Microencapsulation Methods for Delivery of Protein Drugs

Microencapsulation Methods for Delivery of Protein Drugs

Microencapsulation Methods for Delivery of Protein Drugs

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Biotechnol. Bioprocess Eng. 2001, 6: 213-230<br />

<strong>Microencapsulation</strong> <strong>Methods</strong> <strong>for</strong> <strong>Delivery</strong> <strong>of</strong> <strong>Protein</strong> <strong>Drugs</strong><br />

Yoon Yeo, Namjin Baek, and Kinam Park*<br />

Departments <strong>of</strong> Pharmaceutics and Biomedical Engineering, Purdue University, West Lafayette, IN 47907, USA<br />

INTRODUCTION<br />

Recent advances in recombinant DNA technology have resulted in development <strong>of</strong><br />

Abstract<br />

new protein drugs. Due to the unique properties <strong>of</strong> protein drugs, they have to be delivered<br />

many<br />

parenteral injection. Although delivery <strong>of</strong> protein drugs by other routes, such as pulmonary<br />

by<br />

nasal routes, has shown some promises, to date most protein drugs are administered by par-<br />

and<br />

routs. For long-term delivery <strong>of</strong> protein drugs by parenteral administration, they have been<br />

enteral<br />

into biodegradable microspheres. A number <strong>of</strong> microencapsulation methods have been<br />

<strong>for</strong>mulated<br />

and the currently used microencapsulation methods are reviewed here. The microen-<br />

developed,<br />

methods have been divided based on the method used. They are: solvent evaporacapsulation<br />

phase separation (coacervation); spray drying; ionotropic gelation/polyelectrolyte<br />

tion/extraction;<br />

interfacial polymerization; and supercritical fluid precipitation. Each method is de-<br />

complexation;<br />

scribed <strong>for</strong> its applications, advantages, and limitations.<br />

Keywords: protein, peptide, drug delivery, microparticle, microencapsulation<br />

advances in biotechnology have brought<br />

Significant<br />

availability <strong>of</strong> recombinant peptide pro-<br />

ever-increasing<br />

drugs in large quantities. The successful completein<br />

<strong>of</strong> the human genome project will undoubtedly<br />

tion<br />

to the explosion <strong>of</strong> new protein drugs with exqui-<br />

lead<br />

bioactivities. Since protein drugs carry out biologisite<br />

processes and reactions with high specificity and<br />

cal<br />

protein drugs will continue to be drugs <strong>of</strong><br />

potency,<br />

<strong>for</strong> treating various diseases. Formulating pro-<br />

choices<br />

drug delivery systems, however, poses several probtein<br />

Due to extremely low bioavailability <strong>of</strong> protein<br />

lems.<br />

by oral administration, which is the most conven-<br />

drugs<br />

mode <strong>of</strong> drug delivery, protein drugs are usually<br />

ient<br />

by parenteral route. One way <strong>of</strong> minimizing<br />

administered<br />

and improving patient compliance is to pro-<br />

discom<strong>for</strong>t<br />

sustained-release <strong>for</strong>mulations that deliver protein<br />

duce<br />

continuously over long periods <strong>of</strong> time. Another<br />

drugs<br />

in protein drug delivery is to maintain the terti-<br />

challenge<br />

protein structure, which is essential to bioactivity. Exary<br />

<strong>of</strong> protein drugs to unfavorable conditions during<br />

posure<br />

tends to reduce their bioactivities.<br />

<strong>for</strong>mulation<br />

widely used approach <strong>for</strong> long-term delivery <strong>of</strong><br />

Most<br />

drugs has been parenteral administration <strong>of</strong><br />

protein<br />

drugs in microspheres made <strong>of</strong> biodegradable<br />

protein<br />

Preparation <strong>of</strong> protein drug-containing mi-<br />

polymers.<br />

without reducing bioactivity has been the<br />

crospheres<br />

<strong>of</strong> microencapsulation methods. A number <strong>of</strong> mi-<br />

goal<br />

methods have been developed through<br />

croencapsulation<br />

the years, but none <strong>of</strong> the methods has been ideal <strong>for</strong><br />

Corresponding author<br />

*<br />

+1-765-494-7759 Fax: +1-765-496-1903<br />

Tel:<br />

e-mail: kpark@purdue.edu<br />

protein drugs. Each method has its own advan-<br />

loading<br />

as well as limitations. For further improvement in<br />

tages<br />

technologies, it is important to un-<br />

microencapsulation<br />

the strengths and drawbacks <strong>of</strong> each method.<br />

derstand<br />

1 lists examples <strong>of</strong> microencapsulation processes<br />

Table<br />

in the literature. <strong>Microencapsulation</strong> processes<br />

found<br />

been frequently classified either chemical or me-<br />

have<br />

[1]. Chemical processes refer to methods that<br />

chanical<br />

the change <strong>of</strong> solvent property, chemical reaction<br />

utilize<br />

monomers, or complexation <strong>of</strong> polyelectro-<br />

between<br />

In mechanical processes, a gas phase is utilized at<br />

lytes.<br />

stage to provide <strong>for</strong>ce to break up materials to<br />

some<br />

particles. There are many situations, however,<br />

small<br />

such a distinction is not clear.<br />

where<br />

MICROENCAPSULATION METHODS<br />

SOLVENT EVAPORATION/EXTRACTION<br />

evaporation/extraction methods have been<br />

Solvent<br />

used to prepare microspheres loaded with vari-<br />

widely<br />

drugs, especially hydrophobic drugs. For the encapous<br />

<strong>of</strong> peptide and protein drugs, oil/water (o/w),<br />

sulation<br />

(o/o) and water/oil/water (w/o/w) emulsifica-<br />

oil/oil<br />

methods have been used. Depending on the numtion<br />

<strong>of</strong> emulsions produced during the preparation <strong>of</strong><br />

ber<br />

solvent evaporation/extraction can be<br />

microspheres,<br />

into two methods, single emulsion and double<br />

divided<br />

(Fig. 1).<br />

emulsion<br />

<strong>Methods</strong><br />

Emulsion (o/o or o/w) <strong>Methods</strong><br />

Single<br />

single emulsion methods, peptides/proteins are pre-<br />

In

214 Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4<br />

Table 1. Examples <strong>of</strong> microencapsulation methods<br />

Chemical processes<br />

1.<br />

evaporation and extraction<br />

Solvent<br />

solvent extraction<br />

Crygenic<br />

separation (Coacervation)<br />

Phase<br />

addition<br />

Non-solvent<br />

change<br />

Temperature<br />

polymer or salt addition<br />

Incompatible<br />

interaction (complex coacervation)<br />

Polymer-polymer<br />

complexation<br />

Polyelectrolyte<br />

polymerization<br />

Interfacial<br />

Mechanical processes<br />

2.<br />

drying<br />

Spray<br />

chilling<br />

Spray<br />

desolvation<br />

Spray<br />

Supercritical fluid precipitation<br />

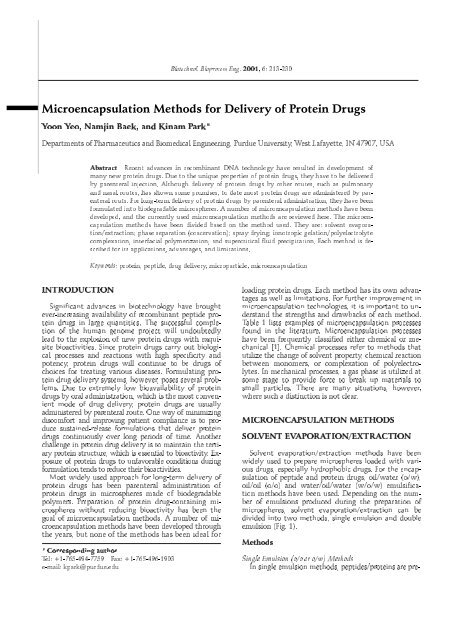

Single Emulsion Double Emulsion<br />

suspension/solution<br />

<strong>Protein</strong><br />

polymer solution (oil)<br />

in<br />

Emulsion (o/o or o/w)<br />

solution<br />

<strong>Protein</strong><br />

water in<br />

oil or water oil<br />

removal<br />

Solvent<br />

drying &<br />

Hardened microsphere<br />

Primary emulsion (w/o)<br />

water<br />

Secondary emulsion (w/o/w)<br />

removal<br />

Solvent<br />

drying &<br />

Hardened microsphere<br />

1. Single emulsion (left) and double emulsion (right) sol-<br />

Fig.<br />

evaporation methods <strong>for</strong> microencapsulation <strong>of</strong> proteins.<br />

vent<br />

in a dispersed phase, which is a polymer solution in<br />

sent<br />

solvent such as dichloromethane or ethyl ace-<br />

organic<br />

Polylactic acid (PLA) and poly(lactide-co-glycolide)<br />

tate.<br />

are the most widely used biodegradable syn-<br />

(PLGA)<br />

polymers <strong>for</strong> sustained-release preparations. The<br />

thetic<br />

kinetics <strong>of</strong> active components can be controlled<br />

release<br />

changing molecular weight and/or copolymer ratio<br />

by<br />

those polymers. <strong>Drugs</strong> can be dispersed as solid parti-<br />

<strong>of</strong><br />

or dissolved in polymer solution. The drug solution<br />

cles<br />

suspension is added into a continuous phase, which<br />

or<br />

be mineral oil (o/o) or aqueous solution (o/w) con-<br />

can<br />

emulsifiers. Emulsification is carried out by agitaining<br />

homogenization, or sonication. Emulsifiers in<br />

tation,<br />

continuous phase stabilize o/o or o/w emulsions<br />

the<br />

produced. Emulsifiers such as Span 85 [2], sorbi-<br />

being<br />

sesquioleate [3], aluminium tristearate [4] have<br />

tan<br />

used <strong>for</strong> o/o interface, and Carbopol been ® [2], 951<br />

cellulose [5], polyvinyl alcohol (PVA) [6] have<br />

methyl<br />

used <strong>for</strong> o/w interface.<br />

been<br />

solvent in dispersed phase is removed by sol-<br />

Organic<br />

evaporation or by solvent extraction. In solvent<br />

vent<br />

process, hardening <strong>of</strong> emulsion occurs<br />

evaporation<br />

volatile organic solvent in dispersed phase leaches<br />

when<br />

continuous phase and evaporates from continuous<br />

into<br />

at atmospheric pressure. Using vacuum or a mod-<br />

phase<br />

increase in temperature can accelerate the evapoerate<br />

<strong>of</strong> organic solvent. In solvent extraction process,<br />

ration<br />

emulsion is transferred to a large amount <strong>of</strong> water<br />

the<br />

other quenching medium, and the extraction <strong>of</strong> or-<br />

or<br />

solvent occurs faster than in solvent evaporation<br />

ganic<br />

Thus, microspheres produced by solvent ex-<br />

process.<br />

process are more porous than the ones protraction<br />

by solvent evaporation. The porous structure<br />

duced<br />

results in faster release <strong>of</strong> peptide/protein drugs.<br />

usually<br />

long-term sustained release, solvent evaporation is<br />

For<br />

The prepared microspheres are collected by<br />

preferred.<br />

centrifugation or filtration, and freeze-dried.<br />

Emulsion (w/o/w) <strong>Methods</strong><br />

Double<br />

double emulsion methods, an aqueous drug solu-<br />

In<br />

is first emulsified in a polymer-dissolved organic<br />

tion<br />

The w/o emulsion is then added into an aque-<br />

solvent.<br />

phase that contains emulsifier, thereby <strong>for</strong>ming w/<br />

ous<br />

emulsion. Then, the organic solvent is removed by<br />

o/w<br />

extracting into external aqueous phase and evaporation.<br />

Applications<br />

Emulsion<br />

Single<br />

emulsion solvent evaporation method has been<br />

Single<br />

to prepare microspheres/nanospheres containing<br />

used<br />

peptide and protein drugs. Insulin solution in<br />

various<br />

solvent was used in emulsification to prepare<br />

organic<br />

[7]. Other researchers used solid particles<br />

nanospheres<br />

bovine serum albumin (BSA) [2] or ovalbumin (OVA)<br />

<strong>of</strong><br />

instead <strong>of</strong> protein solution, in a hope that protein<br />

[4],<br />

can be preserved in organic solvent. High en-<br />

activity<br />

efficiency was obtained using protein particapsulation<br />

The prepared microparticles tend to show initial<br />

cles.<br />

release pr<strong>of</strong>iles. Table 2 lists some examples <strong>of</strong><br />

burst<br />

preparation using protein particles. A<br />

microparticle<br />

approach <strong>of</strong> protein particle preparation was used<br />

novel<br />

the encapsulation <strong>of</strong> bovine superoxide dismutase<br />

<strong>for</strong><br />

into PLGA/PLA microspheres [5]. <strong>Protein</strong><br />

(bSOD)<br />

particles were prepared by lyophilization <strong>of</strong><br />

spherical<br />

glycol (PEG) aqueous mixture.<br />

protein-polyethylene<br />

approach resulted in high encapsulation efficiency<br />

This<br />

and high activity <strong>of</strong> the loaded enzyme (95%). In<br />

(88%)

Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4 215<br />

2. Encapsulation <strong>of</strong> protein particles by single emul-<br />

Table<br />

evaporation methods<br />

sion/solvent<br />

<strong>Protein</strong><br />

particles<br />

Spray-dried<br />

BSA<br />

Micronized<br />

OVA<br />

Lyophilized<br />

bSOD/PEG<br />

)<br />

(% 75<br />

S<br />

O<br />

D<br />

o<br />

f b<br />

e<br />

50<br />

le<br />

a<br />

s<br />

e<br />

re<br />

u<br />

la<br />

tiv<br />

Q<br />

u<br />

m<br />

100<br />

25<br />

Polymer Type<br />

PLGA o/o<br />

o/w<br />

Encapsulation<br />

efficiency<br />

>90%<br />

20-50%<br />

Initial<br />

in release<br />

1 day<br />

216 Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4<br />

100<br />

)<br />

e<br />

(%<br />

m<br />

75 z<br />

y<br />

o<br />

s<br />

o<br />

f ly<br />

e<br />

50<br />

le<br />

a<br />

s<br />

e<br />

re<br />

u<br />

la<br />

tiv<br />

Q<br />

u<br />

m<br />

25<br />

0<br />

3. Release <strong>of</strong> lysozyme from PEG-PBT microspheres. Mo-<br />

Fig.<br />

weight <strong>of</strong> PEG segment was 600. Polyvinyl alcohol<br />

lecular<br />

was used as a stabilizer in the external aqueous phase.<br />

(4%)<br />

percentage <strong>of</strong> PBT in PEG-PBT block copolymer<br />

Increasing<br />

resulted in slower release <strong>of</strong> lysozyme. From reference [16].<br />

<strong>of</strong> glycolide in PLGA polymers result in rapid deg-<br />

tents<br />

<strong>of</strong> the polymer, resulting in faster release <strong>of</strong> the<br />

radation<br />

drugs. The release pr<strong>of</strong>ile can also be controlled<br />

loaded<br />

the processing factors, such as shear <strong>for</strong>ces, since<br />

by<br />

shear <strong>for</strong>ces tend to produce smaller microparticles<br />

high<br />

release drugs at a faster rate due to higher surface<br />

which<br />

area and shorter diffusion path length.<br />

Limitations<br />

0 10 20 30 40 50<br />

Time (days)<br />

23%<br />

45%<br />

solvent evaporation/extraction methods have<br />

While<br />

used widely in preparing microparticles <strong>for</strong> pep-<br />

been<br />

delivery, the methods are still not ideal and<br />

tide/protein<br />

many aspects to be improved. First, the drug<br />

have<br />

efficiency into microspheres is not high.<br />

encapsulation<br />

protein drugs can be produced in larger scale<br />

Although<br />

to development <strong>of</strong> genetic engineering technique,<br />

due<br />

cost is still high. Thus, increasing the encapsulation<br />

the<br />

is still quite important <strong>for</strong> preparing micro-<br />

efficiency<br />

Second, the solvent evaporation/extraction<br />

spheres.<br />

require use <strong>of</strong> toxic organic solvents, such as<br />

methods<br />

and ethyl acetate, as a solvent <strong>for</strong> dis-<br />

dichloromethane<br />

biodegradable polymers. To meet the regulatory<br />

solving<br />

regarding the residual solvent in the final<br />

requirement<br />

the use <strong>of</strong> toxic organic solvent should be<br />

products,<br />

or avoided. Third, in most situations, the<br />

minimized<br />

proteins are released with the initial burst release,<br />

loaded<br />

in many situations the loaded proteins are not re-<br />

and<br />

completely. The initial burst release may cause<br />

leased<br />

response in patients due to abnormally high<br />

abnormal<br />

concentration in blood. Incomplete release <strong>of</strong> the<br />

drug<br />

proteins is <strong>of</strong>ten related to protein stability. Pro-<br />

loaded<br />

have to maintain their 3-dimensional con<strong>for</strong>mateins<br />

to keep their bioactivity. <strong>Protein</strong>s, however, are<br />

tion<br />

prone to be denatured and to <strong>for</strong>m aggregates by vari-<br />

factors, including exposure to large interface beous<br />

organic and aqueous phases, shear <strong>for</strong>ce in the<br />

tween<br />

steps (e.g., homogenization, and sonication),<br />

processing<br />

protein-polymer interaction. Some reports showed<br />

or<br />

the loss <strong>of</strong> protein activity or denaturation/ aggre-<br />

that<br />

<strong>of</strong> protein could be minimized by using stabilizgation<br />

such as poloxamer, BSA or hydroxypropyl-βers<br />

[13,14,18]. Fourth, although continuous<br />

cyclodextrin<br />

<strong>of</strong> peptide/protein drugs is desirable, there are<br />

release<br />

where pulsatile release is preferred as in the<br />

situations<br />

<strong>of</strong> insulin delivery. Furthermore, the timing and the<br />

case<br />

amount <strong>of</strong> the released insulin need to be con-<br />

exact<br />

carefully. This type <strong>of</strong> release can not be obtrolled<br />

by biodegradable microspheres prepared by soltained <br />

vent evaporation/extraction methods.<br />

Modifications <strong>of</strong> Solvent Extraction<br />

an ef<strong>for</strong>t to protect proteins from denaturation<br />

In<br />

microencapsulation processes, alternative methods<br />

during<br />

been developed to minimize exposure <strong>of</strong> protein<br />

have<br />

to denaturing conditions, such as high tempera-<br />

drugs<br />

ture and water-oil interfaces [19].<br />

Spray-desolvation<br />

involves spraying a polymer solu-<br />

Spray-desolvation<br />

onto desolvating liquid. For example, microdroplets<br />

tion<br />

made by spraying PVA aqueous solution onto ace-<br />

were<br />

bath, where the polymer solvent (water) was extone<br />

into acetone and PVA precipitated to <strong>for</strong>m solid<br />

tracted<br />

[20]. This method was also applied to<br />

microparticles<br />

peptides and BSA as model drugs in PLGA.<br />

encapsulate<br />

micronized drug was suspended in a PLGA-acetone<br />

The<br />

and atomized ultrasonically into ethanol bath,<br />

solution<br />

where microspheres were precipitated [21].<br />

Solvent Extraction<br />

Cryogenic<br />

is dissolved in an organic solvent such as di-<br />

PLGA<br />

together with protein powders. As shown<br />

chloromethane,<br />

Fig. 4, the polymer/protein mixture is atomized over<br />

in<br />

bed <strong>of</strong> frozen ethanol overlaid with liquid nitrogen, at<br />

a<br />

temperature below the freezing point <strong>of</strong> the poly-<br />

a<br />

solution. The microdroplets freeze upon<br />

mer/protein<br />

the liquid nitrogen, then sink onto the fro-<br />

contacting<br />

ethanol layer. As the ethanol layer thaws, the mizen<br />

which are still frozen sink into the ethanol.<br />

croparticles<br />

the solvent in the microparticles<br />

Dichloromethane,<br />

thaws and is slowly extracted into ethanol, result-<br />

then<br />

in hardened microparticles containing proteins and<br />

ing<br />

matrix.<br />

polymer<br />

process was used to produce a microsphere <strong>for</strong>-<br />

This<br />

<strong>for</strong> human growth hormone (hGH) [23-26].<br />

mulation<br />

to the encapsulation process, hGH is <strong>for</strong>mulated<br />

Prior<br />

zinc to produce insoluble Zn:hGH complex. The<br />

with<br />

<strong>of</strong> this complex contributed to stabilize<br />

encapsulation<br />

during the fabrication process and within the mi-<br />

hGH<br />

after hydration [23,24]. An in vivo study <strong>of</strong><br />

crospheres<br />

<strong>for</strong>mulation demonstrated a lower Cmax and an ex-<br />

this<br />

serum level <strong>for</strong> weeks, but a similar bioavailabiltended<br />

as compared with the protein in solution [26]. The<br />

ity,

Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4 217<br />

suspension<br />

<strong>Protein</strong><br />

polymer solution<br />

in<br />

Liquid nitrogen<br />

Frozen<br />

microspheres<br />

4. Schematic diagram <strong>of</strong> the ProLease Fig. ® encapsulation<br />

From reference [22].<br />

process.<br />

<strong>for</strong>mulation using this method (referred to as<br />

hGH<br />

ProLease ® was approved by the FDA in December 1999,<br />

)<br />

an injectable suspension <strong>for</strong> once- or twice-a-month<br />

as<br />

under a brand name <strong>of</strong> Nutropin depot adminitration, ® .<br />

this process, all manipulations are per<strong>for</strong>med at<br />

In<br />

temperatures, there<strong>for</strong>e thermal denaturation <strong>of</strong><br />

low<br />

drugs can be prevented. There are no aqueous<br />

protein<br />

thus the protein is not subjected to oil-water<br />

phases,<br />

where some proteins may denature. In addi-<br />

interfaces<br />

the process utilizes solvents in which most protion,<br />

are insoluble (dichloromethane as a polymer solteins<br />

ethanol as an extraction solvent), there<strong>for</strong>e a high<br />

vent,<br />

efficiency can be achieved [22,27]. How-<br />

encapsulation<br />

this system is not easy to apply to various protein<br />

ever,<br />

The use <strong>of</strong> liquid nitrogen also makes scale-up<br />

drugs.<br />

difficult. The system still utilizes toxic organic<br />

rather<br />

and thus it has similar problems associated<br />

solvents,<br />

solvent evaporation/extraction methods.<br />

with<br />

PHASE SEPARATION (COACERVATION)<br />

<strong>Methods</strong><br />

Nozzle<br />

Extraction solvent<br />

Atomized<br />

droplets<br />

<strong>of</strong> solvent<br />

Extraction<br />

microspheres<br />

from<br />

Drug particle<br />

Release modifier<br />

PLG microsphere<br />

by phase separation is basically a<br />

<strong>Microencapsulation</strong><br />

process: (1) phase separation <strong>of</strong> the coating<br />

three-step<br />

to <strong>for</strong>m coacervate droplets; (2) adsorption <strong>of</strong><br />

polymer<br />

coacervate droplets onto the drug surface; and (3)<br />

the<br />

<strong>of</strong> the microcapsules [28], as shown in Fig.<br />

solidification<br />

Phase separation techniques can be classified accord-<br />

5.<br />

to the method to induce phase separation; noning<br />

addition, temperature change, incompatible<br />

solvent<br />

or salt addition, and polymer-polymer interac-<br />

polymer<br />

[29]. tion<br />

Addition<br />

Non-solvent<br />

polymer to be coated is dissolved in a good sol-<br />

The<br />

and drug may be dissolved or suspended or emulvent,<br />

in the polymer solution. Then the first nonsified<br />

(also called ‘coacervating agent’ or ‘phase insolvent<br />

which is miscible with the good solvent but<br />

ducer’)<br />

not dissolve the polymer is slowly added to the<br />

does<br />

solution system. The polymer is concen-<br />

polymer-drug<br />

as the solvent <strong>for</strong> the polymer is slowly extracted<br />

trated<br />

the first non-solvent. The polymer is then induced<br />

into<br />

by<br />

Induced<br />

Non-solvent<br />

1.<br />

Temperature change<br />

2.<br />

Salt / Incompatible polymer<br />

3.<br />

4. Polymer-polymer interaction<br />

separation<br />

Phase<br />

the coating polymer<br />

<strong>of</strong><br />

Drug particle<br />

<strong>of</strong><br />

Adsorption<br />

droplets<br />

coacervate<br />

<strong>of</strong><br />

Solidification<br />

microcapsules<br />

the<br />

5. Schematic diagram <strong>of</strong> the <strong>for</strong>mation <strong>of</strong> a coacervate<br />

Fig.<br />

From reference [30].<br />

microcapsule.<br />

phase separate and <strong>for</strong>m coacervate droplets that<br />

to<br />

the drug (Fig. 6(A)). The coacervate droplet size<br />

contain<br />

be controlled by adjusting the stirring speed. At this<br />

can<br />

<strong>of</strong> the process, the coacervates are usually too s<strong>of</strong>t<br />

point<br />

be collected, and thus they are usually transferred to<br />

to<br />

large body <strong>of</strong> a second non-solvent (also called ‘hard-<br />

a<br />

agent’) to harden the microparticles [31].<br />

ening<br />

polyesters, such as PLA and PLGA, are used,<br />

When<br />

widely used solvents are dichloromethane, ethyl<br />

most<br />

and acetonitrile. The first non-solvents <strong>for</strong> the<br />

acetate,<br />

are low-molecular weight liquid polybutadi-<br />

polymers<br />

low-molecular weight liquid methacrylic polymers,<br />

ene,<br />

oil, vegetable oil, and light liquid paraffine oils.<br />

silicone<br />

hydrocarbons, such as heptane, hexane, and<br />

Aliphatic<br />

ether, have been used as the second non-<br />

petroleum<br />

solvent.<br />

Change<br />

Temperature<br />

system comprised <strong>of</strong> a polymer and a solvent exists<br />

A<br />

a single phase at all points above the phase boundary.<br />

as<br />

is dispersed in the polymer solution with stirring.<br />

Drug<br />

the temperature is decreased below the curve (Fig.<br />

As<br />

phase separation <strong>of</strong> the dissolved polymer occurs<br />

6(B)),<br />

the <strong>for</strong>m <strong>of</strong> immiscible liquid and the polymer coa-<br />

in<br />

around the dispersed drug particles, thus <strong>for</strong>ming<br />

lesces<br />

Further cooling accomplishes gelation<br />

microcapsules.<br />

solidification <strong>of</strong> the coating. The microcapsules are<br />

and<br />

from the solvent by filtration, decantation, or<br />

collected<br />

techniques [32].<br />

centrifugation<br />

Polymer Addition or Salt Addition<br />

Incompatible<br />

two chemically different polymers dissolved in<br />

When<br />

common solvent are incompatible and do not mix in<br />

a<br />

phase separation takes place. This phenome-<br />

solution,<br />

is well described by the phase diagram <strong>of</strong> a ternary<br />

non<br />

consisting <strong>of</strong> a solvent, and two polymers, X<br />

system<br />

Y (Fig. 6(C)). A drug is dispersed in a solution <strong>of</strong><br />

and<br />

Y (point a in Fig. 6(C)) and polymer X is added<br />

polymer<br />

the system, denoted by the arrowed line. When the<br />

to<br />

boundary is passed with the further addition <strong>of</strong><br />

phase<br />

X, polymer rich phase begins to separate to<br />

polymer<br />

immiscible droplets containing the drug, and coa,-<br />

<strong>for</strong>m

218 Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4<br />

( A )<br />

1 0 0 %<br />

0 0 % 1 0 0 %<br />

1<br />

o n s o l v e n t P o l y m e r<br />

N<br />

( C )<br />

S o l v e n t<br />

S o l v e n t<br />

2 p h a s e s<br />

1 0 0 %<br />

2 p h a s e s<br />

1 0 0 %<br />

1 0 0 %<br />

o l y m e r Y P X r e m y l o P<br />

6. General phase diagrams <strong>of</strong> phase separation techniques based on solvent (A), temperature (B), incompatible polymers (C),<br />

Fig.<br />

interpolymer interactions (D). From reference [32].<br />

and<br />

to make microcapsules [32]. In a similar manner<br />

lesce<br />

salts can be added to aqueous solution <strong>of</strong> wa-<br />

inorganic<br />

ter-soluble polymers to cause phase separation.<br />

Interaction (Complex Coacervation)<br />

Polymer-polymer<br />

interaction <strong>of</strong> oppositely charged polyelectro-<br />

The<br />

can result in the <strong>for</strong>mation <strong>of</strong> a complex with relytes<br />

solubility leading to phase separation (Fig. 6(D)).<br />

duced<br />

method is <strong>of</strong>ten called complex coacervation [1].<br />

This<br />

method differs from incompatible polymer addi-<br />

The<br />

in that both polymers become part <strong>of</strong> the final caption<br />

wall. Gelatin is normally used as a cationic polymer<br />

sule<br />

pH below its isoelectric point. A variety <strong>of</strong> natural<br />

at<br />

synthetic anionic polymers are available <strong>for</strong> interac-<br />

and<br />

with gelatin to <strong>for</strong>m complex coacervates. A well<br />

tion<br />

example <strong>of</strong> natural polyanion <strong>for</strong> making com-<br />

known<br />

coacervates with gelatin is gum arabic. Aqueous<br />

plex<br />

<strong>of</strong> gum arabic and gelatin are adjusted to pH<br />

solutions<br />

and warmed to 40-45°C. The pI <strong>of</strong> gelatin is 8.9. The<br />

4.5<br />

charged macromolecules interact to undergo<br />

oppositely<br />

separation, to which a water insoluble liquid core<br />

phase<br />

is added and emulsified to yield the desired<br />

material<br />

size. The mixture is then slowly cooled <strong>for</strong> an<br />

droplet<br />

During the cooling cycle, phase separation is<br />

hour.<br />

enhanced, resulting in the microcapsules <strong>for</strong>med<br />

further<br />

the core material with thin film <strong>of</strong> coacervate [32].<br />

on<br />

harden the microcapsules, the capsules are normally<br />

To<br />

further and treated with glutaraldehyde. This<br />

cooled<br />

a<br />

( B )<br />

( D )<br />

1 0 0 %<br />

1 0 0 %<br />

- e P + e P<br />

is mainly <strong>for</strong> water insoluble materials, include-<br />

method<br />

inks <strong>for</strong> carbonless paper, perfumes <strong>for</strong> advertising<br />

ing<br />

inserts, and liquid crystals <strong>for</strong> display devices.<br />

Applications<br />

2 p h a s e s<br />

P O L Y M E R C O N C E N T R A T I O N - w t %<br />

W a t e r<br />

1 0 0 %<br />

2 p h a s e s<br />

the non-solvent addition method does not in-<br />

Since<br />

an aqueous continuous phase as in w/o/w double<br />

clude<br />

methods, the water-soluble drugs may be pro-<br />

emulsion<br />

from partitioning into the water phase. This<br />

tected<br />

the non-solvent addition method one <strong>of</strong> the<br />

makes<br />

widely used techniques <strong>for</strong> encapsulating water-<br />

most<br />

compounds [28,33-41]. Triptoreline (luteinizing<br />

soluble<br />

releasing hormone analogue)-containing micro-<br />

hormone<br />

were prepared by the non-solvent addition<br />

capsules<br />

and the effect <strong>of</strong> the physicochemical nature <strong>of</strong><br />

method,<br />

polymer on the stability <strong>of</strong> the coacervate droplets<br />

the<br />

examined [34,35]. Triptoreline was suspended in<br />

was<br />

solution, and silicone oil was<br />

PLGA-dichloromethane<br />

added to the suspension as the first non-solvent.<br />

then<br />

embryonic microspheres were further hardened in<br />

The<br />

the second non-solvent. It was found that as<br />

n-heptane,<br />

copolymer became more hydrophobic, it dissolved<br />

the<br />

in dichloromethane and thus more silicone oil<br />

better<br />

necessary to desolvate the copolymer. The average<br />

was<br />

<strong>of</strong> the microspheres increased with the volume<br />

diameter<br />

silicone oil, thereby lowering the initial burst effect.<br />

<strong>of</strong><br />

was also observed from in vivo experiments. With op-<br />

It

Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4 219<br />

d<br />

s<br />

e<br />

a<br />

R<br />

e<br />

le<br />

e<br />

%<br />

u<br />

la<br />

tiv<br />

C<br />

u<br />

m<br />

100<br />

75<br />

50<br />

25<br />

0<br />

0 2 4 6 8<br />

Time (days)<br />

100/0<br />

80/20<br />

0/100<br />

7. Release <strong>of</strong> GM-CSF from microspheres prepared from<br />

Fig.<br />

PLA (MW 6,100) (0/100), 80%/20% mixture <strong>of</strong> PLGA<br />

100%<br />

40,400)/PLA (80/20), and 100% PLGA (100/0). From<br />

(MW<br />

[41].<br />

reference<br />

microspheres, the in vivo peptide release reached<br />

timized<br />

peak level on day 15 and the effect lasted <strong>for</strong> 1<br />

the<br />

month.<br />

colony-stimulating factor<br />

Granulocyte-macrophage<br />

was encapsulated in different blends <strong>of</strong><br />

(GM-CSF)<br />

and low molecular weight PLA by the non-<br />

PLGA<br />

addition method, and the prepared microsolvent<br />

were characterized both in vitro and in vivo [41].<br />

spheres<br />

microspheres with high encapsulation efficiency<br />

The<br />

obtained within a size range between 20 µm and<br />

were<br />

µm. The in vitro release kinetics was dependent on<br />

80<br />

ratio <strong>of</strong> blended polymers. Steady release <strong>of</strong> GM-<br />

the<br />

could be achieved over a period <strong>of</strong> one week with-<br />

CSF<br />

significant burst effect using blend <strong>of</strong> low molecular<br />

out<br />

PLA and high molecular weight PLGA (Fig. 7).<br />

weight<br />

released from the microspheres was found to<br />

GM-CSF<br />

physically intact and biologically active both in vitro<br />

be<br />

in vivo. and<br />

avoid the aggregation <strong>of</strong> microparticles <strong>of</strong>ten en-<br />

To<br />

in non-solvent addition, a modified method<br />

countered<br />

developed [42]. Instead <strong>of</strong> adding non-solvent to a<br />

was<br />

mixture, the polymer solution was added<br />

polymer-drug<br />

an emulsion <strong>of</strong> aqueous ovalbumin in the non-<br />

to<br />

silicon oil. The obtained microspheres appeared<br />

solvent<br />

and remained individual, and displayed a small<br />

smooth<br />

release <strong>of</strong> entrapped ovalbumin over the first 12<br />

initial<br />

with the subsequent release pr<strong>of</strong>ile close to a<br />

hours,<br />

order kinetics <strong>for</strong> a month. Another modification<br />

zero<br />

the non-solvent addition method was introduced to<br />

<strong>of</strong><br />

protein entities from denaturation at the or-<br />

protect<br />

interface or unfolding and/or aggregaganic/aqueous<br />

within hydrophobic polymer matrix [40,43,44].<br />

tion<br />

hydrophilic nanoparticles were pre-<br />

Drug-containing<br />

prior to encapsulation with hydrophobic polymer.<br />

pared<br />

[40], agarose [43], and poly(vinyl alcohol) (PVA)<br />

Gelatin<br />

were used as nanoparticle matrices <strong>for</strong> BSA or insu-<br />

[44]<br />

Nanoparticles were suspended in PLGA-dichlorolin.<br />

solution. Microparticles embedded with nanomethane<br />

were made by phase separation method using<br />

particles<br />

oil as the first non-solvent and heptane as the<br />

silicone<br />

non-solvent. The average diameter <strong>of</strong> the hydro-<br />

second<br />

nanoparticle-hydrophobic microsphere composi-<br />

philic<br />

was 150-180 µm. The protein release from the mi-<br />

tes<br />

was prolonged to nearly two months, withcrospheres<br />

degradation nor aggregation <strong>of</strong> the protein as<br />

out<br />

by size exclusion chromatograms [44].<br />

shown<br />

separation by salt addition was adopted in<br />

Phase<br />

<strong>of</strong> ionotropic hydrogel in an attempt to<br />

preparation<br />

the size distribution <strong>of</strong> microspheres [45]. Prior<br />

control<br />

cross-linking with calcium ions, salts <strong>of</strong> monovalent<br />

to<br />

(e.g., sodium chloride) were added to aqueous solu-<br />

ions<br />

<strong>of</strong> poly [di(carboxylatophenoxy) phosphazene]<br />

tion<br />

to <strong>for</strong>m coacervate microdroplets with a size in<br />

(PCPP)<br />

range 1-10 µm. Upon addition <strong>of</strong> calcium chloride,<br />

the<br />

microdroplets were stabilized via cross-linking be-<br />

the<br />

PCPP and calcium salts without changing the<br />

tween<br />

and shape. The microsphere size increased linearly<br />

size<br />

the sodium chloride concentration, incubation<br />

with<br />

and polymer concentration. This method avoided<br />

time,<br />

use <strong>of</strong> organic solvents, heat, and complicated<br />

the<br />

equipment. Gelatin/Chondroitin 6-sulfate<br />

manufacturing<br />

microspheres were prepared to encapsulate pro-<br />

(CS6)<br />

using complex coacervation <strong>for</strong> the joint therapy<br />

teins<br />

Gelatin (a polycation) and CS6 (a polyanion) solu-<br />

[46].<br />

containing model proteins were mixed and vortions<br />

at 37°C, pH 5.5 to <strong>for</strong>m coacervates. The resulting<br />

texed<br />

microspheres were crosslinked with glu-<br />

coacervate<br />

It was claimed that proteins could be entaraldehyde.<br />

with high encapsulation efficiency, retaining<br />

capsulated<br />

bioactivity. The release <strong>of</strong> protein depended on the<br />

high<br />

<strong>of</strong> human matrix metalloprotease (MMP), since<br />

level<br />

coacervate was degraded by its gelatinase<br />

gelatin/CS6<br />

The MMP concentration is one <strong>of</strong> the factors<br />

activity.<br />

<strong>for</strong> the joint pain, and thus the MMP-<br />

responsible<br />

release property is <strong>of</strong> distinctive advantage<br />

responsive<br />

the delivery <strong>of</strong> MMP inhibitors or the receptors <strong>for</strong><br />

<strong>for</strong><br />

stimulating the synthesis <strong>of</strong> MMP to diseased<br />

cytokines<br />

Gelatin/CS6 showed no significant cytotoxic<br />

joints.<br />

effect in vitro.<br />

Advantages<br />

non-solvent addition method is preferred in en-<br />

The<br />

<strong>of</strong> water-soluble drugs, such as proteins,<br />

capsulation<br />

and vaccines, since drug-polymer mixtures are<br />

peptides,<br />

exposed to the continuous aqueous phase. This<br />

not<br />

the loss <strong>of</strong> water-soluble drugs to the water<br />

minimizes<br />

and results in the high encapsulation efficiency.<br />

phase<br />

advantage <strong>of</strong> the phase separation method is<br />

Another<br />

it enables efficient control <strong>of</strong> the particle size with<br />

that<br />

narrower size distribution by simply varying the<br />

a<br />

variables, such as concentration <strong>of</strong> added<br />

component<br />

[45] or the viscosity and amount <strong>of</strong> the non-<br />

salts<br />

and/or molecular weight <strong>of</strong> polymer used [47].<br />

solvent

220 Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4<br />

Limitations<br />

many successful phase separation systems<br />

Although<br />

been demonstrated, each method has several limi-<br />

have<br />

The microspheres tend to aggregate and the<br />

tations.<br />

<strong>for</strong> mass production is difficult [48]. Agglom-<br />

scale-up<br />

occurs when the coacervate droplets are sticky<br />

eration<br />

adhere to each other be<strong>for</strong>e the solvent is com-<br />

and<br />

removed or be<strong>for</strong>e the droplets are hardened [31].<br />

pletely<br />

produce well-defined microspheres, wide ‘stability<br />

To<br />

is required. The stability window is defined as<br />

window’<br />

step where addition <strong>of</strong> non-solvent does not induce<br />

a<br />

but <strong>for</strong>ms stable coacervates [34]. The<br />

agglomeration<br />

window is affected by the physicochemical<br />

stability<br />

<strong>of</strong> polymers used and/or the viscosity <strong>of</strong> the<br />

nature<br />

added. The presence <strong>of</strong> residual solvents is<br />

non-solvent<br />

concern in the non-solvent addition method. The<br />

a<br />

includes at least three different solvents, i.e.,<br />

method<br />

polymer solvent and two polymer non-solvents. In<br />

the<br />

the polymer solvents are toxic compounds,<br />

general,<br />

as halogenated hydrocarbons (e.g., dichloro-<br />

such<br />

<strong>for</strong> which the exposure limits are regulated<br />

methane),<br />

the authority. For example, the concentration limit<br />

by<br />

dichloromethane is 600 ppm [49]. In addition to the<br />

<strong>for</strong><br />

solvent, two non-solvents are generally known<br />

polymer<br />

remain in a substantial quantity. A study showed<br />

to<br />

depending on the type <strong>of</strong> solvent and polymer used,<br />

that<br />

residual solvents could be minimized by appropriate<br />

the<br />

methods [38]. The solvents, however, were in<br />

drying<br />

hard to remove. High levels <strong>of</strong> residues may al-<br />

general<br />

the microsphere morphology due to their plasticizter<br />

effect. Moreover, it may cause a toxicity problem<br />

ing<br />

influence crucial properties such as release pr<strong>of</strong>iles<br />

and<br />

drug stability. Undoubtedly, the search <strong>for</strong> toxico-<br />

and<br />

and technologically acceptable solvents and<br />

logically<br />

should continue <strong>for</strong> the non-solvent addi-<br />

non-solvents<br />

method to be more useful.<br />

tion<br />

a polymer-polymer interaction (complex coacerva-<br />

In<br />

the limited pH range and the use <strong>of</strong> cross-linking<br />

tion),<br />

can be potential problems. Since the technique is<br />

agent<br />

on electrostatic interactions between two polye-<br />

based<br />

pH <strong>of</strong> the medium is an important factor.<br />

lectrolytes,<br />

example, in a gelatin-acacia system, the pH should<br />

For<br />

below the isoelectric point <strong>of</strong> gelatin (pH 8.9) to<br />

be<br />

it positively charged. The pH range suitable <strong>for</strong><br />

make<br />

gelatin-acacia system is between 2.6 and 5.5 [30].<br />

the<br />

condition, however, is not appropriate <strong>for</strong> encapsu-<br />

This<br />

<strong>of</strong> acid-labile drug entities. The pH range could<br />

lation<br />

extended by the addition <strong>of</strong> water-soluble nonionic<br />

be<br />

such as polyethylene glycol [50,51]. Glutaral-<br />

polymers,<br />

and <strong>for</strong>maldehyde are commonly used as crossdehyde<br />

agents to harden the microcapsules in this techlinking<br />

A condensation reaction occurs between the<br />

nique.<br />

groups <strong>of</strong> the protein (e.g., gelatin) and the alde-<br />

amino<br />

The cross-linking agents may diffuse into the<br />

hydes.<br />

and also react with drug entities, there<strong>for</strong>e this<br />

core<br />

may not be appropriate <strong>for</strong> the protein drugs.<br />

method<br />

toxicity problems arise as well [30].<br />

Potential<br />

SPRAY DRYING<br />

drying has been widely used in the pharmaceu-<br />

Spray<br />

food, and biochemical industries. The main applitical,<br />

in the pharmaceutical field include drying proccations<br />

granulation, preparation <strong>of</strong> solid dispersions, alteraess,<br />

<strong>of</strong> polymorphism <strong>of</strong> a drug, preparation <strong>of</strong> dry<br />

tion<br />

<strong>for</strong> aerosols, and encapsulation <strong>of</strong> drugs <strong>for</strong><br />

powders<br />

masking and protection from oxidation [52]. Since<br />

taste<br />

late 1970s, the spray drying technique has been<br />

the<br />

<strong>for</strong> making microparticulate systems <strong>for</strong> controlled<br />

used<br />

delivery.<br />

drug<br />

<strong>Methods</strong><br />

hydrophilic or hydrophobic polymer is dis-<br />

Either<br />

in a suitable solvent. Drug can be dissolved or<br />

solved<br />

in the solvent. Alternatively, drug solution<br />

suspended<br />

be emulsified in the polymer solution. The mixture<br />

can<br />

then sprayed through a nozzle <strong>of</strong> a spray dryer,<br />

is<br />

in solid microspheres that precipitated into<br />

resulting<br />

bottom collector [53]. Sometimes, the process<br />

the<br />

the use <strong>of</strong> plasticizers to <strong>for</strong>m microcapsules <strong>of</strong><br />

include<br />

spherical shape and smooth-surface by reducing<br />

regular<br />

rigidity <strong>of</strong> polymer chain [54].<br />

the<br />

Alternative Technique<br />

(congealing): Spray congealing includes<br />

Spray-chilling<br />

dissolution or dispersion <strong>of</strong> the drug in a melted<br />

the<br />

without using solvent. This mixture fluid is then<br />

carrier<br />

into a cold air stream to make small droplets<br />

sprayed<br />

solidified by cooling at the temperature lower than<br />

and<br />

melting point <strong>of</strong> the carrier. This method was used<br />

the<br />

encapsulate bovine somatotropin (bST) in fat or wax<br />

to<br />

bST was dispersed in molten fat or wax and<br />

[55].<br />

through an air/liquid spray nozzle. The micro-<br />

sprayed<br />

were <strong>for</strong>med as the molten droplets and were<br />

spheres<br />

on sieves in the desired size range (45-180 µm).<br />

collected<br />

was demonstrated that the microspheres were effec-<br />

It<br />

in maintaining increased level <strong>of</strong> bST in the blood<br />

tive<br />

treated animals <strong>for</strong> 4 weeks, increasing weight gains<br />

<strong>of</strong><br />

and milk production.<br />

Applications<br />

spray-drying is relatively simple, fast and easy<br />

Since<br />

scale-up, it has been tried as an attractive alternative<br />

to<br />

the conventional methods, such as coacervation and<br />

to<br />

method to encapsulate protein drugs [48,56-<br />

emulsion<br />

The spray drying technique was applied to produce<br />

65].<br />

microparticles containing thyrotropin releasing<br />

PLGA<br />

(TRH) [48]. TRH in water and PLGA in ace-<br />

hormone<br />

were mixed to <strong>for</strong>m a clear solution and then<br />

tonitrile<br />

Since the microparticles produced by conven-<br />

sprayed.<br />

spray dryer tended to agglomerate and adhere to<br />

tional<br />

surface <strong>of</strong> the chamber, they designed a double noz-<br />

the<br />

system such that additional nozzle might spray a<br />

zle<br />

solution as an anti-adherent simultaneously<br />

mannitol<br />

8). Microparticles with mean particle size <strong>of</strong> 20 µm<br />

(Fig.

Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4 221<br />

Raw<br />

materials<br />

8. Schematic diagram <strong>of</strong> a spray dryer used <strong>for</strong> prepara-<br />

Fig.<br />

<strong>of</strong> PLGA microparticles containing TRH. From reference<br />

tion<br />

[48].<br />

obtained, from which zero order release <strong>of</strong> TRH<br />

were<br />

<strong>for</strong> one month with a minimal initial burst.<br />

continued<br />

4 lists some examples <strong>of</strong> microspheres prepared by<br />

Table<br />

drying.<br />

spray<br />

Advantages<br />

<strong>of</strong> the major advantages <strong>of</strong> spray drying is its<br />

One<br />

applicability. Both hydrophilic and hydrophobic<br />

general<br />

can be used with proper selection <strong>of</strong> the sol-<br />

polymer<br />

[52]. Spray drying is useful <strong>for</strong> encapsulating even<br />

vent<br />

drugs, such as proteins or peptides, be-<br />

heat-sensitive<br />

it involves mild temperatures [52]. Although<br />

cause<br />

drying includes hot air stream, the temperature <strong>of</strong><br />

spray<br />

droplets may be maintained below the drying air<br />

the<br />

due to rapid evaporation <strong>of</strong> the solvent.<br />

temperature<br />

effective temperature applied to the drug itself is<br />

The<br />

enough to be used <strong>for</strong> proteins. Moreover, spray<br />

mild<br />

is time effective. Spray drying can yield results<br />

drying<br />

to those <strong>of</strong> conventional methods in terms<br />

equivalent<br />

size distribution, particle morphology, and release<br />

<strong>of</strong><br />

yet with the advantage <strong>of</strong> high encapsulation<br />

kinetics,<br />

and the short duration <strong>of</strong> the preparation<br />

efficiency<br />

[53]. The spray drying equipment is easily<br />

procedure<br />

at the manufacturing site. Also, as a one-stage<br />

available<br />

process, spray drying is ideal <strong>for</strong> production <strong>of</strong><br />

closed<br />

materials and good manufacturing practice<br />

sterile<br />

(GMP) [30].<br />

Limitations<br />

TRH-PLGA<br />

solution<br />

Air filter<br />

Pump<br />

air<br />

Double<br />

nozzle<br />

Heater<br />

Drying<br />

chamber<br />

Mannitol<br />

solution<br />

Spray<br />

nozzle<br />

Blower<br />

Cyclone<br />

Receiver<br />

During spray drying, considerable amounts <strong>of</strong> the<br />

4. Examples <strong>of</strong> microencapsulation <strong>of</strong> proteins by spray<br />

Table<br />

drying<br />

Polymer Solvent <strong>Protein</strong> Particle<br />

size<br />

β-glucuronidase<br />

Bovine<br />

somatotropin<br />

Human<br />

erythropoietin<br />

Albumin/<br />

with<br />

Acacia<br />

as PVP<br />

coacervate<br />

stabilizer<br />

anhy- Poly<br />

dride<br />

PLGA<br />

Distilled<br />

water<br />

5 µm<br />

Dichloro-<br />

1-5 µm<br />

methane <br />

Dichloro-<br />

10 µm<br />

methane<br />

Release kinetics Ref.<br />

initial burst<br />

Biphasic:<br />

within 6h followed<br />

(31%)<br />

zero order release <strong>for</strong> 2<br />

by<br />

weeks<br />

release <strong>for</strong> 6 h due to<br />

90%<br />

fast degradation <strong>of</strong><br />

the<br />

and small parti-<br />

polymer<br />

size cle<br />

burst during 24 h<br />

Initial<br />

no further release <strong>for</strong><br />

and<br />

months, likely due to<br />

2<br />

interac-<br />

protein-polymer<br />

and insoluble protein<br />

tion<br />

aggregates<br />

can be lost during the process due to sticking<br />

material<br />

the microparticles to the wall <strong>of</strong> the drying chamber.<br />

<strong>of</strong><br />

drying process can <strong>of</strong>ten lead to change <strong>of</strong> poly-<br />

Spray<br />

<strong>of</strong> the spray dried drugs [66,67]. For exammorphism<br />

progesterone crystal in its original alpha <strong>for</strong>m (m.p.<br />

ples,<br />

turned into beta <strong>for</strong>m (m.p. 395K) when it was<br />

402K)<br />

dried in combination with PLA. Fiber <strong>for</strong>mation<br />

spray<br />

be another major problem in spray drying PLA [67].<br />

can<br />

are <strong>for</strong>med due to insufficient <strong>for</strong>ces present to<br />

Fibers<br />

up the liquid filament into droplets. It depends on<br />

break<br />

the type <strong>of</strong> polymer and, to a lesser extent, the<br />

both<br />

<strong>of</strong> the spray solution. For example, ethyl cellu-<br />

viscosity<br />

solutions made spherical droplets at relatively high<br />

lose<br />

however PLA solutions <strong>of</strong> considerably<br />

concentrations,<br />

concentration and viscosity resulted in fibers.<br />

low<br />

are a number <strong>of</strong> process variables that should be<br />

There<br />

<strong>for</strong> drug encapsulation. They include feed<br />

optimized<br />

properties, such as viscosity, uni<strong>for</strong>mity, and<br />

material<br />

<strong>of</strong> drug and polymer mixtures, feed rate,<br />

concentration<br />

<strong>of</strong> atomization, and the inlet and outlet tem-<br />

method<br />

[32]. The dependence on so many variables<br />

peratures<br />

become a problem in terms <strong>of</strong> reproducibility and a<br />

may<br />

process. In addition, the amount <strong>of</strong> polymer<br />

scale-up<br />

drugs <strong>for</strong> encapsulation may be limited, since<br />

and/or<br />

fluid <strong>of</strong> high viscosity cannot be sprayed.<br />

GELATION /<br />

IONOTROPIC<br />

COMPLEXATION<br />

POLYELECTROLYTE<br />

gelation (IG) is based on the ability <strong>of</strong><br />

Ionotropic<br />

to crosslink in the presence <strong>of</strong> counter<br />

polyelectrolytes<br />

to <strong>for</strong>m hydrogels. Since the use <strong>of</strong> alginate <strong>for</strong> cell<br />

ions<br />

[68], ionotropic gelation has been widely<br />

encapsulation<br />

used <strong>for</strong> both cell and drug encapsulation.<br />

Method<br />

is one <strong>of</strong> the most widely used polyanion <strong>for</strong><br />

Alginate<br />

Alginate is composed <strong>of</strong> 1,4-linked<br />

microencapsulation.<br />

beta-D-mannuronic acid and alpha-D-guluronic acid<br />

[60]<br />

[56]<br />

[62]

222 Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4<br />

(A)<br />

(B)<br />

HO HO<br />

-OOC<br />

OHO<br />

9. Monomer units (A) found in alginate and the alginate<br />

Fig.<br />

structure (B). From reference [69].<br />

polymer<br />

Divalent and trivalent cations induce gelation<br />

residues.<br />

binding mainly to the guluronic blocks (Fig. 9). The<br />

by<br />

and macro-spheres are produced by dropping a<br />

microor<br />

drug-loaded alginate solution into aqueous cal-<br />

cell-<br />

chloride solution. Calcium ions diffuse into the<br />

cium<br />

drops, <strong>for</strong>ming a three dimensional lattice <strong>of</strong><br />

alginate<br />

crosslinked alginate. Polyelectrolyte complexa-<br />

ionically<br />

(PEC) with oppositely charged polyelectrolytes<br />

tion<br />

be added to increase the mechanical strength <strong>of</strong><br />

may<br />

hydrogel and/or to provide a permeability barrier.<br />

the<br />

instance, addition <strong>of</strong> polycation (usually poly-L-<br />

For<br />

allows a membrane <strong>of</strong> polyelectrolyte complex<br />

lysine)<br />

<strong>for</strong>m on the surface <strong>of</strong> alginate beads [69]. A number<br />

to<br />

natural and synthetic polyelectrolytes have been in-<br />

<strong>of</strong><br />

Examples are listed in Table 5.<br />

vestigated.<br />

most <strong>of</strong> the droplets have been made with sy-<br />

Since<br />

needles, the particle sizes have been relatively<br />

ringe<br />

Smaller droplets can be <strong>for</strong>med using a vibration<br />

large.<br />

or air atomization method to extrude the algi-<br />

system<br />

solution (Fig. 10) [30]. The latter involves a Turbonate<br />

air-atomizer. Pressurized air is fed to mix with the<br />

tak<br />

alginate solution, <strong>for</strong>cing tiny liquid droplets<br />

sodium<br />

through the orifice <strong>of</strong> a nozzle. The calcium ions<br />

out<br />

the droplets <strong>of</strong> sodium alginate on contact to<br />

crosslink<br />

microgel droplets, which were further crosslinked<br />

<strong>for</strong>m<br />

poly-L-lysine to <strong>for</strong>m a membrane on the droplets.<br />

by<br />

obtained using this method were within<br />

Microparticles<br />

size range 5-15 µm [91].<br />

the<br />

Applications<br />

OH<br />

Mannuronate (M)<br />

OH<br />

O -OOC<br />

O<br />

OH<br />

-OOC OHO<br />

O HO<br />

O<br />

HO<br />

-OOC<br />

OHO<br />

-OOC<br />

has been widely used in microcapsule sys-<br />

IG/PEC<br />

<strong>for</strong> cell encapsulation [82,87-89,92-94] and drug<br />

tems<br />

systems [76,77,83,85,86,95,96]. Due to mild<br />

delivery<br />

conditions, IG/PEC has recently attracted a new<br />

process<br />

<strong>for</strong> an application to protein delivery [71,78-<br />

attention<br />

Calcium alginate hydrogels have been<br />

81,84,90,97,98].<br />

<strong>for</strong> delivery <strong>of</strong> vascular endothelial growth factor<br />

used<br />

[71]. The alginate beads demonstrated the abil-<br />

(VEGF)<br />

to incorporate VEGF with efficiency between 30%<br />

ity<br />

67% and constant release (5%/day) <strong>of</strong> VEGF <strong>for</strong> up<br />

and<br />

O<br />

OH<br />

O<br />

OH<br />

OH<br />

OH<br />

(G)<br />

Guluronate<br />

-OOC<br />

OH<br />

OH<br />

O<br />

OH<br />

O -OOC<br />

G M M G G<br />

O<br />

OH<br />

O<br />

5. Examples <strong>of</strong> ionotropic gelation (IG) and polyelec-<br />

Table<br />

complexation (PEC)<br />

trolyte<br />

Polyelectrolytes IG with PEC with References<br />

Alginate (-) Calcium (+) - [70-72]<br />

Alginate (-) Calcium (+) Poly-L-Lysine (+) [73]<br />

Alginate (-) Calcium (+) Chitosan (+) [74, 75]<br />

Chitosan (+)<br />

Carboxymethyl<br />

cellulose (-)<br />

Tripolyphosphate<br />

(TPP)(-)<br />

- [76-81]<br />

Aluminium (+) Chitosan (+) [82]<br />

κ-carrageenan (-) Potassium (+) Chitosan (+) [83]<br />

ι-carrageenan (-) Amines (+) - [84]<br />

Pectin (-) Calcium (+) - [85]<br />

Gelan gum (-) Calcium (+) - [86]<br />

Alginate and<br />

cellulose sulfate (-)<br />

Calcium (+)<br />

Poly (methylene-<br />

co-guanidine) (+)<br />

[87, 88]<br />

Polyphosphazene (-) Calcium (+) Poly-L-Lysine (+) [89, 90]<br />

Sodium<br />

alginate<br />

10. Schematic diagram <strong>of</strong> the preparation <strong>of</strong> alginate-<br />

Fig.<br />

microcapsules.<br />

polylysine<br />

14 days. The ionic interaction between VEGF and<br />

to<br />

contributed to maintaining the biological activ-<br />

alginate<br />

ity <strong>of</strong> VEGF.<br />

Advantages<br />

main advantage <strong>of</strong> IG/PEC is the mild <strong>for</strong>mula-<br />

The<br />

conditions <strong>for</strong> maintaining cell viability and protion<br />

integrity. All <strong>of</strong> the polyelectrolytes are watertein<br />

and thus proteins can be encapsulated without<br />

soluble,<br />

<strong>of</strong> organic solvents or elevated temperatures, both<br />

use<br />

which may damage protein integrity. Also, this sys-<br />

<strong>of</strong><br />

tem is simple, fast and cost-effective.<br />

Limitations<br />

Turbotak<br />

atomizer<br />

chloride<br />

Calcium<br />

solution<br />

Polylysine<br />

added<br />

Pressurized<br />

gas<br />

Microcapsule<br />

biggest problem in applications <strong>of</strong> IG/PEC <strong>for</strong><br />

The<br />

protein delivery, in spite <strong>of</strong> the great advan-<br />

controlled<br />

<strong>of</strong> mild conditions, is that the matrix and memtage<br />

<strong>for</strong>med by IG/PEC is not capable <strong>of</strong> controlling<br />

brane<br />

release rate <strong>for</strong> a long period <strong>of</strong> time. It does not<br />

the<br />

in cell encapsulation, where the membrane<br />

matter<br />

should provide sufficient permeability <strong>for</strong> the cell prod-

Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4 223<br />

i.e., a therapeutic protein. However, <strong>for</strong> IG/PEC to<br />

uct,<br />

used <strong>for</strong> controlled delivery <strong>of</strong> protein entities, a cer-<br />

be<br />

type <strong>of</strong> dense membrane (e.g., biodegradable polytain<br />

preferably capable <strong>of</strong> controlling the release rate,<br />

mers),<br />

be incorporated or alternative combinations <strong>of</strong><br />

should<br />

should be explored to control the<br />

polyelectrolytes<br />

<strong>of</strong> the membrane, so that the release rate<br />

permeability<br />

be controlled over the desired span. Thus far, the<br />

may<br />

rate <strong>of</strong> the protein is likely to depend on the<br />

release<br />

properties <strong>of</strong> the model protein or the<br />

physicochemical<br />

medium in which the microparticles are placed<br />

release<br />

In case <strong>of</strong> alginate-poly-L-lysine system, all para-<br />

[71].<br />

are tied to a single chemical complex, there<strong>for</strong>e<br />

meters<br />

is not easy to optimize the capsule condition. For this<br />

it<br />

new combinations <strong>of</strong> polyelectrolytes were<br />

reason,<br />

to allow independent modification <strong>of</strong> capsule<br />

proposed<br />

including size, wall thickness, mechanical<br />

parameters<br />

permeability, and surface characteristics [99].<br />

strength,<br />

issue in IG/PEC is that some polyelectrolytes<br />

Another<br />

have biocompatibility problem. There have been<br />

might<br />

arguments concerning the biocompatibil-<br />

contradictory<br />

<strong>of</strong> alginates [100-102]. A host <strong>for</strong>eign-body reaction<br />

ity<br />

occurred on account <strong>of</strong> the implanted algi-<br />

(fibrosis)<br />

particles and mannuronic acid block was<br />

nate-based<br />

to be responsible <strong>for</strong> the fibrotic response, as a<br />

found<br />

stimulator <strong>of</strong> IL-1 and TNF-α production. Use <strong>of</strong><br />

potent<br />

<strong>of</strong> high guluronic acid content was suggested<br />

alginates<br />

minimize the cytokine response. On the other hand,<br />

to<br />

study indicated that alginate particles with<br />

another<br />

guluronic acid contents provoked stronger re-<br />

high<br />

than the high mannuronic acid alginate particles<br />

sponse<br />

In general, polyionic hydrogels obtained by<br />

[102].<br />

have rather low mechanical strength. A few<br />

IG/PEC<br />

have suggested ways to overcome this problem<br />

papers<br />

exploring alternative combinations <strong>of</strong> polyanions<br />

by<br />

polycations [87,99], introducing a different process<br />

and<br />

[103], or applying additional coating [82,98].<br />

INTERFACIAL POLYMERIZATION<br />

polymerization features in situ polymeri-<br />

Interfacial<br />

<strong>of</strong> reactive monomers on the surface <strong>of</strong> a droplet<br />

zation<br />

or particles.<br />

Method<br />

reactive monomers (typically dichloride and<br />

Two<br />

are respectively dissolved in immiscible sol-<br />

diamine)<br />

and mixed to <strong>for</strong>m o/w emulsion (dichloride in oil<br />

vents<br />

and diamine in water phase). The monomers dif-<br />

phase<br />

to the o/w interface where they react to <strong>for</strong>m a<br />

fuse<br />

membrane (Fig. 11). A typical example <strong>of</strong> this<br />

polymeric<br />

is making nylon microcapsules [104]. Nona-<br />

method<br />

phase (chloro<strong>for</strong>m/cyclohexane) containing surqueous<br />

(e.g., sorbitan trioleate) and aqueous buffer confactant<br />

drugs to be incorporated (enzymes or proteins),<br />

taining<br />

protein (e.g., BSA or hemoglobin) and dia-<br />

protective<br />

are prepared respectively. Two phases are mixed<br />

mine<br />

and stirred to make an w/o emulsion in an ice bath un-<br />

11. <strong>Microencapsulation</strong> by interfacial polymerization<br />

Fig.<br />

From reference [104].<br />

method.<br />

the desired droplet size is reached. Another nonaque-<br />

til<br />

phase containing acid chloride is added to the emulous<br />

<strong>for</strong> interfacial polymerization. Polymerization is<br />

sion<br />

by addition <strong>of</strong> excess nonaqueous phase.<br />

quenched<br />

are allowed to sediment and collected<br />

Microcapsules<br />

then washed in saline several times to remove or-<br />

and<br />

solvents and byproducts.<br />

ganic<br />

combinations <strong>of</strong> monomers can be used to<br />

Various<br />

a range <strong>of</strong> polymer membranes [104]. Sebacoyl<br />

obtain<br />

and 1,6-hexane diamine can be used to <strong>for</strong>m<br />

chloride<br />

polyamide nylon 6, 10. The microcapsules using<br />

the<br />

system, however, tend to be fragile and difficult to<br />

this<br />

Terephthaloyl chloride and 1,6-hexane diamine<br />

handle.<br />

yield polyester membrane. Alternatively tere-<br />

can<br />

chloride can be used in combination with Lphthaloyl<br />

to yield poly(terephthaloyl L-lysine). Typically<br />

lysine<br />

chlorides and diamines are reactive monomers;<br />

acid<br />

isocyanates can be used instead <strong>of</strong> or as a par-<br />

however,<br />

substitute <strong>for</strong> acid chloride [105]. Alternatively, the<br />

tial<br />

composed <strong>of</strong> only one type <strong>of</strong> monomer can be<br />

polymer<br />

on the interface (Interfaicial addition polymeri-<br />

<strong>for</strong>med<br />

[104]. Polyalkylcyanoacrylate belongs to this<br />

zation)<br />

Aqueous drug solution and oil phase containing<br />

type.<br />

monomer are mixed to <strong>for</strong>m an w/o<br />

cyanoacrylate<br />

The polymerization is initiated by water in<br />

emulsion.<br />

aqeous phase with cyanoacrylate dissolved in the oil<br />

the<br />

phase.<br />

Application<br />

Monomer B<br />

Monomer A<br />

Polymer membrane<br />

insulin nanoparticles were prepared using<br />

Recently<br />

addition polymerization techniques [106].<br />

interfacial<br />

were prepared by addition <strong>of</strong> ethyl 2-<br />

Nanoparticles<br />

to a stirred w/o microemulsion consistcyanoacrylate<br />

<strong>of</strong> aqueous insulin solution, oil and surfactant. To<br />

ing<br />

exhaustive washing steps after polymerization<br />

avoid<br />

biocompatible oils (caprylic/capric triglyc-<br />

reaction,<br />

and mono-/diglycerides) and surfactants (polyerides<br />

80 and sorbitan monooleate) were used to <strong>for</strong>sorbate<br />

the microemulsions. The obtained poly(ethyl 2mulate<br />

is known to be biodegradable. Since incyanoacrylate)<br />

was confined to the aqueous phase in w/o emulsulin <br />

sions, a high encapsulation efficiency (86%) could be

224 Biotechnol. Bioprocess Eng. 2001, Vol. 6, No. 4<br />

Insulin was released with initial burst over<br />

achieved.<br />

first 30 minutes followed by a constant release up<br />

the<br />

to 3 h, after which the release rate declined.<br />

Limitations<br />

this method was initially proposed <strong>for</strong> en-<br />

Although<br />

encapsulations, it has some serious problems in<br />

zyme<br />

First, large w/o interface is produced during<br />

practice.<br />

reaction, where proteins or enzymes are likely to be<br />

the<br />

Second, large amounts <strong>of</strong> proteins may par-<br />

inactivated.<br />

in the polymerization reaction changing its bioticipate<br />

activity. Third, it is <strong>of</strong>ten hard to control the<br />

logical<br />

reaction. The yield and quality <strong>of</strong> the<br />

polymerization<br />

obtained by interfacial polymerization may<br />

membrane<br />

controlled by a number <strong>of</strong> factors, such as chemical<br />

be<br />

<strong>of</strong> reactive monomers, and reaction conditions.<br />

natures<br />

monomer concentrations, temperature, the mixing<br />

The<br />

and the reaction time are likely to be important<br />

rate,<br />

[105]. Fourth, exhaustive washing steps are<br />

parameters<br />

to remove monomers, byproducts, organic sol-<br />

required<br />

and surfactants. At the same time, several washvents,<br />

steps may lead to further loss <strong>of</strong> water soluble drugs.<br />

ing<br />

pH change due to HCl byproduct <strong>for</strong>med by reac-<br />

Fifth,<br />

<strong>of</strong> an acid chloride and an amine can damage the<br />

tion<br />

labile drugs.<br />

acid<br />

SUPERCRITICAL FLUID PRECIPITATION<br />

fluid is defined as a fluid <strong>of</strong> which tem-<br />

Supercritical<br />

and pressure are simultaneously higher than at<br />

perature<br />

critical point, i.e. critical temperature Tc and critical<br />

the<br />

Pc, at which the density <strong>of</strong> gas is equal to that<br />

pressure<br />

the remaining liquid and the surface between the<br />

<strong>of</strong><br />

phases disappears (Fig. 12). In practice, the term is<br />

two<br />

used to describe a fluid in the relative vicinity <strong>of</strong><br />

<strong>of</strong>ten<br />