layout, design and construction handbook - California Department of ...

layout, design and construction handbook - California Department of ...

layout, design and construction handbook - California Department of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

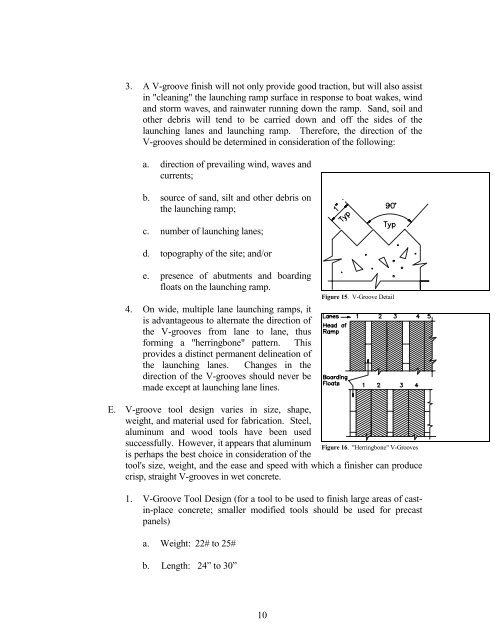

3. A V-groove finish will not only provide good traction, but will also assist<br />

in "cleaning" the launching ramp surface in response to boat wakes, wind<br />

<strong>and</strong> storm waves, <strong>and</strong> rainwater running down the ramp. S<strong>and</strong>, soil <strong>and</strong><br />

other debris will tend to be carried down <strong>and</strong> <strong>of</strong>f the sides <strong>of</strong> the<br />

launching lanes <strong>and</strong> launching ramp. Therefore, the direction <strong>of</strong> the<br />

V-grooves should be determined in consideration <strong>of</strong> the following:<br />

a. direction <strong>of</strong> prevailing wind, waves <strong>and</strong><br />

currents;<br />

b. source <strong>of</strong> s<strong>and</strong>, silt <strong>and</strong> other debris on<br />

the launching ramp;<br />

c. number <strong>of</strong> launching lanes;<br />

d. topography <strong>of</strong> the site; <strong>and</strong>/or<br />

e. presence <strong>of</strong> abutments <strong>and</strong> boarding<br />

floats on the launching ramp.<br />

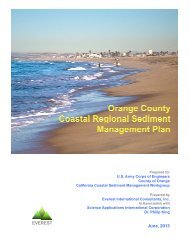

4. On wide, multiple lane launching ramps, it<br />

is advantageous to alternate the direction <strong>of</strong><br />

the V-grooves from lane to lane, thus<br />

forming a "herringbone" pattern. This<br />

provides a distinct permanent delineation <strong>of</strong><br />

the launching lanes. Changes in the<br />

direction <strong>of</strong> the V-grooves should never be<br />

made except at launching lane lines.<br />

E. V-groove tool <strong>design</strong> varies in size, shape,<br />

weight, <strong>and</strong> material used for fabrication. Steel,<br />

aluminum <strong>and</strong> wood tools have been used<br />

successfully. However, it appears that aluminum Figure 16. "Herringbone" V-Grooves<br />

is perhaps the best choice in consideration <strong>of</strong> the<br />

tool's size, weight, <strong>and</strong> the ease <strong>and</strong> speed with which a finisher can produce<br />

crisp, straight V-grooves in wet concrete.<br />

1. V-Groove Tool Design (for a tool to be used to finish large areas <strong>of</strong> castin-place<br />

concrete; smaller modified tools should be used for precast<br />

panels)<br />

a. Weight: 22# to 25#<br />

b. Length: 24” to 30”<br />

10<br />

Figure 15. V-Groove Detail