World-class welding technologies - Subsea 7

World-class welding technologies - Subsea 7

World-class welding technologies - Subsea 7

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10<br />

Fleet development update<br />

<strong>Subsea</strong> 7’s industry-leading commitment to fleet<br />

development is directly driven by our identification and<br />

anticipation of our clients’ needs for their increasingly<br />

challenging subsea field developments.<br />

Whether for highly complex deepwater installations, extended<br />

Life-of-Field operations or enhanced <strong>welding</strong> performance,<br />

<strong>Subsea</strong> 7 is committed to working in close collaboration with<br />

our vessel-build and equipment partners to incorporate client<br />

requirements in the design of new vessels and upgrading of<br />

existing vessels.<br />

The five new vessels profiled here all reflect, in their different<br />

ways, elements of our commitment to deploy a fleet of<br />

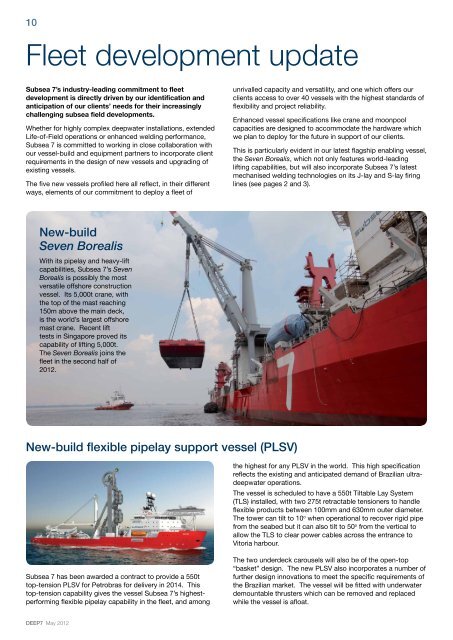

New-build<br />

Seven Borealis<br />

With its pipelay and heavy-lift<br />

capabilities, <strong>Subsea</strong> 7’s Seven<br />

Borealis is possibly the most<br />

versatile offshore construction<br />

vessel. Its 5,000t crane, with<br />

the top of the mast reaching<br />

150m above the main deck,<br />

is the world’s largest offshore<br />

mast crane. Recent lift<br />

tests in Singapore proved its<br />

capability of lifting 5,000t.<br />

The Seven Borealis joins the<br />

fleet in the second half of<br />

2012.<br />

New-build flexible pipelay support vessel (PLSV)<br />

<strong>Subsea</strong> 7 has been awarded a contract to provide a 550t<br />

top-tension PLSV for Petrobras for delivery in 2014. This<br />

top-tension capability gives the vessel <strong>Subsea</strong> 7’s highestperforming<br />

flexible pipelay capability in the fleet, and among<br />

DEEP7 May 2012<br />

unrivalled capacity and versatility, and one which offers our<br />

clients access to over 40 vessels with the highest standards of<br />

flexibility and project reliability.<br />

Enhanced vessel specifications like crane and moonpool<br />

capacities are designed to accommodate the hardware which<br />

we plan to deploy for the future in support of our clients.<br />

This is particularly evident in our latest flagship enabling vessel,<br />

the Seven Borealis, which not only features world-leading<br />

lifting capabilities, but will also incorporate <strong>Subsea</strong> 7’s latest<br />

mechanised <strong>welding</strong> <strong>technologies</strong> on its J-lay and S-lay firing<br />

lines (see pages 2 and 3).<br />

the highest for any PLSV in the world. This high specification<br />

reflects the existing and anticipated demand of Brazilian ultradeepwater<br />

operations.<br />

The vessel is scheduled to have a 550t Tiltable Lay System<br />

(TLS) installed, with two 275t retractable tensioners to handle<br />

flexible products between 100mm and 630mm outer diameter.<br />

The tower can tilt to 10o when operational to recover rigid pipe<br />

from the seabed but it can also tilt to 50o from the vertical to<br />

allow the TLS to clear power cables across the entrance to<br />

Vitoria harbour.<br />

The two underdeck carousels will also be of the open-top<br />

“basket” design. The new PLSV also incorporates a number of<br />

further design innovations to meet the specific requirements of<br />

the Brazilian market. The vessel will be fitted with underwater<br />

demountable thrusters which can be removed and replaced<br />

while the vessel is afloat.