World-class welding technologies - Subsea 7

World-class welding technologies - Subsea 7

World-class welding technologies - Subsea 7

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technology news from <strong>Subsea</strong> 7 - May 2012<br />

<strong>World</strong>-<strong>class</strong><br />

<strong>welding</strong><br />

<strong>technologies</strong><br />

What’s inside...<br />

02 Pipeline <strong>welding</strong> enhancements<br />

04 New riser <strong>technologies</strong><br />

05 Precision performance on Pazflor<br />

06 Groundbreaking geotechnics<br />

07 Cutting-edge simulation<br />

08 Mechanically lined pipe extends<br />

reach<br />

<strong>Subsea</strong> hydrocarbon sampling skid<br />

09 Swaged end connection for reel-lay<br />

pipe-in-pipe<br />

10 Fleet development update<br />

12 AIV commercialised<br />

New multipass and backfill<br />

ploughs<br />

deep<br />

seabed-to-surface

02<br />

In-depth technology news<br />

More than ever before, <strong>Subsea</strong> 7 continues to<br />

commit to the development and commercialisation<br />

of new technology, vessels and equipment that<br />

deliver technical and cost-effective solutions to our<br />

clients in their increasingly challenging environments<br />

and operational scenarios.<br />

Many of our most effective <strong>technologies</strong> are<br />

developed in active collaboration with key suppliers<br />

from our supply chain. Our development partners<br />

play an important role in the emergence of effective<br />

new ideas and solutions for our clients, and they<br />

cover a unique range of <strong>technologies</strong> which reflect<br />

our global expertise and capability.<br />

We are proud to<br />

have received<br />

recent industry<br />

recognition of one<br />

of our pipeline<br />

<strong>technologies</strong><br />

from the Pipeline<br />

Industries Guild.<br />

One of the industry’s<br />

foremost bodies,<br />

the Guild presented<br />

<strong>Subsea</strong> 7 with the<br />

prestigious “<strong>Subsea</strong><br />

Pipeline Technology Award” at their annual dinner<br />

in London in March for our development work on<br />

the installation of mechanically lined pipe using the<br />

reel–lay method, (see page 8 for details of current<br />

development work).<br />

In this latest issue of deep7, you can read<br />

about our latest applied technology advances<br />

in disciplines ranging from pipeline <strong>welding</strong> to<br />

geotechnics, and from advanced vessel design<br />

to the installation of ground-breaking subsea<br />

infrastructure.<br />

To find out more about any of the<br />

<strong>technologies</strong> featured in this issue contact<br />

John Mair, Technology Development Director<br />

at john.mair@subsea7.com or email<br />

communications@subsea7.com<br />

DEEP7 May 2012<br />

Welding<br />

enhancements<br />

in the pipeline<br />

<strong>Subsea</strong> 7 is developing and implementing leading-edge pipeline<br />

<strong>welding</strong> <strong>technologies</strong> to satisfy evolving market demand - both<br />

in terms of technical specifications and volume - and to meet<br />

increasingly stringent pipeline fabrication codes and operator<br />

specifications.<br />

Underpinning this technology development are three important<br />

strategic investments by the company:<br />

• entering into a technical partnership with CRC-Evans Pipeline<br />

International (CRC), one of the world’s leading designers and<br />

manufacturers of automatic <strong>welding</strong> systems for pipeline<br />

construction<br />

• committing to an extensive <strong>welding</strong> R&D programme to meet future<br />

industry demands<br />

• the opening in 2013 of a new Global Welding Development Centre<br />

in Glasgow, managed by <strong>Subsea</strong> 7’s Pipeline Production Group<br />

(PPG).<br />

Pipeline performance is currently being challenged on a number of<br />

fronts – not only by high demands on the performance of pipeline<br />

<strong>welding</strong> processes and the assurance of the integrity of girth welds,<br />

but also by the increasing usage of higher strength steels, clad/lined<br />

and solid corrosion-resistant alloy (CRA) pipe.<br />

<strong>Subsea</strong> 7 is implementing a <strong>welding</strong> methodology which meets the<br />

following criteria:<br />

• Adoption of a common approach to <strong>welding</strong> processes and<br />

equipment across all fabrication sites<br />

• Use of <strong>welding</strong> processes which allow the heat input to be<br />

controlled precisely to optimise weld mechanical and corrosion<br />

properties whilst ensuring weld soundness<br />

• Use of mechanised <strong>welding</strong> whenever practical in order to minimise<br />

welder intervention.<br />

<strong>Subsea</strong> 7’s reeled pipeline production facility at Vigra in Norway,<br />

accommodates the latest mechanised <strong>welding</strong> technology, and

demonstrates how careful assessment of project requirements<br />

and production factors can deliver cost-effective <strong>welding</strong><br />

solutions. The new technology is about to be deployed in<br />

Brazil, and will thereafter be rolled out to <strong>Subsea</strong> 7’s other<br />

fabrication sites worldwide.<br />

In the case of larger-diameter carbon steel pipelines, the use<br />

of the mechanised Pulsed Gas Metal Arc Welding (PGMAW)<br />

process is now established as the <strong>welding</strong> method of choice<br />

for both riser and flowline applications. The process utilises<br />

low-heat input which results in excellent mechanical properties<br />

in the girth welds.<br />

The process can be deployed using either single torch, or in<br />

the case of larger diameter pipe, dual torch <strong>welding</strong> in order<br />

to improve productivity. This system is highly mechanised so<br />

that the role of the <strong>welding</strong> operator is simply to supervise the<br />

process with minimal intervention required.<br />

Since the current <strong>welding</strong> system was introduced to Vigra in<br />

early 2011, about 400km of carbon steel pipeline have been<br />

fabricated, with productivity and quality exceeding targets.<br />

The overall weld repair rate, which is a key quality indicator, is<br />

less than 0.5%.<br />

<strong>Subsea</strong> 7 has further developed the PGMAW process for use<br />

in the fabrication of metallurgically clad pipe.<br />

Welding of clad pipe requires the use of dissimilar <strong>welding</strong> filler<br />

material, i.e. Alloy 625. <strong>Subsea</strong> 7 has carried out extensive<br />

<strong>welding</strong> trials to optimise pulsed <strong>welding</strong> parameters and<br />

shielding gas composition.<br />

The qualified PGMAW solution makes use of the Controlled<br />

Metal Transfer (CMT) process for root <strong>welding</strong>, an advanced<br />

PGMAW technique which allows the weld root to be deposited<br />

very precisely, giving good control of the root bead quality and<br />

profile. These features are essential to maintain the corrosion<br />

03<br />

performance of the clad pipeline. During production, an<br />

internal camera and laser profiling device is utilised to perform<br />

an assessment of the quality of the root bead.<br />

The developed <strong>welding</strong> solution will be implemented in<br />

production this year for a number of pipeline projects, which<br />

will involve over 70km of metallurgically clad and mechanically<br />

lined pipe risers.<br />

For smaller diameter pipes (4-inches and below) a mechanised<br />

<strong>welding</strong> system has been developed by <strong>Subsea</strong> 7 and<br />

implemented at Vigra. A key benefit of this system is to<br />

provide a more precise control of the heat input in order to<br />

maintain the optimum mechanical and corrosion performance.<br />

This solution, initially deployed on a 2-inch duplex stainless<br />

steel service line, was based on the use of the orbital Gas<br />

Tungsten Arc Welding (GTAW) process using the Polysoude<br />

<strong>welding</strong> system. Production <strong>welding</strong> has been in progress<br />

since November 2011 with weld quality and productivity<br />

meeting expectations, and has confirmed that this technology<br />

can be successfully deployed on a global basis.<br />

The 2-inch duplex line was also a Vigra “first” for the use of an<br />

automatic arc monitoring system on the firing line to capture<br />

and record the essential <strong>welding</strong> parameters.<br />

Operations will begin in 2013 at <strong>Subsea</strong> 7’s new Global<br />

Welding Development Centre in Glasgow, which will<br />

incorporate 18 <strong>welding</strong> bays including facilities for J-lay and<br />

S-lay pipeline <strong>welding</strong>, and will act as a central technical<br />

authority for the development and qualification of all <strong>welding</strong><br />

procedures for all <strong>Subsea</strong> 7 pipeline fabrication bases around<br />

the world.<br />

This major initiative by <strong>Subsea</strong> 7 will give clients the assurance<br />

of quality and delivery of pipeline <strong>welding</strong> performance at a<br />

competitive cost.<br />

For further information contact eric.law@subsea7.com<br />

seabed-to-surface

04<br />

New riser <strong>technologies</strong><br />

under construction<br />

Many years of applied research and<br />

construction experience have given<br />

<strong>Subsea</strong> 7 the significant advantage<br />

of being a SURF contractor capable<br />

of providing all types of riser systems<br />

for deepwater and ultra-deepwater<br />

installation, depending on the field<br />

architecture and client needs.<br />

This in-house capability includes<br />

design, procurement, construction,<br />

installation and maintenance.<br />

Riser systems installed on a worldwide<br />

basis by <strong>Subsea</strong> 7 fall into two<br />

categories - those coupled directly<br />

to the host facility, and un-coupled<br />

systems which in most cases are<br />

connected to the host by flexible<br />

jumpers and are increasingly being<br />

applied in recent deepwater and ultradeepwater<br />

field developments.<br />

<strong>Subsea</strong> 7 continues to develop<br />

innovative un-coupled riser concepts<br />

designed for harsh and challenging<br />

environments.<br />

HRTs<br />

Hybrid Riser Towers (HRTs) are<br />

recognised to have significant benefits<br />

for deepwater riser applications in<br />

terms of flow assurance, thermal<br />

performance and robustness of<br />

layout. This latter issue is especially<br />

significant when a large number of<br />

risers are considered. An HRT provides<br />

the required flexibility by avoiding<br />

a crowded layout and allowing a<br />

progressive deployment. The concept<br />

is applicable to deepwater and ultradeepwater,<br />

and to spread-moored and<br />

turret-moored FPSO installations.<br />

The first HRT application installed by<br />

<strong>Subsea</strong> 7 was Girassol in Angola for<br />

Total in 1998. The field, incorporating<br />

three HRTs, has been producing for<br />

over ten years to the specified stringent<br />

flow assurance requirements.<br />

HRTs have now become accepted as a<br />

robust solution for deepwater and ultradeepwater<br />

developments. The latest<br />

<strong>Subsea</strong> 7 HRT technology is currently<br />

being applied to Total’s CLOV projects<br />

offshore Angola where two HRTs will be<br />

installed in 2013.<br />

For further information contact john.mair@subsea7.com<br />

DEEP7 May 2012<br />

BSR<br />

The Buoyancy Supported Riser (BSR)<br />

system is being delivered by<br />

<strong>Subsea</strong> 7 for the Guará and Lula NE<br />

field development in Brazil under<br />

contract to Petrobras for installation in<br />

late 2012/early 2013.<br />

The BSR concept consists of a large<br />

sub-surface buoy which is anchored<br />

to the seabed by eight tethers, two on<br />

each corner of the buoy. The buoy<br />

supports multiple Steel Catenary Risers<br />

(SCRs) which are connected to the<br />

FPSO by non-bonded flexible jumpers.<br />

This BSR system absorbs the dynamics<br />

from the FPSO, resulting in almost no<br />

dynamic stresses on the SCRs, making<br />

them behave like a long free-spanning<br />

pipeline with the major fatigue response<br />

coming from the Vortex Induced<br />

Vibration due to the local currents.<br />

Since there is very little dynamic<br />

response for the SCRs, mechanically<br />

lined pipe is used for the SCR section,<br />

thereby optimising the riser design.<br />

COBRA<br />

<strong>Subsea</strong> 7’s most recent riser concept<br />

is the Catenary Offset Buoyant Riser<br />

Assembly (COBRA), which consists<br />

of a catenary riser section with a long,<br />

slender buoyancy module on top which<br />

is tethered down to the sea bed. Similar<br />

to the multi–riser BSR, the top of the<br />

catenary riser section is connected to<br />

the host by a flexible jumper.<br />

COBRA is a highly compatible riser<br />

arrangement for host platforms with<br />

large motions, like FPSOs or semisubmersibles.<br />

This riser concept has the advantages<br />

of excellent dynamic performance with<br />

little or no fatigue response, and can<br />

therefore be designed for pipeline<strong>class</strong><br />

welds. This therefore allows the<br />

use of mechanically lined pipe where<br />

appropriate, as in the case of the<br />

Buoyancy Supported Riser.<br />

Other riser systems such as Grouped<br />

SLOR and Single Hybrid Risers are also<br />

part of <strong>Subsea</strong> 7’s un-coupled Riser<br />

portfolio.<br />

Hydrid Riser Towers (HRTs)<br />

Buoyancy Supported Riser (BSR)<br />

Buoyancy<br />

SCR<br />

Jumper<br />

Mooring lines<br />

Catenary Offset Buoyant Riser Assembly (COBRA)

Planning and precision<br />

combine on Pazflor<br />

The successful installation by<br />

<strong>Subsea</strong> 7 of three subsea separation<br />

units (SSUs), operated by Total E&P<br />

Angola, proved critical to the early<br />

completion of the landmark Pazflor<br />

project on Block 17, offshore Angola.<br />

The challenging project involved the<br />

world’s first deployment of vertical<br />

SSUs to separate the oil, gas and<br />

water produced from Pazflor’s<br />

Miocene reservoirs.<br />

Installing each SSU (weighing in excess<br />

of 1,000t, including suction anchors)<br />

required an unprecedented level of<br />

precision in water depths around 800m<br />

and a close working relationship with<br />

Total and the SSU manufacturer, FMC,<br />

to ensure the final design included<br />

offshore installation requirements.<br />

Operational requirements necessitated<br />

exceptionally tight installation<br />

tolerances of +/- 0.5° from horizontal<br />

when installing the cluster of four<br />

suction anchor foundations. To achieve<br />

this target, <strong>Subsea</strong> 7 developed the<br />

lifting arrangement, and interfaced with<br />

FMC to accurately operate the levelling<br />

system based on differential suction.<br />

Early analyses showed a risk of<br />

resonance of the subsea hardware<br />

during lowering, potentially leading<br />

to significant weather sensitivity. To<br />

mitigate this issue, <strong>Subsea</strong> 7 developed<br />

a real-time monitoring system receiving<br />

acceleration data from sensors located<br />

on the crane tip and on top of the<br />

hardware as they were lowered.<br />

Extensive dry and shallow water testing<br />

in Norway allowed the team to test<br />

the SSU installation before the units<br />

were finally transported to Angola.<br />

Working in close liaison with FMC,<br />

<strong>Subsea</strong> 7 coordinated transportation<br />

and designed a specific sea fastening<br />

to minimise fatigue of the SSUs. Prior<br />

to deployment on site by <strong>Subsea</strong> 7’s<br />

installation vessel the Acergy Polaris,<br />

the structure’s integrity was re-tested in<br />

Luanda bay.<br />

Connecting each SSU to the subsea<br />

manifold was a complex and delicate<br />

operation in which the ROV operators<br />

had to first remove caps from the<br />

SSU shallow water tests in Norway<br />

manifold followed by the operation of<br />

a jacking system to slide the 400t, sixstorey<br />

high SSU towards the manifold to<br />

mate three connections simultaneously.<br />

The Seven Eagle performed the SSU<br />

umbilical installation and the tie-in of the<br />

first pair of four multi-phase pumps.<br />

The landmark project, in which first<br />

oil was achieved ahead of schedule<br />

including the development and<br />

installation of new technology,<br />

underlines the importance of effective<br />

interfaces between suppliers,<br />

contractors and client.<br />

<strong>Subsea</strong> 7 continues to develop new<br />

deployment systems including fibrerope<br />

and active-heave compensation<br />

that are deemed essential in the<br />

deployment and retrieval of sensitive<br />

rotating machinery and processing<br />

systems in ever-increasing water depths<br />

of the future.<br />

A Pazflor SSU being installed<br />

05<br />

seabed-to-surface

06<br />

Groundbreaking geotechnics<br />

In 2011, <strong>Subsea</strong> 7 commenced<br />

accelerated development in the<br />

field of Geotechnics in two areas of<br />

great significance for our clients’<br />

deepwater operations, how seabed<br />

soils and pipelines interact, and how<br />

an enhanced appreciation of soil<br />

behaviour and failure mechanisms<br />

can optimise foundation design,<br />

particularly for very soft deepwater<br />

clays.<br />

Pipelines<br />

<strong>Subsea</strong> 7 actively participates in the<br />

Safebuck series of JIPs - currently in its<br />

third phase - but we have also internally<br />

funded work investigating the dynamic<br />

embedment (and hence friction and<br />

stability) of pipes laid on soft clays which<br />

are typically found at the deepwater sites<br />

where we work.<br />

Another key challenge being addressed<br />

is an improved understanding of the<br />

behaviour of carbonate sediments which<br />

are widespread in some developing oil<br />

and gas-rich regions such as Australia.<br />

Carbonate-rich soils exhibit different<br />

behaviour to their non-carbonate<br />

counterparts, so <strong>Subsea</strong> 7 undertook<br />

a study to investigate the response of<br />

carbonate soils to cyclic pipe loads<br />

by model testing in a geotechnical<br />

centrifuge.<br />

Model pipe set up for axial friction test<br />

The results of this study are counterintuitive<br />

to those predicted by <strong>class</strong>ical<br />

soil mechanics, and the work represents<br />

a significant step forward in evolving a<br />

new constitutive model to describe the<br />

behaviour of carbonate soils.<br />

For further information contact paul.brunning@subsea7.com<br />

DEEP7 May 2012<br />

Apparent friction derived from cyclic axial friction tests<br />

Foundations<br />

In our subsea construction business,<br />

there is constant pressure to optimise<br />

foundation design to be as efficient as<br />

possible in terms of installation without<br />

compromising functionality.<br />

<strong>Subsea</strong> 7 has produced recent research<br />

at the highly respected Centre for<br />

Offshore Foundation Systems at the<br />

University of Western Australia into an<br />

optimised design methodology that has<br />

led to the possibility of reducing the size<br />

of shallow foundations such as PLET<br />

mudmats by 20%, or alternatively able<br />

to withstand larger jumper loads.<br />

The geotechnical engineer is always<br />

interested in finding the most critical<br />

failure mechanism of a foundation.<br />

<strong>Subsea</strong> 7 has teamed up with the<br />

university to develop a new 3D analysis<br />

tool which could potentially halve the<br />

engineering hours spent designing<br />

foundations under complex loading.<br />

FE analysis for optimised foundation design<br />

Mudmats for PLET applications<br />

Looking to the future…<br />

Emerging challenges in the<br />

geotechnical industry are likely to<br />

include:<br />

• developing and improving<br />

the constitutive model for<br />

carbonate soils and applying<br />

it to foundation and pipeline<br />

design<br />

• how to quantify the degrading<br />

effects of solid hydrate and<br />

hydrate dissociation on soil<br />

properties<br />

• further optimisation of<br />

foundation designs as large<br />

and heavy processing facilities<br />

are moved subsea<br />

• developing design methods<br />

for ultra-deepwater soils where<br />

soil strength is more dominated<br />

by viscous behaviour than<br />

traditional shear strength<br />

• finding novel and effective<br />

ways to protect subsea<br />

infrastructure in the Arctic or<br />

ice-prone regions.

Cutting-edge simulation<br />

<strong>Subsea</strong> 7 has developed one of the<br />

most powerful installation simulation<br />

packages ever built, including<br />

unique finite element analysis<br />

(FEA) capabilities, and successfully<br />

installed the hardware on board<br />

construction vessel the Seven<br />

Seas for effective on-site operative<br />

training.<br />

The programme was developed over a<br />

two-year period for the Block 31 project<br />

offshore Angola. An unusual aspect of<br />

this deepwater project is the mid-water<br />

pull-in of the flexible risers that connect<br />

the vertical risers to the FPSO. These<br />

operations are carried out at an average<br />

depth of 200m, which presented<br />

uncommon problems.<br />

Unlike most pull-ins, the tasks are<br />

performed in a situation where<br />

everything in the scenario is mobile.<br />

The Upper Riser Assembly (URA), while<br />

weighing several hundred tonnes, can<br />

be easily moved and rotated should the<br />

ROV push it. When the flexible risers<br />

are attached to the subsea winch wires<br />

and the load transferred from the vessel<br />

crane to the winches, the URA, which<br />

in itself is dynamic, tends to follow the<br />

riser lay direction for many metres -<br />

which has the potential to compromise<br />

the minimum bending radius (MBR) of<br />

the flexible.<br />

The situation was risk-assessed, and<br />

it was decided that the risks could be<br />

mitigated by building the nine different<br />

scenarios (there are nine flexible<br />

risers) in a simulator. This would allow<br />

procedures to be checked, and also<br />

facilitate pilot training. The simulation<br />

predictions were shown to correlate well<br />

with measurements taken before and<br />

during the actual offshore operation.<br />

The development of the simulator<br />

though 2010 and 2011 pushed the pilottraining<br />

software and hardware well<br />

beyond their existing capacity, due to<br />

the large number of flexible and moving<br />

objects in each scenario.<br />

Most simulation training takes place at<br />

<strong>Subsea</strong> 7’s site in Aberdeen, but for this<br />

project it proved more effective to train<br />

the ROV pilots, superintendents, and<br />

Block 31 installation simulator in use on board the Seven Seas<br />

bridge supervisors on board the Seven<br />

Seas, in an environment with which they<br />

are already familiar.<br />

The simulations feature:<br />

• Variable sea conditions which can<br />

produce realistic motions of the<br />

Seven Seas (<strong>Subsea</strong> 7’s construction<br />

vessel on Block 31)<br />

• Sea currents that can be varied<br />

in both strength and direction at<br />

different depths to replicate the<br />

currents throughout the entire<br />

2,100m water column<br />

• Two Hercules ROV systems, each<br />

with fully working manipulators and<br />

three selectable onboard cameras<br />

• Real-time FEA package calculating<br />

loads on, and MBR of, the flexibles<br />

• Two subsea winches complete with<br />

working line-out meters and load<br />

cells.<br />

The simulation FEA calculates the minimum<br />

bending radius of the flexible during ROV<br />

operations<br />

07<br />

The on-board simulator uses the<br />

existing Hercules 23 control console,<br />

with an additional six powerful PCs. A<br />

switch disconnects the topside control<br />

system from the ROV and changes<br />

operations from normal ROV control to<br />

simulation mode (this is only done when<br />

the vehicle is on deck!).<br />

For further information contact mike.bramley@subsea 7.com<br />

seabed-to-surface

08<br />

Mechanically lined pipe extends reach<br />

<strong>Subsea</strong> 7’s ground-breaking development work into the<br />

installation of mechanically lined pipe has recently been<br />

undergoing further qualification following the world’s<br />

first contract award to use BuBi ® mechanically lined pipe<br />

installed by the reel-lay method for the Guará and Lula NE<br />

pre-salt project in Brazil.<br />

Working in collaboration with BuBi ® manufacturer BUTTING,<br />

<strong>Subsea</strong> 7 has already qualified BuBi ® mechanically lined<br />

pipe for reel-lay installation for flowlines and low-fatigue riser<br />

applications globally as a cost-effective alternative to solid<br />

corrosion-resistant alloys or metallurgically clad pipe. We are<br />

now broadening the product’s applications into areas of higher<br />

pressure and fatigue applications.<br />

Current testing has demonstrated higher fatigue performance<br />

to DNV <strong>class</strong> C/2 at the time of print to extend the applicability<br />

of the technology to even greater water depths and more<br />

challenging design criteria.<br />

The rigorous fatigue testing programme included:<br />

• Manufacture of three test strings (12 girth welds) comprising<br />

carbon steel grade X65 for the outer pipe and alloy 625 for<br />

the liner, made up of BuBi ® pipe sections welded together<br />

using the mechanised PGTAW process (see page 3) with<br />

alloy 625 filler metal<br />

• A conservative cyclic bending test or reeling simulation,<br />

using a radius of curvature of 7.5m<br />

• Resonance fatigue testing of the string post-reeling<br />

simulation. The endurance of the pipe and its welds was<br />

thus confirmed to achieve the minimum target level of<br />

fatigue <strong>class</strong> C/2.<br />

DEEP7 May 2012<br />

The full programme was<br />

performed in accordance with<br />

DNV Qualification (DNV-<br />

RP-A203) and was previously<br />

awarded the certificate for<br />

‘fitness for service’.<br />

An extensive NDE validation programme was conducted<br />

between <strong>Subsea</strong> 7 and BUTTING to qualify the inspection<br />

technology (DNV) and demonstrate the capacity to detect any<br />

minute defects in the pipe end overlay welds and seal weld at<br />

the transition between liner and overlay.<br />

The combination of the high-quality manufacturing process and<br />

inspection technology is fundamental to ensure the in-service<br />

reliability of the technology.<br />

<strong>Subsea</strong> Hydrocarbon Sampling Skid (SHSS)<br />

Following the successful<br />

development of its<br />

<strong>Subsea</strong> Hydrocarbon<br />

Sampling Skid (SHSS),<br />

<strong>Subsea</strong> 7 is now able<br />

to offer clients ROVdeployed<br />

sampling from<br />

live production wells<br />

with zero emissions<br />

to the environment<br />

while maintaining full<br />

isothermic and isobaric<br />

conditions.<br />

Hydrocarbon samples are required in order to determine<br />

fluid chemistry to enable calibration of the subsea flowmeter<br />

and potential fiscal allocations. The <strong>Subsea</strong> 7 SHSS takes<br />

a true sample with no need to alter production flow or<br />

temperature.<br />

It also takes samples from individual wells before they<br />

are mixed together at manifold or FPSO, and enables<br />

production samples or gases from individual wells to be<br />

analysed independently.<br />

The Welding Institute (TWI)<br />

Fatigue Test Rig<br />

S-N curves showing the number of<br />

fatigue cycles reached to date on three<br />

test strings (RF1, RF2, RF3). No failure<br />

of the pipe or liner seal welds has been<br />

recorded at the DNV <strong>class</strong> C.<br />

For further information contact gregory.toguyeni@subsea7.com<br />

The skid comprises the following key elements:<br />

• A number of sampling cylinders allowing several samples<br />

to be taken from multiple locations/wells<br />

• A controlled rate of fill and heating system ensures the<br />

sample is taken in an isobaric and isothermal manner.<br />

• The host ROV provides the skid with power and telemetry.<br />

• Topsides control is via a robust laptop PC.<br />

• A heating system maintains the sample cylinders and<br />

pipework at a sufficiently elevated temperature in order<br />

to mitigate the formation of hydrates during the sampling<br />

process and dissolved gases coming out of solution.<br />

• A fail-safe connection tool ensures the safe shutdown<br />

of the sample interface at the well should the ROV<br />

experience a vessel run-off or dead vehicle situation.<br />

The SHSS is the latest in a long <strong>Subsea</strong> 7 tradition of<br />

developing pioneering high-quality, cost-effective ROV<br />

tooling, including a standard range of manipulator-deployed<br />

tools, component change-out tools, bespoke intervention<br />

tools and skids.<br />

For further information contact mick.fowkes@subsea7.com

Swaged end connection for reel-lay<br />

high performance pipe-in-pipe<br />

In collaboration with its development partner ITP InTerPipe,<br />

<strong>Subsea</strong> 7 currently offers the market its DNV-qualified<br />

Enhanced Thermal Performance Pipe-in-Pipe system for<br />

installation by the reel-lay method. This superior technical<br />

solution, which benefits from the combination of Izoflex<br />

insulation material in conjunction with a reduced pressure in<br />

the PIP annulus section, has recently been further enhanced<br />

by the development and qualification of the Swaged Field<br />

Joint.<br />

The Swaged End Connection has already been widely used by<br />

<strong>Subsea</strong> 7 on J-lay and S-lay PIP projects, but this new concept<br />

relates to reel-lay applications.<br />

The Swaged End Connection is fabricated by swaging the<br />

pipe ends of the outer sleeve pipe, followed by <strong>welding</strong> to the<br />

flowline at each end of the fabricated stalk, typically 750m long<br />

for reel-lay applications. The sealed annulus within the stalk<br />

can then have the pressure drawn down within the annulus offline<br />

in advance of reeling onto the reel-lay vessel.<br />

As each stalk is subsequently reeled onto the vessel, the PIP<br />

swaged end stalks are fabricated together by firstly girth<strong>welding</strong><br />

of the flowlines and the use of welded half shells for<br />

the outer sleeve pipe.<br />

The Swaged End Connection’s primary function is to provide<br />

the following:<br />

• A leak-tight seal for draw-down of pressure within the<br />

annulus<br />

• A robust mechanical barrier to act as a water stop in all<br />

envisaged water depths in the event that the outer pipe is<br />

breached, thus preventing the entire pipeline annulus from<br />

flooding<br />

• A means of mechanical connection between the flowline and<br />

outer sleeve pipe that can be reeled.<br />

Testing and qualification<br />

has focused primarily on<br />

the following areas in order<br />

to attain DNV “Fitness for<br />

Service” Qualification in<br />

compliance with DNV-RP<br />

A-203:<br />

• FEA modelling<br />

• Simulated reeling and straightening trials<br />

• Welding and inspection<br />

• Post-reeling FEA analysis using strain data collated from the<br />

simulated reeling and straightening trials<br />

• Material testing<br />

• Annulus pressure test<br />

Enhanced Thermal Performance PIP incorporating<br />

Izoflex insulation material with reduced pressure and no<br />

centralisers in the annulus section<br />

Sleeve Pipe<br />

Flowline<br />

Pipe-in-Pipe cross section<br />

FE analysis<br />

Svalin C reeled PIP<br />

<strong>Subsea</strong> 7’s expertise in high performance Pipe-in-<br />

Pipe (PIP) installations covers full-scope design,<br />

procurement, construction and installation, and extends<br />

to over 40 successful PIP projects including bundle<br />

technology, S-lay, J-lay and reel-lay.<br />

Our latest project comprises a 5-inch/8-inch gas lift<br />

Pipe-in-Pipe, to be designed, constructed and installed<br />

for Statoil between the Svalin C Template and the<br />

Grane platform in the central North Sea. The contract<br />

also covers the installation of the Svalin C template and<br />

manifold, a highly wet-insulated production flowline,<br />

and an umbilical.<br />

In addition to our market-leading versatility in the<br />

installation of high performance Pipe-in-Pipe, <strong>Subsea</strong> 7<br />

can also install electrically trace-heated flowline (ETHF)<br />

PIP solutions by reel-lay or in towed bundles.<br />

ETHF technology has been successfully<br />

commercialised by <strong>Subsea</strong> 7 in partnership with<br />

manufacturer ITP InTerPipe to combine highperformance<br />

thermal insulation with low-power resistive<br />

heating elements. Now technologically qualified by<br />

DNV for reel-lay installation, ETHF offers a highly<br />

efficient means of maintaining product temperature in<br />

the most challenging subsea environments.<br />

09<br />

For further information contact paul.booth@subsea7.com<br />

seabed-to-surface

10<br />

Fleet development update<br />

<strong>Subsea</strong> 7’s industry-leading commitment to fleet<br />

development is directly driven by our identification and<br />

anticipation of our clients’ needs for their increasingly<br />

challenging subsea field developments.<br />

Whether for highly complex deepwater installations, extended<br />

Life-of-Field operations or enhanced <strong>welding</strong> performance,<br />

<strong>Subsea</strong> 7 is committed to working in close collaboration with<br />

our vessel-build and equipment partners to incorporate client<br />

requirements in the design of new vessels and upgrading of<br />

existing vessels.<br />

The five new vessels profiled here all reflect, in their different<br />

ways, elements of our commitment to deploy a fleet of<br />

New-build<br />

Seven Borealis<br />

With its pipelay and heavy-lift<br />

capabilities, <strong>Subsea</strong> 7’s Seven<br />

Borealis is possibly the most<br />

versatile offshore construction<br />

vessel. Its 5,000t crane, with<br />

the top of the mast reaching<br />

150m above the main deck,<br />

is the world’s largest offshore<br />

mast crane. Recent lift<br />

tests in Singapore proved its<br />

capability of lifting 5,000t.<br />

The Seven Borealis joins the<br />

fleet in the second half of<br />

2012.<br />

New-build flexible pipelay support vessel (PLSV)<br />

<strong>Subsea</strong> 7 has been awarded a contract to provide a 550t<br />

top-tension PLSV for Petrobras for delivery in 2014. This<br />

top-tension capability gives the vessel <strong>Subsea</strong> 7’s highestperforming<br />

flexible pipelay capability in the fleet, and among<br />

DEEP7 May 2012<br />

unrivalled capacity and versatility, and one which offers our<br />

clients access to over 40 vessels with the highest standards of<br />

flexibility and project reliability.<br />

Enhanced vessel specifications like crane and moonpool<br />

capacities are designed to accommodate the hardware which<br />

we plan to deploy for the future in support of our clients.<br />

This is particularly evident in our latest flagship enabling vessel,<br />

the Seven Borealis, which not only features world-leading<br />

lifting capabilities, but will also incorporate <strong>Subsea</strong> 7’s latest<br />

mechanised <strong>welding</strong> <strong>technologies</strong> on its J-lay and S-lay firing<br />

lines (see pages 2 and 3).<br />

the highest for any PLSV in the world. This high specification<br />

reflects the existing and anticipated demand of Brazilian ultradeepwater<br />

operations.<br />

The vessel is scheduled to have a 550t Tiltable Lay System<br />

(TLS) installed, with two 275t retractable tensioners to handle<br />

flexible products between 100mm and 630mm outer diameter.<br />

The tower can tilt to 10o when operational to recover rigid pipe<br />

from the seabed but it can also tilt to 50o from the vertical to<br />

allow the TLS to clear power cables across the entrance to<br />

Vitoria harbour.<br />

The two underdeck carousels will also be of the open-top<br />

“basket” design. The new PLSV also incorporates a number of<br />

further design innovations to meet the specific requirements of<br />

the Brazilian market. The vessel will be fitted with underwater<br />

demountable thrusters which can be removed and replaced<br />

while the vessel is afloat.

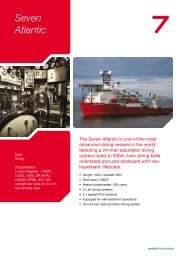

Seven Viking<br />

Due for launch in late 2012, the Seven Viking is designed as a “next<br />

generation” Inspection, Maintenance and Repair (IMR) vessel, with<br />

enhanced seakeeping qualities and environmental performance. The<br />

Seven Viking will enter a long-term frame agreement with Statoil for<br />

operations in the North, Norwegian and Barents Seas.<br />

The Seven Viking incorporates a number of design features to minimise<br />

mobilisation times and optimise transit speeds, most notably an<br />

innovative hull shape which offers increased foreship volume and<br />

slender waterlines. As well as offering improved seakeeping capabilities<br />

(fully operational in 5m significant wave height), this design also provides<br />

a larger working deck area, with a raised freeboard and working stations<br />

enclosed in a heated indoor hangar to enable IMR operations in rough<br />

seas and extreme temperatures.<br />

Other innovations which facilitate harsh weather operations include a<br />

skidding module handling system to store and move up to eight different<br />

modules into the moonpool, eliminating the risk of hanging loads, and<br />

de-ice facilities and a strengthened hull for operations in Arctic areas.<br />

Seven Inagha<br />

<strong>Subsea</strong> 7 has an impressive track record in<br />

developing innovative equipment, and this is<br />

confirmed by a new vessel joining the fleet in 2012.<br />

The Seven Inagha started her life in 2011 as a<br />

high-capacity Gulf of Mexico liftboat. During her<br />

construction, she was purchased by <strong>Subsea</strong> 7 and<br />

began her conversion into an extremely capable<br />

platform for hook-up operations in West Africa.<br />

The Seven Inagha is effectively a vessel with<br />

legs, and, unlike most conventional jack-ups,<br />

can mobilise to a work site under her own power.<br />

She has an impressive lifting capacity with two<br />

295t cranes fitted, and will commence operations<br />

offshore Nigeria. With enhanced facilities able to<br />

accommodate up to 150 people on board, she will<br />

provide utility services and support to hook-up<br />

teams on offshore installations.<br />

The three eye-catching tubular 97.5m legs have<br />

pairs of racks which allow the 36 planetary motors<br />

to jack the hull at a speed of 2.4m per minute,<br />

elevating the hull to a maximum height of 88m<br />

above the seabed in water depths of up to 76m<br />

when operating in hook-up mode.<br />

Seven Havila<br />

The state-of-the-art diving support vessel, the<br />

Seven Havila, which is owned by <strong>Subsea</strong> 7 and<br />

Havila Shipping and is widely considered to<br />

be the most advanced<br />

vessel of its type in the<br />

world, has achieved<br />

a world first by<br />

simultaneously deploying<br />

eight saturation divers<br />

from a single vessel.<br />

The advanced diving<br />

system on the vessel includes a ten-chamber,<br />

24-men fully computerised saturation suite,<br />

with a double bell handling system capable of<br />

working down to 400m and up to 6m significant<br />

wave height.<br />

11<br />

seabed-to-surface

Autonomous Inspection Vehicle (AIV) commercialised<br />

Following extensive inwater<br />

testing in 2011, the<br />

final software systems<br />

and design adjustments<br />

on <strong>Subsea</strong> 7’s pioneering<br />

Autonomous Inspection<br />

Vehicle (AIV) have been<br />

implemented, and<br />

this game-changing<br />

technology is now<br />

being successfully<br />

commercialised.<br />

The Mark 1 inspection<strong>class</strong><br />

vehicle is being<br />

deployed into customer<br />

qualification programmes AIV deployment system<br />

during 2012, and the<br />

development paths of the next generations of fully capable,<br />

work-<strong>class</strong> sized intervention vehicles are already being laid.<br />

A differentiating element of the AIV is its ability to recognise<br />

and respond to its surroundings - it will correct its trajectory in<br />

real time, based on the information it gathers from its onboard<br />

sensors. This level of intelligence and decision-making has had<br />

to be de-risked and made as robust as possible, so a powerful<br />

virtual reality simulator was used to ensure that every option was<br />

identified and assessed.<br />

New multipass and backfill ploughs<br />

<strong>Subsea</strong> 7 has recently invested in two high-performance<br />

subsea ploughs that will significantly enhance our delivery<br />

capability on the burial of trenched pipelines.<br />

Our new Variable Multi-Pass Plough (VMP), as the name<br />

suggests, has the capability to perform a number of passes<br />

through the seabed to achieve the specified depth. However,<br />

where the VMP has a significant advantage over other ploughs<br />

is in its ability to alter its cut depth without recovery, thereby<br />

reducing operational timings.<br />

Another design innovation is the VMP’s fore-cutter, in front of<br />

the main cutting tool, which enables this plough to function in<br />

stiffer soil conditions.<br />

The VMP already has a proven track record, completing an<br />

extensive variety of pre- and post-cut trenches in varying soil<br />

www.subsea7.com<br />

DEEP7 May 2012<br />

Variable Multi-Pass Plough<br />

© <strong>Subsea</strong> 7, 2012. Information correct at time of going to press.<br />

In collaboration with one of the world’s leading underwater<br />

simulator suppliers, a detailed specification was developed<br />

to allow “hardware-in-the-loop” testing. The final system,<br />

probably one of the most sophisticated in existence, allows<br />

the real AIV computational hardware to control a dynamic<br />

simulation model of the AIV within a virtual world that<br />

contains a full 3D representation of an offshore oilfield. This<br />

package provides full emulation of the sensor packages<br />

and simulation of the vehicle dynamics operating around<br />

representative subsea infrastructure.<br />

Although this simulation uses a bank of some of the fastest<br />

industrial computers available, it allows AIV missions to<br />

be run hundreds of times to ensure that the AIV decisionmaking<br />

behaviour is robust.<br />

The visual inspection capability of the AIV Mark 1 will lead<br />

to more cost-efficient and effective integrity management<br />

throughout the lifetime of a subsea field development.<br />

As customer qualification of the visual inspection vehicle<br />

proceeds, <strong>Subsea</strong> 7 is simultaneously engaging with<br />

subsea developers, industry bodies and field development<br />

strategists to explore how autonomous technology can<br />

further enhance the challenging subsea operations of the<br />

future.<br />

For further information contact hugh.ferguson@subsea7.com<br />

conditions around the world for large-diameter pipelines,<br />

trucklines and flowlines.<br />

To complement the VMP, <strong>Subsea</strong> 7 has also invested in a<br />

Backfill Plough (BFP), which redeposits the soil from the VMPcut<br />

trench back into the void once the product is laid. The<br />

ability to provide a quality backfill with the BFP significantly<br />

enhances both the thermal insulation and resistance to<br />

upheaval buckling.<br />

Backfill Plough 2<br />

The ploughs have already been deployed by another recent<br />

addition to the <strong>Subsea</strong> 7 fleet - the highly versatile Skandi<br />

Skansen which, with a 250t heave-compensated crane, a<br />

300t A-Frame and a bollard pull of 350t, is ideally suited to<br />

support many field installation operations, including ploughing<br />

campaigns.<br />

For further information contact farquhar.mitchell@subsea7.com