Catalogue "Privod" ver 1.1

Catalogue "Privod" ver 1.1

Catalogue "Privod" ver 1.1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

OIL AND GAS SYSTEMS • PRIVOD<br />

9.3 Centrifugal submersible pumps such as ЭЦН5<br />

Centrifugal submersible pumps are intended for pumping -out layer liquid in firmness of 1400 kg/m 3 and<br />

temperature not more than 120° C from oil wells of group 5 and 5А with displacement angle of a shaft of a <strong>ver</strong>tical<br />

in a place of suspender УЭЦН no more than 60°, and are furnishing items of settings УЭЦН.<br />

Radial flow pumps of dimension of group 5 are deli<strong>ver</strong>ed by productivity from 30 up to 200 m 3 /day. And head<br />

up to 2250 meters. The pump of section type will consist of the source unit, sections of the pump, the unit of the<br />

head, a gate of an in<strong>ver</strong>se tight, switch gate.<br />

At will of the Customer the source unit can be miss, thus hydroprotection of the electromotor is deli<strong>ver</strong>ed in the<br />

plucking with the receiving system that allows to reduce quantity of joints. In sections of the pump the intermediate<br />

and radial bearings providing reliable and durating operation of the pump are established. According to individual<br />

specifications of the Customer in the pump it is applied 6 and 8 stud-flange connection and the additional bearing<br />

in the head (for reduction of vibration) is established. The design of pumps allows to produce sections without an<br />

axial bearing part therefore axial loads are perceived by hydroprotection of the electromotor.<br />

Pumps can be completed by working steps, as two-point design and, with oblong nave of the driving wheel,<br />

obtained by a method of powder metallurgy; or driving wheels with a short nave from carbon fiber-reinforced<br />

plastic with guiding meanses from cast iron. Use of working steps of a two-point design augments interrepair<br />

time of УЭЦН and allows to maintain pumps in a close conditions with the heightened contents in layer liquids of<br />

mechanical impurities.<br />

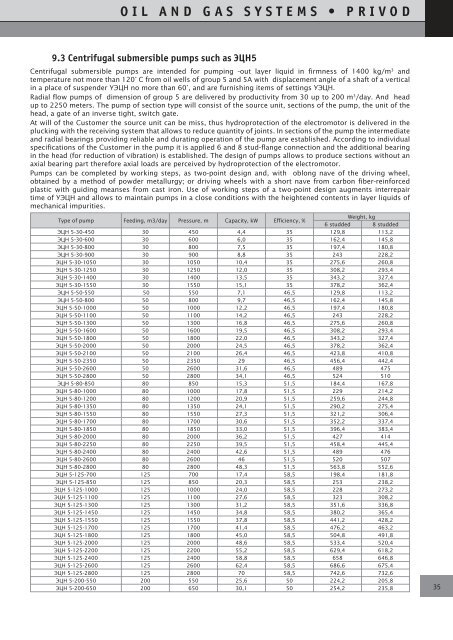

Type of pump Feeding, m3/day Pressure, m Capacity, kW Efficiency, %<br />

Weight, kg<br />

6 studded 8 studded<br />

ЭЦН 5-30-450 30 450 4,4 35 129,8 113,2<br />

ЭЦН 5-30-600 30 600 6,0 35 162,4 145,8<br />

ЭЦН 5-30-800 30 800 7,5 35 197,4 180,8<br />

ЭЦН 5-30-900 30 900 8,8 35 243 228,2<br />

ЭЦН 5-30-1050 30 1050 10,4 35 275,6 260,8<br />

ЭЦН 5-30-1250 30 1250 12,0 35 308,2 293,4<br />

ЭЦН 5-30-1400 30 1400 13,5 35 343,2 327,4<br />

ЭЦН 5-30-1550 30 1550 15,1 35 378,2 362,4<br />

ЭЦН 5-50-550 50 550 7,1 46,5 129,8 113,2<br />

ЭЦН 5-50-800 50 800 9,7 46,5 162,4 145,8<br />

ЭЦН 5-50-1000 50 1000 12,2 46,5 197,4 180,8<br />

ЭЦН 5-50-1100 50 1100 14,2 46,5 243 228,2<br />

ЭЦН 5-50-1300 50 1300 16,8 46,5 275,6 260,8<br />

ЭЦН 5-50-1600 50 1600 19,5 46,5 308,2 293,4<br />

ЭЦН 5-50-1800 50 1800 22,0 46,5 343,2 327,4<br />

ЭЦН 5-50-2000 50 2000 24,5 46,5 378,2 362,4<br />

ЭЦН 5-50-2100 50 2100 26,4 46,5 423,8 410,8<br />

ЭЦН 5-50-2350 50 2350 29 46,5 456,4 442,4<br />

ЭЦН 5-50-2600 50 2600 31,6 46,5 489 475<br />

ЭЦН 5-50-2800 50 2800 34,1 46,5 524 510<br />

ЭЦН 5-80-850 80 850 15,3 51,5 184,4 167,8<br />

ЭЦН 5-80-1000 80 1000 17,8 51,5 229 214,2<br />

ЭЦН 5-80-1200 80 1200 20,9 51,5 259,6 244,8<br />

ЭЦН 5-80-1350 80 1350 24,1 51,5 290,2 275,4<br />

ЭЦН 5-80-1550 80 1550 27,3 51,5 321,2 306,4<br />

ЭЦН 5-80-1700 80 1700 30,6 51,5 352,2 337,4<br />

ЭЦН 5-80-1850 80 1850 33,0 51,5 396,4 383,4<br />

ЭЦН 5-80-2000 80 2000 36,2 51,5 427 414<br />

ЭЦН 5-80-2250 80 2250 39,5 51,5 458,4 445,4<br />

ЭЦН 5-80-2400 80 2400 42,6 51,5 489 476<br />

ЭЦН 5-80-2600 80 2600 46 51,5 520 507<br />

ЭЦН 5-80-2800 80 2800 48,3 51,5 563,8 552,6<br />

ЭЦН 5-125-700 125 700 17,4 58,5 198,4 181,8<br />

ЭЦН 5-125-850 125 850 20,3 58,5 253 238,2<br />

ЭЦН 5-125-1000 125 1000 24,0 58,5 228 273,2<br />

ЭЦН 5-125-1100 125 1100 27,6 58,5 323 308,2<br />

ЭЦН 5-125-1300 125 1300 31,2 58,5 351,6 336,8<br />

ЭЦН 5-125-1450 125 1450 34,8 58,5 380,2 365,4<br />

ЭЦН 5-125-1550 125 1550 37,8 58,5 441,2 428,2<br />

ЭЦН 5-125-1700 125 1700 41,4 58,5 476,2 463,2<br />

ЭЦН 5-125-1800 125 1800 45,0 58,5 504,8 491,8<br />

ЭЦН 5-125-2000 125 2000 48,6 58,5 533,4 520,4<br />

ЭЦН 5-125-2200 125 2200 55,2 58,5 629,4 618,2<br />

ЭЦН 5-125-2400 125 2400 58,8 58,5 658 646,8<br />

ЭЦН 5-125-2600 125 2600 62,4 58,5 686,6 675,4<br />

ЭЦН 5-125-2800 125 2800 70 58,5 742,6 732,6<br />

ЭЦН 5-200-550 200 550 25,6 50 224,2 205,8<br />

ЭЦН 5-200-650 200 650 30,1 50 254,2 235,8<br />

35