ball and roller bearings - NTN Bearing Corporation of

ball and roller bearings - NTN Bearing Corporation of

ball and roller bearings - NTN Bearing Corporation of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECHNICAL<br />

INFORMATION<br />

Lubrication<br />

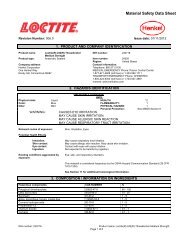

<strong>Bearing</strong> lubricants are <strong>of</strong> two basic types: oil or<br />

grease. The purpose <strong>of</strong> bearing lubrication is to prevent<br />

direct metal to metal contact between the various rolling<br />

<strong>and</strong> sliding elements. This is accomplished through the<br />

formation <strong>of</strong> a thin film on the contact surfaces, <strong>and</strong> is<br />

necessary for the following reasons:<br />

• Friction <strong>and</strong> wear reduction<br />

• Dissipation <strong>of</strong> heat generated within the bearing<br />

• Prolonged bearing life<br />

• Prevention <strong>of</strong> rust<br />

• Protection from foreign material entering bearing<br />

Grease lubricants are composed <strong>of</strong> either a mineral<br />

oil base or a synthetic oil base combined with a thicken-<br />

242<br />

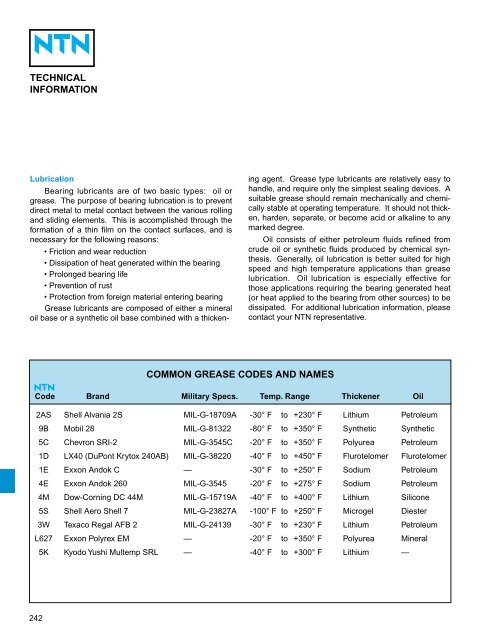

COMMON GREASE CODES AND NAMES<br />

ing agent. Grease type lubricants are relatively easy to<br />

h<strong>and</strong>le, <strong>and</strong> require only the simplest sealing devices. A<br />

suitable grease should remain mechanically <strong>and</strong> chemically<br />

stable at operating temperature. It should not thicken,<br />

harden, separate, or become acid or alkaline to any<br />

marked degree.<br />

Oil consists <strong>of</strong> either petroleum fluids refined from<br />

crude oil or synthetic fluids produced by chemical synthesis.<br />

Generally, oil lubrication is better suited for high<br />

speed <strong>and</strong> high temperature applications than grease<br />

lubrication. Oil lubrication is especially effective for<br />

those applications requiring the bearing generated heat<br />

(or heat applied to the bearing from other sources) to be<br />

dissipated. For additional lubrication information, please<br />

contact your <strong>NTN</strong> representative.<br />

Code Br<strong>and</strong> Military Specs. Temp. Range Thickener Oil<br />

2AS Shell Alvania 2S MIL-G-18709A -30° F to +230° F Lithium Petroleum<br />

9B Mobil 28 MIL-G-81322 -80° F to +350° F Synthetic Synthetic<br />

5C Chevron SRI-2 MIL-G-3545C -20° F to +350° F Polyurea Petroleum<br />

1D LX40 (DuPont Krytox 240AB) MIL-G-38220 -40° F to +450° F Flurotelomer Flurotelomer<br />

1E Exxon Andok C — -30° F to +250° F Sodium Petroleum<br />

4E Exxon Andok 260 MIL-G-3545 -20° F to +275° F Sodium Petroleum<br />

4M Dow-Corning DC 44M MIL-G-15719A -40° F to +400° F Lithium Silicone<br />

5S Shell Aero Shell 7 MIL-G-23827A -100° F to +250° F Microgel Diester<br />

3W Texaco Regal AFB 2 MIL-G-24139 -30° F to +230° F Lithium Petroleum<br />

L627 Exxon Polyrex EM — -20° F to +350° F Polyurea Mineral<br />

5K Kyodo Yushi Multemp SRL — -40° F to +300° F Lithium —