BERMAD Fire Protection

BERMAD Fire Protection

BERMAD Fire Protection

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

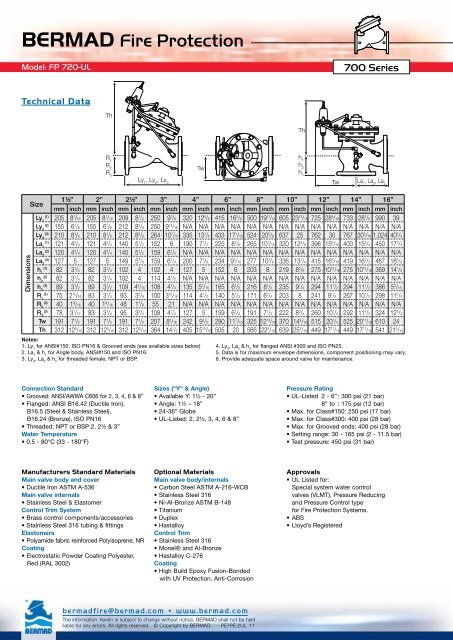

<strong>BERMAD</strong> <strong>Fire</strong> <strong>Protection</strong><br />

Model: FP 720-UL<br />

Technical Data<br />

Dimensions<br />

Th<br />

R 1<br />

R 2<br />

R 3<br />

Connection Standard<br />

• Grooved: ANSI/AWWA C606 for 2, 3, 4, 6 & 8”<br />

• Flanged: ANSI B16.42 (Ductile Iron),<br />

B16.5 (Steel & Stainless Steel),<br />

B16.24 (Bronze), ISO PN16<br />

• Threaded: NPT or BSP 2, 2½ & 3”<br />

Water Temperature<br />

• 0.5 - 80°C (33 - 180°F)<br />

Manufacturers Standard Materials<br />

Main valve body and cover<br />

• Ductile Iron ASTM A-536<br />

Main valve internals<br />

• Stainless Steel & Elastomer<br />

Control Trim System<br />

• Brass control components/accessories<br />

• Stainless Steel 316 tubing & fittings<br />

Elastomers<br />

• Polyamide fabric reinforced Polyisoprene, NR<br />

Coating<br />

• Electrostatic Powder Coating Polyester,<br />

Red (RAL 3002)<br />

Ly 1 , Ly 2 , Ly 3<br />

Tw<br />

Sizes (“Y” & Angle)<br />

• Available Y: 1½ - 20”<br />

• Angle: 1½ – 18”<br />

• 24-36” Globe<br />

• UL-Listed: 2, 2½, 3, 4, 6 & 8”<br />

Optional Materials<br />

Main valve body/internals<br />

• Carbon Steel ASTM A-216-WCB<br />

• Stainless Steel 316<br />

• Ni-Al-Bronze ASTM B-148<br />

• Titanium<br />

• Duplex<br />

• Hastalloy<br />

Control Trim<br />

• Stainless Steel 316<br />

• Monel® and Al-Bronze<br />

• Hastalloy C-276<br />

Coating<br />

• High Build Epoxy Fusion-Bonded<br />

with UV <strong>Protection</strong>, Anti-Corrosion<br />

Th<br />

h 1<br />

h 2<br />

h 3<br />

Tw<br />

La 1 , La 2 , La 3<br />

Size<br />

1½”<br />

mm inch<br />

2”<br />

mm inch<br />

2½”<br />

mm inch<br />

3”<br />

mm inch<br />

4”<br />

mm inch<br />

6”<br />

mm inch<br />

8”<br />

mm inch<br />

10”<br />

mm inch<br />

12”<br />

mm inch<br />

14”<br />

mm inch<br />

16”<br />

mm inch<br />

(1) Ly1 205 1 8 /16 205 1 8 /16 209 1 8 /4 250 7 9 /8 320 5 12 /8 415 3 16 /8<br />

11 500 19 /16<br />

13 605 23 /16 725 9 28 /16 733 7 28 /8 990 39<br />

(2) Ly2 155 1 6 /8 155 1 6 /8 212 3 8 /8 250 13 9 /16 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A<br />

(3) Ly3 210 1 8 /4 210 1 8 /4 212 3 8 /8 264 7 10 /16 335 1 13 /4 433 1 17 /16 524 5 20 /8 637 25 762 30 767 3 3 30 /16 1,024 40 /4<br />

(1) La1 121 3 4 /4 121 3 4 /4 140 1 5 /2 152 6 190 1 7 /2 225 7 8 /8 265 7 10 /16 320 5 12 /8 396 9 15 /16 400 3 15 /4 450 3 17 /4<br />

(2) La2 120 3 4 /4 120 3 4 /4 140 1 5 /2 159 1 6 /4 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A<br />

(3) La3 127 5 127 5 149 7 5 /8 159 1 6 /4 200 7 7 /8 234 3 9 /16 277 7 10 /8 336 1 13 /4 415 5 16 /16 419 1 16 /2 467 3 18 /8<br />

(1) h1 82 31 /4 82 31 /4 102 4 102 4 127 5 152 6 203 8 219 85 /8 275 1013 /16 275 1013 /16 369 141 /2<br />

(2) h2 82 31 /4 82 31 /4 102 4 114 41 /2 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A<br />

(3) h3 89 31 /2 89 31 /2 109 45 /16 108 41 /4 135 55 /16 165 61 /2 216 81 /2 235 91 /4 294 111 /2 294 111 /2 386 53 /16<br />

(1) R1 75 215 /16 83 31 /4 93 35 /8 100 315 /16 114 41 /2 140 51 /2 171 63 /4 203 8 241 91 /2 267 101 /2 298 113 /4<br />

(2) R2 40 19 /16 40 19 /16 48 17 /8 55 21 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A<br />

(3) R3 78 31 /16 83 31 /4 95 33 /4 108 41 /4 127 5 159 61 /4 191 71 /2 222 83 /4 260 101 /4 292 111 /2 324 123 /4<br />

Tw 191 71 /2 191 71 /2 191 71 /2 207 81 /16 242 91 /2 290 117 /16 325 1213 /16 370 149 /16 515 201 /4 525 2011 /16 610 24<br />

Th 312 125 /16 312 125 /16 312 125 /16 364 141 /2 405 15 15 /16 505 20 566 225 /16 639 253 /16 449 1711 /16 449 1711 /16 541 215 /16<br />

Notes:<br />

1. Ly for ANSI#150, ISO PN16 & Grooved ends (see available sizes below)<br />

1<br />

2. La & h for Angle body, ANSI#150 and ISO PN16.<br />

1 1<br />

3. Ly , La & h for threaded female, NPT or BSP.<br />

2 2 2<br />

4. Ly , La & h for flanged ANSI #300 and ISO PN25.<br />

3 3 3<br />

5. Data is for maximum envelope dimensions, component positioning may vary.<br />

6. Provide adequate space around valve for maintenance.<br />

bermadfire@bermad.com • www.bermad.com<br />

The information herein is subject to change without notice. <strong>BERMAD</strong> shall not be held<br />

liable for any errors. All rights reserved. © Copyright by <strong>BERMAD</strong>. PE7PE-2UL 11<br />

700 Series<br />

Pressure Rating<br />

• UL-Listed 2 - 6” : 300 psi (21 bar)<br />

8” to : 175 psi (12 bar)<br />

• Max. for Class#150: 250 psi (17 bar)<br />

• Max. for Class#300: 400 psi (28 bar)<br />

• Max. for Grooved ends: 400 psi (28 bar)<br />

• Setting range: 30 - 165 psi (2 - 11.5 bar)<br />

• Test pressure: 450 psi (31 bar)<br />

Approvals<br />

• UL Listed for:<br />

Special system water control<br />

valves (VLMT), Pressure Reducing<br />

and Pressure Control type<br />

for <strong>Fire</strong> <strong>Protection</strong> Systems.<br />

• ABS<br />

• Lloyd’s Registered