Brick Shapes - Glen-Gery Brick

Brick Shapes - Glen-Gery Brick

Brick Shapes - Glen-Gery Brick

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Brick</strong> <strong>Shapes</strong>

One main reason for brick’s popularity with architects, designers and<br />

builders is its ability to adapt to design criteria. It can be shaped<br />

and used in a wide variety of traditional and contemporary detailing –<br />

from arches to sills, copings, columns and treads. <strong>Glen</strong>-<strong>Gery</strong> manufactures<br />

a complete selection of brick shapes to match its comprehensive line of<br />

extruded, molded, and handmade brick.<br />

This catalog illustrates the standardized shapes that are available from<br />

<strong>Glen</strong>-<strong>Gery</strong>’s manufacturing facilities. Their availability may differ from plant to<br />

plant depending on the size and type of brick produced. Unit identification,<br />

size availability and dimensioning are noted on each shape type, making the<br />

ordering process simple and straightforward. For these standard shapes, no<br />

drawings are necessary; simply call your <strong>Glen</strong>-<strong>Gery</strong> representative with the<br />

ordering information.<br />

While these shapes can accomplish a wide variety of architectural<br />

detailing, <strong>Glen</strong>-<strong>Gery</strong> realizes that the creative process may require shapes<br />

that do not fall within standardized design. To meet this need, <strong>Glen</strong>-<strong>Gery</strong><br />

<strong>Brick</strong> is equipped to produce customized shapes that conform to the<br />

designer’s specifications. Custom shapes can be produced in either<br />

extruded, molded or handmade brick types, although some textures may<br />

not be available. Because of the technical expertise necessary to produce<br />

these custom shapes, it is important to consult with a <strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong>work<br />

Design Center or technical advisor for the most practical and cost-effective<br />

method of achieving the desired shape.<br />

<strong>Glen</strong>-<strong>Gery</strong>’s network of Design Advisors are available to coordinate<br />

the design and production of custom brick shapes. Please contact them<br />

early in the design stage so that all practical options can be explored.<br />

INTRODUCTION 1<br />

TECHNICAL INFORMATION 2-3<br />

<strong>Brick</strong>work Design Services 3<br />

WATER TABLES 4-9<br />

On-the-flat 5-7<br />

Rowlock 8-9<br />

SILLS, COPINGS, AND TREADS 10-13<br />

Sills 11-12<br />

Copings 12-13<br />

Treads 13<br />

CORNERS, LIPPED, AND RADIALS 14-19<br />

Corners 14-15<br />

Lipped 15<br />

Radials 16-19<br />

ARCHES 20-21<br />

8-SQUARE SHAPES 22<br />

COATED BRICK SHAPES 23<br />

CUSTOM SHAPES 24<br />

1

2<br />

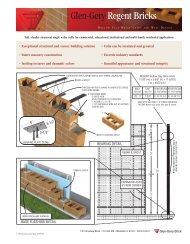

Technical and Specification Information<br />

G<br />

len-<strong>Gery</strong> standardized shapes can be easily ordered by following<br />

the established format. An accurate specification should include<br />

the number of pieces, proper shape identification, brick size,<br />

brick type and color range, as described in this section. Your <strong>Glen</strong>-<strong>Gery</strong><br />

representative will be glad to answer any questions or provide more<br />

detailed information on standardized shapes, custom shapes, or other<br />

aspects of brickwork design and detailing.<br />

Position of <strong>Brick</strong> in the Wall<br />

Interesting brickwork design<br />

effects can be achieved by placing<br />

brick in other than the normal<br />

stretcher position, as illustrated<br />

below. Regardless of how the<br />

brick is installed in the wall, size<br />

dimensions (thickness, height<br />

and length of the unit) are always<br />

assigned from the stretched position.<br />

Stretcher<br />

t<br />

Rowlock<br />

Sailor<br />

l<br />

t<br />

h<br />

t<br />

h<br />

Rowlock<br />

Stretcher<br />

<strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong> Sizes<br />

for Standard <strong>Shapes</strong><br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

*HMOS<br />

*Handmade Oversize<br />

l<br />

l<br />

h<br />

h<br />

l<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

Header<br />

Soldier<br />

t h l<br />

l<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

t<br />

8"<br />

t<br />

h<br />

t<br />

7-5/8"<br />

8"<br />

7-5/8"<br />

7-5/8"<br />

h<br />

l<br />

11-5/8"<br />

8-1/2"

<strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong> Types<br />

Extruded<br />

ETD<br />

Molded<br />

M<br />

Handmade<br />

HM<br />

Glazed<br />

GL<br />

Shape Identification<br />

W – Water Table<br />

H – Header<br />

S – Stretcher<br />

EX – External<br />

IN – Internal<br />

R – Rowlock<br />

ST – Starter<br />

LT – Left<br />

RT – Right<br />

SL – Sill<br />

CO – Coping<br />

T – Tread<br />

RA – Radial<br />

LP – Lipped<br />

O – Octagon<br />

<strong>Brick</strong> Colors & Textures<br />

<strong>Glen</strong>-<strong>Gery</strong> provides a wide<br />

selection of brick colors including<br />

ranges of white, buff, grey, red,<br />

and brown in both through-thebody<br />

and sand finished brick.<br />

Glazed and claycoat brick are<br />

available in standard colors as<br />

well as an unlimited range of<br />

custom colors. Custom colors often<br />

require a minimum order. More than<br />

thirty different textures are available<br />

ranging from architectural smooth<br />

and glazed to a rough bark finish.<br />

Availability of color and texture<br />

varies from plant to plant depending<br />

on the type of brick produced.<br />

Coring<br />

Coring of standardized brick<br />

shapes is a plant option. Any coring<br />

requirements to these shapes<br />

places them into a custom shape<br />

category – requiring drawings.<br />

HB – Hingebrick<br />

8SQ – Eight Square<br />

K – Kerfed<br />

FA – Flat Arch<br />

(or) – Requires Choice<br />

x/y – Unit serves both functions<br />

1-1/1 – Specific unit size<br />

Throughout this catalog shaded areas denote finished faces.<br />

For Example<br />

W1- R-ST-(LT or RT) Requires that left or right be specified<br />

for the shape.<br />

Indicates a starter shape.<br />

Identifies a rowlock position.<br />

Identifies a specific watertable shape.<br />

Designates a watertable shape.<br />

Shape Specification<br />

The following information is<br />

required when ordering shapes<br />

from this catalog.<br />

Please check with your <strong>Glen</strong>-<strong>Gery</strong><br />

representative to ensure that the<br />

standardized shape & size<br />

requested is available in the<br />

specified type and color.<br />

500 W1-R-ST-RT ECONOMO ETD FALL GREY<br />

# pieces Shape ID <strong>Brick</strong> Size <strong>Brick</strong> Type <strong>Brick</strong> Color<br />

<strong>Glen</strong>-<strong>Gery</strong> Design Advisors<br />

share their expertise.<br />

Since its founding a century ago,<br />

<strong>Glen</strong>-<strong>Gery</strong> has been committed<br />

to providing high quality products<br />

and professional services to the<br />

design/builder community.<br />

Our team of Design Advisors fulfill<br />

this promise by offering practical<br />

advice, valuable insights and useful<br />

recommendations. As professional<br />

engineers, they have a complete<br />

understanding of the technical<br />

applications, requirements and<br />

considerations for proper brickwork<br />

design. Some of their many areas<br />

of expertise include preventing<br />

water penetration, custom shape<br />

design, differential movement and<br />

exterior paving with brick.<br />

As a service to clients, <strong>Glen</strong>-<strong>Gery</strong><br />

Design Advisors are also available<br />

to consult on plan reviews and<br />

perform on-site field investigations.<br />

These complimentary services are<br />

provided to the professional design<br />

and construction community to<br />

underscore <strong>Glen</strong>-<strong>Gery</strong>’s dedication<br />

to the promotion of excellence in<br />

brickwork design.<br />

3

4<br />

On-the-flat Water Table<br />

Systems<br />

There are two types of<br />

on-the-flat water table<br />

systems based on the<br />

brick position in the wall.<br />

1) Water table in the header<br />

position (H).<br />

2) Water table in the stretcher<br />

position (S).<br />

Each system is available<br />

with companion exterior<br />

and interior corners.<br />

Rowlock Water Table<br />

Systems<br />

1) Water table in the rowlock<br />

brick position (R).<br />

In this application, rowlock<br />

water tables have been<br />

rotated to the header<br />

position (H).<br />

Water tables can also be<br />

turned upside down to<br />

achieve a cornice detail.<br />

H<br />

R<br />

H<br />

H<br />

S

Water Tables<br />

owlock and on-the-flat<br />

water tables, once used to<br />

reduce water penetration, are now<br />

used by architects and designers to<br />

achieve decorative design details.<br />

These details can range from the<br />

use of a single style<br />

for simplicity to a<br />

combination of<br />

styles to achieve<br />

highly ornate brickwork.<br />

In addition to<br />

their traditional use,<br />

these shapes can be used to add<br />

dimension to flat walls, rotated to<br />

form door and window jambs, or<br />

inverted to form cornice brickwork.<br />

Continuity of design can also be<br />

transferred into the landscape<br />

by using the water tables as caps<br />

for walls or edging accents for<br />

walkways.<br />

W1-H<br />

R<br />

W1-H<br />

1-3/4”<br />

1-3/4”<br />

1-3/4”r<br />

1-3/4”r<br />

A<br />

A<br />

*W1-H-EX<br />

*W1-S-EX<br />

h<br />

l<br />

ON-THE-FLAT<br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS<br />

Water Tables on-the-flat<br />

t<br />

*W1-H-IN<br />

*W1-S-IN<br />

h<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

W1-S<br />

W1-S<br />

l<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

t<br />

*NOTE:<br />

The header and<br />

stretcher shapes of<br />

the W1-EX and W1-IN<br />

can be used with either<br />

the W1-H or W1-S.<br />

t h l A<br />

8"<br />

7-5/8"<br />

8"<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

8-1/2"<br />

1-3/4”r<br />

1-3/4”r<br />

1/2"<br />

1/2"<br />

1"<br />

1"<br />

1-7/8"<br />

1-7/8"<br />

1"<br />

A<br />

A<br />

5

6<br />

Water Tables on-the-flat<br />

W2-H<br />

h<br />

W2-H-EX<br />

W2-S-EX<br />

h<br />

t<br />

ON-THE-FLAT<br />

STANDARD<br />

l<br />

l<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS<br />

t<br />

W2-H-IN<br />

W2-S-IN<br />

h<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

1-1/2"r<br />

W2-S<br />

h<br />

l<br />

A<br />

t<br />

l<br />

t<br />

t h l A<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

8"<br />

7-5/8"<br />

8"<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

8-1/2"<br />

3/4"<br />

3/4"<br />

1-1/4"<br />

1-1/4"<br />

2-1/8"<br />

2-1/8"<br />

1-1/4"<br />

1-1/2"r<br />

A<br />

W3-H<br />

h<br />

W3-H-EX<br />

W3-S-EX<br />

h<br />

t<br />

ON-THE-FLAT<br />

STANDARD<br />

l<br />

l<br />

135°<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS<br />

t<br />

W3-H-IN<br />

W3-S-IN<br />

h<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

1-1/2"<br />

W3-S<br />

h<br />

l<br />

A<br />

t<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

l<br />

t<br />

t h l A<br />

8"<br />

7-5/8"<br />

8"<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

8-1/2"<br />

3/4"<br />

3/4"<br />

1-1/4"<br />

1-1/4"<br />

2-1/8"<br />

2-1/8"<br />

1-1/4"<br />

135°<br />

A

7<br />

Water Tables on-the-flat<br />

W4-H<br />

h<br />

t<br />

A<br />

1-3/4"<br />

1-1/16"r<br />

1-5/16"r<br />

l<br />

W5-H<br />

W5-S<br />

HMOS ONLY<br />

3/8"<br />

3/8"<br />

1"<br />

8-1/2"<br />

4"<br />

2-3/4"<br />

4"<br />

2-3/4"<br />

8-1/2"<br />

W4-S<br />

A<br />

t<br />

h<br />

l<br />

W4-H-IN<br />

W4-S-IN<br />

t<br />

l<br />

h<br />

W4-H-EX<br />

W4-S-EX<br />

t<br />

l<br />

h<br />

W6-H-IN<br />

W6-S-IN<br />

4"<br />

8-1/2"<br />

2-3/4"<br />

4"<br />

8-1/2"<br />

2-3/4"<br />

W6-H-EX<br />

W6-S-EX<br />

4"<br />

8-1/2"<br />

2-3/4"<br />

W5-H-IN<br />

W5-S-IN<br />

4"<br />

8-1/2"<br />

2-3/4"<br />

W5-H-EX<br />

W5-S-EX<br />

1-3/8"r<br />

W6-H HMOS ONLY<br />

1/2"<br />

5/16"<br />

8-1/2"<br />

2-3/4"<br />

4"<br />

1-3/8"r<br />

1-15/16"r<br />

2-1/4"<br />

W5-S-ST-LT(SHOWN)<br />

W5-S-ST-RT<br />

4"<br />

2-3/4"<br />

8-1/2"<br />

6"<br />

2-1/4"<br />

W6-S-ST-LT(SHOWN)<br />

W6-S-ST-RT<br />

4"<br />

2-3/4"<br />

8-1/2"<br />

6"<br />

1-15/16"r<br />

W6-S<br />

4"<br />

2-3/4"<br />

8-1/2"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

8"<br />

7-5/8"<br />

8"<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

8-1/2"<br />

t h l A<br />

3/8"<br />

3/8"<br />

1-1/4"<br />

1-1/4"<br />

3/8"<br />

ON-THE-FLAT<br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS

8<br />

Water Tables rowlock<br />

W7-R<br />

t<br />

h<br />

ROWLOCK<br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS<br />

l<br />

W8-R<br />

t<br />

h<br />

W9-R<br />

t<br />

h<br />

l<br />

l<br />

W10-R<br />

t<br />

h<br />

l<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

1-3/4"<br />

2"<br />

2-3/8"<br />

2"<br />

A<br />

3/4"<br />

B<br />

t h l A B C D E F<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

1-3/4"r<br />

135°<br />

8"<br />

7-5/8"<br />

8"<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

8-1/2"<br />

2"r<br />

2-3/8" t<br />

C<br />

D<br />

2-1/8"r<br />

2-1/8"r<br />

1-7/8"<br />

1-7/8"<br />

1-7/8"<br />

1-7/8"<br />

1-7/8"<br />

1-7/8"<br />

2-1/4"<br />

W7-R-EX-l<br />

W7-R-EX-t<br />

t<br />

7/8"<br />

7/8"<br />

7/8"<br />

7/8"<br />

7/8"<br />

7/8"<br />

l<br />

W8-R-EX-l<br />

W8-R-EX-t<br />

t<br />

l<br />

W9-R-EX-l<br />

W9-R-EX-t<br />

l<br />

W10-R-EX-l<br />

W10-R-EX-t<br />

t<br />

1-1/4"<br />

t<br />

l t<br />

t<br />

t<br />

1-1/4"<br />

1-1/4"<br />

1-1/4"<br />

1-1/4"<br />

1-1/4"<br />

1-1/4"<br />

1-5/8" 3/8"<br />

3/8"<br />

3/8"<br />

3/8"<br />

3/8"<br />

3/8"<br />

3/8"<br />

3/4"<br />

3/4"<br />

3/4"<br />

3/4"<br />

3/4"<br />

3/4"<br />

3/4"<br />

1-1/8"<br />

W7-R-IN-l<br />

W7-R-IN-t<br />

t<br />

l<br />

W8-R-IN-l<br />

W8-R-IN-t<br />

t<br />

l<br />

W9-R-IN-l<br />

W9-R-IN-t<br />

t<br />

l<br />

W10-R-IN-l<br />

W10-R-IN-t<br />

t<br />

l<br />

t<br />

t<br />

t<br />

t<br />

Table at left refers to isometric drawings<br />

W7-R through W12-R.

W11-R<br />

t<br />

h<br />

l<br />

W12-R<br />

t<br />

h<br />

l<br />

W13-R<br />

4"<br />

2-3/4"<br />

8-1/2"<br />

W14-R<br />

4"<br />

2-3/4"<br />

8-1/2"<br />

6-3/4"<br />

5-3/4"<br />

2-3/4"<br />

2-3/4"<br />

1/2"<br />

1/2"<br />

E<br />

3/4"<br />

F<br />

HMOS ONLY<br />

3/8"<br />

1-5/8"<br />

2-3/4"r<br />

2-1/4"r<br />

2"r<br />

W13-R-ST-LT(SHOWN)<br />

W13-R-ST-RT<br />

1/2"<br />

4"<br />

3/4"<br />

4"<br />

8-1/2"<br />

1-1/2"r<br />

W11-R-EX-l<br />

W11-R-EX-t<br />

t<br />

1-1/2"r<br />

1-1/4"r<br />

2-1/2"<br />

6"<br />

l<br />

W12-R-EX-l<br />

W12-R-EX-t<br />

t<br />

l<br />

W13-R-EX-8 1 /2"<br />

W13-R-EX-4"<br />

W14-R-EX-8 1 /2"<br />

W14-R-EX-4"<br />

t<br />

4"<br />

t<br />

8-1/2"<br />

8-1/2"<br />

t<br />

4"<br />

4"<br />

W14-R-ST-LT(SHOWN)<br />

W14-R-ST-RT<br />

4"<br />

4"<br />

8-1/2"<br />

Water Tables rowlock<br />

W11-R-IN-l<br />

W11-R-IN-t<br />

t<br />

l<br />

W12-R-IN-l<br />

W12-R-IN-t<br />

t<br />

l<br />

W13-R-IN-8 1 /2"<br />

W13-R-IN-4"<br />

4"<br />

8-1/2"<br />

t<br />

t<br />

4"<br />

W14-R-IN-8 1 /2"<br />

W14-R-IN-4"<br />

4"<br />

1-1/4"<br />

6"<br />

8-1/2"<br />

4"<br />

9

10<br />

Sill Systems<br />

Sills are used to protect the<br />

brick masonry below a window<br />

or door opening from water<br />

penetration. Their design<br />

forces water away from these<br />

critical areas. These shapes<br />

are available with companion<br />

left and right starters. When<br />

ordering these starters,<br />

please specify left or right.<br />

Coping Systems<br />

Copings form a cap on top of<br />

a wall that protects the brick<br />

masonry below from water<br />

penetration. Their design forces<br />

water to run off while exposing<br />

a minimum number of mortar<br />

joints. These shapes and their<br />

companion exterior/ interior<br />

corners and starters are<br />

available in sizes that cap<br />

walls constructed of 1-3 wythes<br />

of brick.<br />

Tread Systems<br />

Treads are designed with<br />

curves that add safety and<br />

beauty to a stairway. They are<br />

available in 3-5/8" and 7-5/8"<br />

units (4" and 8-1/2" for HMOS)<br />

along with their companion<br />

corner units.

Sills, Copings,<br />

and Treads<br />

T<br />

he basic function of copings<br />

and sills is to reduce the<br />

potential for water penetration. This<br />

is easily and attractively accomplished<br />

with a variety of <strong>Glen</strong>-<strong>Gery</strong><br />

brick shapes. Their profiles, whether<br />

SL1-3 5 /8"<br />

SL1-7 5 /8"<br />

3-1/4"<br />

5-3/4"<br />

SL2 7-5/8"<br />

3-1/4"<br />

SL3<br />

4-1/8"<br />

4-3/4"<br />

3-5/8"<br />

2-1/4"<br />

6-1/8"<br />

7-5/8"<br />

6-3/8"<br />

7-5/8"<br />

2-1/4"<br />

1/2"<br />

1-1/16"r<br />

1-5/8"r<br />

SL1-ST-(LT OR RT)-3 5 /8"<br />

SL1-ST-(LT OR RT)-7 5 /8"<br />

angular or curvilinear, add distinctive<br />

detailing to wall caps, windows, and<br />

door openings. Tread shapes are<br />

manufactured to properly finish brick<br />

steps and other paving applications.<br />

5-3/4" 7-5/8"<br />

3-5/8"<br />

SL2-ST-(LT OR RT)<br />

3-1/4"<br />

7-5/8"<br />

SL3-ST-(LT OR RT)<br />

4-1/8"<br />

4-3/4"<br />

6-3/8"<br />

7-5/8"<br />

6-1/8"<br />

1/2"<br />

SL1-EX<br />

5-3/4”<br />

2-1/4”<br />

1 OR 2 COURSE STARTERS<br />

AVAILABLE AS CUSTOM<br />

SHAPES (DRAWINGS REQUIRED)<br />

1 OR 2 COURSE STARTERS<br />

AVAILABLE AS CUSTOM<br />

SHAPES (DRAWINGS REQUIRED)<br />

2-1/4”<br />

11

8"<br />

O3<br />

12<br />

Sills and Copings<br />

SL4<br />

t<br />

*MAX.<br />

11-5/8"<br />

2"<br />

*Length is variable and must be specified.<br />

CO2<br />

t<br />

h<br />

CO3<br />

3-1/8" 3-1/8"<br />

F<br />

CO1<br />

t<br />

l<br />

h<br />

2"<br />

135°<br />

135°<br />

t<br />

l<br />

1-3/4"r 1-3/4"r<br />

3-5/8"<br />

FF<br />

t l<br />

t l<br />

t l<br />

l<br />

3-5/8"<br />

A<br />

CO1-EX/IN<br />

t<br />

CO2-ST<br />

3-5/8" 3-5/8"<br />

3-1/8"<br />

r<br />

3-1/8" 3-1/8"<br />

CO2-EX/IN<br />

t<br />

l<br />

SL4-ST-(LT OR RT)<br />

CO3-ST-(LT OR CO3-ST-(LT RT) OR CO3-EX<br />

RT)<br />

FF<br />

CO3-ST-(LT OR RT)<br />

F<br />

CO1-ST<br />

t<br />

t l<br />

t l<br />

l<br />

3-1/8”<br />

t l<br />

3-5/8"<br />

CO1<br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS<br />

3-5/8" 3-5/8"<br />

CO2<br />

SL4<br />

STANDARD<br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS<br />

3-5/8”<br />

CO3<br />

8"<br />

7-5/8"<br />

8"<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

8-1/2"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

t h<br />

1-13/16"<br />

1-13/16"<br />

1-13/16"<br />

1-13/16"<br />

1-13/16"<br />

1-13/16"<br />

2"<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

t l r A<br />

3-1/8”<br />

STANDARD<br />

MODULAR<br />

HMOS<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

3/8"<br />

3/8"<br />

3/8"<br />

3/8"<br />

3/8"<br />

3/8"<br />

3/4"<br />

t h l<br />

F<br />

8"<br />

7-5/8"<br />

8-1/2"<br />

8"<br />

7-5/8"<br />

8"<br />

CO3-IN<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

8-1/2"<br />

t l<br />

8"<br />

F<br />

7-5/8"<br />

8-1/2"

1/2"<br />

1-1/2"<br />

4"<br />

2"<br />

3/4"<br />

4-1/2"r<br />

CO4<br />

2"r<br />

1/2"<br />

1-1/2"<br />

4"<br />

2"<br />

10"<br />

T1-3 5 /8" T1-7 5 /8"<br />

2-1/4"<br />

2-1/4"<br />

7-5/8"<br />

3-5/8"<br />

7-5/8"<br />

3-5/8"<br />

7-5/8"<br />

7-1/16"<br />

8-3/4"<br />

T2-3 5 /8" T2-7 5 /8"<br />

T3-81 T3-4"<br />

/2"<br />

2-1/4"<br />

CO4<br />

CO4<br />

CO4<br />

1-1/2"<br />

1/2" 3/4" 1/2"<br />

5"r<br />

2"<br />

1-1/2"<br />

10"<br />

3/4"<br />

1/2"<br />

2"r<br />

12"<br />

2"r 3/4"<br />

2"r<br />

8-1/2"<br />

4"<br />

7"<br />

10"<br />

2"r<br />

5"r<br />

CO5<br />

5"r<br />

CO5<br />

4"<br />

CO5<br />

CO5<br />

12"<br />

4"<br />

2"<br />

12"<br />

12"<br />

10"<br />

12"<br />

10"<br />

5"r<br />

t CO4-ST t<br />

t<br />

t<br />

4-1/2"r<br />

t<br />

t<br />

4-1/2"r2"r<br />

4-1/2"r<br />

2"r<br />

5/16"<br />

4"r 1-1/4"r<br />

5/16"<br />

2"r 4"r<br />

1-1/4"r<br />

2"r<br />

5/16"<br />

4"r 1-1/4"r<br />

5/16"<br />

4"r 1-1/4"r<br />

t<br />

t<br />

5/16"<br />

8-1/2"<br />

8"<br />

CO4-ST<br />

CO4-ST<br />

CO4-ST<br />

3/8"<br />

10"<br />

CO5-ST<br />

CO5-ST<br />

CO5-ST<br />

5/16" CO5-ST<br />

t<br />

10"<br />

5/16"<br />

5/16"<br />

10"<br />

5/16"<br />

12"<br />

HMOS ONLY<br />

CO4-EX/IN<br />

CO4-EX/IN<br />

CO4-EX/IN<br />

CO4-EX/IN<br />

3-1/2"<br />

10"<br />

10"<br />

12"<br />

1-1/8"r<br />

15/16"r<br />

7/8"r<br />

12"<br />

12"<br />

3-1/2"<br />

10"<br />

6"<br />

12"<br />

5/8"r<br />

3-1/2"<br />

3-1/2"<br />

T1-CR-(LT OR RT)-3 5 /8"<br />

3-5/8"<br />

3-5/8"<br />

7-5/8"<br />

T2-CR-(LT OR RT)-3 5 /8"<br />

3/8"<br />

3-1/2"<br />

10"<br />

6"<br />

6"<br />

10"<br />

10"<br />

3-1/2"<br />

6"<br />

4"<br />

10"<br />

<br />

3-1/2" CO5-EX/IN <br />

CO5-EX/IN<br />

<br />

6" CO5-EX/IN<br />

CO5-EX/IN<br />

7-1/16"<br />

T3-CR-(LT OR RT)-4"<br />

4"<br />

3-1/2"<br />

4"<br />

6"<br />

4"<br />

6"<br />

4"<br />

12"<br />

6"<br />

4"<br />

4"<br />

7"<br />

4"<br />

4"<br />

12"<br />

Copings and Treads<br />

12"<br />

12"<br />

12"<br />

T1-CR-7 5 /8"<br />

7-5/8"<br />

T2-CR-7 5 /8"<br />

7-1/16"<br />

CO4 or CO5<br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS<br />

T3-CR-8 1 /2"<br />

7"<br />

7-5/8"<br />

7-1/16"<br />

7"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

t<br />

13

14<br />

Corner <strong>Brick</strong><br />

The octagon and hingebrick are<br />

designed to provide alternative<br />

corner treatments that do not<br />

require field cutting. The octagon<br />

brick shapes form 135° interior or<br />

exterior angles while maintaining<br />

coursing and visual continuity.<br />

The unique design of the<br />

hingebrick offers even greater<br />

design flexibility. It allows an<br />

unlimited range of angles at<br />

corners and can be adapted for<br />

use in other brickwork details.<br />

Lipped <strong>Brick</strong><br />

When used with a structurally<br />

fixed shelf angle, lipped brick<br />

provide inconspicuous, vertical<br />

expansion joints for brick masonry<br />

structures. They can also be used<br />

with loose shelf angles to form<br />

lintels above window and door<br />

openings.<br />

7/16"<br />

HB<br />

O1-EX<br />

A<br />

l<br />

t<br />

135°<br />

h<br />

t<br />

l<br />

h<br />

O1-IN<br />

A<br />

F<br />

1-11/16"r<br />

l<br />

t<br />

h<br />

135°<br />

HINGEBRICK<br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

*UTILITY<br />

HMOS<br />

* 1/3 Bond<br />

O1-EX & O1-IN<br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

*UTILITY<br />

**UTILITY<br />

HMOS<br />

*1/3 Bond **1/2 Bond<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

t h l<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

6-3/16"<br />

6"<br />

6-3/16"<br />

6"<br />

6"<br />

6"<br />

8"<br />

6-7/8"<br />

3-13/16"<br />

3-5/8"<br />

3-13/16"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

t h l A<br />

2"<br />

2"<br />

2"<br />

2"<br />

2"<br />

2"<br />

2"<br />

2-3/8"

Corners, Lipped,<br />

and Radials<br />

G<br />

len-<strong>Gery</strong>’s corner, lipped,<br />

and radial brick shapes<br />

are manufactured to provide the<br />

masonry units necessary to achieve<br />

sound brickwork detailing while<br />

offering greater design flexibility.<br />

LP1<br />

B LP1<br />

A<br />

5/8"<br />

3/4"<br />

LP1-CR-(LT OR RT) LP1-CR-(LT OR LP1-CR-(LT RT)<br />

OR RT)<br />

3/4"<br />

(BOTTOM VIEW) (BOTTOM VIEW) (BOTTOM VIEW)<br />

5/8" 5/8"<br />

(BOTTOM VIEW)<br />

5/8"<br />

B<br />

A<br />

F<br />

5/8"<br />

LP1-CR-(LT OR RT)<br />

F<br />

3/4”<br />

LP1<br />

B<br />

t<br />

h<br />

Unfinished lip<br />

5/8"<br />

5/8"<br />

unless specified<br />

F<br />

LP1-CR-(LT or RT)<br />

F<br />

A<br />

(BOTTOM VIEW)<br />

3/4"<br />

Unfinished lip<br />

unless specified<br />

LP2 t<br />

h<br />

LP2<br />

l<br />

B<br />

t<br />

h<br />

A<br />

l<br />

l<br />

C<br />

h<br />

C<br />

Unfinished lip Unfinished lip<br />

unless specified unless specified<br />

l<br />

Unfinished lip<br />

C<br />

unless specified<br />

5/8"<br />

F<br />

LP1<br />

3/4"<br />

t<br />

h<br />

3/4"<br />

3/4"<br />

h<br />

A<br />

A<br />

3/4"<br />

LP2<br />

t<br />

t<br />

l<br />

l<br />

LP1 & LP2<br />

STANDARD<br />

STANDARD MOD<br />

ENGINEER STD<br />

ENGINEER MOD<br />

ECONOMO<br />

UTILITY<br />

HMOS<br />

LP2<br />

t h<br />

5/8"<br />

3/4" 3/4"<br />

Unfinished lip Unfinished lip<br />

A<br />

unless specified 5/8" unless specified<br />

Unfinished lip<br />

unless specified<br />

5/8"<br />

Unfinished lip<br />

unless specified<br />

LP2-CR-(LT or RT)<br />

3/4"<br />

F<br />

F<br />

F<br />

Unfinished lip Unfinished lip<br />

unless specified unless specified<br />

Unfinished<br />

3/4”<br />

lip<br />

unless specified<br />

(BOTTOM VIEW)<br />

h<br />

A<br />

C<br />

l<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

t<br />

5/8"<br />

3/4"<br />

l<br />

t h l A B C<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

8"<br />

7-5/8"<br />

8"<br />

5/8"<br />

5/8" F<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

8-1/2"<br />

LP2-CR-(LT OR LP2-CR-(LT RT) LP2-CR-(LT<br />

OR RT)<br />

(BOTTOM VIEW) (BOTTOM VIEW) (BOTTOM VIEW)<br />

LP2-CR-(LT OR RT)<br />

F F<br />

(BOTTOM VIEW)<br />

2-7/8"<br />

2-7/8"<br />

2-7/8"<br />

2-7/8"<br />

2-7/8"<br />

2-7/8"<br />

3-1/4"<br />

5/8"<br />

3/4"<br />

1-5/8"<br />

1-5/8"<br />

2-1/8"<br />

2-1/8"<br />

3"<br />

3"<br />

2-1/8"<br />

F<br />

F<br />

Unfinished lip Unfinished lip<br />

unless 3/4" specified unless specified<br />

7-3/8"<br />

7"<br />

7-3/8"<br />

7"<br />

7"<br />

11"<br />

F<br />

3/4" 5/8"<br />

Unfinished lip<br />

unless specified<br />

7-7/8"<br />

F<br />

15<br />

3/4"

16<br />

Radials<br />

Radial <strong>Brick</strong><br />

Internal and external radial<br />

brick shapes, along with their<br />

companion starters, can be<br />

used to create details ranging<br />

from curtain-like walls to<br />

towering columns. These shapes<br />

are designed to form smooth,<br />

sweeping curves in brickwork<br />

without producing shadows or<br />

requiring field cuts.<br />

FPO-10436

Dimensions for <strong>Glen</strong>-<strong>Gery</strong>’s<br />

standardized radial brick<br />

are computed so that the arc<br />

length appears equal to the<br />

length of the accompanying<br />

stretcher units. They are<br />

also designed so that a<br />

whole number of brick fall<br />

within a 90° segment,<br />

eliminating the need to cut<br />

brick to achieve tangency<br />

at 90°, 180° or 270°.<br />

Other radii are available as<br />

custom shapes and require<br />

architectural drawings.<br />

PLAN VIEW<br />

RA-IN-ST & RA-IN-S<br />

PLAN VIEW<br />

RA-EX-ST & RA-EX-S<br />

Radials<br />

17

Radials<br />

18<br />

VARIES<br />

w/RADIUS<br />

r<br />

RA-IN-S<br />

RA-IN-S<br />

*STANDARD<br />

t<br />

CHORD l<br />

*STANDARD MOD<br />

*ENGINEER STD<br />

*ENGINEER MOD<br />

*ECONOMO<br />

**UTILITY<br />

*HMOS<br />

ARC l<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

l (MAX)<br />

t h l (MAX)<br />

*Standardized radii available in all brick sizes<br />

except utility.<br />

RADII<br />

16"<br />

24"<br />

36"<br />

48"<br />

60"<br />

ARC l<br />

8"<br />

7-3/16"<br />

7-11/16" 7-11/16"<br />

8"<br />

7-1/2"<br />

CHORD<br />

l<br />

7-15/16"<br />

7-1/8"<br />

8"<br />

7-1/2"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

**Standardized radii available in utility size unit.<br />

RADII<br />

24"<br />

36"<br />

48"<br />

60"<br />

ARC l<br />

9-1/16"<br />

9-1/16"<br />

10-3/8"<br />

10-1/16<br />

CHORD<br />

l<br />

9"<br />

9"<br />

10-3/8"<br />

10-1/16"<br />

#/90 o<br />

3<br />

5<br />

7<br />

9<br />

12<br />

#/90 o<br />

4<br />

6<br />

7<br />

9<br />

h<br />

VARIES<br />

w/RADIUS<br />

RA-IN-ST<br />

r<br />

t<br />

RA-IN-ST<br />

ARC l<br />

*STANDARD<br />

*STANDARD MOD<br />

*ENGINEER STD<br />

*ENGINEER MOD<br />

*ECONOMO<br />

**UTILITY<br />

*HMOS<br />

1/2 BOND<br />

1/3 BOND<br />

2/3 BOND<br />

A<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

l (MAX)<br />

t h A l (MAX)<br />

*Standardized radii available in<br />

all brick sizes except utility.<br />

RADII<br />

16"<br />

24"<br />

36"<br />

48"<br />

60"<br />

ARC l<br />

4"<br />

3-9/16"<br />

4"<br />

3-13/16"<br />

4"<br />

3-13/16"<br />

4"<br />

3-3/4"<br />

3-13/16"<br />

3-13/16"<br />

5-13/16"<br />

3-13/16"<br />

7-13/16"<br />

4-1/4"<br />

**Standardized radii available in utility size unit.<br />

RADII<br />

24"<br />

36"<br />

48"<br />

60"<br />

1/2B<br />

ARC l<br />

1/3B 2/3B<br />

4-1/2" 6" 3"<br />

4-1/2"<br />

5-3/16"<br />

5"<br />

6"<br />

6-7/8"<br />

7-1/4"<br />

3"<br />

3-7/16"<br />

3-3/8"<br />

h<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"

h<br />

t<br />

RA-EX-S<br />

ARC l<br />

RA-EX-S<br />

*STANDARD<br />

*STANDARD MOD<br />

*ENGINEER STD<br />

*ENGINEER MOD<br />

*ECONOMO<br />

**UTILITY<br />

*HMOS<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

*Standardized radii available<br />

in all brick sizes except utility.<br />

RADII<br />

16"<br />

24"<br />

36"<br />

48"<br />

60"<br />

l (MAX)<br />

t h l (MAX)<br />

ARC l<br />

8"<br />

7-3/16"<br />

7-11/16"<br />

8"<br />

7-1/2"<br />

**Standardized radii available<br />

in utility size unit.<br />

RADII<br />

24"<br />

36"<br />

48"<br />

60"<br />

ARC l<br />

9-1/16"<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

10-5/16"<br />

10-3/8"<br />

11-3/8"<br />

3<br />

5<br />

7<br />

9<br />

12<br />

8"<br />

7-5/8"<br />

8"<br />

#/90 o<br />

#/90 o<br />

4<br />

5<br />

7<br />

8<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

8-1/2"<br />

r<br />

VARIES<br />

w/RADIUS<br />

h<br />

t<br />

RA-EX-ST<br />

A<br />

RA-EX-ST<br />

*STANDARD<br />

*STANDARD MOD<br />

*ENGINEER STD<br />

*ENGINEER MOD<br />

*ECONOMO<br />

**UTILITY<br />

*HMOS<br />

1/2 BOND<br />

1/3 BOND<br />

2/3 BOND<br />

RADII<br />

24"<br />

36"<br />

48"<br />

60"<br />

ARC l<br />

RADII<br />

16"<br />

24"<br />

36"<br />

48"<br />

60"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

4"<br />

2-1/4"<br />

2-1/4"<br />

2-3/4"<br />

2-3/4"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

2-3/4"<br />

5-7/16"<br />

5-3/16"<br />

5-11/16<br />

l (MAX)<br />

*Standardized radii available in<br />

all brick sizes except utility.<br />

ARC l<br />

3-1/16"<br />

**Standardized radii available in utility size unit.<br />

3"<br />

4"<br />

3-13/16"<br />

4"<br />

3-13/16"<br />

3-13/16"<br />

5-13/16"<br />

3-13/16"<br />

7-13/16"<br />

4-1/4"<br />

3-7/16"<br />

3-11/16"<br />

3-1/2"<br />

7-1/4"<br />

6-7/8"<br />

7-1/2"<br />

Radials<br />

r<br />

VARIES<br />

w/RADIUS<br />

t h A l (MAX)<br />

8"<br />

1/2B<br />

ARC l<br />

1/3B 2/3B<br />

4-1/2" 6" 3"<br />

3-5/8"<br />

3-7/16"<br />

3-3/4"<br />

7-5/8"<br />

8"<br />

7-5/8"<br />

7-5/8"<br />

11-5/8"<br />

11-5/8"<br />

11-5/8"<br />

8-1/2"<br />

19

20<br />

Flat Arch<br />

<strong>Glen</strong>-<strong>Gery</strong>’s flat arches<br />

achieve the look of the<br />

classical jack arch without<br />

the cost of custom-made<br />

arch pieces. The voussoirs<br />

are designed with a 70°<br />

skew-back angle and 3/8"<br />

nominal mortar joint. All the<br />

flat arch pieces, except the<br />

keystone, are the same size<br />

and shape and have parallel<br />

vertical sides. Please specify<br />

the masonry opening and<br />

the face brick unit size<br />

when ordering.<br />

FA1-K<br />

JA1<br />

JA2<br />

B<br />

t<br />

h<br />

A<br />

MASONRY OPENING<br />

MASONRY OPENING<br />

70°<br />

70°<br />

7-5/8" (2-1/4")<br />

9-1/8" (2-3/4")<br />

FA1-V<br />

A<br />

10-1/4" (2-1/4")<br />

12-3/8" (2-3/4")<br />

15-5/8" (3-5/8")<br />

h<br />

t<br />

JA3<br />

MASONRY OPENING<br />

FA1-K & FA1-V t h A B<br />

STANDARD 3-5/8" 2-1/4" •7-5/8" 7-13/1<br />

STANDARD MOD 3-5/8" 2-1/4" •7-5/8" 6"<br />

ENGINEER STD 3-5/8" 2-3/4" •9-1/8" 7-13/1<br />

ENGINEER MOD 3-5/8" 2-3/4" •9-1/8" 6"<br />

ECONOMO 3-5/8" 3-5/8" °7-5/8" 9-3/8"<br />

UTILITY<br />

3-5/8" 3-5/8" °7-5/8" 9-3/8"<br />

HMOS<br />

4" 2-3/4" •9-1/8" 9-3/16"<br />

• Equals 3 courses of companion facebrick stretchers.<br />

° Equals 2 courses of companion facebrick stretchers.<br />

MASONRY OPENING<br />

12-15/16" (2-1/4")<br />

15-9/16" (2-3/4")<br />

19-5/8" (3-5/8")<br />

Classical Jack Arch<br />

The typical 1, 2, and 3-brick classical<br />

jack arches, as manufactured by<br />

<strong>Glen</strong>-<strong>Gery</strong>, are calculated with a 70°<br />

skew-back angle and a 3/8" nominal<br />

mortar joint. To order a jack arch,<br />

the type of arch, masonry opening<br />

and the face brick unit size must be<br />

specified. The jack arch brick are<br />

individually boxed and tagged<br />

for location.

Arches<br />

B RISE<br />

rick arches invoke a sense<br />

of tradition and strength and<br />

have become a standard element<br />

in many architectural styles. For<br />

structural integrity and appeal,<br />

arches should be constructed with<br />

brick shapes to properly span the<br />

opening. <strong>Glen</strong>-<strong>Gery</strong> offers a variety<br />

of standard arches which can be<br />

used as functional or decorative<br />

elements in a building design.<br />

C<br />

RADIUS<br />

SEMI-CIRCULAR ARCH<br />

SEGMENTAL ARCH C<br />

MASONRY OPENING<br />

THREE-CENTERED ARCH<br />

CIRCULAR ARCH<br />

RADIUS<br />

r<br />

MASONRY OPENING<br />

C<br />

R<br />

Circular, Semi-Circular,<br />

Segmental, and Three-<br />

Centered Arches<br />

These arches are manufactured<br />

only from architects’ full-size details<br />

and must include the following<br />

information:<br />

1. Type of arch.<br />

2. Dimension of the masonry opening.<br />

3. Rise.<br />

4. Thickness of the mortar joint.<br />

5. Radii of the arch.<br />

6. Whether it is a one or two brick arch.<br />

7. Size of brick to be used.<br />

<strong>Glen</strong>-<strong>Gery</strong>’s team of Design Advisors<br />

will provide technical design assistance<br />

for arches or any other brickwork<br />

applications.<br />

R<br />

C<br />

RISE<br />

21

22<br />

8-Square<br />

len-<strong>Gery</strong>’s 8-Square Panelbrik ®<br />

and Stylo ® G were developed as<br />

large masonry unit alternatives for<br />

commercial construction. These<br />

large units speed construction while<br />

providing a unique pattern effect for<br />

larger structures. A system of shapes<br />

is available to enhance design<br />

flexibility. All Stylo shapes are<br />

available in wire-cut texture only.<br />

8SQ 7-5/8"<br />

7-5/8"<br />

3-5/8"<br />

8SQ-SH-CR-(LT OR 8SQ-O-IN 3-5/8" * 8SQ-SH*<br />

RT) *<br />

3-5/8"<br />

*<br />

2"<br />

6"<br />

7-5/8"<br />

135°<br />

6"<br />

8SQ-K 8SQ-O-EX<br />

7-5/8"<br />

7-5/8"<br />

7-5/8"<br />

3-5/8" 3-5/8"<br />

*<br />

3-5/8"<br />

*<br />

7-5/8"<br />

(BOTTOM VIEW)<br />

Not available in glazed<br />

3/4"<br />

45°<br />

7"<br />

6"<br />

2-7/8"<br />

7-5/8"<br />

2"<br />

3-5/8"<br />

*<br />

6"<br />

(BOTTOM VIEW)<br />

7-5/8"<br />

3-5/8"<br />

7-5/8"<br />

3/4"

10<br />

-5/8"<br />

2<br />

-5/8"<br />

4<br />

-5/8"<br />

1"r<br />

7-5/8"<br />

7-5/8"<br />

7-5/8"<br />

S10<br />

S10<br />

2-1/4"<br />

2-1/4"<br />

S2<br />

S2<br />

2-1/4"<br />

2-1/4"<br />

S4<br />

S4<br />

2-1/4"<br />

2-1/4"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

3-5/8"<br />

1"r<br />

7-5/8"<br />

F<br />

** S10 **<br />

F<br />

3-5/8"<br />

3-5/8"<br />

**<br />

1"r<br />

2-1/4"<br />

S3*<br />

S5*<br />

2-1/4"<br />

3-3/4"<br />

3-3/4"<br />

1"r<br />

7-5/8"<br />

7-5/8"<br />

7-5/8"<br />

7-5/8"<br />

7-5/8"<br />

F<br />

F<br />

8"<br />

8"<br />

**<br />

S3*<br />

S3*<br />

2-1/4"<br />

2-1/4"<br />

S5*<br />

S5*<br />

2-1/4"<br />

2-1/4"<br />

3-3/4"<br />

3-3/4"<br />

3-3/4"<br />

3-3/4"<br />

Coated <strong>Brick</strong><br />

1"r<br />

1"r<br />

Available in glazed & engobe<br />

G<br />

len-<strong>Gery</strong>’s coated brick meet<br />

the highest standards of<br />

uniformity, quality, and durability.<br />

In addition to these brick shapes,<br />

<strong>Glen</strong>-<strong>Gery</strong>’s Hanley plant can<br />

provide custom shapes unique<br />

to its architectural line of coated<br />

face brick.<br />

2-1/4"<br />

F<br />

F<br />

S2<br />

S83<br />

2-1/4"<br />

2-1/4"<br />

8"<br />

3-5/8"<br />

8"<br />

3-5/8"<br />

S4<br />

S85<br />

2-1/4"<br />

3-5/8"<br />

8"<br />

8"<br />

*Not available 2-1/4" in glazed<br />

*Not available in glazed<br />

3-5/8"<br />

3-3/4"<br />

1"r<br />

1"r<br />

**<br />

1"r<br />

7-5/8"<br />

7-5/8"<br />

7-5/8"<br />

7-5/8"<br />

8"<br />

F<br />

F<br />

S83<br />

S83<br />

2-1/4"<br />

2-1/4"<br />

S85<br />

S85<br />

2-1/4"<br />

2-1/4"<br />

3-5/8"<br />

3-5/8"<br />

3-3/4"<br />

3-3/4"<br />

1"r<br />

1"r<br />

2-1/4"<br />

S3*<br />

8"<br />

3-3/4"<br />

8"<br />

S5*<br />

1"r<br />

1"r<br />

2-1/4"<br />

3-3/4"<br />

1"r<br />

7-5/8"<br />

7-5/8"<br />

23<br />

F<br />

F<br />

F F<br />

F<br />

F

24<br />

Custom <strong>Shapes</strong><br />

M<br />

any interesting brickwork<br />

design details can be<br />

achieved with the <strong>Glen</strong>-<strong>Gery</strong><br />

standardized shapes illustrated in<br />

this catalog. There are projects,<br />

however, that require a custom<br />

designed brick shape to achieve<br />

a specific detail or unusual effect.<br />

<strong>Glen</strong>-<strong>Gery</strong> welcomes the<br />

opportunity to produce unusual<br />

shapes, but it must be remembered<br />

that an intricate design demands<br />

a considerable degree of skill and<br />

expertise to make and may take<br />

longer to produce than a<br />

standardized shape. Custom<br />

shapes also require detailed,<br />

contractor-approved drawings<br />

prior to production.<br />

Consult your <strong>Glen</strong>-<strong>Gery</strong> representative<br />

early in the project to discuss<br />

the procedure and requirements of<br />

specifying <strong>Glen</strong>-<strong>Gery</strong> custom<br />

shapes. Our technical staff and<br />

manufacturing personnel stand<br />

ready to offer you assistance in<br />

turning your ideas into reality in the<br />

most practical and cost-effective<br />

manner.<br />

<strong>Brick</strong> Sculptures<br />

The ultimate brick shaping process<br />

takes place when an artist uses the<br />

material to create beautiful brick<br />

sculptures. Each sculpture can be<br />

designed to meet the requirements<br />

of the owner, the building or the<br />

environment, and can be executed<br />

in any size for interior and exterior<br />

walls or panels. From abstract to<br />

realistic, brick bas-relief adds a<br />

unique and timeless element of<br />

artistic expression to any building.<br />

<strong>Glen</strong>-<strong>Gery</strong> has experience in<br />

bringing artist and material together<br />

to create specialized sculptures.<br />

For more information, please contact<br />

your <strong>Glen</strong>-<strong>Gery</strong> representative.

<strong>Glen</strong>-<strong>Gery</strong> Corporation<br />

SALES/BRICK CENTERS<br />

IOWA<br />

<strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong> Center<br />

101 Ashworth Road<br />

W. Des Moines, IA 50265<br />

TEL (515) 224-4110<br />

KANSAS<br />

<strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong> Center<br />

336 S. 42nd Street<br />

Kansas City, KS 66106<br />

TEL (913) 281-2800<br />

MICHIGAN<br />

Midwest Regional Sales Office<br />

37720 Hills Tech Drive<br />

Farmington Hills, MI 48331<br />

TEL (248) 489-9338<br />

NEW JERSEY<br />

Northeast Regional Sales Office<br />

75 Hamilton Road<br />

Hillsborough, NJ 08844<br />

TEL (908) 359-7305<br />

PENNSYLVANIA<br />

<strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong> Center<br />

2750 Commerce Drive<br />

Turnpike Industrial Park<br />

Middletown, PA 17057<br />

TEL (717) 939-6061<br />

<strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong> Center<br />

423 Susquehanna Trail<br />

Watsontown, PA 17777<br />

TEL (570) 742-4721<br />

<strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong> Center<br />

200 Hartman Road<br />

Reading, PA 19605<br />

TEL (610) 939-1721<br />

<strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong> Center<br />

1090 E. Boundary Avenue<br />

P.O. Box 2903<br />

York, PA 17403<br />

TEL (717) 854-8802<br />

VIRGINIA<br />

<strong>Glen</strong>-<strong>Gery</strong> <strong>Brick</strong> Centerr<br />

9905 Godwin Drive<br />

P.O. Box 3410<br />

Manassas, VA 20108<br />

TEL (703) 368-3178<br />

MANUFACTURING FACILITIES<br />

Bigler Plant<br />

Bigler, PA<br />

Caledonia Plant<br />

Caledonia, OH<br />

Capitol Plant<br />

Manassas, VA<br />

Hanley Plant<br />

Summerville, PA<br />

Iberia Plant<br />

Iberia, OH<br />

Jersey Shale Plant<br />

Hillsborough, NJ<br />

Marseilles Plant<br />

Marseilles, IL<br />

Mid-Atlantic Plant<br />

Shoemakersville, PA<br />

Redfield Plant<br />

Redfield, IA<br />

York Plant<br />

York, PA<br />

GLEN-GERY CORPORATION<br />

Corporate Office<br />

<strong>Glen</strong>-<strong>Gery</strong> Corporation<br />

1166 Spring Street<br />

P.O. Box 7001<br />

Wyomissing, PA 19610-6001<br />

(610) 374-4011<br />

Fax: (610) 374-1622<br />

E-Mail: gg@glengerybrick.com<br />

http://www.glengerybrick.com<br />

07/06 ©2006 GLEN-GERY CORPORATION PRINTED IN U.S.A.