N123-138 Series Snap Trac Dither Generator and ... - Moog Inc

N123-138 Series Snap Trac Dither Generator and ... - Moog Inc

N123-138 Series Snap Trac Dither Generator and ... - Moog Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

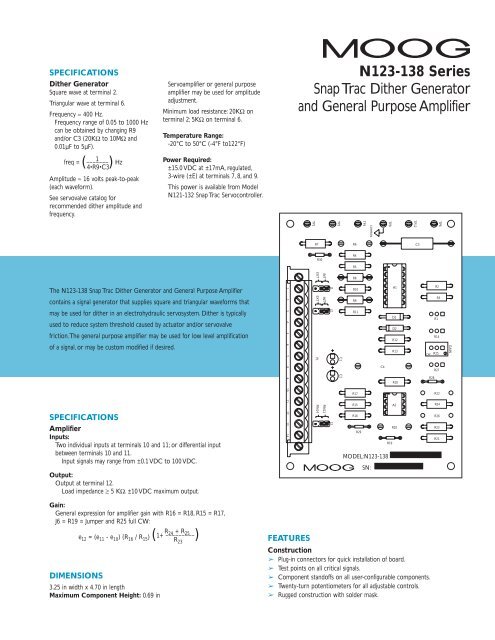

SPECIFICATIONS<br />

<strong>Dither</strong> <strong>Generator</strong><br />

Square wave at terminal 2.<br />

Triangular wave at terminal 6.<br />

Frequency ≈ 400 Hz.<br />

Frequency range of 0.05 to 1000 Hz<br />

can be obtained by changing R9<br />

<strong>and</strong>/or C3 (20KΩ to 10MΩ <strong>and</strong><br />

0.01µF to 5µF).<br />

freq =<br />

1 ( –––––––) Hz<br />

4•R9•C3<br />

Amplitude ≈ 16 volts peak-to-peak<br />

(each waveform).<br />

See servovalve catalog for<br />

recommended dither amplitude <strong>and</strong><br />

frequency.<br />

The <strong>N123</strong>-<strong>138</strong> <strong>Snap</strong> <strong>Trac</strong> <strong>Dither</strong> <strong>Generator</strong> <strong>and</strong> General Purpose Amplifier<br />

contains a signal generator that supplies square <strong>and</strong> triangular waveforms that<br />

may be used for dither in an electrohydraulic servosystem. <strong>Dither</strong> is typically<br />

used to reduce system threshold caused by actuator <strong>and</strong>/or servovalve<br />

friction.The general purpose amplifier may be used for low level amplification<br />

of a signal, or may be custom modified if desired.<br />

SPECIFICATIONS<br />

Servoamplifier or general purpose<br />

amplifier may be used for amplitude<br />

adjustment.<br />

Minimum load resistance: 20KΩ on<br />

terminal 2; 5KΩ on terminal 6.<br />

Temperature Range:<br />

-20°C to 50°C (-4°F to122°F)<br />

Power Required:<br />

±15.0 VDC at ±17mA, regulated,<br />

3-wire (±E) at terminals 7, 8, <strong>and</strong> 9.<br />

This power is available from Model<br />

N121-132 <strong>Snap</strong> <strong>Trac</strong> Servocontroller.<br />

Amplifier<br />

Inputs:<br />

Two individual inputs at terminals 10 <strong>and</strong> 11; or differential input<br />

between terminals 10 <strong>and</strong> 11.<br />

Input signals may range from ±0.1 VDC to 100 VDC.<br />

Output:<br />

Output at terminal 12.<br />

Load impedance ≥ 5 KΩ. ±10 VDC maximum output.<br />

Gain:<br />

General expression for amplifier gain with R16 = R18, R15 = R17,<br />

J6 = R19 = Jumper <strong>and</strong> R25 full CW:<br />

R24 + R25 e12 = (e11 - e10) (R16 / R15) ( 1+ –––––––––)<br />

R23 DIMENSIONS<br />

3.25 in width x 4.70 in length<br />

Maximum Component Height: 0.69 in<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14<br />

<strong>N123</strong>-<strong>138</strong> <strong>Series</strong><br />

<strong>Snap</strong> <strong>Trac</strong> <strong>Dither</strong> <strong>Generator</strong><br />

<strong>and</strong> General Purpose Amplifier<br />

TP1<br />

R7<br />

R30<br />

EXT EXT<br />

P1<br />

PIN14<br />

INT INT<br />

PIN13<br />

J1<br />

J2<br />

J3<br />

TP2<br />

C1<br />

C2<br />

R6<br />

R4<br />

R5<br />

R8<br />

R10<br />

R9<br />

R11<br />

R17<br />

R15<br />

R16<br />

R29<br />

COMMON<br />

TP3<br />

C4<br />

R19<br />

MODEL:<strong>N123</strong>-<strong>138</strong><br />

SN:<br />

TP8<br />

A1<br />

D1<br />

D2<br />

R12<br />

R13<br />

R18<br />

A2<br />

R20<br />

TP12<br />

C3<br />

CW R25<br />

FEATURES<br />

Construction<br />

➢ Plug-in connectors for quick installation of board.<br />

➢ Test points on all critical signals.<br />

➢ Component st<strong>and</strong>offs on all user-configurable components.<br />

➢ Twenty-turn potentiometers for all adjustable controls.<br />

➢ Rugged construction with solder mask.<br />

R28<br />

R2<br />

R1<br />

R14<br />

R27<br />

R22<br />

R24<br />

R26<br />

R23<br />

R21<br />

TP6<br />

R3<br />

GAIN

<strong>N123</strong>-<strong>138</strong> DITHER GENERATOR AND GENERAL PURPOSE AMPLIFIER<br />

INPUT SIGNAL<br />

0 TO +15.0 VDC<br />

SIGNAL GROUND<br />

SEE NOTE 5<br />

UNUSED INPUT<br />

INPUT SIGNAL<br />

0 TO -15.O VDC<br />

SINGLE<br />

INPUT SIGNAL<br />

INDIVIDUAL INPUTS OR<br />

DIFFERENTIAL INPUT<br />

CIRCUITRY<br />

<strong>Dither</strong> <strong>Generator</strong><br />

The dither generator consists of a<br />

comparator stage (A1A), amplitude<br />

limiting stages (A1C/D2 <strong>and</strong> A1D/D1)<br />

<strong>and</strong> an integrating amplifier stage<br />

(A1B). Upon startup,A1A will attempt<br />

to go to + or - saturation. However,<br />

the peak voltage will be limited to<br />

approximately ±8 VDC by D1/A1D or<br />

D2/A1C.A1B ramps up or down, as<br />

the case may be, until the output<br />

voltage is sufficient to cause the<br />

feedback voltage at the comparator<br />

(through voltage divider R8, R11) to<br />

change polarity.At this point,A1A<br />

switches polarity <strong>and</strong> A1B begins to<br />

ramp in the opposite direction.<br />

+E<br />

7<br />

5<br />

R2<br />

R1<br />

NF<br />

CW<br />

R3<br />

+E<br />

+AMPLITUDE LIMIT<br />

SIGNAL GROUND<br />

C1<br />

10uF<br />

C2<br />

10uF<br />

TP8<br />

8<br />

POWER<br />

INPUTS<br />

(REGULATED)<br />

49.9K<br />

49.9K<br />

POWER<br />

INPUTS<br />

-E<br />

9<br />

TP3<br />

+E<br />

(REGULATED)<br />

TP2<br />

3<br />

J2 INT<br />

EXT<br />

12 4<br />

13<br />

A1D<br />

14<br />

TL084CN<br />

11<br />

-E<br />

D1<br />

2<br />

SQUARE<br />

WAVE<br />

OUTPUT<br />

SIGNAL<br />

5<br />

COMPARATOR<br />

R6<br />

TYPICAL STANDOFF<br />

INTEGRATOR<br />

NF<br />

C3<br />

-E<br />

0.01uF<br />

TP6<br />

4 X<br />

R30<br />

0<br />

R4<br />

24.9K<br />

R5<br />

100K<br />

2<br />

3<br />

11<br />

A1A<br />

1<br />

TL084CN<br />

4<br />

+E<br />

R7<br />

2K<br />

R8<br />

49.9K<br />

R9<br />

61.9K R10<br />

49.9K<br />

6<br />

5<br />

-E<br />

11<br />

7<br />

A1B<br />

TL084CN<br />

4<br />

+E<br />

R11<br />

49.9K<br />

6<br />

TRIANGULAR WAVE<br />

OUTPUT SIGNAL<br />

-E<br />

1<br />

J1<br />

EXT<br />

INT<br />

TP1<br />

9 11<br />

8<br />

10 A1C<br />

TL084CN<br />

4<br />

D2<br />

GENERAL PURPOSE AMP<br />

+E -AMPLITUDE LIMIT<br />

R21<br />

R22<br />

R12<br />

R13<br />

10K<br />

NF<br />

(TEST POINT)<br />

TP12<br />

49.9K 49.9K<br />

6<br />

R19 5<br />

5<br />

R14 CW<br />

NF<br />

-E<br />

+E<br />

0<br />

R20<br />

NF<br />

7<br />

6 A2B<br />

TL082CP<br />

12<br />

GAIN<br />

13<br />

R27<br />

NF<br />

6 R26<br />

NF<br />

R24<br />

10K<br />

R25<br />

CW<br />

100K<br />

11<br />

R15<br />

100K<br />

DIFFERENTIAL AMP<br />

R16<br />

100K<br />

+E<br />

R28<br />

0<br />

TL082CP<br />

CW<br />

-E<br />

BIAS<br />

R23<br />

10K<br />

6<br />

OUTPUT SIGNAL<br />

10<br />

R17<br />

100K<br />

3<br />

2<br />

8<br />

A2A<br />

4<br />

R29<br />

0<br />

R18 -E<br />

1<br />

J3<br />

PIN 13<br />

PIN 14<br />

14<br />

100K<br />

NOTES:<br />

C4<br />

NF<br />

1. NF = NOT FURNISHED<br />

2. ■ = PIN 1 (SQUARE PIN)<br />

3. = INDICATES COMPONENT MOUNTED ON STANDOFFS<br />

4. CW = CLOCKWISE<br />

General Purpose Amplifier<br />

A differential input amplifier (A2A)<br />

<strong>and</strong> a non-inverting amplifier (A2B)<br />

are mounted on this board for<br />

general signal amplification. Input<br />

signals are applied to terminal 10<br />

<strong>and</strong> 11, with the output signal at<br />

terminal 12.Amplification of each<br />

stage should be between 0.1 <strong>and</strong> 10<br />

volts/volt with resistor values between<br />

10KΩ <strong>and</strong> 100 KΩ.<br />

SPECIAL MODIFICATIONS / SET-UP / OPTIONS<br />

Refer to section on set-up instructions <strong>and</strong> technical information for additional<br />

assistance on card usage <strong>and</strong> application. R1, R14, R27, R26, R24, R19 sizing<br />

options are located in set-up instruction section of literature.<br />

5 DO NOT CONNECT DC SIGNAL TO PIN-4. REFER TO SET-UP<br />

INSTRUCTION SECTION FOR ADDITIONAL INFORMATION.<br />

6 REFER TO “SPECIAL MODIFICATION” OPTIONS<br />

ADJUSTMENTS<br />

Gain (R25) – provides 12:2<br />

amplification range of A2B.<br />

Bias (R27) – not furnished.<br />

(Recommended size is 100K)<br />

MOUNTING:<br />

Mount using Curtiss type TR-3<br />

plastic track (<strong>Moog</strong> P/N 65419-1)

SET-UP INSTRUCTIONS<br />

The card is factory built to supply a<br />

<strong>Dither</strong> Frequency of Approx. 400Hz<br />

Calculated Outputs<br />

➢Determine required <strong>Dither</strong><br />

frequency needed<br />

➢Calculate <strong>Dither</strong> Frequency ➡<br />

f DITHER = [1 / (4xR9xC3)]Hz (using<br />

Triangle waveform)<br />

➢Refer to Servovalve Catalog for<br />

recommended dither amplitude &<br />

frequency; Consult factory as<br />

required<br />

➢Use Square Waveform for most<br />

valve applications<br />

➢Steady State Triangular Waveform<br />

output at Pin-6:<br />

E6 = (R5 / R4 + R5) E4<br />

Vdc (Error Correction)<br />

➢Slope of Output:<br />

Slope = (-E2 / R9 x C3)<br />

Volts/Sec<br />

Pos Slope Rate = +12V/msec<br />

Neg Slope Rate = -12V/msec<br />

Preliminary Test Set-Up<br />

➢R25 full CCW<br />

➢Set Jumpers J1 & J2 to INT<br />

(Internal) position<br />

➢Set J3 to PIN-13 position<br />

EXT (External) Control of Ramp<br />

Rate<br />

➢For + Slope, J1 = EXT<br />

➢Rate controlled by input signal at<br />

Pin-1 (0 to -15V)<br />

➢For - Slope, J1 = EXT<br />

➢Rate controlled by input signal at<br />

Pin-1 (0 to +15V)<br />

Frequency Test Set-Up<br />

➢Verify <strong>Dither</strong> Frequency signal at<br />

TP2 is 400±40 Hz<br />

➢Verify factory set Amplitude at TP2<br />

is 16Vp-p<br />

For Slope or Ramp Adjust<br />

Capability over 12:2 range<br />

➢Install a 100K pot in the R1 & R14<br />

position<br />

➢Remove R2, R3, R12 & R13 (49.9K)<br />

resistors<br />

➢Adjusting R1 will increase the Neg<br />

Slope of the waveform<br />

➢Adjusting R14 will increase the Pos<br />

Slope of the waveform<br />

➢Offset Voltage may be provided by<br />

R1 & R14 which will result in unsymmetrical<br />

waveforms<br />

Setting the (+) Amplitude Limit<br />

➢R2 & R3 (49.9K) resistors provides<br />

a balanced positive voltage divider<br />

(+15V)<br />

➢This along with D1 / A1D limits the<br />

Pos. Peak voltage to +8Vdc<br />

(Approx. 1/2 of +15V)<br />

Setting the (-) Amplitude Limit<br />

➢R12 & R13 (49.9K) resistors<br />

provide a balanced negative voltage<br />

divider (-15V)<br />

➢This along with D2 / A1C limits the<br />

Neg Peak voltage to -8Vdc<br />

(Approx. 1/2 of -15V)<br />

General Purpose Amplifier<br />

➢The General Purpose Amplifier can<br />

be used for <strong>Dither</strong> Amplitude<br />

Adjustment using R25 of A2B<br />

Non-Inverting Stage ➡ provides<br />

12:2 amplification range<br />

➢Auxiliary Non-Inverting Amplifier<br />

(A2B): Gain Equation<br />

Av = Gain = e12 / e13 =<br />

[ 1 + (R24 + R25) / R23 ]<br />

➢A differential input Amp (A2A) & a<br />

Non-Inverting Amp (A2B) are<br />

supplied for general signal<br />

amplification<br />

➢J3 provides jumper select options<br />

to “combine” or “isolate” stages<br />

A2A & A2B<br />

➢Input signals are applied to<br />

Differential Pin-10 & Pin-11 with<br />

output signal at Pin-12<br />

OR<br />

➢Connect Pin-2 (Sq Wave output) or<br />

Pin-6 (Triangle Wave output) to<br />

Pin-13 (Single Input Signal) for<br />

Amplitude Adjust using R25 with<br />

output signal at Pin-12<br />

➢With Input applied to Pin-11 <strong>and</strong><br />

Pin-10 grounded, a positive output<br />

will result<br />

➢Adjust R25 for 12:2 ratio<br />

amplification ➡ ±10Vdc max<br />

output is possible<br />

➢Zero Offset pot (R27) may be<br />

installed for Bias control of signal;<br />

Set R27 to 100K Pot <strong>and</strong> R26 to<br />

100K / 1% resistor<br />

➢Set Gain Pot R25 (Amplitude Adj)<br />

full CCW for min Gain / full CW<br />

for max Gain<br />

Special Modification Information / Options<br />

➢Comparator Stage (A1A)<br />

Configured as a ‘Square-Wave’ <strong>Generator</strong> providing a 400Hz<br />

Square Wave output signal at Pin-2.A ‘Triangular-Wave’ output<br />

signal at Pin-6 is provided via use of Integrator Stage (A1B) with<br />

frequency dependent on selection of R9 & C3.<br />

➢No Input Signal is required at Pin-4 with R30 connected to<br />

ground via 0Ω jumper<br />

➢R9 & C3 are installed at factory to provide a fixed 400Hz frequency<br />

at approximately 16VP-P amplitude.Amplitude may be varied by<br />

using General Purpose Amplifier Stage.<br />

➢Other frequencies from 0.05Hz to 1KHz are available by changing<br />

R9 & C3<br />

General Purpose Amplifier (A2B)<br />

➢Gain ➡ eo / ein = [1 + (R24 + R25 / R23 ]<br />

➢Configured as a ‘Non-Inverting’ Amplifier for general signal<br />

amplification with optional NF component selection / sizing & reconfiguration<br />

options<br />

➢Input Amplification resulting in Output Voltage >10Vdc are limited by<br />

Saturation<br />

➢R25 provides 12:2 amplification range of A2B<br />

➢R19 may be adjusted to obtain Custom Signal Scaling (See<br />

Application Example)<br />

➢R24 may be adjusted to obtain a different amplification range<br />

including:<br />

R24 Min Gain<br />

Examples<br />

Max Gain Max Output @ Pin-12<br />

0Ωjumper 1 11 ±10Vdc<br />

1K 0.1 11.1 ±10Vdc<br />

Example: Custom Signal Scaling Application using Aux Amp<br />

➢Scaling ±8Vdc Input Square Wave ➡ ±1Vdc at Output Pin-12<br />

➢Refer to Fig.A<br />

e 13<br />

R19<br />

0Ω<br />

VREF<br />

R23<br />

10K<br />

R21<br />

10K<br />

Fig A - General Purpose Amp Configuration<br />

+<br />

-<br />

R24<br />

10K<br />

A2B<br />

R25 cw<br />

100K<br />

Jumper<br />

e 12

SET-UP INSTRUCTIONS<br />

➢Determine V REF needed to reduce +8v to +1v<br />

➢Calculate resistor value R19<br />

➢Jumper R24 (This changes Gain Ratio from 12:2 to 11:1)<br />

➢Remove R19 (0Ω) & replace with 70K, 1% resistor<br />

➢Set R25 Pot full CCW for ‘Min’ Gain of ‘1’<br />

➢Verify +1Vdc Output at Pin-12<br />

Calculations<br />

➢@1Vdc = V REF ➡ V REF = +e 13 [R21 / (R21 + R19)]<br />

➢Solve for R19 ➡ R19 = 70K<br />

➢Calculate Gain ➡ e 12 / e 13 = [1 + (R24 + R25) / R23]<br />

➢With R24 = 0 ➡ Min Gain = 1 @ R25 full CCW<br />

➡ Max Gain = 11 @ R25 full CW<br />

➢Resultant Output ➡ +1Vdc Output @ Pin-12 @<br />

+8Vdc Input<br />

CLOSED LOOP POSITION CONTROL<br />

MODEL N121-132A<br />

SERVOCONTROLLER<br />

(<strong>Snap</strong>-<strong>Trac</strong> Card)<br />

A1A<br />

R8<br />

SCALE<br />

MODEL <strong>N123</strong>-<strong>138</strong><br />

DITHER GENERATOR<br />

(<strong>Snap</strong>-<strong>Trac</strong> Card)<br />

DITHER FREQ WAVEFORM<br />

A1A<br />

R8<br />

LOOP GAIN-1<br />

R9<br />

R11<br />

A1B A2B<br />

A1B<br />

Note: Consult <strong>Moog</strong> Servovalve Catalog for recommended<br />

dither Amplitude & Frequency. Select 'waveform' as per<br />

requirements of application <strong>and</strong> actual desired response.<br />

C3<br />

R46<br />

+E<br />

-E<br />

-E<br />

+E<br />

26<br />

27<br />

28<br />

29<br />

22<br />

18<br />

3<br />

12<br />

13<br />

19<br />

17<br />

21<br />

10<br />

2<br />

2<br />

6<br />

7<br />

9<br />

8<br />

115 VAC<br />

50-60 Hz<br />

Position Servo with <strong>Dither</strong> <strong>Generator</strong> Application<br />

-15V<br />

+15V<br />

+15V<br />

-15V<br />

Ps<br />

C2 C1<br />

ACTUATOR<br />

POSITION COMMAND<br />

SERVOVALVE<br />

R<br />

Questions & Answers<br />

Question: Can the <strong>Dither</strong> Frequency<br />

be set-up for either a ‘square wave’ or<br />

‘triangular wave’?<br />

Answer: The valve is usually run with<br />

the square wave output signal but will<br />

depend on the actual desired response.<br />

Square wave will provide a more<br />

abrupt control from hard over position<br />

whereas the Triangular wave will<br />

provide a softer control response. It<br />

will depend on valve ‘friction’ or<br />

‘sticking’ action caused by actuator or<br />

servovalve response. Research indicates<br />

that the type of waveform, whether<br />

sine, square or triangular shape, will not<br />

significantly effect the valve<br />

performance. It is strictly related to<br />

required frequency & amplitude for the<br />

specified valve hardware.<br />

Question: Does the type of<br />

servovalve used determine the<br />

frequency & amplitude?<br />

Answer: The card is factory set for<br />

400Hz frequency with an amplitude of<br />

16Vp-p.The <strong>Moog</strong> Servovalve Catalog<br />

should be consulted for recommended<br />

dither amplitude & frequency. If a<br />

competitors valve is used, consult the<br />

appropriate Factory as required.The<br />

actual frequency / amplitude will also<br />

be determined on the system set-up.<br />

Fine tuning may need to be applied to<br />

reach satisfactory results.As an<br />

example, a 760 <strong>Series</strong> valve may require<br />

a dither frequency of approximately<br />

400Hz at a current amplitude of 10mA<br />

peak-to-peak (series coil configuration).<br />

Caution is advised since the use of<br />

higher dither frequency other than<br />

specified, can excite internal valve<br />

resonance which may lead to valve<br />

failure or degrade the valve life. Proper<br />

FORCE<br />

ON<br />

LOAD<br />

POSITION FEEDBACK<br />

amplitude (% of valve current) should<br />

also be stressed so as not to exceed<br />

20% of rated current.<br />

Question: What purpose do the NF<br />

(non-furnished) components provide in<br />

the circuit such as pots R1, R14 <strong>and</strong><br />

R27? What are the recommended<br />

component sizes for setting up these<br />

feature adjustments?<br />

Answer: Installation of R1 provides<br />

adjustment of the ‘negative’ slope or<br />

ramp rate over a 12:1 ratio. R14<br />

provides adjustment of the ‘positive’<br />

slope or ramp rate over a 12:1 range.<br />

Recommended size is 100K for each.<br />

The voltage divider resistors must be<br />

removed for this feature to operate.<br />

(Remove R2, 3, 12 & 13)<br />

Question: What is the purpose of<br />

the Auxiliary general purpose amp?<br />

Answer: This stage is used for <strong>Dither</strong><br />

Amplitude Adj using R25 (Gain) pot of<br />

A2B Non-Inverting Stage. Connect<br />

Output Pin-2 (Sq Wave) or Pin-6<br />

(Triangle Wave) to Pin-13 (Single Input<br />

Signal) for amplitude adjustment using<br />

R25 for a 12:2 ratio amplification.A<br />

Zero Offset pot (R27) may be installed<br />

for ‘Bias’ signal control. Set R27 to<br />

100K Pot & R26 to 100K / 1% resistor.<br />

Question: How much <strong>Dither</strong> should<br />

be applied?<br />

Answer: If external dither is applied<br />

to Pin-1 or Pin-3, typically adjust for<br />

±10% of valve rated current. J1 & J2<br />

MUST be in the appropriate position.<br />

This follows true for Internal dither.<br />

Internal dither ±Slope is adjusted by<br />

pots R1 & R14 (customer installed).<br />

<strong>Dither</strong> current thru a servovalve<br />

should NOT exceed 20% of rated<br />

current.<br />

Industrial Controls Division<br />

<strong>Moog</strong> <strong>Inc</strong>., East Aurora, NY 14052-0018<br />

Telephone: 716/655-3000<br />

Fax: 716/655-1803<br />

Toll Free: 1-800-272-MOOG<br />

CDL6173 Rev B 500-199 1198