ball and roller bearings - NTN Bearing Corporation of

ball and roller bearings - NTN Bearing Corporation of

ball and roller bearings - NTN Bearing Corporation of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

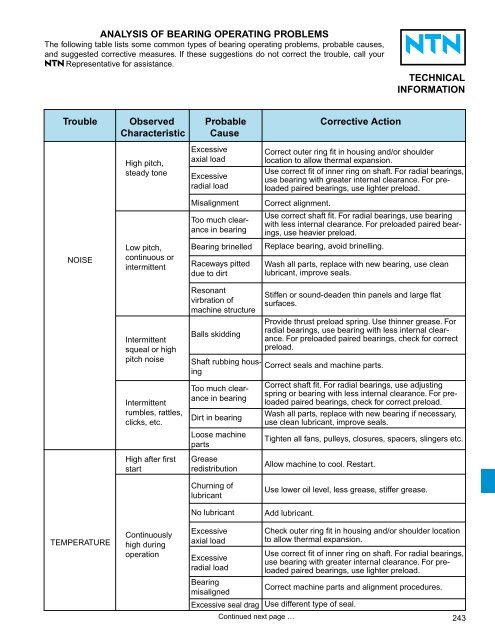

ANALYSIS OF BEARING OPERATING PROBLEMS<br />

The following table lists some common types <strong>of</strong> bearing operating problems, probable causes,<br />

<strong>and</strong> suggested corrective measures. If these suggestions do not correct the trouble, call your<br />

Representative for assistance.<br />

Trouble Observed Probable Corrective Action<br />

Characteristic Cause<br />

NOISE<br />

TEMPERATURE<br />

High pitch,<br />

steady tone<br />

Low pitch,<br />

continuous or<br />

intermittent<br />

Intermittent<br />

squeal or high<br />

pitch noise<br />

Intermittent<br />

rumbles, rattles,<br />

clicks, etc.<br />

High after first<br />

start<br />

Continuously<br />

high during<br />

operation<br />

Excessive<br />

axial load<br />

Excessive<br />

radial load<br />

Misalignment<br />

Too much clearance<br />

in bearing<br />

<strong>Bearing</strong> brinelled<br />

Raceways pitted<br />

due to dirt<br />

Resonant<br />

virbration <strong>of</strong><br />

machine structure<br />

Balls skidding<br />

Shaft rubbing housing<br />

Too much clearance<br />

in bearing<br />

Dirt in bearing<br />

Loose machine<br />

parts<br />

Grease<br />

redistribution<br />

Churning <strong>of</strong><br />

lubricant<br />

No lubricant<br />

Excessive<br />

axial load<br />

Excessive<br />

radial load<br />

<strong>Bearing</strong><br />

misaligned<br />

Excessive seal drag<br />

Continued next page …<br />

TECHNICAL<br />

INFORMATION<br />

Correct outer ring fit in housing <strong>and</strong>/or shoulder<br />

location to allow thermal expansion.<br />

Use correct fit <strong>of</strong> inner ring on shaft. For radial <strong>bearings</strong>,<br />

use bearing with greater internal clearance. For preloaded<br />

paired <strong>bearings</strong>, use lighter preload.<br />

Correct alignment.<br />

Use correct shaft fit. For radial <strong>bearings</strong>, use bearing<br />

with less internal clearance. For preloaded paired <strong>bearings</strong>,<br />

use heavier preload.<br />

Replace bearing, avoid brinelling.<br />

Wash all parts, replace with new bearing, use clean<br />

lubricant, improve seals.<br />

Stiffen or sound-deaden thin panels <strong>and</strong> large flat<br />

surfaces.<br />

Provide thrust preload spring. Use thinner grease. For<br />

radial <strong>bearings</strong>, use bearing with less internal clearance.<br />

For preloaded paired <strong>bearings</strong>, check for correct<br />

preload.<br />

Correct seals <strong>and</strong> machine parts.<br />

Correct shaft fit. For radial <strong>bearings</strong>, use adjusting<br />

spring or bearing with less internal clearance. For preloaded<br />

paired <strong>bearings</strong>, check for correct preload.<br />

Wash all parts, replace with new bearing if necessary,<br />

use clean lubricant, improve seals.<br />

Tighten all fans, pulleys, closures, spacers, slingers etc.<br />

Allow machine to cool. Restart.<br />

Use lower oil level, less grease, stiffer grease.<br />

Add lubricant.<br />

Check outer ring fit in housing <strong>and</strong>/or shoulder location<br />

to allow thermal expansion.<br />

Use correct fit <strong>of</strong> inner ring on shaft. For radial <strong>bearings</strong>,<br />

use bearing with greater internal clearance. For preloaded<br />

paired <strong>bearings</strong>, use lighter preload.<br />

Correct machine parts <strong>and</strong> alignment procedures.<br />

Use different type <strong>of</strong> seal.<br />

243