Lincoln Electric Welding & Cutting Solutions Equipment Catalog

Lincoln Electric Welding & Cutting Solutions Equipment Catalog

Lincoln Electric Welding & Cutting Solutions Equipment Catalog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

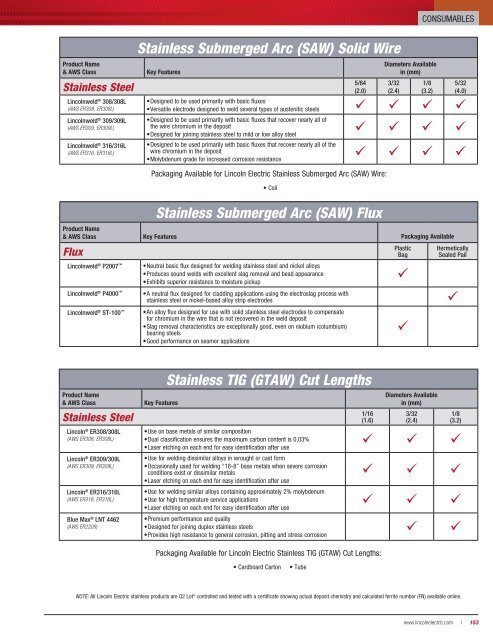

Product Name<br />

& AWS Class Key Features<br />

Stainless Steel<br />

<strong>Lincoln</strong>weld ® 308/308L<br />

(AWS ER308, ER308L)<br />

<strong>Lincoln</strong>weld ® 309/309L<br />

(AWS ER309, ER309L)<br />

<strong>Lincoln</strong>weld ® 316/316L<br />

(AWS ER316, ER316L)<br />

Stainless Submerged Arc (SAW) Flux<br />

CONSUMABLES<br />

Product Name<br />

& AWS Class Key Features Packaging Available<br />

Flux<br />

Plastic<br />

Bag<br />

Hermetically<br />

Sealed Pail<br />

<strong>Lincoln</strong>weld ® P2007 •Neutral basic flux designed for welding stainless steel and nickel alloys<br />

•Produces sound welds with excellent slag removal and bead appearance<br />

•Exhibits superior resistance to moisture pickup<br />

<br />

<strong>Lincoln</strong>weld ® P4000 •A neutral flux designed for cladding applications using the electroslag process with<br />

stainless steel or nickel-based alloy strip electrodes <br />

<strong>Lincoln</strong>weld ® ST-100 •An alloy flux designed for use with solid stainless steel electrodes to compensate<br />

for chromium in the wire that is not recovered in the weld deposit<br />

•Slag removal characteristics are exceptionally good, even on niobium (columbium)<br />

bearing steels<br />

•Good performance on seamer applications<br />

<br />

Product Name<br />

& AWS Class Key Features<br />

Stainless Steel<br />

<strong>Lincoln</strong> ® ER308/308L<br />

(AWS ER308, ER308L)<br />

<strong>Lincoln</strong> ® ER309/309L<br />

(AWS ER309, ER309L)<br />

<strong>Lincoln</strong> ® ER316/316L<br />

(AWS ER316, ER316L)<br />

Blue Max ® LNT 4462<br />

(AWS ER2209)<br />

Stainless Submerged Arc (SAW) Solid Wire<br />

Stainless TIG (GTAW) Cut Lengths<br />

Diameters Available<br />

in (mm)<br />

3/32<br />

(2.4)<br />

•Use on base metals of similar composition<br />

•Dual classification ensures the maximum carbon content is 0.03%<br />

•Laser etching on each end for easy identification after use <br />

•Use for welding dissimilar alloys in wrought or cast form<br />

•Occasionally used for welding “18-8” base metals when severe corrosion<br />

conditions exist or dissimilar metals<br />

•Laser etching on each end for easy identification after use<br />

NOTE: All <strong>Lincoln</strong> <strong>Electric</strong> stainless products are Q2 Lot ® controlled and tested with a certificate showing actual deposit chemistry and calculated ferrite number (FN) available online.<br />

1/16<br />

(1.6)<br />

1/8<br />

(3.2)<br />

<br />

•Use for welding similar alloys containing approximately 2% molybdenum<br />

•Use for high temperature service applications<br />

•Laser etching on each end for easy identification after use <br />

•Premium performance and quality<br />

•Designed for joining duplex stainless steels<br />

•Provides high resistance to general corrosion, pitting and stress corrosion <br />

Packaging Available for <strong>Lincoln</strong> <strong>Electric</strong> Stainless TIG (GTAW) Cut Lengths:<br />

• Cardboard Carton • Tube<br />

5/64<br />

(2.0)<br />

Diameters Available<br />

in (mm)<br />

•Designed to be used primarily with basic fluxes<br />

•Versatile electrode designed to weld several types of austenitic steels <br />

•Designed to be used primarily with basic fluxes that recover nearly all of<br />

the wire chromium in the deposit<br />

•Designed for joining stainless steel to mild or low alloy steel <br />

•Designed to be used primarily with basic fluxes that recover nearly all of the<br />

wire chromium in the deposit<br />

•Molybdenum grade for increased corrosion resistance <br />

Packaging Available for <strong>Lincoln</strong> <strong>Electric</strong> Stainless Submerged Arc (SAW) Wire:<br />

• Coil<br />

3/32<br />

(2.4)<br />

1/8<br />

(3.2)<br />

5/32<br />

(4.0)<br />

www.lincolnelectric.com | 153