Petersen Aluminum PAC-CLAD catalog Reed First Source

Petersen Aluminum PAC-CLAD catalog Reed First Source

Petersen Aluminum PAC-CLAD catalog Reed First Source

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

07 61 00/PET<br />

BuyLine 3008

<strong>PAC</strong>-<strong>CLAD</strong> Applications Page 3<br />

<strong>PAC</strong>-<strong>CLAD</strong> Color Availabiliy Page 4<br />

<strong>PAC</strong>-<strong>CLAD</strong> Color Chart Page 5<br />

SNAP-<strong>CLAD</strong> Page 6 & 7<br />

Tite-Loc & Tite-Loc Plus Panels Page 8 & 9<br />

Snap-On Panels Page 10<br />

Redi-Roof Panels Page 11<br />

Integral Panels Page 12<br />

Flush Panels Page 13<br />

M & R Panels Page 14 & 15<br />

Soffit Panels Page 16 & 17<br />

Snow Guards Page 18<br />

Composite Panels/ Column Covers Page 19<br />

<strong>PAC</strong>-Continuous / Tite-Loc / Page 20<br />

<strong>PAC</strong>-LOC Coping<br />

<strong>PAC</strong>-1-Ply / Thrift-Loc / Page 21<br />

Built-Up Gravel Stops<br />

General Considerations/TCS Page 22<br />

Specifications Page 23<br />

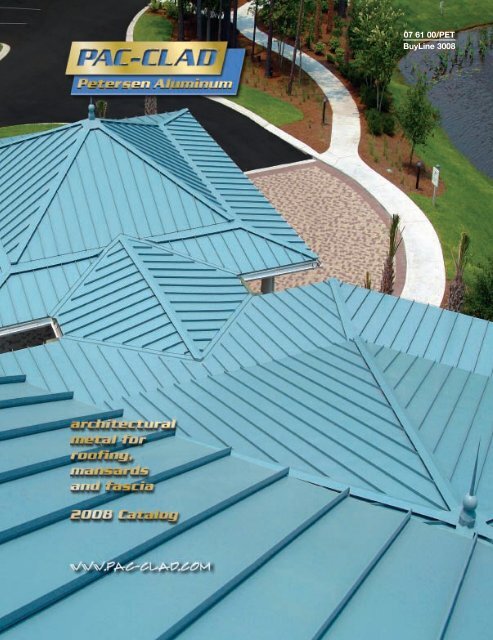

Cover Photo:<br />

Marriott Surfwatch Resort Condominiums, Hilton Head Island, SC<br />

Architect: NCG Architects Inc.<br />

General Contractor: Hardin Construction Company<br />

Roofing Contractor: Southern Roof & Wood Care Corporation<br />

Color: Custom Color - Charlotte Slate<br />

Cabela’s, Buda, TX<br />

Architect: Crabtree, Rohrbauch & Associates<br />

General Contractor: Kraus Anderson<br />

Roofing Contractor: K Post Company<br />

Color: Forest Green<br />

Profile: Snap-Clad & Flush Panel<br />

2<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation was founded in 1965 as a metals service center to the architectural metal<br />

industry. At <strong>Petersen</strong> we strive to provide products of the highest possible quality within reliable, dependable<br />

lead-times. Our strong national sales base allows <strong>PAC</strong> to maintain large inventories and cost economies to our<br />

customers.<br />

In addition to our Chicago-based headquarters, we maintain full production facilities in Annapolis Junction,<br />

Maryland; Tyler, Texas; and Atlanta, Georgia. In addition to the information found in this <strong>catalog</strong>, we maintain<br />

an extensive web site (www.pac-clad.com) and our complete <strong>catalog</strong> is available in standard 3-ring<br />

binder as well as CD-ROM format.<br />

Technical assistance and service are provided by our staff and complimented locally by our nationwide<br />

organization of architectural representatives. We are prepared to offer assistance in material selection, finish<br />

specification, and budgeting. As the scope of our applications is so wide, we encourage your inquiries.<br />

<strong>PAC</strong>-<strong>CLAD</strong> Architectural Sheet and Coil<br />

<strong>PAC</strong>-<strong>CLAD</strong> is a versatile prefinished sheet metal coating (Kynar 500® or Hylar 5000® ) that is applied to<br />

both G-90 galvanized steel and 3105-H14 aluminum. Originally developed for use in abrasive environments,<br />

<strong>PAC</strong>-<strong>CLAD</strong> has proven to be ideally suited for application in roofing, curtainwall, storefront and trim applications.<br />

<strong>PAC</strong>-<strong>CLAD</strong> is now available in thirty-six colors carefully selected to complement a range of building<br />

materials.<br />

<strong>PAC</strong>-<strong>CLAD</strong> Panels<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation maintains extensive roll-forming equipment in each of our regional facilities.<br />

Each of our rollformers provides panels that have been Herr-Voss corrective leveled. Standing seam,<br />

flush, wall and soffit panels are all factory formed in lengths up to 55 feet. Longer lengths are available.<br />

Please consult our factory. Matching flashing and trim may also be factory formed or field formed from <strong>PAC</strong>-<br />

<strong>CLAD</strong> material.<br />

<strong>PAC</strong>-<strong>CLAD</strong> Accessories<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation fabricates a wide range of roofing accessories. Coping, gravel stops, gutters<br />

and downspouts are all formed from our 36 standard <strong>PAC</strong>-<strong>CLAD</strong> colors. <strong>Petersen</strong> <strong>Aluminum</strong> also is a distributor<br />

of Follansbee TCS.<br />

The Descriptions Herein Are Not Warranties<br />

The descriptions in this <strong>catalog</strong> of <strong>Petersen</strong> <strong>Aluminum</strong> Corporation products are given for informational purposes only,<br />

and are not warranties. No express warranties are contained in this <strong>catalog</strong>. <strong>Petersen</strong> <strong>Aluminum</strong> Corporation does not<br />

build or design buildings. It acts solely as a supplier of materials, and assumes no responsibility for the proper use or<br />

installation of those materials, nor for the suitability of those materials for any specific use or for compliance with local<br />

building codes.

Ruffner Hall, Longwood University<br />

Farmsville, VA<br />

Owner: Longwood College<br />

Architect: Kuntz & Associates, Architects<br />

Scoggin-Dickey Hummer Dealership<br />

Lubbock, TX<br />

Owner: Scoggin-Dickey Buick<br />

Architect: Joe D. McKay Architects<br />

General Contractor: Lee Lewis Construction Inc.<br />

Roofing Contractor: Hamilton Roofing<br />

Profile: Curved Tite-Loc Panels<br />

Material: Galvalume Plus<br />

General Contractor: English Construction<br />

Roofing Contractor: Roof Systems of Virginia<br />

Color: Colonial Red<br />

Profile: Tite-Loc Plus<br />

07 61 00/PET<br />

BuyLine 3008<br />

Sea Turtle Village & Cinemas<br />

Bluffton, SC<br />

Distributor: JGA Southern Roof Center/Beacon Sales<br />

Architect: KRA Architecture Inc.<br />

Roofing Contractor: Southern Roof & Wood Care<br />

Profile: Snap-Clad<br />

Color: Forest Green<br />

3

Steel <strong>Aluminum</strong><br />

<strong>PAC</strong>-<strong>CLAD</strong> Cool Colors<br />

Almond<br />

Bone White<br />

Cardinal Red<br />

Charcoal<br />

Colonial Red<br />

Dark Bronze<br />

Evergreen<br />

Granite<br />

Hemlock Green<br />

Hunter Green<br />

Mansard Brown<br />

Medium Bronze<br />

Military Blue<br />

Musket Gray<br />

Patina Green<br />

Sandstone<br />

Sierra Tan<br />

Slate Blue<br />

Slate Gray<br />

Stone White<br />

Teal<br />

Terra Cotta<br />

Matte Black**<br />

<strong>PAC</strong>-<strong>CLAD</strong> Metallic<br />

Aged Copper<br />

Champagne<br />

Copper Penny<br />

Silver<br />

Weathered Zinc<br />

Reflectivity Emissivity<br />

0.56 0.89<br />

0.73 0.89<br />

0.37 0.89<br />

0.28 0.89<br />

0.32 0.89<br />

0.25 0.89<br />

0.26 0.88<br />

0.36 0.89<br />

0.30 0.90<br />

0.26 0.88<br />

0.25 0.88<br />

0.27 0.90<br />

0.34 0.88<br />

0.31 0.89<br />

0.34 0.89<br />

0.53 0.89<br />

0.36 0.89<br />

0.26 0.87<br />

0.36 0.89<br />

0.64 0.88<br />

0.26 0.88<br />

0.36 0.89<br />

0.25 0.85<br />

0.28 0.89<br />

0.41 0.80<br />

0.49 0.87<br />

0.60 0.83<br />

0.30 0.81<br />

3 Yr Exposure<br />

0.57<br />

0.71<br />

0.38<br />

0.35<br />

0.49<br />

0.35<br />

0.59<br />

0.37<br />

0.40<br />

0.47<br />

0.55<br />

SRI*<br />

66<br />

89<br />

41<br />

29<br />

34<br />

25<br />

26<br />

40<br />

32<br />

26<br />

25<br />

28<br />

36<br />

33<br />

37<br />

62<br />

40<br />

26<br />

40<br />

77<br />

26<br />

40<br />

23<br />

29<br />

43<br />

56<br />

70<br />

28<br />

24 ga.<br />

•<br />

•* •<br />

•<br />

22 ga.<br />

•<br />

•<br />

•* •<br />

•<br />

•<br />

•<br />

•<br />

.032<br />

•<br />

•* •<br />

•<br />

.040<br />

•<br />

•<br />

•* •<br />

•<br />

•<br />

•<br />

•<br />

.050<br />

•<br />

•*<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

.063<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

0.31 34<br />

Zinc 0.32 0.89 • • •<br />

<strong>PAC</strong>-<strong>CLAD</strong> Standard Colors (do not meet cool roof requirements)<br />

Arcadia Green • •<br />

Award Blue • • •<br />

Berkshire Blue • *<br />

Burgundy • • •<br />

Forest Green • • • • •<br />

Hartford Green • • • •<br />

Interstate Blue • • •<br />

<strong>PAC</strong>-<strong>CLAD</strong> ® Metallic finishes are available from stock at a moderate extra cost. <strong>PAC</strong>-<strong>CLAD</strong> ® Copper Penny is a Non-Weathering finish. *Solar Reflectance Index calculated according to ASTM E-1980. **Matte Black (SRI Color) in steel only.<br />

Energystar® Performance Criteria<br />

Emissivity uses ASTM C1371/E408. Reflectivity uses ASTM E903/C1549.<br />

Installation<br />

<strong>PAC</strong>-<strong>CLAD</strong> ® can be cut, formed, nailed, screwed, or riveted using hand or power<br />

tools. Fabricate and install in accordance with drawings and normal sheet metal practices<br />

using hand or power tools. Keep cutting edges sharp, clean, and properly<br />

aligned. Exercise care during fabrication and installation to avoid damage.<br />

Maintenance<br />

Maintenance is not required. This finish is a member of the Teflon ® family, and is<br />

self-cleaning. If cleaning is desired, it can be washed with a mild soap and water followed<br />

by a clean-water rinse.<br />

Samples<br />

These color reproductions are as accurate as modern printing technology will permit.<br />

Free material samples are available on request.<br />

4<br />

Textures<br />

<strong>PAC</strong>-<strong>CLAD</strong> ® is available with a smooth texture or a standard E-5 stucco embossed pattern,<br />

available at extra cost.<br />

* Low Gloss/Low Sheen<br />

This finish is a full Kynar 500 ® /Hylar 5000 ® finish, but is formulated in a low<br />

gloss/low sheen in order to minimize the appearance of oil-canning.<br />

Technical Data for Kynar 500 ® /Hylar 5000 ® Coating<br />

•Life Expectancy—20 years exposure – Chalk: rating of 8 or better. Color: 5∆E<br />

(Hunter Units) change.<br />

•Accelerated Weathering—(ASTM G-23 Type EH) 5,000 hours - Chalk: rating of 8<br />

or better. Color: ≤5∆E (Hunter Units) color change.<br />

•Humidity Resistance—(ASTM 2247) 2,000 hours - No change in pencil hardness.<br />

•Salt Spray Resistance—(ASTM B 117) – 2,000 hours for <strong>Aluminum</strong>, creepage at<br />

scribe ≤1/32”, no blisters. 2,000 hours for hot dipped Galvanized, creepage at<br />

scribe 1/8”, few #8 blisters.<br />

•Chemical/Acid Pollution Resistance—(ASTM D 1808) – Pass.<br />

•Solvent Resistance—(NCCA procedure 11-18, no comparable ASTM test) – Pass.<br />

•Formability—(ASTM D 3281 and ASTM D 1737) – Can be formed without film<br />

fracture using normal metal shop practices to a 1 to 2-T bend radius<br />

•Hardness—(ASTM D 3363) – ≥F pencil hardness.<br />

•Gloss—30 ± 5 at 60º (low gloss/sheen available).<br />

•Abrasion Resistance—(ASTM D 968) - Coefficient of 65 ± 10.<br />

•Adhesion—(ASTM D 3359 and NCCA procedure No. 11-5) – Pass.<br />

•Impact Resistance—(ASTM D 2794 and NCCA Technical Bulletin No. 11-6) – 70<br />

inch/lbs., no tape pick-off.<br />

Recycled Content<br />

•<strong>PAC</strong>-<strong>CLAD</strong> <strong>Aluminum</strong> - 91%<br />

•<strong>PAC</strong>-<strong>CLAD</strong> Steel - 28 to 35%

Standard Colors<br />

▲Stone White ▲Bone White ▲Slate Gray ▲Musket Gray ▲Charcoal<br />

▲ Almond ▲Sandstone ▲Granite ▲Medium Bronze ▲Dark Bronze<br />

▲ Sierra Tan ▲Terra Cotta ▲Colonial Red ▲Cardinal Red Burgundy<br />

▲Patina Green Arcadia Green ▲Hemlock Green ▲Teal Hartford Green<br />

Berkshire Blue Award Blue ▲Hunter Green Forest Green ▲Evergreen<br />

▲Slate Blue ▲Military Blue Interstate Blue ▲Mansard Brown ▲Matte Black<br />

<strong>PAC</strong>-<strong>CLAD</strong> Metallic Colors<br />

▲Zinc ▲Silver ▲Copper Penny ▲Aged Copper<br />

▲Champagne ▲Weathered Zinc<br />

▲ <strong>PAC</strong>-<strong>CLAD</strong> Cool Colors<br />

Due to the limitations of the four color printing process, this color chart is not an accurate representation of our actual colors. Color<br />

charts and sample chips are available on request at no charge.<br />

07 61 00/PET<br />

BuyLine 3008<br />

Materials<br />

<strong>PAC</strong>-<strong>CLAD</strong> is available in prime quality aluminum, 24<br />

gauge and 22 gauge G-90 galvanized steel finished with a<br />

<strong>PAC</strong>-<strong>CLAD</strong> Kynar 500 ®/Hylar 5000 ® finish (top side) and a<br />

polyester washcoat (bottom side). Other metals available<br />

include mill finish aluminum, copper, galvanized steel, ternecoated<br />

stainless steel, stainless, Galvalume Plus and<br />

anodized.<br />

A strippable vinyl film can be applied for protection during<br />

fabrication and installation, if desired. Vinyl masking is recommended<br />

on all applications requiring extra handling. The<br />

vinyl must be removed immediately after installation.<br />

Warranty<br />

Life expectancy is 20 years plus. A 20-year, non-prorated<br />

warranty covering color fade, chalking, and film integrity is<br />

available at no extra charge. Warranty terms vary slightly for<br />

Cardinal Red, Award Blue, Interstate Blue and embossed finishes.<br />

<strong>PAC</strong>-<strong>CLAD</strong> Metallics<br />

Due to new technology, <strong>Petersen</strong> <strong>Aluminum</strong> can now supply<br />

metallic finishes with the economy of a one-pass, two-coat<br />

system. These colors are ideal for curtainwall and roofing<br />

applications. A <strong>PAC</strong>-<strong>CLAD</strong> Metallic 20 year, non-prorated finish<br />

warranty applies. This is a directional finish.<br />

▲ Cool Colors<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation is pleased to introduce<br />

<strong>PAC</strong>-<strong>CLAD</strong> Cool Colors: a new and updated color palette<br />

designed to improve the energy saving performance of our<br />

metal roofing products without requiring compromise in color<br />

selection.<br />

In creating this new product line, we worked with our coating<br />

supplier, The Valspar Corporation, to significantly broaden<br />

the range of <strong>PAC</strong>-Clad colors that would meet ENERGY<br />

STAR ®, LEED and/or cool roof certification requirements<br />

for solar reflectance and emissivity ratings.<br />

This color chart includes solar reflectance and emissivity<br />

ratings for each color. It also includes availability by material<br />

and gauge. In addition, we are able to provide reflectance<br />

and emissivity ratings for custom color projects where<br />

required. If you have any questions regarding the information<br />

herein, please contact us at 1-800-323-1960; or visit our<br />

website at www.pac-clad.com.<br />

Recycled Content:<br />

• <strong>PAC</strong>-<strong>CLAD</strong> <strong>Aluminum</strong> - 91%<br />

Post Consumer - 35%<br />

Post Industrial - 53%<br />

• <strong>PAC</strong>-<strong>CLAD</strong> Steel - 28 to 35%<br />

Post Consumer - 23%<br />

Post Industrial - 7.3%<br />

5

NEW<br />

NEW<br />

NEW<br />

6<br />

Product Features<br />

•Architectural/structural panel<br />

•Herr-Voss corrective leveled<br />

•Factory applied sealant available<br />

•Continuous interlock<br />

•Labor-saving one-piece design<br />

•Stiffener beads available<br />

•Striations available<br />

•Factory eave notching available<br />

Material<br />

•.040 aluminum panel available<br />

•16 oz. cold rolled copper<br />

•36 standard colors (24 gauge steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 gauge steel)<br />

•Smooth and stucco embossed available<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available<br />

UL Classification<br />

•UL-580 Class 90 wind uplift<br />

•UL-1897 wind uplift<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance rated<br />

•UL-90 rated aluminum panel up to 16” O.C.<br />

ASTM Tests<br />

•ASTM E1592 tested<br />

•ASTM E283/1680 tested<br />

•ASTM E331/1646 tested<br />

Florida Building Product Approvals<br />

•.032 <strong>Aluminum</strong>: FL Prod. Approv. #5569<br />

•24 ga. Steel: FL Prod. Approv. #5569<br />

Miami-Dade Product Approvals<br />

•.032 <strong>Aluminum</strong>: NOA No.: 05-0830.02<br />

•24 ga. Steel: NOA No.: 07-0301.01<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

SNAP-<strong>CLAD</strong> Panels feature architectural panel aesthetics as well as structural panel performance. SNAP-<br />

<strong>CLAD</strong> Panels, produced in continuous lengths, are corrective leveled to provide superior flatness and feature<br />

an optional factory-applied sealant bead for improved weather resistance. (minimum panel length is 4 feet)<br />

SNAP-<strong>CLAD</strong> Panels feature a 1-3/4” leg height and a continuous interlock for improved structural performance<br />

and wind resistance. A concealed fastener clip system has been designed to allow for thermal expansion/contraction<br />

while providing extraordinary hold-down strength. Two clips are available: a standard clip<br />

for most mansard and fascia applications and a high-performance clip for roofing application and UL 90 rated<br />

assemblies.<br />

UL 90 Classified<br />

SNAP-<strong>CLAD</strong> Panels carry a UL 90 classification over a wide variety of substrates and assemblies including<br />

5/8” plywood, purlins, and rigid insulation in conjunction with bearing plates (UL Construction No. 254,<br />

255, 261, 303, 343, 508). For further details, contact <strong>Petersen</strong> <strong>Aluminum</strong> .<br />

Air and Water Infiltration<br />

SNAP-<strong>CLAD</strong> Panels meet the full performance requirements of the ASTM E283/1680 air infiltration test<br />

and the ASTM E331/1646 water penetration test. Please contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation for complete<br />

test results.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel d) .040 3105-H14 aluminum<br />

b) 22 ga. G-90 hot-dipped galvanized steel e) 16 oz. cold rolled copper<br />

c) .032 3105-H14 aluminum<br />

Trim<br />

All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.080 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> steel (24 ga. or 22 ga. as specified). A 20 year,<br />

non-prorated finish warranty shall be supplied covering finish performance.<br />

Installation<br />

SNAP-<strong>CLAD</strong> Panels are intended for use in roofing, mansard, and fascia applications. Substrates may<br />

include 5/8” (min.) plywood, nailboard insulation or equal with an underlayment of 30# (min.) roofing felt<br />

applied horizontally from eave to ridge. Other substrates may include metal decking, purlins or rigid insulation<br />

in conjunction with bearing plates. A minimum 2:12 pitch is recommended in most applications.<br />

Contact <strong>Petersen</strong> for detail assistance on projects requiring lower slopes. For Coastal applications, aluminum<br />

panels along with stainless steel clips must be used for warranty. Consult a local architect/engineer for compliance<br />

with local codes and conditions.<br />

Eave Notching<br />

Factory-produced eave notching is now available at nominal additional cost on SNAP-<strong>CLAD</strong> Panels and<br />

Redi-Roof Standing Seam Panels. Factory eave notching saves on labor cost by eliminating the need for cost-<br />

EAVE NOTCHING<br />

USE HEMMING<br />

TOOL TO FIELD<br />

BEND AT NOTCH<br />

EAVE NOTCH (OPTIONAL)<br />

AT FORMED SEAMS<br />

ly field cutting in providing a properly trimmed<br />

eave detail.<br />

Note: SNAP-<strong>CLAD</strong> has UL-90 classification up<br />

to 16” O.C. on .032 and .040 aluminum. See<br />

roof deck construction in Underwriter Laboratories<br />

roofing materials and systems directory.

SNAP-<strong>CLAD</strong><br />

10", 12", 16” or 18" O.C. .032 aluminum*<br />

1-3/4" high .040 aluminum*<br />

24 gauge steel<br />

22 gauge steel<br />

16 oz. copper* NEW<br />

sealant bead (optional)<br />

10", 12," 16" or 18" O.C.<br />

1-3/4"<br />

*UL-90 rated 18 “O.C. is not available in aluminum or<br />

copper.<br />

UL Construction Code Maximum Clip Spacing<br />

S U B S T R A T E S<br />

OPEN FRAME 5/8” PLYWOOD RIGID INSULATION 3<br />

GAUGE WIDTH PURLINS 2 OVER 22 GA. STEEL DECK<br />

WITH BEARING PLATES<br />

22 ga. 10” UL 261 (5’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

22 ga. 12” UL 254 (5’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

24 ga. 10” UL 261 (4’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

24 ga. 12” UL 254 (4’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

24 ga. 16” UL 255 (4’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

24 ga. 18” UL 255 (4’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

.032. 10” UL 261 (3’-0”)<br />

.032. 16” UL 508 (1’-6”) UL 303 (1’-6”)<br />

16 oz. copper 16” UL 614 (2”-0”)<br />

1. Contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation for complete UL construction assemblies.<br />

2. For complete information regarding appropriate purlin spacing, contact <strong>Petersen</strong><br />

<strong>Aluminum</strong> Corporation directly.<br />

3. Insulation thickness varies between 1” and 4 1/2” according to R-value desired. Refer to UL<br />

Roofing Materials Directory.<br />

4. See roof deck construction in Underwriter Laboratories roofing materials and systems directory.<br />

5. Please consult <strong>Petersen</strong> <strong>Aluminum</strong> for projects specifying open purlins.<br />

Amicalola Falls State Park & Lodge<br />

Dawsonville, GA<br />

Owner: Georgia Department of Natural Resources<br />

Roofing Contractor: Roof Craft Systems Inc.<br />

Distributor: CRS<br />

Color: Greystone<br />

Profile: Snap-Clad<br />

Top Photo: Cabela’s, Buda, TX<br />

Architect: Crabtree, Rohrbauch & Associates<br />

General Contractor: Kraus Anderson<br />

Roofing Contractor: K Post Company<br />

Color: Forest Green<br />

Profile: Snap-Clad & Flush Panel<br />

07 61 00/PET<br />

BuyLine 3008<br />

7

NEW<br />

NEW<br />

Product Features<br />

•Herr-Voss corrective leveled<br />

•Stiffener beads available<br />

•Striations available<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 ga. steel)<br />

•20 year non-prorated finish warranty<br />

•Smooth and stucco embossed available<br />

•Galvalume Plus available<br />

UL Classification<br />

•UL-580 Class 90 rated up to 18”O.C.<br />

•UL-1897 wind uplift<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance<br />

ASTM Tests<br />

•ASTM E1592 tested<br />

•ASTM E331 tested<br />

•ASTM E283 tested<br />

Florida Building Product Approvals<br />

•.032 <strong>Aluminum</strong>: FL Prod. Approv. #6191<br />

•24 ga. Steel: FL Prod. Approv. #6191<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

Top Photo:<br />

Gaylord Texan<br />

Grapevine, TX<br />

Owner: Gaylord Properties<br />

Architect: Hnedak/Bobo Architects - Memphis, TN<br />

General Contractor: Centex<br />

Roofing Contractor: Supreme Systems - Dallas TX<br />

Profile: Tite-Loc, Snap-Clad, Snap On Standing Seam,<br />

Corrugated Panels<br />

Material: Galvalume Plus<br />

Woodholme Elementary School<br />

Baltimore, MD<br />

Owner: Baltimore County Public Schools<br />

Architect: Grimm and Parker<br />

General Contractor: Oak Contracting<br />

Roofing Contractor: Cole Roofing<br />

Color: Custom Color - Medium Green Metallic<br />

Profile: Curved and Straight Tite-Loc Panels<br />

8<br />

NEW<br />

TITE-LOC Panels combine structural panel performance with architectural panel aesthetics. TITE-LOC Panels<br />

are corrective leveled to provide superior panel flatness. A factory-applied sealant bead is applied for additional<br />

weather resistance.(minimum panel length is 4 feet)<br />

TITE-LOC Panels feature a 2” leg height that requires mechanical field seaming after installation. Panels<br />

have a concealed-fastener floating clip system designed to allow for thermal expansion/contraction. For further<br />

details, please contact <strong>PAC</strong>.<br />

UL 90 Classified<br />

TITE-LOC Panels carry a UL 90 classification over a wide variety of substrates and assemblies including<br />

5/8” plywood, purlins, and rigid insulation in conjunction with bearing plates (UL Construction No. 90, 176,<br />

180, 238B, 437, 449, 451, 452, 487, 616, 617). For further details, contact <strong>Petersen</strong> <strong>Aluminum</strong> Corp.<br />

Air and Water Infiltration<br />

TITE-LOC Panels meet the full performance requirements of the ASTM E283/1680 air infiltration test and<br />

the ASTM E331/1646 water penetration test. Please contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation for complete<br />

test results.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel c) .032 3105-H14 aluminum<br />

b) 22 ga. G-90 hot-dipped galvanized steel d) .040 3105-H14 aluminum (Tite-Loc Panel only)<br />

Trim<br />

All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.063 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> steel (24 ga. or 22 ga. as specified). A 20 year,<br />

non-prorated finish warranty shall be supplied covering finish performance.<br />

Installation<br />

TITE-LOC Panels are intended for use in architectural and structural roofing. Substrates may include 5/8”<br />

(min.) plywood, nailboard insulation or equal with an underlayment of 30# (min.) roofing felt applied horizontally<br />

from eave to ridge. Other substrates may include metal decking, purlins or rigid insulation in conjunction<br />

with bearing plates. A minimum 1/2:12 roof pitch is required. Contact <strong>Petersen</strong> for further detail<br />

assistance on projects. For Coastal applications, aluminum panels along with stainless steel clips must be<br />

used for warranty. Consult a local architect/engineer for compliance with local codes and conditions.<br />

Tite-Loc Panels<br />

Tite-Loc Panels are factory-formed to length and field seamed to a 90º lock. Tite-Loc panels have been<br />

designed for application on roof slopes as low as 1/2:12 pitch. As an additional labor-saver, the Tite-Loc<br />

seamer has been designed to travel both up and down slope during installation. Tite-Loc panels are available<br />

in 12”, 16” and 18" widths. Materials available include 22 and 24 gage steel; .032 and .040 aluminum.<br />

Tite-Loc Plus Panels<br />

Tite-Loc Plus Panels are factory-formed to length and designed to be field-seamed to 180º. The panel<br />

combines an attractive thin-rib profile with superior structural performance. Tite-Loc Plus panels are designed<br />

for application over a wide variety of substrates in slopes as low as 1/2:12 pitch. Tite-Loc Plus panels are<br />

available in 12”, 16” and 18" widths. Materials available include 22 and 24 ga. steel; .032 aluminum.<br />

Curved Tite-Loc Panels<br />

Tite-Loc Panels can be curved to a minimum radius of 20’-0”. Tite-Loc curving can be done in the field or<br />

at the factory depending on the radius and length of the panel. For more details about our capabilities,<br />

please contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

*24 ga. and 22 ga. panels listed in bold print are UL-90 classified over solid substrate. See roof deck construction in<br />

Underwriter Laboratories roofing materials and systems directory. Tite-Loc and Tite-Loc Plus Panels are shown with<br />

optional striations. Standard product offering is smooth.

*<br />

Tite-Loc Panel<br />

12”, 16” or 18” O.C. .032 aluminum<br />

2” high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

2"<br />

2"<br />

2"<br />

NEW<br />

FM<br />

APPROVED<br />

* *<br />

Tite-Loc Plus Panel<br />

12”, 16” or 18” O.C. .032 aluminum<br />

2” high 24 gauge steel<br />

22 gauge steel<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

2"<br />

2"<br />

2"<br />

NEW<br />

Tite-Loc HS Panel<br />

12”, 16” or 17-5/8” O.C. .032 aluminum<br />

2” high 24 gauge steel<br />

22 gauge steel<br />

NEW<br />

12", 16" or 17-5/8" O.C.<br />

12", 16" or 17-5/8" O.C.<br />

12", 16" or 17-5/8" O.C.<br />

07 61 00/PET<br />

BuyLine 3008<br />

2"<br />

2"<br />

2"<br />

9

NEW<br />

NEW<br />

10<br />

Product Features<br />

•Ideal for transition roofs<br />

•Herr-Voss corrective leveled<br />

•Stiffener beads available<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 ga. steel)<br />

•20 year non-prorated finish warranty<br />

•Smooth and stucco embossed available<br />

•Galvalume Plus available<br />

UL Classification<br />

•UL-580 Class 90 rated over solid substrate<br />

(steel only – up to 18”O.C.)<br />

•UL-1897 wind uplift<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance<br />

ASTM Tests<br />

•ASTM E331 tested<br />

•ASTM E283 tested<br />

Florida Building Product Approvals<br />

•.032 <strong>Aluminum</strong>:<br />

FL Prod. Approv. #6191<br />

•24 ga. Steel:<br />

FL Prod. Approv. #6191<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

*<br />

Snap-on Standing Seam<br />

12", 18", 19" or 20" O.C. 24 gauge steel<br />

1" high 22 gauge steel<br />

.032 aluminum<br />

12", 18", 19" or 20" O.C.<br />

1"<br />

Snap-On Panels have been designed for use in roofing, mansard and fascia applications. Snap-On Panels<br />

are designed to be installed over a waterproofed solid substrate and a minimum 3:12 roof pitch. Snap-On<br />

Panels are to be factory roll formed in continuous lengths (minimum panel length is 4 feet).<br />

These panels are ideal for specificationon applications where roof transitions are required. The simplicity of<br />

the pan design combined with corrective leveling provides superior flatness and allows for greater workability<br />

on site.<br />

UL 90 Classified<br />

Steel Snap-On Standing Seam and High Snap-On Standing Seam Panels carry a UL 90 classification for wind<br />

uplift when fastened to an underlayment assembly including 5/8” plywood or OSB (oriented strand board) laminated<br />

to rigid insulation (UL Construction No. 351 & 352). This is one of the few UL 90 Systems that does not<br />

require sealant between plywood boards. For further details contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Air and Water Infiltration<br />

<strong>Petersen</strong> Snap-On Panels meet the full performance requirements of the ASTM E 283 air infiltration test<br />

and the ASTM E 331 water penetration test when applied over a solid substrate. For complete test results,<br />

contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel<br />

b) .032 3105-H14 aluminum<br />

Trim<br />

All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.080 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> steel (22 ga. or 24 ga. as specified). A 20 year,<br />

non-prorated warranty shall be supplied covering finish performance.<br />

Curved Panels<br />

The 1" high Snap-On Standing Seam Panel can now be curved to a concave or convex radius, with a minimum<br />

radius of 9 ft. This panel is ideal for barrel vaults and entranceways. Curved panels must be installed<br />

over a waterproofed solid substrate.<br />

Installation<br />

<strong>PAC</strong>-<strong>CLAD</strong> Snap-On Panels shall be installed over solid decking (5/8" plywood, nailboard insulation or<br />

equal) with an underlayment of 30# (min.) roofing felt applied horizontally from eave to ridge. Panels shall<br />

be fastened using <strong>Petersen</strong> Non-Penetrating Clips, fastening on 18" centers (max.). Minimum slope at 3:12<br />

pitch. Consult a local architect or engineer for requirements of local codes and conditions.<br />

Snap-on Batten<br />

11", 12", or 18" O.C. 24 gauge steel<br />

1-1/2" high .032 aluminum<br />

11", 12" or 18" O.C.<br />

1-1/2"<br />

*<br />

High Snap-on Standing Seam<br />

11", 18", or 19" O.C. 24 gauge steel<br />

1-1/2" high .032 aluminum<br />

11", 18" or 19" O.C.<br />

1-1/2"<br />

*24 ga. panels listed in bold print are UL-90 Classified over solid substrate.<br />

See roof deck construction in Underwriter Laboratories roofing<br />

materials and systems directory.

NEW<br />

NEW<br />

Product Features<br />

•Available with or without offsets<br />

•Factory eave notching available<br />

•Herr-Voss corrective leveled<br />

•Labor-saving one-piece design<br />

•Stiffener beads available<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•Smooth and stucco embossed available<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available<br />

•16 oz. cold rolled copper<br />

UL Classification<br />

•UL-580 Class 90 wind uplift<br />

(steel & copper only – copper up to 16 O.C.<br />

only)<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance rated<br />

•UL-90 rated copper panel up to 12” O.C.<br />

ASTM Tests<br />

•ASTM E283 tested<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

Curved Batten Panel<br />

The Redi-Roof Batten Panel is the industry's only<br />

batten panel which can be radiused concave or convex<br />

with a minimum radius of 9 ft. This panel is ideal for<br />

barrel vaults and cornices. Curved panels must be<br />

installed over a waterproofed solid substrate.<br />

Top Photo, page 10:<br />

Bitterman Residence<br />

Orlando, FL<br />

Owner: Bitterman Family<br />

Roofing Contractor: RAE CO of Ocala<br />

Color: Copper Penny<br />

Profile: Snap-Clad<br />

Top Photo, page 11:<br />

Mandarin Oriental Hotel<br />

Washington DC<br />

Architect: Brennan Beer Gorman & Monk.<br />

General Contractor: Armada Hoffler Construction<br />

Roofing Contractor: Progressive Services, Inc.<br />

Color: Hemlock Green<br />

Profile: Redi-Roof Batten Panel<br />

12" O.C.<br />

07 61 00/PET<br />

BuyLine 3008<br />

Redi-Roof is an architectural metal roofing system available exclusively from <strong>Petersen</strong> <strong>Aluminum</strong><br />

Corporation. It may be specified in either a batten or standing seam profile and is intended for application<br />

over a solid substrate with a minimum 3:12 roof pitch. Typical underlayments include plywood, nailboard insulation<br />

or equal. Panels are to be factory roll-formed in continuous lengths (minimum panel length is 4 feet).<br />

Redi-Roof Panels feature an offset profile which adds strength and allows room for a hex head fastener.<br />

The clip, with it's button punched design, insures an extra-snug fit. The one-piece design of the Redi-Roof<br />

Standing Seam allows for ease of installation.<br />

UL 90 Classified<br />

Steel Redi-Roof Panels carry a UL-90 classification for wind uplift when fastened to an underlayment assembly<br />

including 5/8” plywood or OSB (oriented strand board) laminated to rigid insulation (UL Construction No.<br />

350, 353 & 615). For further details contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Air and Water Infiltration<br />

<strong>Petersen</strong> Redi-Roof Panels meet the full performance requirements of the ASTM E 283 air infiltration test<br />

and the ASTM E 331 water penetration test when applied over a solid substrate. For complete test results,<br />

contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Materials<br />

a) 24 ga. G-90 hot dipped galvanized steel<br />

b) .032 3105-H14 aluminum or equal<br />

c) 16 oz. cold rolled copper (standing seam only)<br />

Trim All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.080 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> steel (22 ga. or 24 ga. as specified). A 20 year warranty<br />

shall be supplied covering finish performance.<br />

Installation<br />

<strong>PAC</strong>-<strong>CLAD</strong> Redi-Roof shall be installed over solid decking with an underlayment of 30# (min.) roofing felt<br />

applied horizontally from eave to ridge. Panels shall be fastened using <strong>Petersen</strong> non-penetrating clips, fastening<br />

on 18" centers (max.). Minimum slope at 3:12 pitch. Redi-Roof Batten panels cannot be lapped in the field.<br />

Consult a local architect/engineer for requirements of local codes and conditions.<br />

*<br />

Redi-Roof Standing Seam<br />

12", 16 or 18” O.C. 24 gauge steel<br />

1-9/16" high .032 aluminum<br />

16 oz. copper<br />

12", 16" or 18" O.C.<br />

12", 16" or 18" O.C.<br />

1-9/16"<br />

1-3/8"<br />

*<br />

Redi-Roof Batten<br />

12" O.C. 24 gauge steel<br />

1-1/4" high .032 aluminum<br />

1-1/4"<br />

*24 ga. panels listed in bold print are UL-90 Classified over solid substrate.<br />

See roof deck construction in Underwriter Laboratories roofing<br />

materials and systems directory.<br />

11

NEW<br />

Product Features<br />

•Herr-Voss corrective leveled<br />

•Labor saving one-piece design<br />

•Stiffener beads available<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•Smooth & stucco available<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available<br />

UL Classification<br />

•UL 580 Class 90 rated over solid substrate<br />

(steel only)<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance<br />

•Wind load testing results available<br />

ASTM Tests<br />

•ASTM E283 tested<br />

•ASTM E331 tested<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

*24 ga. panels listed in bold print are UL-90 Classified over solid substrate.<br />

See roof deck construction in Underwriter Laboratories roofing<br />

materials and systems directory.<br />

Top Photo:<br />

Boyds Bear Factory<br />

Gettysburg, PA<br />

Architect: LCS Design<br />

General Contractor: Kinsley Construction, Inc.<br />

Roofing Contractor: M. Potteiger, Inc.<br />

Profile: Snap-On Batten & Snap-Clad<br />

Color: Custom Color, Dark Colonial Red & Charcoal<br />

12<br />

<strong>PAC</strong>-<strong>CLAD</strong> Integral Panels are designed for roofing applications, mansards, canopies and fascia. The onepiece<br />

design of the Integral Panels minimizes labor and allows for quick and easy installation. Integral panels<br />

are to be factory roll formed in continuous lengths (minimum panel length is 4 feet).<br />

Standard on-center dimensions are 11”, 18" and 19", but for renovation projects or additions, on-center<br />

dimensions may be custom matched to your requirements. Neoprene panel closures are available for installation<br />

at the eave.<br />

UL 90 Classified<br />

Steel <strong>PAC</strong>-<strong>CLAD</strong> Integral Panels carry a UL 90 Classification for wind uplift when fastened to an underlayment<br />

assembly including 5/8” plywood or OSB laminated to rigid insulation. (UL Construction No. 346 &<br />

347) For further details contact <strong>Petersen</strong> <strong>Aluminum</strong> Corp.<br />

Air and Water Infiltration<br />

<strong>Petersen</strong> Integral Panels meet the full performance requirements of the ASTM E 283 air infiltration test<br />

and the ASTM E 331 water penetration test when applied over a solid substrate. For complete test results,<br />

contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel<br />

b) .032 3105-H14 aluminum or equal<br />

Fasteners<br />

For roofing applications, use <strong>Petersen</strong> non-penetrating clips. Clips shall be 606l-T6 extruded aluminum,<br />

fastened on 18" centers. Use wood-type screws in fastening clips. For fascia and mansard applications, panels<br />

should be positively fastened to the substrate.<br />

Trim<br />

All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.080 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> 24 ga. steel. A 20 year warranty shall be supplied<br />

covering finish performance.<br />

Installation<br />

Roofing Applications: <strong>PAC</strong>-<strong>CLAD</strong> Integral Seam Panels shall be installed over solid decking (5/8" plywood,<br />

nailboard insulation or equal) with an underlayment of 30# (min.) roofing felt applied horizontally<br />

from eave to ridge. Panels shall be fastened using <strong>Petersen</strong> non-penetrating clips, fastened on 18" centers<br />

(max.). Minimum slope at 3:12 pitch. Consult a local architect/engineer for requirements of local codes and<br />

conditions.<br />

*<br />

Integral Standing Seam<br />

11", 18" or 19" O.C. 24 gauge steel<br />

1-1/2" high .032 aluminum<br />

11", 18" or 19" O.C.<br />

1-1/2"<br />

*<br />

Integral Batten<br />

11", 18" or 19" O.C. 24 gauge steel<br />

1-1/2" high .032 aluminum<br />

11", 18" or 19" O.C.<br />

1-1/2"<br />

1-1/2"

NEW<br />

NEW<br />

Product Features<br />

•Corrective leveled for superior flatness<br />

•Available with up to 3 stiffener beads<br />

•Rounded interlock leg provides improved<br />

flush fit<br />

•.040 aluminum panel<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 gauge steel)<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available<br />

Florida Building Product Approvals<br />

•.032 & .040 <strong>Aluminum</strong>,<br />

22 & 24 ga. Steel:<br />

FL Prod. Approv. #7547<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

Top Photo:<br />

The Shoppes at Farmington Valley<br />

Canton, CT<br />

Owner: S.R. Weiner<br />

Architect: ADD Inc.<br />

General Contractor: Tanglewood Inc.<br />

Roofing Contractor: R & S Construction Services<br />

Profile: Snap-Clad<br />

Color: Musket Gray Stucco Embossed<br />

<strong>PAC</strong>-<strong>CLAD</strong> Flush Panels are designed for wall, fascia and soffit applications where a flush or flat appearance is<br />

desired. A rounded interlock leg and concealed fastening system act to improve the flush appearance while providing<br />

additional strength. Panels are factory-formed to length to minimize field cutting (minimum panel length<br />

is 4 feet).<br />

<strong>PAC</strong>-<strong>CLAD</strong> Flush Panels are available in on-center dimensions designed to complement our roofing panel product<br />

line. Flush Panels are available in two configurations:<br />

•Flush Panel<br />

•Reveal Panel<br />

Flush Panels<br />

Uses: <strong>PAC</strong>-Flush Panels are intended for use as vertical wall panels, fascia and soffit applications. Flush<br />

Panels are not intended for use in roofing or mansard applications.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel b) 22 ga. G-90 hot-dipped galvanized steel<br />

c) .032 3105-H14 aluminum or equal d) .040 3105-H14 aluminum or equal<br />

Stiffening Beads<br />

The Flush Panel and Reveal Panel are available with optional stiffening beads. Stiffening beads are recommended<br />

for longer panel lengths. One, two or three beads are available.<br />

Installation<br />

<strong>PAC</strong>-<strong>CLAD</strong> Flush Panels shall be installed over a solid underlayment or over framing sections as manufactured<br />

by <strong>Petersen</strong> <strong>Aluminum</strong> Corporation. When used in a windscreen application, panels must be fastened (stitched)<br />

through side joints. Consult a local architect/engineer for requirements of local codes and conditions.<br />

Corrective Leveling<br />

<strong>Petersen</strong> Flush Panels are formed on precision roll-forming equipment that includes in-line Herr-Voss corrective<br />

levelers. Corrective leveling works to remove typical metal conditions including coil set, crowning and edge<br />

wave. In-line leveling capabilities allow us to work with source material that is "still-water" flat. The result is a<br />

panel that exhibits superior flatness. Corrective leveling is available at no extra charge. This panel is not available<br />

vented.<br />

Flush Panel**<br />

7", 11", 12” or 18" O.C. .032 aluminum<br />

1" high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel*<br />

7", 11" or 18" O.C.<br />

7", 11" or 18" O.C.<br />

7", 11" or 18" O.C.<br />

1"<br />

1"<br />

1"<br />

7", 11" or 18" O.C.<br />

07 61 00/PET<br />

BuyLine 3008<br />

Reveal Panel<br />

7", 11" or 18" O.C. .032 aluminum<br />

1" high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel<br />

1-1/2"<br />

*Limited color availability<br />

**18” O.C. available in limited applications. Consult<br />

factory for details. 12” O.C. has reduced fastening<br />

flange.<br />

1"<br />

13

14<br />

Product Features<br />

•36 Kynar Colors available in Steel<br />

•34 Kynar Colors available in aluminum<br />

•22ga or 24ga Steel available<br />

•.032 or .040 aluminum<br />

•20-year non-prorated finish warranty<br />

•Galvalume plus available<br />

•Matching Screws and Rivets<br />

•Closure Strips Available<br />

•Precut Short Lengths (2’-0” minimum)<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation has introduced the “M” and “R” exposed fastener<br />

panels in the past and has now expanded it’s panel offerings even more.<br />

We are introducing the 7.2 Rib, 7/8” and 1/2” Corrugated to the line-up. These<br />

corrugated are the most economically and architecturally attractive metal panels.<br />

<strong>Petersen</strong> has these profiles available in a wide range of on-centers and gauges to<br />

give the architect design flexibility on the project. These panels are excellent for<br />

use on walls, equipment screens, linear panels and parapet wall applications.<br />

Note: This panel is not intended for use in the construction of a metal<br />

building or structural roof applications. Please consult with <strong>Petersen</strong><br />

<strong>Aluminum</strong> regarding the application of this panel.<br />

Heifer International<br />

Little Rock, AR<br />

Owner: Heifer International<br />

Architect: Polk Stanley Rowland Curzon Porter Architects, LTD.<br />

Contractors: Ace Glass Co., Harness Roofing<br />

Color: Silver Metallic<br />

Profile: 7/8” Corrugated, M - Panels, Coping

NEW<br />

NEW<br />

M-42 Panel<br />

6"<br />

M-36 Panel<br />

?"<br />

7.2 Panel<br />

?<br />

1"<br />

42"<br />

36"<br />

36"<br />

3/4"<br />

1/2"<br />

?"<br />

NEW<br />

NEW<br />

NEW<br />

R-41 Panel<br />

13-21/32"<br />

R-36 Panel<br />

?"<br />

1/2” Corrugated<br />

2-2/3"<br />

7/8” Corrugated<br />

2-2/3"<br />

41"<br />

36"<br />

40"<br />

34.6"<br />

1"<br />

1-1/4"<br />

1/2"<br />

1/2"<br />

7/8"<br />

07 61 00/PET<br />

BuyLine 3008<br />

15

NEW<br />

NEW<br />

NEW<br />

Product Features<br />

•3 profiles available<br />

•Perforation available for ventilation<br />

(<strong>PAC</strong>-750 & <strong>PAC</strong>-850)<br />

•Roll-formed to exact lengths<br />

•Matching “J” trim available<br />

•Flush panels now available with venting.<br />

Material<br />

•36 standard colors (24 gauge steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 gauge steel)<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available(flush panel only)<br />

UL Classification<br />

•UL 580 Class 90 rated over solid substrate<br />

(steel only)<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance<br />

•Wind load testing results available<br />

Florida Building Product Approvals<br />

•<strong>PAC</strong>-850<br />

.032 <strong>Aluminum</strong>:<br />

FL Prod. Approv. #4483<br />

•Flush Panels<br />

.032 & .040 <strong>Aluminum</strong>,<br />

22 & 24 ga. Steel:<br />

FL Prod. Approv. #7547<br />

Open Air Percentages (<strong>PAC</strong> 750/850)<br />

•Half vented - 6%<br />

•Full vented - 12%<br />

These percentages are nominal and may<br />

vary per profile.<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

Florida Welcome Center<br />

Jennings, FL<br />

Owner: FL DOT<br />

General Contractor: Centex Construction<br />

Roofing Contractor: Perry Roofing Contractors<br />

Colors: Silver Metallic<br />

Profiles: Snap-Clad, Flush Panel<br />

16<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation offers a wide variety of pre-formed profiles designed for use in soffit applications.<br />

Steel is not recommended for use in vented soffit applications.<br />

<strong>PAC</strong>-750 Soffit Panels<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation offers a pre-formed soffit panel suitable for both commercial and residential<br />

use. These panels are roll-formed of .032 aluminum. Panels are 12" wide with a “vee” groove every 6" center-to-center<br />

and furnished in continuous lengths of up to 20 feet. Steel is not available in this profile.<br />

<strong>PAC</strong>-850 Soffit Panels<br />

<strong>Petersen</strong> <strong>Aluminum</strong> <strong>PAC</strong>-850 Soffit Panels utilize an innovative hook and grab interlock. These panels are<br />

roll-formed of .032 aluminum. Panels are 12" wide with a “vee” groove every 6" center-to-center and furnished<br />

in continuous lengths of up to 20 feet. Steel is not available in this profile.<br />

Soffit Venting<br />

The <strong>PAC</strong>-750 and <strong>PAC</strong>-850 Soffit Panels can be perforated to allow for air flow and under eave ventilation.<br />

Both <strong>PAC</strong>-750 and <strong>PAC</strong>-850 can come fully vented, half vented, or solid. Contact factory for information<br />

regarding open air percentage. See illustrations as an example.<br />

Soffit "J" Channel<br />

<strong>Petersen</strong> <strong>Aluminum</strong> can provide Soffit “J” Channel as trim to match any of our soffit panels. “J” Channel is<br />

available in lengths up to 12 feet in matching colors.<br />

Flush Panels<br />

The Flush Panel and Reveal Panel may be specified for use as soffit panels. They are roll-formed from .032<br />

aluminum, .040 aluminum, 24 or 22 ga. galvanized and tension-leveled to ensure flatness.<br />

Stiffener beads can be added to the Flush Panel for increased strength and aesthetics. Stiffener beads are<br />

recommended for longer panel lengths. One, two or three beads are available at no additional cost.<br />

Flush Venting<br />

The Flush Panels are available with optional venting strips. Venting is available with one or two strips.

<strong>PAC</strong>-750 Soffit<br />

12" O.C. .032 aluminum<br />

12" O.C.<br />

Flush Panel<br />

7", 11” or 12" O.C. .032 aluminum<br />

1" high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel*<br />

1"<br />

7", 11" or 12" O.C.<br />

*12” O.C. has reduced fastening flange.<br />

1"<br />

7" or 11" O.C.<br />

12" O.C.<br />

1/2"<br />

1/2"<br />

7" or 11" O.C.<br />

<strong>PAC</strong>-750 & <strong>PAC</strong>-850 are also available in vented profiles:<br />

1"<br />

half vent full vent<br />

1"<br />

<strong>PAC</strong>-850 Soffit<br />

12" O.C. .032 aluminum<br />

Soffit Reveal<br />

7" or 11" O.C. .032 aluminum<br />

1" high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel*<br />

1-1/2"<br />

*Limited color availability<br />

12" O.C.<br />

12" O.C.<br />

7" or 11" O.C.<br />

1/2"<br />

07 61 00/PET<br />

BuyLine 3008<br />

Top Photo:<br />

Kenneth Copeland Ministries<br />

Newark, TX<br />

Owner: Kenneth Copeland Ministries<br />

Roofing Contractor: Hipwell Sheet Metal<br />

Profile: Snap-Clad, Reveal Panels<br />

Color: Medium Bronze<br />

17

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation is stocking the patented<br />

ColorGard Snow Retention System. ColorGard is the only<br />

product available which will perfectly match the color of<br />

the roof. ColorGard achieves this by utilizing a strip of the<br />

actual roof material, which is then mounted directly into<br />

ColorGard for a perfect match. This strip can be cut in the<br />

field or at our factory. An architectural alternative to<br />

ColorGard is SnoFence, which uses posts and continuous<br />

rods.<br />

ColorGard utilizes the patented S-5 Clamp for its<br />

strength. The S-5 technology involves gripping the seam<br />

in such a way that there is no penetration to the panel<br />

material. S-5 utilizes round-point set screws for attachment<br />

which are speciallymade for the S-5 ColorGard or<br />

SnoFenceTM Snow Retention System. These systems<br />

eliminate minimum temperature installation requirements<br />

and messy adhesives to apply. ColorGard and SnoFence<br />

can be installed at any temperature. For more information<br />

regarding ColorGard or SnoFence please contact your local<br />

<strong>Petersen</strong> representative.<br />

CLEET- Council Law Enforcement Education & Training<br />

Ada, OK<br />

Architect: Dewberry Design Group Inc.<br />

General Contractor: Atlas General Contractors<br />

Roofing Contractor: Oklahoma Roofing and Sheet Metal, Inc.<br />

Color: Custom Color - Zinc Gray<br />

Profile: Snap-Clad & Flush Panel<br />

18

The <strong>PAC</strong> Composite Wall Panel is a caulked joint panel<br />

system utilizing a composite material comprised of a thermoplastic<br />

core bonded to aluminum skins. This panel system<br />

offers simplicity of fabrication and installation using a<br />

caulked joint. Staggered clip angles allow for non-progressive<br />

installation and adjustable reach to substructure.<br />

The “rout-and-return” fabrication provides sharp edged<br />

panels in a wide variety of shapes. Curved column cover<br />

are avilable. High gloss, andized and stone finishes are<br />

available.<br />

<strong>PAC</strong>-1000 & 2000 Series<br />

The design of the <strong>PAC</strong>-1000 and 2000 “F” Series Column<br />

Covers allows them to be installed leaving only a clean, hairline<br />

joint. The column sections are assembled using a rivnut/<br />

keyhole system to provide a tight inconspicuous vertical seam.<br />

The design of <strong>PAC</strong>-1000 and 2000 “C” and “R” Series<br />

Columns are installed leaving a small open vertical reveal<br />

where the sections meet. Backer rod and caulk are applied to<br />

the vertical reveal joint to complete the installation of our “C”<br />

Series Column Cover. For the “F” Series Column, a metal<br />

channel filler is fabricated to fit into the vertical joint, and is<br />

set in sealant.<br />

Your project may require column or section designs that are<br />

not shown here. <strong>Petersen</strong> <strong>Aluminum</strong> Corporation’s fabrication<br />

capabilities offer a great deal of flexibility and go far beyond<br />

what we can display on this page. Please contact us with<br />

your fabrication needs.<br />

Loeber Motors Mercedes Benz<br />

Lincolnwood, IL<br />

Architect: Valerio, Dewalt, Train Assoc. Inc.<br />

General Contractor: Pepper Construction<br />

Roofing Contractor: Sullivan Roofing, Inc.<br />

Color: Anodic Clear<br />

Profile: Composite Wall Panel<br />

INSIDE CORNER DETAIL<br />

BACKER ROD<br />

& SEALANT<br />

1000 Series<br />

VAPOR BARRIER<br />

ATTACHMENT CLIPS<br />

<strong>PAC</strong>-WALL<br />

INSIDE<br />

CORNER<br />

PANEL<br />

5/8" OR<br />

AS REQ'D<br />

Available in the following variations:<br />

•<strong>PAC</strong>-1000F (Flush Joint)<br />

•<strong>PAC</strong>-1000C (Caulk Joint)<br />

•<strong>PAC</strong>-1000R (Reveal Joint)<br />

2000 Series<br />

Available in the following variations:<br />

•<strong>PAC</strong>-2000F (Flush Joint)<br />

•<strong>PAC</strong>-2000C (Caulk Joint)<br />

•<strong>PAC</strong>-2000R (Reveal Joint)<br />

OUTSIDE CORNER DETAIL<br />

<strong>PAC</strong>-WALL<br />

ROUT &<br />

RETURN<br />

OUTSIDE<br />

CORNER<br />

PANEL<br />

5/8" OR<br />

AS REQ'D<br />

BACKER ROD<br />

& SEALANT<br />

VAPOR BARRIER<br />

ATTACHMENT CLIPS<br />

1" TYP.<br />

Flush Joint<br />

Caulk Joint<br />

Reveal Joint<br />

<strong>PAC</strong>-WALL<br />

PANEL<br />

1"TYP.<br />

BACKER ROD<br />

& SEALANT<br />

07 61 00/PET<br />

BuyLine 3008<br />

SOFFIT DETAIL<br />

VAPOR BARRIER<br />

ATTACHMENT CLIPS<br />

SHIM AS REQ'D<br />

19

FM<br />

APPROVED<br />

FM<br />

APPROVED<br />

<strong>PAC</strong>-Continuous Cleat Coping<br />

The innovative design of the continuous cleat permits<br />

the installation of a sloped coping cap over extra wide<br />

walls. The support of the cleat substantially reduces sagging,<br />

which can induce ponding and the possibility of leaks.<br />

For further weather tightness, neoprene strips are factory<br />

applied to each hold down cleat (see illustration).<br />

Factory-supplied fasteners accompany each coping order<br />

to assure proper attachment of the cleats to the wood nailer.<br />

Field-crimping on the inside leg of the coping to the<br />

inside hold down cleat completes the installation.<br />

•FM Rated for .063 and .050 aluminum, 22 ga. and 24<br />

ga. steel<br />

•Available in Kynar 500 painted and anodized finishes<br />

•Available in up to 12’-0” lengths<br />

•For longer lengths, consult factory<br />

•Available with enhanced FACTORY MUTUAL Ratings up to<br />

FM-I80<br />

•Galvalume Plus available<br />

•ANSI/SPRI ES-1 Approved<br />

Gutter Splice System: TITE-LOC Coping<br />

(patent no. 5,289,662)<br />

The system features a built-in sealing mechanism<br />

incorporated into the splice plate (see illustration). This<br />

proprietary feature not only adds rigidity, but insures a<br />

weathertight joint. Proper installation requires that the<br />

hold-down cleat be attached with four top fasteners and<br />

two face fasteners, spaced as shown. TITE-LOC coping<br />

may be specified with either a neoprene compression pad<br />

or a metal compression strip.<br />

•Available for wall sizes 6" - 16".<br />

•Made 3/4" larger than the wall to compensate for<br />

membranes and inconsistencies.<br />

•FACTORY MUTUAL TESTED (see cleat diagram & wind<br />

uplift chart).<br />

Virginia Beach Central Library<br />

Virginia Beach, VA<br />

Architect: City of Virginia Beach<br />

Roofing Contractor: Roof Systems of Virginia<br />

Color: Stone White<br />

Products: <strong>PAC</strong> Continuous Cleat Coping<br />

20<br />

<strong>PAC</strong>-CONTINUOUS<br />

CLEAT COPING<br />

PATENT # 6216408<br />

Wind Uplift<br />

COPING CAP<br />

NEOPRENE STRIPS<br />

SPLICE PLATE<br />

INSIDE<br />

CONTINUOUS<br />

CLEAT<br />

OUTSIDE<br />

CONTINUOUS<br />

CLEAT<br />

<strong>PAC</strong>-CONTINUOUS<br />

CLEAT COPING<br />

WALL FM FM FM FM FM<br />

MATERIAL WIDTH I-90 I-105 I-120 I-165 I-180<br />

24 ga. Steel 16" Max •<br />

22 ga. Steel 16" Max • •<br />

22 ga. Steel 15" Max • • •<br />

.050, .063 Alum. 24" Max • •<br />

.050, .063 Alum. 16" Max • • • •<br />

.050, .063 Alum. 15" Max • • • • •<br />

TITE-LOC COPING<br />

RENE<br />

NEOP<br />

SEALA<br />

NT STRIP<br />

(factory applied)<br />

STRENGTHENING<br />

BEAD<br />

ROOFI NG<br />

ILS NA<br />

NEOPRENE<br />

COMPRESSION<br />

PAD<br />

HOLD DOWN<br />

CLE AT<br />

SNAP-ON<br />

NGCOPI<br />

SPLI<br />

CE<br />

PLATE<br />

A<br />

TITE-LOC<br />

COPING<br />

A<br />

SPLICE PLATE TO<br />

MATCH COPING<br />

3º PITCH<br />

NEOPRENE<br />

SEALANT STRIP<br />

(factory applied)<br />

OUTSIDE INSIDE<br />

CONTINUOUS CONTINUOUS<br />

HOLD DOWN HOLD DOWN<br />

CLEAT CLEAT REAR HEM LEFT OPEN<br />

FOR FIELD-CRIMPING<br />

NOMINAL WALL SIZE<br />

C<br />

1/2"<br />

SPLICE PLATE TO<br />

MATCH COPING<br />

HOLD<br />

DOWN<br />

CLEAT<br />

3º PITCH<br />

STRENGTHENING<br />

BEAD<br />

NOMINAL WALL SIZE<br />

I 60 = 418 lbs. of upward pressure<br />

I 90 = 628 lbs. of upward pressure<br />

WALL GAUGE FACTORY FACTORY<br />

WIDTH MUTUAL - I 60 MUTUAL - I 90<br />

6" - 12" 24 ga., 22 ga.,<br />

.050,.063, .080, .125 • •<br />

12" - 16" .050, .063, .080, .125 • •<br />

Wind Uplift<br />

*Call for test results and hold down cleat spacing.<br />

C<br />

NEOPRENE SEALANT<br />

STRIP (factory applied)<br />

NEOPRENE<br />

COMPRESSION PAD<br />

COPING<br />

B<br />

B

FM<br />

APPROVED<br />

Fuji Film, Hanover Park, IL<br />

Owner: Industrial Developments International<br />

Architect: Formations Architects & Planners<br />

and Sparks Architects Inc.<br />

General Contractor: Kajima Construction<br />

Services, Inc.<br />

Roofing Contractor: Sullivan Roofing Inc.<br />

Color: Clear Anodized<br />

Products: Flush Panel Soffit &<br />

Custom <strong>Aluminum</strong><br />

Fascia System<br />

Single-Ply Roofing:<br />

<strong>PAC</strong>-1-PLY Gravel Stop<br />

The <strong>PAC</strong>-1-PLY Gravel Stop is designed for use with all<br />

single-ply roofing systems. The <strong>PAC</strong> System is non-penetrating<br />

and designed for quick and sure installation. <strong>PAC</strong>-<br />

1-PLY Gravel Stops achieve an FM I-90 rating with a maximum<br />

face dimension of 8”. Minimum gauges required<br />

for the I-90 rating are .063 aluminum and 24 ga. steel.<br />

<strong>PAC</strong>-1-PLY Gravel Stops are available in 25 standard<br />

<strong>PAC</strong>-<strong>CLAD</strong> Kynar 500 ® colors or may be anodized (clear<br />

or bronze shades) or custom finished.<br />

Gravel stops are pre-fabricated from heavy gauge .040<br />

- .125 aluminum as well as 22 ga. and 24 ga. <strong>PAC</strong>-<strong>CLAD</strong><br />

galvanized steel.<br />

Maximum section lengths are 12’. Each section is furnished<br />

with a 6” wide splice plate with matching finish.<br />

A continuous galvanized cant dam is provided with each<br />

section.<br />

THRIFT-LOC Gravel Stop<br />

(patent no. 4549377)<br />

The THRIFT-LOC Gravel Stop features a heavier,<br />

stronger compression than traditional Type-F Gravel Stops.<br />

Its design features a more efficient use of metal and it is<br />

our most economical gravel stop. THRIFT-LOC Gravel<br />

Stops achieve an FM I-90 rating with a maximum face<br />

dimension of 5”. Minimum gauges required for the I-90<br />

rating are .040 aluminum and 24 ga. steel.<br />

This system is available in .040 - .063 aluminum as<br />

well as 24 ga. and 22 ga. steel in lengths up to 12'.<br />

Built-Up/Modified Roofing:<br />

Type-F Gravel Stop<br />

The Type-F Gravel Stops have design characteristics<br />

similar to extruded gravel stops, but with much greater<br />

design flexibility. Face and head dimensions are variable<br />

and can be angled at varying degrees. This system is<br />

available in .032 - .125 aluminum as well as 24 ga. and<br />

22 ga. steel in lengths up to 12'.<br />

Gravel Stop Accessories<br />

Accessories are available for all of our gravel stops:<br />

•Mitred/quick-locked corners<br />

•Extenders<br />

•End caps<br />

•Ledge caps<br />

•Other<br />

<strong>PAC</strong>-1-PLY GRAVEL STOP<br />

GRAVEL STOP<br />

SPLICE PLATE<br />

NEOPRENE<br />

COMPRESSION<br />

STRIP<br />

CONTINUOUS<br />

CANT DAM<br />

THRIFT-LOC GRAVEL STOP<br />

TYPE-F GRAVEL STOP<br />

MITRED CORNER<br />

GRAVEL STOP<br />

SPLICE PLATE<br />

MEMBRANE<br />

CONTINUOUS<br />

CANT DAM<br />

CONTINUOUS<br />

HOLD DOWN CLEAT<br />

6" COVER PLATE<br />

GRAVEL STOP<br />

<strong>PAC</strong>-1-PLY GRAVEL STOP<br />

STANDARD<br />

FACE<br />

DIMENSIONS<br />

5"<br />

7"<br />

9"<br />

*OTHER SIZES MADE<br />

TO YOUR SPECIFICATIONS<br />

THRIFT-LOC GRAVEL STOP<br />

STANDARD<br />

FACE<br />

DIMENSIONS<br />

5"<br />

7"<br />

9"<br />

A<br />

*OTHER SIZES MADE<br />

TO YOUR SPECIFICATIONS<br />

TYPE-F GRAVEL STOP<br />

A<br />

07 61 00/PET<br />

BuyLine 3008<br />

4"<br />

GRAVEL STOP<br />

SPLICE PLATE<br />

CONTINUOUS<br />

CANT DAM<br />

21

22<br />

General Considerations<br />

The following is a summary of conditions and considerations<br />

that we consider important to the design<br />

and specification of <strong>PAC</strong>-<strong>CLAD</strong> PANEL projects. For more<br />

specific information concerning your projects, please<br />

contact us directly on our technical service line: 1-800-<br />

<strong>PAC</strong>-<strong>CLAD</strong>. We will gladly provide you with any additional<br />

information you may need.<br />

Finishes<br />

<strong>PAC</strong>-<strong>CLAD</strong> PANELS are available as standard with a<br />

full strength Kynar 500® or Hylar 5000® finish.<br />

Please refer to the color charts on pages 7 & 9 for<br />

color selection. Samples and photo-accurate color charts<br />

are available for your assistance. Other finishes available<br />

include <strong>PAC</strong> 300 Clear and <strong>PAC</strong> 500 Bronze<br />

anodized coatings; Siliconized polyester and acrylics.<br />

Special Colors<br />

Special colors are available for most applications of<br />

greater than 10,000 square feet and may be applied<br />

to either aluminum or G-90 galvanized steel. Contact<br />

<strong>Petersen</strong> for information concerning relative costs and<br />

availability.<br />

Installation<br />

Special care must be taken to insure that panels are<br />

installed over a flat substrate. For roofing applications,<br />

panels typically must be installed over 5/8” or 3/4”<br />

plywood decking with 30# roofing felt (minimum) horizontally<br />

overlayed from the eave to ridge. It is recommended<br />

that clips be installed on 18” centers for all<br />

applications except Snap-Clad (consult specific UL<br />

Construction assemblies for clip spacing). Consult a<br />

local architect/engineer for requirements of local codes<br />

and conditions.<br />

Many well known buildings, designed by some of<br />

the world’s leading architects, are roofed with TCS.<br />

The corporate headquarters of PPG Industries, Coca-<br />

Cola, Square D, Pitney-Bowes, Procter and Gamble,<br />

Bristol-Myers, IBM and General Re-Insurance Company<br />

are among a few of the commercial, institutional and<br />

industrial buildings protected by TCS Roofs.<br />

What is TCS?<br />

TCS is a product that weathers upon exposure to<br />

atmospheric conditions. In most areas it attains a<br />

Accessories<br />

Most applications require additional metalwork<br />

including fascia, storefront trim, copings, gravel stops,<br />

downspouts, etc. Such metalwork may be specified for<br />

fabrication by manufacturer or for fabrication from flat<br />

sheet as provided by manufacturer. Flashings fabricated<br />

from <strong>PAC</strong>-<strong>CLAD</strong> flat sheet are fully covered under<br />

<strong>Petersen</strong>’s 20 year finish warranty. <strong>PAC</strong>-<strong>CLAD</strong> flat sheet<br />

provides an exact color match to <strong>PAC</strong>-<strong>CLAD</strong> PANELS.<br />

Lengths<br />

All panels are custom cut-to-length before roll-forming<br />

and are available in lengths up to 40’. Minimum<br />

length is 4’-0”. Lengths are accurate to 1/4”. Custom<br />

cut-to-length is available at no up-charge and helps to<br />

improve project economy. Consult factory for lengths<br />

over 55 feet.<br />

Panel Widths<br />

Most of our <strong>PAC</strong>-<strong>CLAD</strong> Panels are available in nonstandard<br />

on-center dimensions. Contact <strong>Petersen</strong><br />

<strong>Aluminum</strong> for product availability and cost. <strong>PAC</strong>-<strong>CLAD</strong><br />

panel standard widths are nominal and could vary.<br />

Pitch<br />

TITE-LOC Panels are designed for a roof pitch of<br />

1/2:12 or greater. SNAP-<strong>CLAD</strong> Panels have been<br />

designed to be installed on applications as low as 2:12<br />

pitch. Integral Panels and Snap-On Panels have been<br />

designed for a minimum 3:12 pitch. Greater pitch may<br />

be required in snow country and in areas of extreme<br />

climate conditions.<br />

Fire Ratings<br />

<strong>PAC</strong>-<strong>CLAD</strong> Panels have been evaluated by<br />

Underwriter’s Laboratories for inclusion in a variety of<br />

fire-rated “P-Assemblies” and are classified in section<br />

CETW of the UL Fire Resistance Directory - Vol. 1.<br />

Several panel assemblies have been evaluated as Class<br />

pleasing slate gray color. The core metal, however,<br />

remains unaffected due to the sacrificial characteristics<br />

of the terne coat.<br />

Terne-coated stainless steel, or TCS II, is type 304<br />

stainless steel coated both sides with terne alloy (50%<br />

tin, 50% zinc). It is highly corrosion resistant which<br />

makes it an ideal roofing or coping material.<br />

<strong>Petersen</strong> <strong>Aluminum</strong> is a distributor of the following<br />

Follansbee TCS materials:<br />

A fire rated. Contact <strong>PAC</strong> for complete information on<br />

components and assemblies.<br />

Oil Canning<br />

All <strong>Petersen</strong> material is prime quality aluminum and<br />