CMT winner by low weight, wear resistance and design - SSAB

CMT winner by low weight, wear resistance and design - SSAB

CMT winner by low weight, wear resistance and design - SSAB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

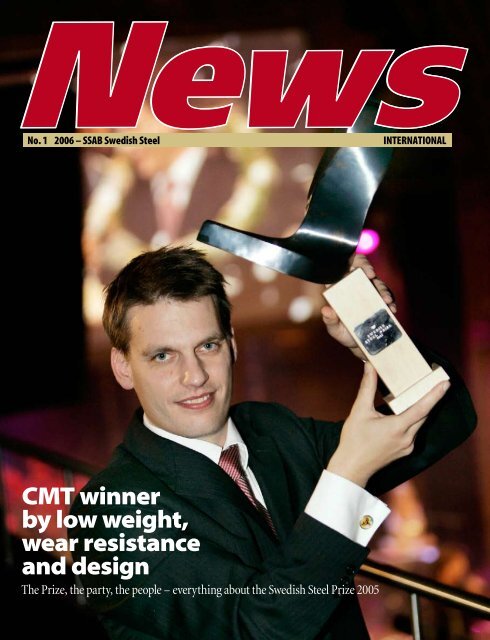

No. 1 2006 – <strong>SSAB</strong> Swedish Steel INTERNATIONAL<br />

<strong>CMT</strong> <strong>winner</strong><br />

<strong>by</strong> <strong>low</strong> <strong>weight</strong>,<br />

<strong>wear</strong> <strong>resistance</strong><br />

<strong>and</strong> <strong>design</strong><br />

The Prize, the party, the people – everything about the Swedish Steel Prize 2005

The steel we will use for the future<br />

D<br />

uring the past months I have met all<br />

the members of the <strong>SSAB</strong> team; that is<br />

people from the production plants in<br />

Borlänge <strong>and</strong> Luleå, the engineers in<br />

R&D, quality control, sales- <strong>and</strong> marketing departments<br />

<strong>and</strong> sales people from all of our international<br />

offices. I am proud to say that everyone employed<br />

within <strong>SSAB</strong> Tunnplåt <strong>and</strong> its subsidiaries today have<br />

a personal knowledge of the strategy that will be our<br />

guiding star into the future.<br />

The <strong>SSAB</strong> News International magazine<br />

is published <strong>by</strong> <strong>SSAB</strong> Tunnplåt AB <strong>and</strong> is<br />

distributed to customers, subscribers <strong>and</strong><br />

other selected groups.<br />

News International is produced in English,<br />

with editions in Swedish, German, French,<br />

Spanish <strong>and</strong> Italian, <strong>and</strong> is published<br />

twice a year.<br />

Anders Elfgren, Marketing Director, is the<br />

publisher legally responsible under<br />

Swedish law.<br />

Editorial board: Göran Hügard, Berit<br />

Arvidsson, Michael Christensen, Peter<br />

Korsgren, Jan Kuoppa, Bert Larsson, Tommy<br />

Löfgren, Magdalena Nillius, Karl-Inge<br />

Nilsson, Lilian Sjans <strong>and</strong> Nils Åkerblom.<br />

Production: Ahrena Media AB<br />

Printed <strong>by</strong>: Color Print Dalarna AB<br />

NEWS 1-2006<br />

<strong>SSAB</strong> Tunnplåt is known to be a leading actor in<br />

the world on the market for advanced high strength<br />

steel. This is a result of strategic decisions in the 1980s<br />

when we decided to make LARGE investments that<br />

made it possible to manufacture lighter <strong>and</strong> stronger<br />

steel with a quality that hardly had been seen at that<br />

time.<br />

Parallel with the development of the advanced high<br />

strength steel, we have been working together with<br />

our customers <strong>and</strong> providing them with knowledge<br />

<strong>SSAB</strong> Tunnplåt AB, SE-781 84 Borlänge<br />

☎ + 46 243–700 00. Fax + 46 243–720 00.<br />

E-mail: office@ssabtunnplat.com<br />

www.ssabtunnplat.com<br />

Brazil: <strong>SSAB</strong> Swedish Steel Ltda<br />

☎ +55 41 3014 9070. Fax: +55 41 3014 7733<br />

China: <strong>SSAB</strong> Swedish Steel,<br />

☎ +86 10 6466 3441. Fax +86 10 6466 3442<br />

Czech Republic: <strong>SSAB</strong> Swedish Steel s.r.o.<br />

☎ 00420/545 422 550. Fax: 00420/545 210 550<br />

Denmark: <strong>SSAB</strong> Svensk Stål A/S<br />

☎ + 45 4320 5000. Fax + 45 4320 5018, -5019.<br />

Finl<strong>and</strong>: Oy <strong>SSAB</strong> Svenskt Stål Ab<br />

☎ + 358 9 68 66 030. Fax +358 9 693 2120.<br />

France: <strong>SSAB</strong> Swedish Steel SA<br />

☎ +33 1 55 61 91 00. Fax +33 1 55 61 91 09.<br />

Germany: <strong>SSAB</strong> Swedish Steel GmbH<br />

☎ +49 211 9125-0. Fax +49 211 9125 129<br />

☎ +49 711 687 84 0. Fax +49 711 687 84 13<br />

Italy: <strong>SSAB</strong> Swedish Steel S.p.A.<br />

☎ +39 030 90 58 811. Fax +39 030 90 58 930.<br />

Korea: <strong>SSAB</strong> Tunnplåt<br />

☎ +82 31 906 2770. Fax +82 31 906 2773.<br />

regarding efficient manufacturing with these steels.<br />

We have created a “Knowledge Service Center” that<br />

can support our customers with everything from<br />

collaboration in industrialisation to data sheets of<br />

our products.<br />

Being a leading producer of a product<br />

means that sooner or later you will have serious<br />

competitors to deal with. This is the moment when<br />

you will experience how important it is to have a<br />

strategy to adhere to. When every single member of<br />

your team is a participant in the race, you really have<br />

the chance to be the <strong>winner</strong>. And this is why we put<br />

so much effort into spreading information about our<br />

strategy within our team.<br />

<strong>SSAB</strong> Tunnplåt will continue to develop<br />

<strong>and</strong> manufacture advanced high strength steel. This<br />

is the core of our business. We will also provide our<br />

customers with the support that they so much appreciate.<br />

Customer Service engineers have helped<br />

customers all over the world find solutions on all<br />

kinds of problems related to their use of our steel<br />

sheet products.<br />

Though our team consists of more than 4,000<br />

players, we are still very flexible. Some say it is typically<br />

Swedish that it is so easy to get in contact with<br />

whoever you want to talk to.<br />

Our strategy is that we will do everything you<br />

expect us to do <strong>and</strong> even better than before. But<br />

exactly what we will do is our own secret. That’s not<br />

strategy, that’s tactics. You don’t win the game if<br />

everybody knows your next step.<br />

And we intend to win!<br />

The Netherl<strong>and</strong>s: <strong>SSAB</strong> Swedish Steel BV<br />

☎ +31 24 67 90 550. Fax +31 24 67 90 555.<br />

<strong>SSAB</strong> Prelaq BV<br />

☎ +31 24 679 07 00. Fax +31 24 679 07 07.<br />

Norway: <strong>SSAB</strong> Svensk Stål AS<br />

☎ +47 23 11 85 80. Fax +47 22 83 55 90.<br />

Anders Werme<br />

President of <strong>SSAB</strong> Tunnplåt<br />

Pol<strong>and</strong>: <strong>SSAB</strong> Swedish Steel Sp z o.o<br />

☎ +48 22 353 13 14. Fax: +48 22 723 04 86<br />

<strong>SSAB</strong> Prelaq, Pol<strong>and</strong><br />

☎ +48 22 353 15 00. Fax: +48 22 723 04 86<br />

Portugal: <strong>SSAB</strong> Swedish Steel Portugal<br />

☎ +351 256 371 610. Fax +351 256 371 619.<br />

South Africa: <strong>SSAB</strong> Swedish Steel (Pty) Ltd<br />

☎ ++27 11 822 2570. Fax +27 11 822 2584.<br />

Spain: <strong>SSAB</strong> Swedish Steel S.L<br />

☎ +34 91 300 5422. Fax +34 91 388 9697.<br />

United Kingdom: <strong>SSAB</strong> Swedish Steel Ltd<br />

☎ +44 1905 79 57 94. Fax +44 1905 79 47 36.<br />

<strong>SSAB</strong> Dobel Coated Steel Ltd<br />

☎ +44 1384 74 660. Fax +44 1384 77 575.<br />

USA: <strong>SSAB</strong> Swedish Steel Inc<br />

☎ +1 412-269 21 20. Fax +1 412-269 21 24.

contents 4<br />

Open Your Mind, the new seminar from <strong>SSAB</strong> Swedish Steel,<br />

creates a channel for direct dialog between technical specialists.<br />

5–7 Experience High Strength Steel Day became a full-day jour-<br />

ney through the manufacturing as well as the evolution of<br />

advanced high strength steel.<br />

8–1 Inspiration Seminars are looking far into the future. When nation-<br />

ally famous Swedish researchers give their picture of the world in<br />

50 years, they predict a quite nice place.<br />

1 – 4 Decreased <strong>weight</strong> with a full ton was only one of the reasons<br />

why Swedish <strong>CMT</strong> won Swedish Steel Prize 2005. The light <strong>design</strong><br />

is tougher then before. Second prize in Swedish Steel Prize was<br />

awarded to Dura Automotive, Germany, Shape Corporation, USA,<br />

4<br />

0– 1<br />

5–7<br />

8–1 1 – 4<br />

– 4<br />

<strong>and</strong> Hardi-Evrard, France. A honourable mention was given<br />

to V.N. Automoveis, Portugal.<br />

5– 7 Spectacular buildings <strong>and</strong> other constructions could very<br />

well be created <strong>by</strong> concrete pumps from German Putzmeister.<br />

8– 9 New EU from Brno. Bernd Schneide is sales responsible at<br />

the new <strong>SSAB</strong> office covering Austria, Czech Republic, Hun-<br />

garia <strong>and</strong> Romania.<br />

0– 1 Prepainted steel sheet is big business for Swedish Lindab.<br />

– 4 Swedes love ice. Swedish Anders Celsius invented the tem-<br />

perature scale. Skating, skiing <strong>and</strong> building ice hotels are all<br />

parts of the love of the frozen water.<br />

NEWS 1-2006

4<br />

Studies of the car parts in the exhibition caused a lot of discussions regarding material as well as production technique. “Open Your Mind” seminars have<br />

created a dialog between technical specialists in the car industry <strong>and</strong> their counterpart in <strong>SSAB</strong>.<br />

Open Your Mind: Steel specialists<br />

in face-to-face talk<br />

“The ‘Open Your Mind’ seminar<br />

exceeded all our expectations,” says<br />

George Glaze at <strong>SSAB</strong> Swedish Steel in<br />

the UK after the first ever seminar of<br />

this kind was held in Birmingham in<br />

November last year.<br />

The intention with this “Open Your Mind” seminar<br />

was to give <strong>design</strong>ers, material <strong>and</strong> other technical<br />

specialists from the automotive industry an opportunity<br />

to meet their counterparts from <strong>SSAB</strong> Swedish<br />

Steel.<br />

“Comments from the participants proved the seminar<br />

was a big success,” he continues.<br />

With “Open Your Mind”, <strong>SSAB</strong> explains how<br />

advanced high strength steels can increase the competitiveness<br />

of car manufacturers. The seminar gives<br />

general information about advanced high strength<br />

steels in the automotive industry, but the main focus,<br />

achieved <strong>by</strong> showing practical examples, is to provide<br />

very detailed technical knowledge about how to <strong>design</strong>,<br />

form <strong>and</strong> join these steels.<br />

“This gave a good basis for the very detailed face-to-<br />

NEWS 1-2006<br />

face discussions that developed when the participants<br />

met our experts in <strong>design</strong>, joining, forming <strong>and</strong> applications<br />

during the day,” says George Glaze.<br />

He is referring to the meetings around the exhibition<br />

of automotive parts that is an important part of<br />

the seminar.<br />

“Every component in this display shows a part that<br />

is manufactured from advanced high strength steel,”<br />

George Glaze explains. “They are all excellent examples<br />

of the advantages that can be achieved with this<br />

type of steel.”<br />

Advanced high strength steels are often used to<br />

reduce <strong>weight</strong> <strong>and</strong> to improve crashworthiness of cars.<br />

Lower <strong>weight</strong> has an immediate effect in reduced fuel<br />

consumption <strong>and</strong> CO 2 -emissions.<br />

There are important reasons why the first “Open<br />

Your Mind” seminar is tailor-made for car manufacturers<br />

<strong>and</strong> their suppliers.<br />

“By focusing on the special dem<strong>and</strong>s from this sector,<br />

we can go deeper into each subject,” explains Mikael<br />

Mitros, sales manager at <strong>SSAB</strong> Swedish Steel after<br />

the second seminar, that was held in Gothenburg.<br />

More than 100 participants, representing a major<br />

part of the automotive industry in each country, attended<br />

these first two seminars.<br />

“Due to a wide communication spectrum through<br />

media, web, invitations <strong>and</strong> other channels, we met<br />

people <strong>and</strong> companies from the automotive field that<br />

have not used these steels in the past, but wanted more<br />

information to focus on them in the future,” George<br />

Glaze explains. The evaluation after the seminar confirms<br />

that the content was very appreciated.<br />

“But also the venue,” says George Glaze. “The<br />

seminar took place at the centrally located National<br />

Motorcycle Museum.”<br />

One of the ideas with the “Open Your Mind” seminar<br />

is to create a channel for direct dialog between<br />

Customers <strong>and</strong> the specialists at <strong>SSAB</strong>.<br />

“It really did,” says George Glaze. “Afterwards, we<br />

got comments like “I enjoyed the opportunity to meet<br />

<strong>SSAB</strong>’s technicians,” “well balanced information” <strong>and</strong><br />

“This makes marketing of advanced high strength<br />

steel more trustworthy”.<br />

During 2006 there will be “Open Your Mind” seminars<br />

in Italy, France, Germany, Spain, Portugal, the US<br />

<strong>and</strong> Brazil. Other worldwide markets like Asia, South<br />

Africa, etc., are under planning.<br />

For more information, please see Internet, www.<br />

ssabdirect.com.<br />

Car parts displaying the<br />

benefits of production<br />

with advanced high<br />

strength steels.

Emmanuel Chevét, <strong>SSAB</strong> France, introducing Gérard<br />

Le Prince, Hardi Evrard, to Lars Ingvarsson, Ortic.<br />

Experience High Strength Steel Day<br />

Curious about<br />

steel solutions<br />

Advanced high strength steels<br />

that make it possible to produce<br />

lighter <strong>and</strong> stronger products are<br />

arousing a great deal of interest.<br />

Visitors from all over the world<br />

attended the Experience High<br />

Strength Steel Day arranged <strong>by</strong><br />

<strong>SSAB</strong> Tunnplåt. 4<br />

NEWS 1-2006 5

Experience High Strength Steel Day<br />

Advanced high strength steels are tomorrow’s<br />

materials that are here today.<br />

Dem<strong>and</strong> is growing at an annual rate of<br />

15 percent <strong>and</strong> <strong>SSAB</strong> Tunnplåt is working<br />

intensively on developing new <strong>and</strong><br />

even better steels in this field.<br />

“There are two decisive reasons why<br />

our high strength steels will contribute<br />

to building the future,” declared<br />

Bo-Erik Pers, Head of Research <strong>and</strong><br />

Development at <strong>SSAB</strong> Tunnplåt, when<br />

he opened the Experience High Strength<br />

Steel Day at the <strong>SSAB</strong> Tunnplåt Head<br />

Office in Borlänge:<br />

• Energy<br />

• The environment<br />

This day served as the run-up to the<br />

Swedish Steel Prize 2005 event. The<br />

seminar attracted an audience from<br />

all over the world. The visitors came to<br />

see the production of advanced high<br />

strength steels - materials that several<br />

of the guests are already using in their<br />

daily production.<br />

Energy prices on the increase<br />

Bo-Erik Pers developed his two themes.<br />

“We can already see that the price of<br />

energy is increasing dramatically,” he<br />

explains. “There are no signs that we<br />

will be able to develop new, less expensive<br />

energy sources in the immediate<br />

future, <strong>and</strong> the cost of energy will probably<br />

continue to rise.”<br />

“As regards the environment, one of<br />

the dem<strong>and</strong>s we face is to reduce the<br />

emissions of carbon dioxide <strong>and</strong> other<br />

substances that affect the environment.<br />

NEWS 1-2006<br />

In both cases, advanced high strength<br />

steels contribute to reducing the pressure<br />

on Nature.”<br />

Those who put high strength steels to<br />

optimum use can reduce substantially<br />

the <strong>weight</strong>s of their products. Lighter<br />

products dem<strong>and</strong> less energy <strong>and</strong> offer<br />

environmental benefits in the whole of<br />

the chain extending from production of<br />

the steel right up to the work done <strong>by</strong><br />

the end products for their users.<br />

<strong>SSAB</strong> Tunnplåt is a world leader in<br />

the development <strong>and</strong> production of<br />

advanced high strength steels.<br />

“We often repeat this assertion, but<br />

we will be giving a deeper insight into<br />

the claim,” explains Bo-Erik Pers. “Our<br />

aim is to provide personal experience<br />

of the work we pursue. Welcome to the<br />

Experience High Strength Steel Day.”<br />

G<strong>low</strong>ing slabs<br />

The guided tour of the high strength<br />

steel world takes the visitors on a trip<br />

extending from the g<strong>low</strong>ing slabs at<br />

1210°C at the hot strip mill, all the way<br />

to an exhibition that shows a number of<br />

examples of products made of advanced<br />

high strength steels.<br />

The colour from the increasingly red<br />

steel strip is reflected in the fascinated<br />

eyes of the visitors as they watch the<br />

slab flash past at incredible speed. The<br />

spectacle is reinforced <strong>by</strong> all of the<br />

activities performed <strong>by</strong> machines <strong>and</strong><br />

automatic control systems. Very few<br />

people are in the vicinity of the process<br />

when the 30 tonne steel slab is hot<br />

rolled down to a minimum thickness<br />

of 1.5 mm. The strip is then up to 2,000<br />

metres long.<br />

The guide opens a door <strong>and</strong> ushers us<br />

into the roll grinding hall. Each pair of<br />

rolls is changed up to three times a day<br />

for inspection <strong>and</strong> adjustment in order<br />

to meet the strict quality dem<strong>and</strong>s.<br />

Rain of questions<br />

<strong>SSAB</strong> Tunnplåt coordinates a vast<br />

amount of research <strong>and</strong> development<br />

work in the Knowledge Service Center.<br />

The company’s customer service engineers<br />

demonstrate here the various tests<br />

that serve as a basis for the product data<br />

sheets for the <strong>SSAB</strong> Tunnplåt br<strong>and</strong><br />

names of Domex, Docol, Dogal <strong>and</strong><br />

Prelaq.<br />

The sound level rises dramatically<br />

when the doors open to an exhibition of<br />

high strength steel application examples<br />

in the automotive industry.<br />

“What material is this? How many<br />

stages in the press? Can we perform<br />

such operations on the equipment we<br />

have?”<br />

Questions rained down <strong>and</strong> the<br />

discussion continued for the rest of the<br />

day, all the way to the “Swedish Steel<br />

Prize Inspiration Seminars” that began<br />

in Stockholm on the fol<strong>low</strong>ing morning.<br />

Text: HÅKAN JOHANSSON<br />

Photo: ULF PALM<br />

Samples from automotive industry inspired the participators at the “Experience High Strength Steel Day” to intensive discussions<br />

about advanced high strength steel <strong>and</strong> stamping technique. 6<br />

The continuous annealing<br />

line is fundamental<br />

for the manufacturing of<br />

advanced high strength<br />

steel. Emmanuel Chevét<br />

describing the principals<br />

for Gérard Le Prince.

NEWS 1-2006 7

8<br />

Stefan Fölster: What is most<br />

important is that we are<br />

about to eradicate poverty<br />

in the world.<br />

NEWS 1-2006<br />

Spare parts for the human body were introduced<br />

as early as 1955. Today we have the third<br />

generation of sophisticated replacements in<br />

production. Within 15 years there will be hearts<br />

mad of titanium, microchip memory <strong>and</strong> artificial<br />

eyes, predicts Peter Thomsen. But you have<br />

to multiply the years with three before these<br />

products reach commercial production.<br />

Christian Azar: We must obviously change<br />

our behaviour, which is not as dramatic as<br />

it may sound. A little thought is sometimes<br />

enough.<br />

Lars Dencik: We will now become what can be described as patchwork<br />

people. We move between different arenas <strong>and</strong> develop<br />

the competence to h<strong>and</strong>le chaos that would have stressed earlier<br />

generations.

“You have already<br />

come far. You have<br />

<strong>low</strong>ered the energy<br />

needed to melt iron<br />

ore from 55 gigajoules<br />

per tonne to<br />

20 gigajoules.”<br />

How to change<br />

behaviour for<br />

“Presenting the future in this way is<br />

absolutely unique. As far as I know,<br />

never have researchers in such<br />

widely differing fields presented<br />

their pictures simultaneously on a<br />

limited futurological theme.”<br />

Peter Thomsen, Professor of Biomaterial Research at Gothenburg<br />

University, describes his experience after Swedish Steel<br />

Prize Inspiration Seminars in Stockholm on 16 November<br />

2005.<br />

The seminars are part of the presentation program for the<br />

Swedish Steel Prize – an international industrial accolade<br />

awarded for a product or <strong>design</strong> that puts to use the properties<br />

of advanced high strength steels.<br />

High strength steel is a material for the future. It is currently<br />

incorporated, for instance, into almost every car, where<br />

beams of high strength steels improve safety <strong>and</strong> comfort<br />

without adding to the vehicle <strong>weight</strong>.<br />

The future was also the theme for the Swedish Steel Prize<br />

Inspiration Seminars – The World in 50 Years.<br />

A fairly reliable picture can be drawn of developments<br />

many years into the future. A glance into the rear-view mirror<br />

today will reveal that a great deal of what we live with today<br />

was predicted back in 1955. And we have no reason to believe<br />

that today’s speakers are not as well equipped as their pre-<br />

decessors to forecast the future.<br />

Author <strong>and</strong> actor Fredrik Härén summarized the seminar: The future tends to be<br />

similar to what our dreams were. But there is an interesting exception – in the<br />

1950s we dreamed of flying cars <strong>and</strong> today we obviously witness a success for the<br />

gigantic Hummer SUV ...<br />

Inspiration Seminars<br />

the next<br />

50 years<br />

Futurological studies are often based on population development,<br />

which gives demography an important role to<br />

play in all such studies.<br />

“By combining the knowledge of age distribution in today’s<br />

population with knowledge of historical relationships,<br />

we can make predictions that are highly probable,” says Bo<br />

Malmberg, Professor of Cultural Geography at Stockholm<br />

University <strong>and</strong> the first futurological speaker for the day.<br />

He describes the age structure as a wave motion through<br />

history <strong>and</strong> he sees no reason for this pattern to sustain any<br />

dramatic changes in the future.<br />

“We know that development in the USA, Hong Kong <strong>and</strong><br />

Japan, for example, will stagnate in the next 15 to 20 years,<br />

while countries such as Mexico can expect to grow,” says Bo 4<br />

Lydia Capolicchio, well known in<br />

Sweden as a journalist <strong>and</strong> TV personality,<br />

received huge applause<br />

as she greeted the Italians in the<br />

audience in their own language.<br />

NEWS 1-2006 9

Inspiration Seminars<br />

Flying into the China Theatre<br />

<strong>and</strong> the Swedish Steel Prize<br />

Seminar: a roll formed beam<br />

with a suitable reinforcement.<br />

The <strong>design</strong> was developed<br />

<strong>by</strong> German Dura Automotive<br />

Body & Glass Systems GmbH.<br />

This side impact beam is one of<br />

four nominees for the Swedish<br />

Steel Prize 2005.<br />

10<br />

NEWS 1-2006

“Within five years, we will be able to produce titanium hearts, within 10–15 years, there will be artificial eyes that can restore vision<br />

to the blind, <strong>and</strong> we believe that at about the same time, there will be memory chips that can be used for replacing parts of the<br />

memory in the brain.”<br />

Malmberg <strong>by</strong> way of an example.<br />

The situation today is based on fairly reliable UN<br />

statistics of both age structure <strong>and</strong> income levels. Bo<br />

Malmberg gives a fairly positive overall picture of the<br />

future.<br />

“But there are exceptions,” he states. “In broad<br />

terms, it can be said that all African countries south of<br />

the Sahara can expect a very uncertain development,<br />

unless they receive assistance from the remainder of<br />

the world.”<br />

So there will be more of us in the world, but our<br />

earnings will be better in 50 years.<br />

Unnecessary warnings<br />

Stefan Fölster, Chief Economist at Swedish Commerce<br />

<strong>and</strong> Industry, then takes the floor. He claims that the<br />

warnings of demographers concerning an ageing<br />

population are totally wrong.<br />

“There is no shortage of people who can work,” he<br />

considers. “There will admittedly be more of us <strong>and</strong><br />

more of us will be older, but we will also be healthier<br />

<strong>and</strong> healthier. The trend towards a declining retirement<br />

age will be a historical aside. In Icel<strong>and</strong>, the retirement<br />

age today is 69 years, <strong>and</strong> many see no reason<br />

for giving up work after having passed a certain age.”<br />

Stefan Fölster is convinced that the global st<strong>and</strong>ard<br />

of living will continue to rise over a period of 50 years.<br />

“This does not mean that the curve will continually<br />

point upwards, but the overall picture will definitely be<br />

on the plus side.”<br />

Poverty halved<br />

“We are about to eradicate poverty in the world,” he<br />

says. “The trend is clear <strong>and</strong> all statistics show that<br />

average incomes are on the increase. In 1981, 40 percent<br />

of the world population had less than 1 dollar a<br />

day to live on, while the corresponding figure today is<br />

23 percent!”<br />

Population growth <strong>and</strong> availability of food are<br />

clouds on tomorrow’s horizon, but they are overshadowed<br />

<strong>by</strong> anxiety for the environment. The dramatic<br />

oil price increases in recent years have made both the<br />

Kenneth Lumsden: The<br />

critical factor for future<br />

transports is the availability<br />

of fuel.<br />

Anders Werme: The most<br />

important skills in today’s<br />

business are to see the<br />

trends that predict the<br />

future.<br />

availability <strong>and</strong> the cost of energy highly uncertain. At<br />

the same time, the effect of the increasing content of<br />

CO 2 in the atmosphere is a real threat, as reflected <strong>by</strong><br />

the rising average temperatures around the world.<br />

Christian Azar, Professor of Sustainable Industrial<br />

Metabolism, describes the changes that are necessary<br />

for solving the problems.<br />

“You have already come far,” he states <strong>and</strong> turns<br />

to face the <strong>SSAB</strong> representative in the audience. “You<br />

have <strong>low</strong>ered the energy needed to melt iron ore from<br />

55 gigajoules per ton to 20 gigajoules.”<br />

And he thinks that it is realistic to expect great improvements<br />

in a number of areas.<br />

“But we must obviously change our behaviour,”<br />

admits Christian Azar, “which is not as dramatic as it<br />

may sound. A little thought is sometimes enough.”<br />

By way of explanation, he shows a few pictures of<br />

our kitchens.<br />

Fifty years ago, we had a great deal of raw material<br />

at home, but only simple kitchen fittings, few machines<br />

<strong>and</strong> cookery books.<br />

Many kitchens today are heavily laden with energy-intensive<br />

technology <strong>and</strong> big refrigerators <strong>and</strong><br />

freezers.<br />

Today’s kitchen has virtually only food semi-<br />

Swedish Steel Prize Inspiration Seminar is introduced <strong>by</strong> a film showing what young people expect from the future. “Not necessarily a<br />

better world, but for sure a different one” states Lydia Capolicchio, moderator of the day.<br />

manufactures, but it also has a long shelf heavily laden<br />

with new, fine cookery books!<br />

The threat of coal<br />

Research <strong>and</strong> development have so far been focused<br />

on readily available energy sources such as coal <strong>and</strong><br />

oil. Sooner or later, we will have used up our oil resources,<br />

but our coal will last far into the future. This<br />

worries Christian Azar. If coal consumption should<br />

increase, this will be a heavy b<strong>low</strong> to our efforts to reduce<br />

CO 2 emissions.<br />

“There is plenty of energy around, but we must<br />

learn how to capture it,” he says. “If we were able to<br />

collect solar energy on a large scale, we would have<br />

10,000 times more energy than we need!”<br />

All of the speakers at the Swedish Steel Prize Inspiration<br />

Seminars have a global perspective in their<br />

vision of the future. The emphasis is on developments<br />

in Europe, the USA <strong>and</strong> Asia, but no one doubts the<br />

strong relationships on the increasingly globalized<br />

market.<br />

Smart transport systems<br />

Kenneth Lumsden, Professor of Integrated Transport<br />

Systems at the Chalmers University of Technology<br />

in Gothenburg, makes no predictions of what future<br />

freight equipment will look like, but he considers that<br />

we will continue to be dependent on smart <strong>and</strong> efficient<br />

transport systems.<br />

“Considering developments in manufacturing,<br />

increasingly efficient units will make production more<br />

economical, but this will dem<strong>and</strong> more advanced distribution,”<br />

he says.<br />

Kenneth Lumsden takes the example of all freight<br />

through the big ports on the American West Coast<br />

being stopped <strong>by</strong> industrial action in 2002.<br />

GM was forced to shut down its factories after two 4<br />

NEWS 1-2006 11

days, fol<strong>low</strong>ed <strong>by</strong> Toyota one day later.<br />

The whole of society soon suffered the<br />

consequences, with chaos in the ports <strong>and</strong><br />

on the roads in the region.<br />

There are strong arguments against production<br />

being concentrated geographically<br />

to places <strong>and</strong> regions that are best suited,<br />

but efficient transport is obviously vital.<br />

This concerns not only reasonable freight<br />

costs, but also new systems for keeping<br />

track of the goods. Intelligent technology<br />

can already fol<strong>low</strong> a product all the way<br />

from production up to the end customer.<br />

Less to gossip about?<br />

This means, for example, that when we go<br />

shopping in the future, we will fill our trolleys<br />

<strong>and</strong> pass through the checkout where<br />

sensors will record exactly what we have<br />

bought. The information goes directly to<br />

the bank, where payment is taken straight<br />

out of the buyer’s personal account. No<br />

more checkout queues where we can gossip<br />

about everything from the evening<br />

paper headlines to neighbours <strong>and</strong> friends.<br />

But will there also be less to gossip<br />

about? In the future, we will be healthier<br />

<strong>and</strong> will be able to cure more illnesses than<br />

we can today.<br />

Peter Thomsen is convinced that there<br />

will be a vast store of spare parts for those<br />

of us who will be ill in 50 years.<br />

“Within five years we will be able to<br />

produce titanium hearts, within 10–15<br />

years there will be artificial eyes that can<br />

restore vision to the blind <strong>and</strong> we believe<br />

that at about the same time there will be<br />

memory chips that can be used for replacing<br />

parts of the memory in the brain.”<br />

“But multiply the time <strong>by</strong> three <strong>and</strong> the<br />

figures will be more realistic. This is often<br />

how long it takes between a possibility<br />

being presented <strong>and</strong> production actually<br />

starting.”<br />

Longer lifespan?<br />

We are already healthier than we were in<br />

the past. Does that mean that we will be<br />

living longer in the future?<br />

“There is much to suggest that we can<br />

keep ourselves going longer <strong>and</strong> that we<br />

can stay in aesthetically better trim. But<br />

that does not automatically mean that<br />

we will be living longer,” answers Peter<br />

Thomsen. “The body is so complex that it<br />

would be impossible to make such promises.”<br />

1<br />

NEWS 1-2006<br />

This is where Lars Dencik takes over.<br />

He is Professor of Social Psychology <strong>and</strong><br />

his focus is on the soul rather than on the<br />

human body.<br />

Lars Dencik interprets time <strong>and</strong> tendencies<br />

<strong>and</strong> uses his conclusions for presenting<br />

a picture of what will be dem<strong>and</strong>ed <strong>by</strong><br />

tomorrow’s people.<br />

More mobile people<br />

According to his analysis, we are developing<br />

from the homo sapiens biological human<br />

being to the “homo zappiens” of the<br />

future – a species characterized <strong>by</strong> extreme<br />

mobility.<br />

“The consequences will be, for example,<br />

that we will increasingly choose to associate<br />

with people who share our experiences<br />

<strong>and</strong> valuations,” says Lars Dencik.<br />

It will not be difficult to find soulmates,<br />

since we are living in a digital era <strong>and</strong> a<br />

well formulated search on the Internet<br />

will immediately put us into contact with<br />

thous<strong>and</strong>s of people who have the same<br />

interests.<br />

But Lars Dencik also extends a warning.<br />

“In the past, we have spent our lives<br />

in the same surroundings,” he says. “We<br />

were then acquainted with only a few people,<br />

but we had deeper relations with them.<br />

Many of us leave this way of living behind<br />

us, but we are still dependent on living in<br />

an underst<strong>and</strong>able context – ‘I need a we<br />

to become truly me’.”<br />

We humans always adapt ourselves to<br />

new situations. When ‘we’ no longer consists<br />

of the family, we look for other groups<br />

in which we can develop as individuals.<br />

Can h<strong>and</strong>le chaos<br />

“But we will now become what can be<br />

described as patchwork people,” considers<br />

Lars Dencik. “We move between different<br />

arenas <strong>and</strong> develop the competence<br />

to h<strong>and</strong>le chaos that would have stressed<br />

earlier generations.”<br />

The broad picture of the future makes<br />

you think. As the day draws to an end, we<br />

have all been able to create our own visions<br />

of the world within 50 years. One of us may<br />

perhaps be perfectly right - who knows? He<br />

or she will then be the <strong>winner</strong> of the future!<br />

So we applaud the researchers <strong>and</strong> make<br />

our way to pay tribute to today’s <strong>winner</strong> of<br />

the Swedish Steel Prize 2005.<br />

Text: HÅKAN JOHANSSON<br />

Photo: ULF PALM<br />

Swedish Steel Prize<br />

“We move between different arenas <strong>and</strong> develop the competence to<br />

“It is an<br />

h<strong>and</strong>le chaos that would have stressed earlier generations.”

honour to be here”<br />

“It is an honour even to be here,” said Martin Wåhlin, <strong>CMT</strong>.<br />

Finally winning Swedish Steel Prize 2005 made him almost<br />

speechless!<br />

<strong>CMT</strong> was nominated for the prize with a hooklift container that<br />

is one tonne lighter <strong>by</strong> using advanced high strength steel.<br />

4<br />

Swedish Steel Prize <strong>winner</strong> 2005 together with Dr. Ing. Werner<br />

Schwamborn of Dura Automotive, Germany, Gérard Le Prince of<br />

Hardi Evrard, France, <strong>and</strong> David Heatherington of Shape Corporation,<br />

USA, who all won second prize.<br />

Swedish Steel Prize <strong>winner</strong> 2005 together with ??, Dura Automotive, Germany,<br />

Gérard Leprince, Hardi Evrard, France, <strong>and</strong> ??? Shape Corporation,<br />

USA, who all won second prize.<br />

NEWS 1-2006 1

The famous<br />

Swedish entertainer<br />

Charlotte<br />

Perrelli added<br />

sweet values<br />

to the Swedish<br />

Steel Prize prizegiving<br />

ceremony<br />

at legendary<br />

restaurant Berns<br />

Salonger in<br />

Stockholm with<br />

singing <strong>and</strong> appearance.<br />

14 NEWS 1-2006<br />

Harder than ever to predict the <strong>winner</strong><br />

To be the <strong>winner</strong> of the Swedish Steel Prize<br />

you should increase your performance as well<br />

as competitiveness for a product or a <strong>design</strong> <strong>by</strong><br />

using advanced high strength steel.<br />

This is the seventh year in a row for the<br />

Swedish Steel Prize <strong>and</strong> it is harder than ever<br />

to predict the <strong>winner</strong> this night. Compare the<br />

nominees yourself:<br />

<strong>CMT</strong>, that is manufacturing hooklift containers<br />

that can take one ton more payload per<br />

container.<br />

Dura Automotive, with a new <strong>design</strong> for<br />

side impact beams that can be reinforced to<br />

fulfill different dem<strong>and</strong>s on performance.<br />

Shape Corporation, that created a<br />

bumper from advanced high strength steel<br />

that can compete in <strong>weight</strong> with <strong>design</strong>s from<br />

aluminium but is superior in economy.<br />

Hardi Evrard, that uses advanced high<br />

strength steel for <strong>low</strong> <strong>weight</strong> <strong>and</strong> good flexibility<br />

in self-propelled sprayers.<br />

Apart from the four nominees there is an<br />

honourable mention for Portuguese V.N.<br />

Automoveis. When Lydia Capolicchio introduces<br />

company representative Antonio<br />

Valente she says:<br />

“If I were you, I would be angry that I’m not<br />

among the nominees.”<br />

“I am, I am,” Antonio Valente answers,<br />

though with a broad smile saying that he is<br />

pleased with being on stage together with the<br />

other four companies.<br />

The final event of the Swedish Steel Prize<br />

opens at 7 PM <strong>and</strong> it will be a nervous evening<br />

for all of the competitors. For the audience it<br />

will be entertaining.<br />

“Swedish Steel Prize has become the party of<br />

the year for technicians <strong>and</strong> <strong>design</strong>ers from<br />

companies working with advanced high<br />

strength steels to enhance their products.”<br />

Swedish Steel Prize

They really have nothing to regret<br />

It is not more than an hour left until the <strong>winner</strong> of<br />

the Swedish Steel Prize will be introduced on stage<br />

<strong>by</strong> Anders Ullberg, CEO of <strong>SSAB</strong> Group, <strong>and</strong> Anders<br />

Werme, president of <strong>SSAB</strong> Tunnplåt. Martin<br />

Wåhlin, from Swedish container manufacturer <strong>CMT</strong> is<br />

interviewed <strong>by</strong> Fredrik Swahn.<br />

“What do you expect from the evening?”<br />

“Being here is honour enough,” says Martin Wåhlin,<br />

<strong>and</strong> admits that he is a little bit nervous.<br />

The same goes for the other nominees when they<br />

enter the scene introduced <strong>by</strong> music significant for<br />

their countries.<br />

Nothing to regret<br />

Gérard Le Prince, General Manager at Hardi Evrard, is<br />

introduced <strong>by</strong> “Rien de rien,” the unforgettable hit song<br />

from Edit Piaf, but now sung <strong>by</strong> Swedish entertainer<br />

Fredrik Swahn.<br />

Gérard Leprince does not regret anything <strong>and</strong> he is<br />

hardly even nervous.<br />

The representatives for Dura Automotive <strong>and</strong> Shape<br />

Corporation are definitely nervous, but admit that it is a<br />

great experience to take part in the competition as well<br />

as in the Swedish Steel Prize Inspiration Seminar.<br />

“The nomination for Swedish Steel Prize means a lot<br />

to all the guys in the company,” says Tom DeVoursney,<br />

president <strong>and</strong> chairman of the board of Shape Corp.,<br />

before exchanging jackets with Fredrik Swahn. When<br />

he goes back to his table he is dressed as a star of the<br />

show!<br />

Finally on stage<br />

Less than one hour later, all the competitors are back<br />

on stage when Anders Ullberg calls the attention before<br />

opening the envelope with the well-kept secret from the<br />

jury. The silence is total when he starts reading.<br />

“The <strong>winner</strong> of Swedish Steel Prize 2005 is ...”<br />

He waits for a few, but very long seconds. All of the<br />

competitors focus on the small piece of paper that he is<br />

holding in his h<strong>and</strong>s.<br />

“... <strong>CMT</strong>, Cargo Modul Trading. <strong>CMT</strong> manufactures<br />

strong, light<strong>weight</strong> <strong>and</strong> impact-resistant hooklift containers<br />

with a <strong>design</strong> that reduces aerodynamic drag.<br />

The result is containers with great environmental <strong>and</strong><br />

economic benefits to the manufacturer, owner <strong>and</strong><br />

haulier.”<br />

Martin Wåhlin receives the Swedish Steel Prize statuette,<br />

obviously moved <strong>by</strong> the moment.<br />

With flashes from photographers shining like stars<br />

in his eyes, Martin Wåhlin does his first interview as<br />

Swedish Steel Prize 2005 is the seventh award in a row. The gala dinner is spectacular <strong>and</strong><br />

an important part in making this evening an unforgettable memory for all the nominees.<br />

Swedish Steel Prize has become an international award<br />

“Our intention is that the Swedish Steel Prize should<br />

serve as an inspiration for people <strong>and</strong> companies creating<br />

new solutions <strong>by</strong> using advanced high strength<br />

steel,” says Anders Werme, chairman of the jury for the<br />

Swedish Steel Prize.<br />

The interest for this annual industrial award has been<br />

increasing for every year gone <strong>by</strong>. As competitors can<br />

choose to remain as participators for several years, they<br />

will get several opportunities to compete for the award.<br />

It is said that nothing is as strong as an idea whose<br />

time has come – <strong>and</strong> of course this does not necessarily<br />

have to be the first time...<br />

“There has been a trend towards reduced <strong>weight</strong> in<br />

steel products for many years in Europe,” says Anders<br />

Werme. “Now we see a rapidly growing interest on the<br />

markets in the US, in Brazil <strong>and</strong> in China.”<br />

Previous <strong>winner</strong>s of Swedish Steel Prize already consist<br />

of competitors from America, Asia <strong>and</strong> Africa.<br />

“Swedish Steel Prize really is an international award,”<br />

says Anders Werme.<br />

owner of the Swedish Steel<br />

Prize 2005. His first promise<br />

is to party all night long.<br />

“But who is the first one<br />

that you are going to call to<br />

tell what happened?” Fredrik<br />

Swahn asks.<br />

No doubt from Anders Wåhlin.<br />

“My-mother-in law. Everybody else, that I could<br />

think of, is already here.”<br />

That is obvious ten minutes later when he is posing<br />

for the photographers on the gallery above the stage. He<br />

is joined <strong>by</strong> the owners <strong>and</strong> board from <strong>CMT</strong>. Martin<br />

Wåhlin will not be alone celebrating the victory this<br />

night.<br />

The Swedish Steel Prize has become the party of the<br />

year for technicians <strong>and</strong> <strong>design</strong>ers from companies<br />

working with advanced high strength steels to enhance<br />

their products. Of course the fol<strong>low</strong>ing hours are a tribute<br />

to <strong>CMT</strong>, but they are also a celebration of the creativity<br />

<strong>and</strong> the engineering that brought five ideas all the<br />

way to Stockholm this evening. And next year’s <strong>winner</strong><br />

could have taken part in this <strong>and</strong> been inspired to apply<br />

for Swedish Steel Prize 2006. It could be you!<br />

HÅKAN JOHANSSON<br />

The <strong>winner</strong> of Swedish Steel<br />

Prize 2006 will be announced<br />

November 29. Last entry date for the<br />

prize is August 15 <strong>and</strong> the Nominations<br />

Committee will send information to<br />

nominated companies during October<br />

or November.<br />

For more information, please visit<br />

Internet, www.steelprize.com.<br />

NEWS 1-2006 15

Swedish Steel Prize<br />

1<br />

<strong>CMT</strong><br />

A thin <strong>and</strong> light but tough container<br />

The world’s lightest <strong>and</strong> toughest<br />

container? Manufactured entirely<br />

from one of the most advanced<br />

high strength steels available on<br />

the market <strong>and</strong> with ultra thin walls. The<br />

material used <strong>and</strong> the new <strong>design</strong> significantly<br />

increases the useful life of the container. The<br />

container became the <strong>winner</strong> of Swedish Steel<br />

Prize 2005.<br />

<strong>CMT</strong> – the company that specialises in<br />

hooklift containers – has been closely fol<strong>low</strong>ing<br />

the development of new high strength<br />

steels. This has enabled <strong>CMT</strong> to develop containers<br />

that are light<strong>weight</strong>, have high strength<br />

<strong>and</strong> offer major cost benefits to its customers.<br />

A decisive factor is that <strong>CMT</strong> has used the new<br />

materials to produce economically beneficial<br />

solutions.<br />

“Some of our customers can pay off their investment in a container in only a few<br />

– The choice of material is directly<br />

related to the economic benefits<br />

we can offer our customers, states<br />

Martin Wåhlin, Managing Director<br />

of <strong>CMT</strong>.<br />

months of operation <strong>and</strong> this is a powerful sales argument,” states Martin Wåhlin,<br />

Managing Director of <strong>CMT</strong>.<br />

<strong>CMT</strong> has three models in its product range, the lightest two of them are of the<br />

<strong>design</strong> now awarded. These are ultra-thin containers for wood chip <strong>and</strong> forestry<br />

materials, whilst the somewhat sturdier, all-round model is intended for a variety of<br />

materials.<br />

Horizontal ridges<br />

The difference between the models is mainly the material thickness <strong>and</strong> the <strong>design</strong><br />

of the walls.<br />

“In the lightest model, the walls are very thin <strong>and</strong> are folded into horizontal ridges<br />

both on the inside <strong>and</strong> on the outside, whereas the walls of the all-round model are<br />

smooth on the inside in order to withst<strong>and</strong> the <strong>wear</strong> caused <strong>by</strong> metal scrap, for instance,”<br />

explains Martin Wåhlin.<br />

The horizontal ridges add strength <strong>and</strong> eliminate the need for the reinforcing<br />

The containers are produced in Pol<strong>and</strong>, with welding <strong>and</strong> bending the two main manufacturing operations.<br />

“We intend to double the production rate while still using the existing production machinery,” states Martin<br />

Wåhlin.<br />

NEWS 1-2006<br />

Swedish Steel Prize 2005/first prize<br />

“<strong>CMT</strong> – Cargo Modul Trading,<br />

Sweden has developed a <strong>design</strong> that clearly demonstrates competence, the ability to put to use<br />

the full range of spearhead properties of high strength steels, <strong>and</strong> the courage to take new paths<br />

towards success. The strategy of being at the cutting edge of development has resulted in a product<br />

that makes both man <strong>and</strong> the environment a <strong>winner</strong>. This is a <strong>design</strong> of the highest world class.”<br />

(Jury verdict)<br />

beams that are normally visible on the outside of other containers. Another feature<br />

of the <strong>design</strong> that arouses interest is the rounded transition between the bottom <strong>and</strong><br />

sides, which is achieved <strong>by</strong> folding up the bottom plate on the sides <strong>and</strong> welding it<br />

to the wall plates. This results in fewer joints <strong>and</strong> increased strength. In addition to<br />

<strong>low</strong>ering the <strong>weight</strong>, the removal of the side beams also provides significant environmental<br />

benefits.<br />

Free f<strong>low</strong> of air<br />

“A container of traditional <strong>design</strong> has a number of horizontal beams on each side,<br />

which jointly form a wide wall since they project <strong>by</strong> about 100 mm <strong>and</strong> restrict the<br />

free f<strong>low</strong> of air,” explains Martin Wåhlin. “By removing these beams – of which<br />

there are often ten – we have eliminated about one metre of wall width on each side<br />

of our container <strong>design</strong>. The result is a reduction of at least 5 percent in the fuel<br />

consumption of the truck carrying the container, which has both economic <strong>and</strong> environmental<br />

benefits!”<br />

The containers also have a new <strong>design</strong> of hook bracket used for loading the container<br />

onto a truck. Instead of two heavy vertical beams serving as reinforcement on<br />

one short side, <strong>CMT</strong> uses a Y-shaped <strong>design</strong> in which the beams are angled half-way<br />

up <strong>and</strong> are run to the top corners of the short side.<br />

Thin walls<br />

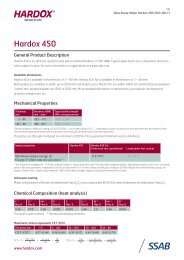

An advanced, cold-rolled high strength steel with a minimum tensile strength of<br />

1400 N/mm 2 is the predominant material used for <strong>CMT</strong> containers. In the ultra-thin<br />

wood chip container, the walls are 1 mm thick <strong>and</strong> the floor is 2 mm thick. The same<br />

grade of steel, but 2 mm thick, is used for the walls of the all-round model. In this<br />

container, the floor is made of 3 mm thick hot-rolled steel with a minimum yield<br />

strength of 650 N/mm 2 .<br />

“We have found out how to h<strong>and</strong>le these materials effectively <strong>and</strong> we are confident<br />

that we will be able to step up our production rate.”<br />

New ideas are already on the drawing board at <strong>CMT</strong>.<br />

“We are considering a number of different options , including one in which the<br />

container will be delivered ‘semi-finished’ for the customer to carry out part of the<br />

final assembly,” reveals Martin Wåhlin.<br />

ROGER BLOMQVIST<br />

The Y-shaped <strong>design</strong> of hook<br />

bracket gives better distribution<br />

of the pulling force <strong>and</strong> a lighter<br />

beam can therefore be used.

The horizontal ridges<br />

on the <strong>CMT</strong> containers<br />

add strength <strong>and</strong><br />

eliminate the need<br />

for the reinforcing<br />

beams. The rounded<br />

transition (small<br />

picture) between<br />

the bottom <strong>and</strong><br />

sides results in fewer<br />

joints <strong>and</strong> increased<br />

strength.<br />

NEWS 1-2006 17

Hardi<br />

Swedish Steel Prize<br />

High strength steel is gentle on the crops<br />

18 NEWS 1-2006<br />

Gérard Leprince,<br />

general manager<br />

at Hardi Evrard.<br />

As wide as an airliner, but now lighter than ever. When a Hardi Evrard<br />

self-propelled sprayer runs across a field, it does so without damaging<br />

the crops. With a width of about 30 metres, these vast machines<br />

resemble giant birds with outstretched wings as their long, lattice<br />

booms extend freely out at the sides. The high stresses that they create are carried <strong>by</strong><br />

an advanced chassis manufacturered from high strength steel. The structure is light<br />

but stable, reliable <strong>and</strong> durable. Hardi Evrard has used an advanced high strength<br />

steel for the <strong>design</strong> of its strong, resilient chassis, which is now 500 kg lighter than<br />

if it had been made of a st<strong>and</strong>ard steel. Additionally, the use of high strength steel in<br />

the new <strong>design</strong> enables it to better withst<strong>and</strong> very high fatigue stresses in the long<br />

spray booms created when the sprayer is travelling.<br />

The <strong>low</strong>er <strong>weight</strong> means that the machines are more gentle on the fields <strong>and</strong> cause<br />

less damage to the crops. The lighter machine does not compact the soil as much<br />

<strong>and</strong> can be <strong>design</strong>ed with a higher ground clearance, so that it travels well clear of<br />

the crops.<br />

Lower <strong>weight</strong> also al<strong>low</strong>s for a larger spray tank <strong>and</strong> more liquid, which makes<br />

operation more efficient <strong>and</strong> reduces the number of topping-up stoppages. Time<br />

Hardi Evrard uses laser cutting <strong>and</strong> riveting, which also contributes to the improved properties.<br />

Swedish Steel Prize 2005/second award<br />

“Hardi-Evrard SA, France has developed a competitive, self-propelled sprayer.<br />

The company combines extra-high strength steel, laser cutting <strong>and</strong> riveting with a resilient chassis <strong>design</strong>. This enables the<br />

product to withst<strong>and</strong> the fatigue stresses that occur when the long spray booms begin to oscillate, while also enabling the chas-<br />

sis <strong>weight</strong> to be substantially reduced.” (Jury verdict)<br />

is almost always of critical importance in spraying as large areas must be sprayed<br />

quickly when the weather is right.<br />

Riveting for sturdiness <strong>and</strong> flexibility<br />

Hardi Evrard began producing this type of chassis in the mid-1990s <strong>and</strong> since then<br />

has gradually refined <strong>and</strong> developed the <strong>design</strong>. The chassis is now made of Domex<br />

650 MC, which has a minimum yield strength of 650 N/mm 2 . Sheet steel between 3<br />

<strong>and</strong> 10 mm thick is used for the various components.<br />

The chassis consists of two longitudinal channel-section members to which the<br />

cross-members are riveted. The components are cut <strong>by</strong> laser <strong>and</strong> are painted before<br />

assembly. The surface treatment must be of a very high quality in order to prevent<br />

corrosion, which could be created due to the environments in which the machines<br />

have to operate. The long spray booms are secured well back on the chassis, which is<br />

where the loads are highest.<br />

The decision to use riveting for the chassis is based on experience gained from<br />

truck manufacturers. Riveting is much quicker than welding <strong>and</strong> eliminates sensitive<br />

welded joints. In addition to faster production, riveting ensures higher strength<br />

<strong>and</strong> better durability of the machines.<br />

Much of the <strong>design</strong> is dictated <strong>by</strong> customers’ individual requirements, <strong>and</strong> riveting<br />

then makes it simpler to adapt the chassis to suit various types of equipment.<br />

The basic <strong>design</strong> utilising a strong chassis was an essential prerequisite for the<br />

advanced suspension <strong>and</strong> springing system recently introduced <strong>by</strong> Hardi Evrard on<br />

the machines. The track of each pair of wheels can be varied while the machine is<br />

travelling to suit the ground conditions <strong>and</strong> the way that the crop has been planted.<br />

Due to the introduction of new springing, the machines are more stable <strong>and</strong> can be<br />

run at a higher speed, which results in higher efficiency.<br />

Global market<br />

Hardi Evrard sprayers – both self-propelled <strong>and</strong> towed <strong>by</strong> an ordinary tractor – are<br />

world leaders. The Head Office of this international group of companies is in Denmark.<br />

Operations in France began in the 1950s. Production <strong>and</strong> development are<br />

now carried out in France, Spain, Denmark, Germany, Australia <strong>and</strong> the USA.<br />

BJÖRN KLEEMAN

Big <strong>and</strong> wide, but much lighter <strong>and</strong> stronger than in the past.<br />

Hardi Evrard in France uses advanced high strength steel for the<br />

chassis of its self-propelled sprayers <strong>and</strong> has made them more<br />

durable, efficient <strong>and</strong> less damaging to the crops.<br />

NEWS 1-2006 19

Shape<br />

Swedish Steel Prize<br />

Ultra-high strength steel for high speed<br />

collisions<br />

The Shape Corporation is an<br />

American automotive component<br />

manufacturer that has developed<br />

a bumper made of advanced<br />

high strength steel, but which weighs only<br />

roughly the same as a much more expensive<br />

aluminium bumper. The new bumper<br />

comprises two members, one of which is roll<br />

formed <strong>and</strong> the other is pressed. The two are<br />

joined together <strong>and</strong> are provided with integral<br />

reinforcement. The automotive industry has<br />

already shown keen interest.<br />

The Shape Corporation has developed its<br />

new patented bumper to meet the automotive<br />

industry’s dem<strong>and</strong> for lighter <strong>weight</strong> bumper<br />

systems that meet both performance <strong>and</strong><br />

safety requirements.<br />

“Our customers dem<strong>and</strong> lighter bumpers, but without<br />

compromising the properties of the roll-formed<br />

bumper,” explains David Heatherington, Head of R&D<br />

at the Shape Corp. of Gr<strong>and</strong> Haven, Michigan. “We<br />

therefore decided to undertake development work<br />

which yielded a hybrid bumper. In this hybrid concept,<br />

we combine the best of two production methods<br />

– roll forming <strong>and</strong> pressing.”<br />

Specialist in roll forming<br />

Shape is well-established as a subcontractor to the<br />

American automotive industry <strong>and</strong> has become<br />

known as a specialist in roll forming, in which the<br />

company has been highly successful. The dem<strong>and</strong><br />

for lighter components has led the company to test<br />

different bumper materials, such as aluminium. This<br />

met the <strong>weight</strong> requirement, but the costs were<br />

too high.<br />

0 NEWS 1-2006<br />

The hybrid concept is developed <strong>by</strong> David Heatherington together with his colleagues<br />

Scott Glasgow <strong>and</strong> Bruce Lyons at The Shape Corporation.<br />

The hybrid concept developed <strong>by</strong> David Heatherington<br />

together with his colleagues Scott Glasgow <strong>and</strong><br />

Bruce Lyons is totally new, achieving a breakthrough<br />

<strong>by</strong> using the properties of ultra-high strength steels,<br />

whilst combining different methods of forming during<br />

production.<br />

The bumper that has been awarded second prize<br />

comprises two members, one of which is roll-formed<br />

<strong>and</strong> the other is pressed. The two members are joined<br />

together into a closed profile, the cross-section of<br />

which varies along the bumper length with the material<br />

changing around the cross section. The<br />

bumper thus has optimum <strong>weight</strong><br />

Swedish Steel Prize 2005/second award<br />

“Shape Corp., USA. The unique <strong>design</strong> <strong>and</strong> production method employed <strong>by</strong><br />

Shape for manufacturing bumpers is based on several forming methods <strong>and</strong> the combination of various types of ultra-high<br />

strength steels to create a closed profile of varying cross-section. The company has thus developed its bumper system still fur-<br />

ther <strong>and</strong> can offer the automotive industry several ways to optimise the combination of crashworthiness, <strong>weight</strong> <strong>and</strong> cost for a<br />

variety of car models.” (Jury verdict)<br />

<strong>and</strong> performance, whilst using both the<br />

type <strong>and</strong> amount of material efficiently.<br />

The rear pressed member is created<br />

in only one operation with reinforcements<br />

<strong>and</strong> mountings as integral parts.<br />

High-speed collisions<br />

“The advanced high strength steels we<br />

are using meet the dem<strong>and</strong>s imposed<br />

for withst<strong>and</strong>ing high-speed collisions,<br />

<strong>and</strong> the more advanced the steel, the<br />

better the protection,” explains David<br />

Heatherington. “No other material<br />

would have enabled us to achieve our<br />

objectives.”<br />

Among the other benefits named <strong>by</strong><br />

David Heatherington is that the company’s<br />

existing equipment can be used<br />

for production, negating the need for<br />

any new investment.<br />

“The hybrid concept has also given us greater scope<br />

for <strong>design</strong>ing the bumper to suit different car models,”<br />

continues David Heatherington. “We have succeeded<br />

in developing a bumper concept that no one believed<br />

would have been possible. The <strong>weight</strong> of the bumper is<br />

at least as <strong>low</strong> as an equivalent aluminium bumper <strong>and</strong><br />

the advanced high strength steels used provide excellent<br />

crashworthiness.”<br />

JAN TANNEFORS<br />

The pressed rear member is made of<br />

1.4 mm thick cold-rolled advanced high<br />

strength steel with a tensile strength of<br />

980 N/mm 2 . The front member is roll-<br />

formed from 1.2 mm thick cold-rolled<br />

advanced high strength steel with a minimum<br />

tensile strength of 1300 N/mm 2 .

The Shape Corporation<br />

combine the<br />

best of two production<br />

methods<br />

– roll forming <strong>and</strong><br />

pressing. The new<br />

light bumber is a<br />

breakthrough <strong>by</strong> using<br />

the properties of<br />

ultra-high strength<br />

steels.<br />

NEWS 1-2006 1

Dura<br />

Swedish Steel Prize<br />

Reinforced roll forming for higher safety<br />

The automotive industry is constantly striving to <strong>low</strong>er the <strong>weight</strong> of its<br />

products, improve crashworthiness <strong>and</strong> rationalise production. The<br />

German company Dura Automotive Body & Glass Systems GmbH has<br />

met all of these three objectives with a new <strong>design</strong> of side impact<br />

protection beam manufactured from ultra-high strength steel with reinforcement.<br />

The company has also developed a system for volume production of the beams.<br />

Advanced high strength steel is an obvious material for safety components of cars<br />

– it makes it possible to produce different types of crash protection components that<br />

are not only light<strong>weight</strong> but also have high energy absorbing capacity.<br />

Side impact beams using advanced high strength steels are currently fitted as<br />

st<strong>and</strong>ard to the vast majority of cars, although the <strong>design</strong> is far from st<strong>and</strong>ardised.<br />

There are many different <strong>design</strong>s – certain carmakers use pressed open profiles,<br />

some employ tubular <strong>design</strong>s <strong>and</strong> others use profiles that have welded-on reinforcements.<br />

Naturally, the optimum solution is a side impact beam capable of being produced<br />

in large volumes that can be used for a number of different car models with only<br />

minor modifications. This has been the basic objective of Dura’s development work.<br />

Another fundamental condition was the use of ultra-high strength Docol 1200 M<br />

steel that has good weldability <strong>and</strong> good roll forming properties. The steel has a<br />

minimum tensile strength of 1200 N/mm 2 , which makes it one of the most advanced<br />

high strength steels available on the market.<br />

All safety parts in a car must be provided with very effective anti-corrosion treatment,<br />

which can be achieved <strong>by</strong> using zinc electroplated Docol 1200 M steel.<br />

Steel of 2 mm<br />

The patented Dura side impact beam is a closed, square-section profile that is<br />

necked on the sides. The <strong>design</strong> of the profile has been optimised to provide the side<br />

impact beam with very high energy absorption capacity.<br />

NEWS 1-2006<br />

The patented Dura side impact beam is a closed, square-section profile<br />

that is necked on the sides. The thickness of the steel in the beam is only<br />

2 mm, which results in a <strong>weight</strong> of 1.75 kg for a 1.1 metre long beam.<br />

Swedish Steel Prize 2005/second award<br />

“DURA Automotive Body & Glass Systems GmbH, Germany has suc-<br />

ceeded practically using the technique of combining core material with ultra-high strength steel facing. By<br />

using a roll-formed, closed profile provided with a suitable internal reinforcement, the load-carrying capacity<br />

of the individual beam is increased. This enables the opportunities offered <strong>by</strong> ultra-high strength steel to be<br />

used to produce very light structures with high energy-absorbing capacity, combined with profitable <strong>and</strong> ef-<br />

ficient production.” (Jury verdict)<br />

The thickness of the steel in the beam is only 2 mm, which results in a <strong>weight</strong> of<br />

1.75 kg for a 1.1 metre long beam.<br />

Reinforcement of <strong>low</strong> <strong>weight</strong><br />

But Dura <strong>design</strong>ers realised that the properties could be improved still further <strong>by</strong><br />

adding a 200-300 mm long reinforcement in the middle of the beam. This is where<br />

the stresses are highest in the event of a crash. The reinforcement increases the<br />

<strong>weight</strong> <strong>by</strong> only 200 grams, but enables the deformation of the beam to be optimised<br />

in a side collision situation.<br />

“We tested virtually every type of material for the reinforcement,” recalls Torsten<br />

Hundt from Dura, whose responsibility it was to test the prototypes. “The extra reinforcement<br />

of ultra-high strength steel enabled us to make the beam much stronger.<br />

But in safety work, efforts are often also made to achieve controlled energy absorption<br />

in which the beam deforms more but without failing. We found that a reinforcement<br />

of a certain type of plastic material produced just these properties.”<br />

The type of reinforcement that is suitable for a particular car is dependent on the<br />

safety philosophy of the carmaker. Certain car manufacturers give priority to closely<br />

controlled deformation, whereas others specify maximum strength.<br />

Easy to adapt<br />

“Depending on the safety philosophy, the beams can be tailored to suit the requirements<br />

<strong>by</strong> varying the type <strong>and</strong> length of reinforcement,” adds Meinhard Schwermann<br />

who participated in the work at Dura.<br />

The type of mounting can also be varied. Depending on the remainder of the <strong>design</strong>,<br />

the beam can be fixed to the door <strong>by</strong> riveting, welding or securing with screws.<br />

The benefit to the carmaker is that the beam can readily be adapted to several different<br />

variants of a given car model.<br />

BJÖRN KLEEMAN<br />

By adding a 200-300 mm long reinforcement in the middle of the beam, the Dura <strong>design</strong>ers<br />

has improved the properties still further. This is where the stresses are highest<br />

in the event of a crash.

The new side impact beam has been developed in Germany <strong>by</strong> Dura<br />

Automotive Body & Glass Systems GmbH in Plettenberg. The beam will<br />

be produced in the company’s factory in Blatna in the Czech Republic,<br />

where the beam production line came on stream in the autumn of 2005.<br />

Dura Automotive Systems is one of the world’s leading producers of<br />

components <strong>and</strong> systems for the automotive industry. The group of<br />

companies is based in the USA, but has development <strong>and</strong> production<br />

units in all corners of the world<strong>and</strong> their list of customers includes all<br />

major American <strong>and</strong> European car makers. The Group has a total of<br />

17,000 employees <strong>and</strong> its turnover is US$ 2.5 billion.<br />

NEWS 1-2006

V.N. Automoveis<br />

Swedish Steel Prize<br />

Smart solution saving <strong>weight</strong> on<br />

small trucks<br />

C<br />

hanging over the body to high strength<br />

steel, a new technically advanced <strong>design</strong><br />

<strong>and</strong> switching to a more advanced welding<br />

method – these three measures have cut<br />

the <strong>weight</strong> of the body used for light trucks <strong>by</strong> almost<br />

30 percent.<br />

The light <strong>weight</strong> means that the trucks can carry<br />

more payload. In addition, the body <strong>design</strong> is more<br />

durable, has a more attractive finish <strong>and</strong> needs less<br />

maintenance. The body <strong>design</strong> developed <strong>by</strong> the<br />

company V.N. Automoveis of Portugal has received an<br />

honourable mention in conjunction with the nominations<br />

for the 2005 Swedish Steel Prize.<br />

The development work on the new body began just<br />

over a year ago <strong>and</strong> was instigated to meet the customer’s<br />

dem<strong>and</strong>s for a lighter body, as the existing body<br />

weighed more than 600 kilos. A further requirement<br />

was that the body should be easier to maintain.<br />

“Our original body was made of ordinary steel <strong>and</strong><br />

the floor alone weighed 268 kilos,” recalls Antonio<br />

Valente, Project Leader for the development project<br />

at V.N. Automoveis. “We were faced with the task of<br />

reducing the <strong>weight</strong>, but without impairing the loadcarrying<br />

capacity <strong>and</strong> durability. In addition, we had<br />

to develop a more efficient production method.”<br />

Surface finish<br />

Focus soon fell on high strength steels as a solution<br />

to the <strong>weight</strong> reduction problem. High strength steels<br />

also offered other important advantages, including<br />

“Every kilo saved on a light truck means much more<br />

than it does on a heavy truck,” says Antonio Valente,<br />

Project Leader at V.N. Automoveis.<br />

4 NEWS 1-2006<br />

By changing over to high strength steel, V.N. Automoveis has reduced the body <strong>weight</strong> <strong>by</strong> 124 kilos, which enables<br />

the trucks to carry about 12 percent more load.<br />

uniform quality <strong>and</strong> a smooth surface.<br />

“In parallel with <strong>weight</strong> reduction, another requirement<br />

was that the body should have the same surface<br />

finish as the truck cab,” continues Antonio Valente.<br />

“This dem<strong>and</strong>ed a new solution that comprised both<br />

new steels <strong>and</strong> a new production method.”<br />

The solution was to use three different high strength<br />

steels to produce the new body. A hot-rolled high<br />

strength steel with a minimum yield strength of 600<br />

N/mm 2 <strong>and</strong> a thickness of 2 mm was used for the<br />