMET does not give any warranty with respect to installation performed by other companies using<br />

this manual.<br />

I . General comments:<br />

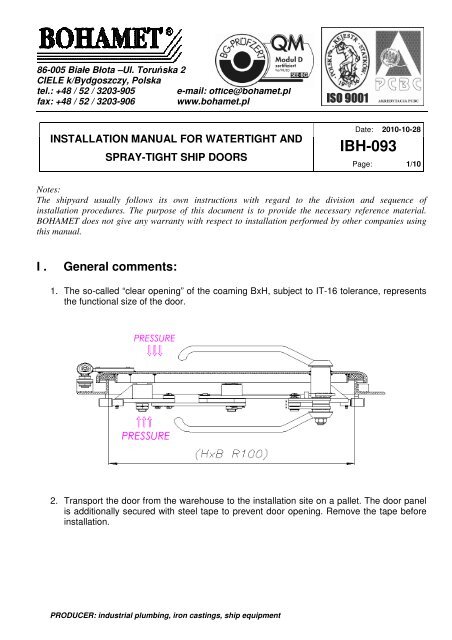

1. The so-called “clear opening” of the coaming BxH, subject to IT-16 tolerance, represents<br />

the functional size of the door.<br />

PRESSURE<br />

PRESSURE<br />

2. Transport the door from the warehouse to the installation site on a pallet. The door panel<br />

is additionally secured with steel tape to prevent door opening. Remove the tape before<br />

installation.

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

Steel<br />

tape<br />

SPRAY-TIGHT SHIP DOORS<br />

3. Transport the door on the pallet on board using a crane.<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

Page: 2/10<br />

4. When manually handling the door to the installation site, remember to set all the closing<br />

devices in the closed position in order to avoid uncontrolled door opening.

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

SPRAY-TIGHT SHIP DOORS<br />

II. Before the installation:<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

Page: 3/10<br />

1. Move the door on the pallet to the installation site using a crane and having previously<br />

checked the relevant item numbers.<br />

2. We recommend welding a lifting lug (made of Ø12 rod) to the upper section of the door<br />

panel, which will facilitate the door installation procedure.<br />

LIFTING LUG

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

SPRAY-TIGHT SHIP DOORS<br />

3. Mark the opening dimensions (in accordance with the diagram).<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

Page: 4/10<br />

4. The gap between the opening and the outside dimension of the door frame should<br />

amount to 2 mm on each side and should not exceed 3 mm for the curved sections.<br />

5. Cut out the opening acc. the marking, check the opening dimensions again, taking into<br />

account the +2 mm tolerance. Grind cutting-out surfaces with elastic grinding discs to<br />

remove burrs resulting from flame-cutting.<br />

ANGLE DOOR FRAME<br />

VERSION<br />

STRAIGHT DOOR FRAME<br />

VERSION

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

SPRAY-TIGHT SHIP DOORS<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

Page: 5/10<br />

6. Check the cut-out surfaces for rectilinearity and the door wall surface for flatness.<br />

Straighten out any deformities maintaining the 2 mm gap between the opening and the<br />

coaming. Check the coaming for flatness using a cross. The maximum admissible<br />

spacing between intersecting cords must not exceed 2 mm.<br />

D i a g o n a l<br />

D i a g o n a l

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

SPRAY-TIGHT SHIP DOORS<br />

7. Disassemble the door by removing the hinge pins. DO NOT REMOVE THE PINS<br />

MARKED AS “PIN COMPLETE”. Remember the number of washers in each hinge – this<br />

will facilitate correct re-assembly.<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

Page: 6/10

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

SPRAY-TIGHT SHIP DOORS<br />

III. Mounting the coaming in the wall.<br />

Put the coaming in the opening in the wall. Use wedges or spacers to ensure correct<br />

installation, bearing in mind to leave the required gap.<br />

1. The gap between the edge of the wall and the coaming surface should not exceed 2 mm.<br />

If the gap is larger, surface weld the edge of the wall to obtain appropriate gap.<br />

2. Weld the door frame in the wall in accordance with the diagram and starting from the<br />

inside. Tack welds must be made in the order specified in the drawing, maintaining a<br />

distance of 200 mm. Final welds (70 to 100 mm long) must be made in the order specified<br />

in the drawing until achieving a continuous weld along the whole frame. The number of<br />

tack welds and final welds depends on the size of the welded frames.<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

Page: 7/10

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

SPRAY-TIGHT SHIP DOORS<br />

3. Once the welds are done, clean the welded areas and repair potential welding defects.<br />

4. Check the flatness of the coaming again, in accordance with item II.6.<br />

INSIDE<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

TACK WELDS<br />

FINAL WELDS<br />

Page: 8/10

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

IV. Door installation:<br />

SPRAY-TIGHT SHIP DOORS<br />

1. Place the door panel over the coaming. Mount all hinges, remember to place all washers.<br />

Do not use too much force when placing hinge pins (in order to ensure correct alignment<br />

of all hinge elements and appropriate door opening/closing).<br />

2. Check whether the door fits tight – use chalk.<br />

3. The door fitting force can be individually adjusted by adjusting the door seal tightness<br />

using the adjusting nuts on the pressure cams. The adjustment range is ±4 mm.<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

Page: 9/10

86-005 Białe Błota –Ul. Toruńska 2<br />

CIELE k/Bydgoszczy, Polska<br />

tel.: +48 / 52 / 3203-905 e-mail: office@bohamet.pl<br />

fax: +48 / 52 / 3203-906 www.bohamet.pl<br />

INSTALLATION MANUAL FOR WATERTIGHT AND<br />

SPRAY-TIGHT SHIP DOORS<br />

PRODUCER: industrial plumbing, iron castings, ship equipment<br />

Date: 2010-10-28<br />

<strong>IBH</strong>-<strong>093</strong><br />

Page: 10/10<br />

4. The door pressure can be individually adjusted with the use of adjusting nuts on the hinge<br />

pin.<br />

M20 NUT<br />

BOHAMET does not assume any liability for door installation conducted by the customer<br />

inconsistent with the instructions provided in this document.