FIRE WORKS/CRACKERS Introduction: Fireworks are very ... - smallB

FIRE WORKS/CRACKERS Introduction: Fireworks are very ... - smallB

FIRE WORKS/CRACKERS Introduction: Fireworks are very ... - smallB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Introduction</strong>:<br />

<strong>FIRE</strong> <strong>WORKS</strong>/<strong>CRACKERS</strong><br />

<strong>Fireworks</strong> <strong>are</strong> <strong>very</strong> popular in our country. These <strong>are</strong> extensively used during celebration of<br />

various festivals. <strong>Fireworks</strong> provide a grand finale to most of the functions. <strong>Fireworks</strong> industry is<br />

labour intensive and it involves a degree of skill and specialization. This industry is concentrated<br />

in Sivakasi, Ramanand District, Tamil Nadu.<br />

The fireworks industry is governed by the Indian Explosives Act and Rules 1940 and the unit has<br />

to comply with all the regulations. A no objection certificate from the District Magistrate for the<br />

establishment of such industry has to be obtained and approval for establishment of the factory<br />

has to be obtained from the Inspector of Explosives of the region.<br />

Further the entrepreneur has to obtain a license from the District Magistrate for possession and<br />

use of sulphur, a license under the Factories Act from the Chief Inspector of the Factories of the<br />

State is required. A Municipal License from the Municipal Commissioner for running the factory<br />

and a License under the Industries (Development & Regulation) Act 1951 from the Ministry of<br />

Industry, Govt. of India, New Delhi, is also required if 50 or more workers <strong>are</strong> employed with<br />

power and 100 or more workers <strong>are</strong> employed without power.<br />

Market Potential:<br />

Corresponding with the present economic development and increase in social activities the<br />

demand for fireworks items e.g. crackers, sparklers, coloured matches, magnesium pencil, pinwheels,<br />

etc. is continuously growing. Except a few such units in and around Barpeta there is no<br />

such manufacturing units existing the N.E. Region. The required fireworks supply for the region<br />

mostly comes from Sivakasi in Tamil Nadu. However, Sivakasi being located at a large distance,<br />

the supply of fireworks involves additional burden transport costs which resulted in increase of<br />

price of fireworks in the region. Besides, too often the supply of fireworks to the region remains<br />

irregular. Therefore, a few fireworks manufacturing units can come up particularly in the states of<br />

Assam & Tripura in the region.<br />

Plant Capacity:<br />

The production basis for a typical tiny unit would be as under:<br />

Working hours/day : 8 (1 shift)<br />

Working days in a year 30<br />

Annual Production capacity : Rocket (15,000 Nos.),<br />

Letter tree (12,000 Nos.)<br />

Cherki (2,700 Nos.),<br />

Mater gash (1,500 Nos. with colour<br />

with sound 1,800 Nos., white 1,200 Nos.),<br />

Phuljari (6,000 Nos.).<br />

The unit has been assumed to operate at 70%, 80% and 90% of its installed capacity in the first,<br />

second and third year and onwards of its operation.<br />

Raw Material:<br />

The main raw materials required for manufacturing the above mentioned fireworks items <strong>are</strong><br />

provided below:<br />

Salt petry : 4,050 Kg.<br />

Sulphur 4,200 Kg.<br />

Carbon 1,425 Kg.<br />

Aluminium powder : 600 Kg.<br />

Berata : 750 Kg.<br />

Bussa : 450 Kg.<br />

Nichiya 150 Kg.<br />

Gun-powder : 60 Kg.<br />

Blasting powder 30 Kg.<br />

Potash : 60 Kg.<br />

Cast iron : 600 Kg.<br />

Phuljari Box<br />

68<br />

: 6,000 Nos.

In addition to the raw materials, consumables like Bamboo, Jute, Polyethylene paper, cover<br />

paper, cover paper, colour paper etc. will be required.<br />

Process:<br />

The chemicals which form ‘explosive mixtures’ have to be properly mixed. The mixture will then<br />

be filled in suitable containers which will be closed after inserting the fuse. There <strong>are</strong> also other<br />

processes such as coating, dipping, etc. depending upon the products manufactured. Later the<br />

articles <strong>are</strong> wrapped and packed in cartons. The process of manufacture depends upon the<br />

nature of article produced. In case of different products, the manufacturing process is briefly<br />

mentioned below:<br />

1. Rocket: For preparation of Rocket, initially bamboo cases or boxes <strong>are</strong> made, which <strong>are</strong><br />

then covered by jute. Thereafter crushed sulphur and salt petry <strong>are</strong> put into the cases. A<br />

stick also is placed into it.<br />

2. Letter Tree: The letter of the letter tree is made of Halpata which is covered by some<br />

pieces of cloth. Then sulphur is applied followed by black gun powder.<br />

3. Cherki: The cases or boxes of Cherki <strong>are</strong> made of bamboo, which is then covered by<br />

jute. Thereafter crushed sulphur and salt petry <strong>are</strong> poured into the cases with the help of<br />

a stick.<br />

4. Mater Gash: Mater gash cases <strong>are</strong> made of paper. Sulphur and salt petry <strong>are</strong> crushed<br />

separately. These crushed substances <strong>are</strong> taken mixed with aluminium powder etc.<br />

Lastly the mixture is poured into the cases and fully covered.<br />

5. Phuljari: The cases of phuljari <strong>are</strong> made of clay. Salphur, salt petry and carbon <strong>are</strong><br />

separately crushed. The mixture is then put into the Phuljari case with the help of a stick.<br />

Machinery:<br />

The major equipment required by the unit for producing the aforesaid fireworks items <strong>are</strong> as<br />

follows:<br />

Paper cutting machine 32” complete with motor: No.<br />

Disintegrator 12” complete with 20 HP motor: No.<br />

Flour Mills 12” complete with 7.5 HP motor: 1 No.<br />

Conical grinders complete with 3 HP motor: 1 No.<br />

Wire straightening & cutting machine: No.<br />

Strapping operation tools (manual): 3 sets.<br />

Location:<br />

The suitable locations for the project may be –<br />

• Guwahati, Tinsukia, Karimganj, Dhubri in Assam.<br />

• Agartala, Dhamanagar in Tripura<br />

The fireworks industry will have to be located on the outskirts of the town or city due to the<br />

hazards involved in the manufacture of the goods. The units should therefore posses a van to<br />

gather raw materials from the railway station as also to transport finished products.<br />

Infrastructure:<br />

The basic infrastructure required <strong>are</strong> :<br />

Land : 50,000 sq.ft.<br />

Building 18,000 sq.ft.<br />

Power : 30 KW<br />

Water : 1,000 Ltr. Per day.<br />

Manpower : 60 Nos. (Administrative (5), Factory Staff (55),<br />

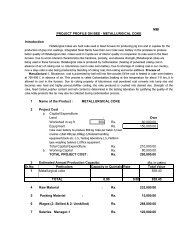

Total Capital Requirement:<br />

The total capital requirement including fixed capital and working capital is estimated at Rs 21.60<br />

lakhs as follows. Of this, the project cost comprising fixed capital and margin money on working<br />

capital is Rs 20.50 lakhs.<br />

69

A. Fixed Capital: (Rs in lakh)<br />

Land 2.00<br />

Building 9.50<br />

Machinery 2.50<br />

Miscellaneous fixed assets 3.50<br />

Preliminary and pre-operative expenses _ 1.50<br />

Total (A) 19.50<br />

B. Working Capital:<br />

Raw materials & Packing material 1 month 0.50<br />

Finished goods weeks 0.60<br />

Working expenses 1 month 1.00<br />

Receivables 1 week _0.50<br />

Total (B) 2.60<br />

====<br />

Total (A)+(B) 21.60<br />

Note: Working capital may be financed as:<br />

Bank Finance ….. Rs 1.10 lakhs<br />

Margin Money ….. Rs 1.50 lakhs<br />

Rs 2.60 lakhs<br />

===========<br />

Means of Finance:<br />

The project cost of Rs 20.50 lakhs including margin money for working capital may be financed<br />

as under:<br />

Promoter’s contribution (35%) . Rs 7.20 lakhs<br />

Term Loan (65%) …. Rs 13.30 lakhs<br />

Rs 20.50 lakhs<br />

===========<br />

Operating Expenses:<br />

The annual operating expenses <strong>are</strong> estimated at Rs 18.50 lakhs (70% capacity utilization) as<br />

given below:<br />

(Rs in Lakhs)<br />

1. Raw materials 6.50<br />

2. Utilities 0.70<br />

3. Wages & Salaries 8.50<br />

4. Overheads 0.60<br />

5. Selling expenses @ 1% on annual sales 0.20<br />

6. Interest on term loan (13.50%) 1.80<br />

7. Interest on Bank Finance<br />

for working capital (12.50%) 0.15<br />

8. Depreciation @10% 0.25<br />

18.50<br />

====<br />

Sales Realization:<br />

The basis on which average ex-factory sales realization from the sale of various fireworks items<br />

<strong>are</strong> based is provided below:<br />

Items Nos. Unit Sales Price (Rs) Annual Sales Price (Rs)<br />

Rocket 15,000 50/- 7,50,000<br />

Latter Tree 12,000 40/- 4,80,000<br />

Cherki 2,700 250/- 6,75,000<br />

Mater Gash:<br />

i) with colour<br />

ii) with sound<br />

iii) white<br />

1,500<br />

1,800<br />

1,200<br />

300/-<br />

250/-<br />

220/-<br />

Phuljari 6,000 50/- 3,00,000<br />

TOTAL 33,69,000<br />

Based on this the annual sales realization is estimated to be Rs 33.69 lakhs and at 70% capacity<br />

utilization the same is Rs 23.60 lakhs.<br />

70<br />

4,50,000<br />

4,50,000<br />

2,64,000

Profitability :<br />

Based on the sales realization and the operating expenses, the profit would be Rs 5.10 lakhs<br />

per year (70% capacity utilization). This works out to a return on investment of 25%. The plant<br />

will break even at 51% of the rated capacity.<br />

Highlight:<br />

The major highlights of the project <strong>are</strong> as follows:<br />

Total capital requirement : Rs 21.60 lakhs<br />

Promoter’s contribution : Rs 7.20 lakhs<br />

Annual sales realization (70% cap.) : Rs 23.60 lakhs<br />

Annual operating expenses (70% cap.) : Rs 18.50 lakhs<br />

Annual profit (pre-tax) : Rs 5.10 lakhs<br />

Pre-tax Return on Sales : 22%<br />

Break Even Point : 51%<br />

No.of persons employed : 60<br />

List of Machinery Suppliers: List of Raw Materials Suppliers:<br />

1. M/s Standard Printing Machinery,<br />

Shanti Building, 9, Mount Road,<br />

Chennai – 600 002<br />

2. M/s Indo European Trading Co.,<br />

10 Sunkurama Chetty Street,<br />

Chennai - 600 001<br />

3. M/s Corporated Engineers,<br />

7, Chittaranjan Avenue,<br />

Kolkara – 700 013<br />

4. M/s Singhasani Engineering Corpn.,<br />

82/25 Factory Area,<br />

Kanpur<br />

(UP)<br />

1. M/s Indian Metal Powder Industries,<br />

5/50 Tardeo A/C Market,<br />

Mumbai – 34<br />

2. M/s Bengal Chemical & Pharmaceutical works,<br />

8, Ganesh Chandra Avenue,<br />

Kolkata – 700 013<br />

3. M/s Anil Starch Products Ltd.,<br />

P.B. No. 1062,<br />

Anil Road,<br />

71<br />

Ahmedabad – 380 002<br />

4. M/s Metal Powder Co. Ltd.,<br />

Maravankualam,<br />

Pudunagar,<br />

P.O: 626709, Thirumangalam,<br />

Madurai Dt.