History Brochure - Avdel Global

History Brochure - Avdel Global

History Brochure - Avdel Global

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Whilst working with the truck and<br />

trailer sector during the 70’s <strong>Avdel</strong><br />

Sales Engineers identifi ed that<br />

there was an opportunity to develop<br />

a blind structural fastener with an<br />

exceptional grip range capability<br />

that could signifi cantly reduce<br />

assembly times and simplify the<br />

repair of damaged trucks and<br />

trailers. The result was introduction<br />

of the world’s fi rst blind structural<br />

fastener Monobolt ® .<br />

<strong>Avdel</strong> developed fasteners for the truck and trailer sector<br />

Typical repair times for truck &<br />

trailers tumbled from 50 hours to<br />

just 2 hours! Wider applications for<br />

this product were soon identifi ed in<br />

ship building, bridge construction,<br />

shipping containers etc.<br />

Managing Director John C. Marley 1974<br />

75 Years of <strong>Avdel</strong><br />

1970 - 1980<br />

When our Sales Engineers showed<br />

this new product to the aerospace<br />

industry it generated a lot of<br />

interest. <strong>Avdel</strong> Engineers took the<br />

Monobolt ® principle and came<br />

up with an Aerospace derivative<br />

and MBC ® was launched into<br />

the market and used by Aircraft<br />

Manufacturers.<br />

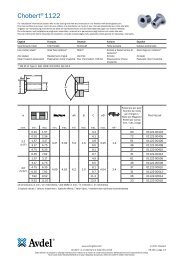

The fi rst and most successful of a<br />

new generation of speed fastener<br />

products was<br />

the Briv ®<br />

with its large<br />

diameter low<br />

profi le head, hiclamp<br />

capability<br />

and bulbed<br />

tail. Briv ® was<br />

highly suitable<br />

for assembly<br />

of plastic,<br />

c o m p o s i t e<br />

and passive materials used in<br />

computers, and both passive and<br />

active electronic devices.<br />

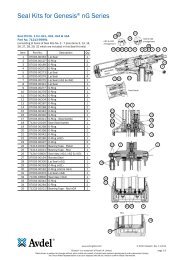

To reduce assembly times a range<br />

of multi-head riveting machines,<br />

using standard hand tools mounted<br />

in a frame were introduced.<br />

Machines subsequently used<br />

specially designed slim hydropneumatic<br />

modules designated<br />

as Hydra ® , that achieved closer<br />

centre distance between fi xings.<br />

These soon became popular<br />

with customers looking to reduce<br />

assembly costs as well as improve<br />

assembly quality. These machines<br />

are capable of placing multiple<br />

Breakstem, Speed and Threaded<br />

products simultaneously and they<br />

can use the fastener as a means of<br />

- 11 -<br />

New developed in this<br />

decade<br />

Monobolt ® Monobolt blind structural fastener<br />

® blind structural fastener<br />

Briv ® speed fastener with<br />

high clamp load<br />

Multi-head riveting machine<br />

Avtainer ® fastener for trailers<br />

Avseal ® Avseal sealing plug<br />

® sealing plug<br />

Hexsert ® insert with hexagonal body<br />

T-Lok ® rivet for wood applications