Microencapsulation Methods for Delivery of Protein Drugs

Microencapsulation Methods for Delivery of Protein Drugs

Microencapsulation Methods for Delivery of Protein Drugs

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

224 Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4<br />

Insulin was released with initial burst over<br />

achieved.<br />

first 30 minutes followed by a constant release up<br />

the<br />

to 3 h, after which the release rate declined.<br />

Limitations<br />

this method was initially proposed <strong>for</strong> en-<br />

Although<br />

encapsulations, it has some serious problems in<br />

zyme<br />

First, large w/o interface is produced during<br />

practice.<br />

reaction, where proteins or enzymes are likely to be<br />

the<br />

Second, large amounts <strong>of</strong> proteins may par-<br />

inactivated.<br />

in the polymerization reaction changing its bioticipate<br />

activity. Third, it is <strong>of</strong>ten hard to control the<br />

logical<br />

reaction. The yield and quality <strong>of</strong> the<br />

polymerization<br />

obtained by interfacial polymerization may<br />

membrane<br />

controlled by a number <strong>of</strong> factors, such as chemical<br />

be<br />

<strong>of</strong> reactive monomers, and reaction conditions.<br />

natures<br />

monomer concentrations, temperature, the mixing<br />

The<br />

and the reaction time are likely to be important<br />

rate,<br />

[105]. Fourth, exhaustive washing steps are<br />

parameters<br />

to remove monomers, byproducts, organic sol-<br />

required<br />

and surfactants. At the same time, several washvents,<br />

steps may lead to further loss <strong>of</strong> water soluble drugs.<br />

ing<br />

pH change due to HCl byproduct <strong>for</strong>med by reac-<br />

Fifth,<br />

<strong>of</strong> an acid chloride and an amine can damage the<br />

tion<br />

labile drugs.<br />

acid<br />

SUPERCRITICAL FLUID PRECIPITATION<br />

fluid is defined as a fluid <strong>of</strong> which tem-<br />

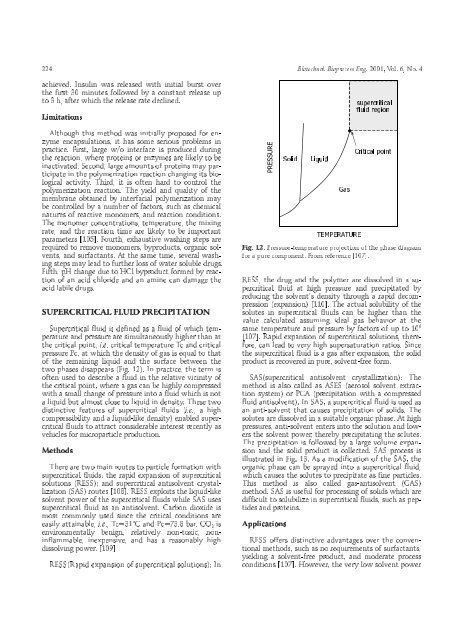

Supercritical<br />

and pressure are simultaneously higher than at<br />

perature<br />

critical point, i.e. critical temperature Tc and critical<br />

the<br />

Pc, at which the density <strong>of</strong> gas is equal to that<br />

pressure<br />

the remaining liquid and the surface between the<br />

<strong>of</strong><br />

phases disappears (Fig. 12). In practice, the term is<br />

two<br />

used to describe a fluid in the relative vicinity <strong>of</strong><br />

<strong>of</strong>ten<br />

critical point, where a gas can be highly compressed<br />

the<br />

a small change <strong>of</strong> pressure into a fluid which is not<br />

with<br />

liquid but almost close to liquid in density. These two<br />

a<br />

features <strong>of</strong> supercritical fluids (i.e., a high<br />

distinctive<br />

and a liquid-like density) enabled super-<br />

compressibility<br />

fluids to attract considerable interest recently as<br />

critical<br />

<strong>for</strong> microparticle production.<br />

vehicles<br />

<strong>Methods</strong><br />

are two main routes to particle <strong>for</strong>mation with<br />

There<br />

fluids: the rapid expansion <strong>of</strong> supercritical<br />

supercritical<br />

(RESS); and supercritical antisolvent crystal-<br />

solutions<br />

(SAS) routes [108]. RESS exploits the liquid-like<br />

lization<br />

power <strong>of</strong> the supercritical fluids while SAS uses<br />

solvent<br />

fluid as an antisolvent. Carbon dioxide is<br />

supercritical<br />

commonly used since the critical conditions are<br />

most<br />

attainable, i.e., Tc=31°C and Pc=73.8 bar. CO2 is<br />

easily<br />

benign, relatively non-toxic, non-<br />

environmentally<br />

inexpensive, and has a reasonably high<br />

inflammable,<br />

dissolving power. [109]<br />

RESS(Rapid expansion <strong>of</strong> supercritical solutions): In<br />

12. Pressure-temperature projection <strong>of</strong> the phase diagram<br />

Fig.<br />

a pure component. From reference [107].<br />

<strong>for</strong><br />

the drug and the polymer are dissolved in a su-<br />

RESS,<br />

fluid at high pressure and precipitated by<br />

percritical<br />

the solvent’s density through a rapid decom-<br />

reducing<br />

(expansion) [110]. The actual solubility <strong>of</strong> the<br />

pression<br />

in supercritical fluids can be higher than the<br />

solutes<br />

calculated assuming ideal gas behavior at the<br />

value<br />

temperature and pressure by factors <strong>of</strong> up to 10 same 6<br />

Rapid expansion <strong>of</strong> supercritical solutions, there-<br />

[107].<br />

can lead to very high supersaturation ratios. Since<br />

<strong>for</strong>e,<br />

supercritical fluid is a gas after expansion, the solid<br />

the<br />

product is recovered in pure, solvent-free <strong>for</strong>m.<br />

antisolvent crystallization): The<br />

SAS(supercritical<br />

is also called as ASES (aerosol solvent extrac-<br />

method<br />

system) or PCA (precipitation with a compressed<br />

tion<br />

antisolvent). In SAS, a supercritical fluid is used as<br />

fluid<br />

anti-solvent that causes precipitation <strong>of</strong> solids. The<br />

an<br />

are dissolved in a suitable organic phase. At high<br />

solutes<br />

anti-solvent enters into the solution and low-<br />

pressures,<br />

the solvent power, thereby precipitating the solutes.<br />

ers<br />

precipitation is followed by a large volume expan-<br />

The<br />

and the solid product is collected. SAS process is<br />

sion<br />

in Fig. 13. As a modification <strong>of</strong> the SAS, the<br />

illustrated<br />

phase can be sprayed into a supercritical fluid,<br />

organic<br />

causes the solutes to precipitate as fine particles.<br />

which<br />

method is also called gas-antisolvent (GAS)<br />

This<br />

SAS is useful <strong>for</strong> processing <strong>of</strong> solids which are<br />

method.<br />

to solubilize in supercritical fluids, such as pep-<br />

difficult<br />

tides and proteins.<br />

Applications<br />

Solid Liquid<br />

Gas<br />

TEMPERATURE<br />

supercritical<br />

region<br />

fluid<br />

Critical point<br />

<strong>of</strong>fers distinctive advantages over the conven-<br />

RESS<br />

methods, such as no requirements <strong>of</strong> surfactants,<br />

tional<br />

a solvent-free product, and moderate process<br />

yielding<br />

[107]. However, the very low solvent power<br />

conditions