Predictive Analytical and Thermal Modeling of Orthogonal Cutting ...

Predictive Analytical and Thermal Modeling of Orthogonal Cutting ...

Predictive Analytical and Thermal Modeling of Orthogonal Cutting ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

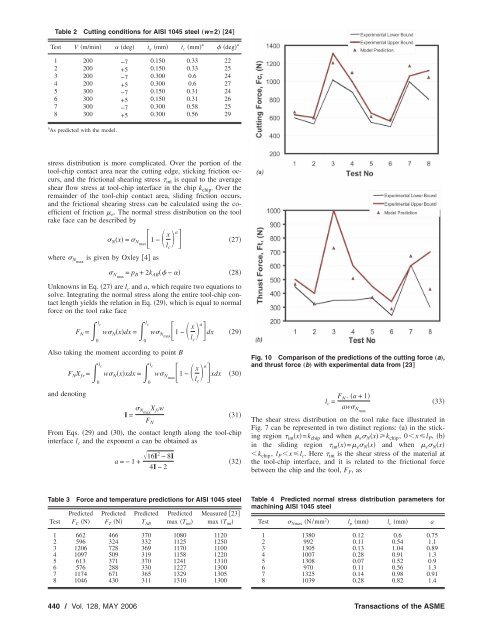

Table 2 <strong>Cutting</strong> conditions for AISI 1045 steel „w=2…†24‡<br />

Test V m/min deg t u mm t c mm a<br />

stress distribution is more complicated. Over the portion <strong>of</strong> the<br />

tool-chip contact area near the cutting edge, sticking friction occurs,<br />

<strong>and</strong> the frictional shearing stress int is equal to the average<br />

shear flow stress at tool-chip interface in the chip kchip. Over the<br />

remainder <strong>of</strong> the tool-chip contact area, sliding friction occurs,<br />

<strong>and</strong> the frictional shearing stress can be calculated using the coefficient<br />

<strong>of</strong> friction e. The normal stress distribution on the tool<br />

rake face can be described by<br />

Nx = Nmax1− x a<br />

lc 27<br />

where Nmax is given by Oxley 4 as<br />

Nmax = p B +2k AB − 28<br />

Unknowns in Eq. 27 are lc <strong>and</strong> a, which require two equations to<br />

solve. Integrating the normal stress along the entire tool-chip contact<br />

length yields the relation in Eq. 29, which is equal to normal<br />

force on the tool rake face<br />

lc lc FN =0<br />

wNxdx =0<br />

wNmax1− x a<br />

dx 29<br />

lc Also taking the moment according to point B<br />

F NX fr =0<br />

<strong>and</strong> denoting<br />

l c<br />

w Nxxdx =0<br />

l c<br />

I = N max X frw<br />

F N<br />

wNmax1− x a<br />

xdx 30<br />

lc 31<br />

From Eqs. 29 <strong>and</strong> 30, the contact length along the tool-chip<br />

interface l c <strong>and</strong> the exponent a can be obtained as<br />

a =−1+ 16I 2 −8I<br />

4I −2<br />

deg a<br />

1 200 −7 0.150 0.33 22<br />

2 200 +5 0.150 0.33 25<br />

3 200 −7 0.300 0.6 24<br />

4 200 +5 0.300 0.6 27<br />

5 300 −7 0.150 0.31 24<br />

6 300 +5 0.150 0.31 26<br />

7 300 −7 0.300 0.58 25<br />

8 300 +5 0.300 0.56 29<br />

a As predicted with the model.<br />

32<br />

Table 3 Force <strong>and</strong> temperature predictions for AISI 1045 steel<br />

Test<br />

Predicted<br />

F C N<br />

Predicted<br />

F T N<br />

Predicted<br />

T AB<br />

Predicted<br />

max T int<br />

Measured 23<br />

max T int<br />

1 662 466 370 1080 1120<br />

2 596 324 332 1125 1250<br />

3 1206 728 369 1170 1100<br />

4 1097 509 319 1158 1220<br />

5 613 371 370 1241 1310<br />

6 576 288 330 1227 1300<br />

7 1174 671 365 1329 1305<br />

8 1046 430 311 1310 1300<br />

Fig. 10 Comparison <strong>of</strong> the predictions <strong>of</strong> the cutting force „a…,<br />

<strong>and</strong> thrust force „b… with experimental data from †23‡<br />

lc = FN . a +1<br />

33<br />

awNmax The shear stress distribution on the tool rake face illustrated in<br />

Fig. 7 can be represented in two distinct regions: a in the sticking<br />

region intx=k chip <strong>and</strong> when eNxk chip, 0xlP, b<br />

in the sliding region intx= eNx <strong>and</strong> when eNx kchip, lPxl c. Here int is the shear stress <strong>of</strong> the material at<br />

the tool-chip interface, <strong>and</strong> it is related to the frictional force<br />

between the chip <strong>and</strong> the tool, FF,as Table 4 Predicted normal stress distribution parameters for<br />

machining AISI 1045 steel<br />

Test Nmax N/mm 2 l p mm l c mm a<br />

1 1380 0.12 0.6 0.75<br />

2 992 0.11 0.54 1.1<br />

3 1305 0.13 1.04 0.89<br />

4 1007 0.28 0.91 1.3<br />

5 1308 0.07 0.52 0.9<br />

6 970 0.11 0.56 1.3<br />

7 1325 0.14 0.98 0.91<br />

8 1039 0.28 0.82 1.4<br />

440 / Vol. 128, MAY 2006 Transactions <strong>of</strong> the ASME