Additional Information for all Xylophone Kits - Rockler.com

Additional Information for all Xylophone Kits - Rockler.com

Additional Information for all Xylophone Kits - Rockler.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.triparinc.<strong>com</strong><br />

CP0205<br />

<strong>Xylophone</strong> Bars, Two Octave, 25 Note Kit<br />

Thank you <strong>for</strong> purchasing our two octave xylophone kit containing full & half<br />

notes. The xylophone can be made from a simple plank of wood with the bars<br />

evenly spaced and supported with soft foam or felt. Taper the plank <strong>for</strong> a more<br />

purposeful look, or use slender bars of exotic wood <strong>for</strong> added pizzazz.<br />

You will need 50 #10 x ¾” long screws. Pan or truss head work best since their<br />

large head diameter will prevent the bars from inadvertently <strong>com</strong>ing off. To make<br />

the m<strong>all</strong>et you will need a ¼” x 12” piece of dowel, and option<strong>all</strong>y, a ½”-1” wooden<br />

b<strong>all</strong>.<br />

Simple Plank Construction:<br />

1) Cut a piece of wood not less than ½” thick, 11-3/4”<br />

wide x 22” long. If you plan on tapering it <strong>for</strong><br />

a more purposeful look, do so only at step<br />

6, as par<strong>all</strong>el edges of the full plank will help<br />

during construction.<br />

®<br />

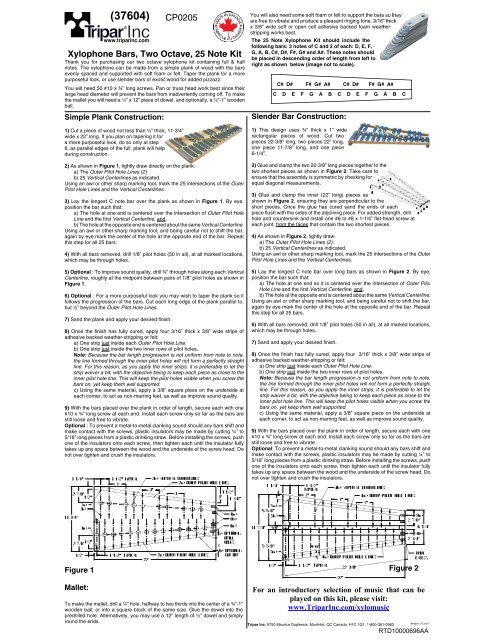

2) As shown in Figure 1 , lightly draw directly on the plank:<br />

a) The Outer Pilot Hole Lines (2)<br />

b) 25 Vertical Centerlines as indicated.<br />

Using an awl or other sharp marking tool, mark the 25 intersections of the Outer<br />

Pilot Hole Lines and the Vertical Centerlines .<br />

3) Lay the longest C note bar over the plank as shown in Figure 1 . By eye,<br />

position the bar such that:<br />

a) The hole at one end is centered over the intersection of Outer Pilot Hole<br />

Line and the first Vertical Centerline , and ,<br />

b) The hole at the opposite end is centered about the same Vertical Centerline .<br />

Using an awl or other sharp marking tool, and being careful not to shift the bar,<br />

again by eye mark the center of the hole at the opposite end of the bar. Repeat<br />

this step <strong>for</strong> <strong>all</strong> 25 bars.<br />

4) With <strong>all</strong> bars removed, drill 1/8” pilot holes (50 in <strong>all</strong>), at <strong>all</strong> marked locations,<br />

which may be through holes.<br />

5) Optional : To improve sound quality, drill ¾” through holes along each Vertical<br />

Centerline , roughly at the midpoint between pairs of 1/8” pilot holes as shown in<br />

Figure 1 .<br />

6) Optional : For a more purposeful look you may wish to taper the plank so it<br />

follows the progression of the bars. Cut each long edge of the plank par<strong>all</strong>el to,<br />

but ½” beyond the Outer Pilot Hole Lines.<br />

7) Sand the plank and apply your desired finish.<br />

8) Once the finish has fully cured, apply four 3/16” thick x 3/8” wide strips of<br />

adhesive backed weather-stripping or felt:<br />

a) One strip just inside each Outer Pilot Hole Line .<br />

b) One strip just inside the two inner rows of pilot holes.<br />

Note: Because the bar length progression is not uni<strong>for</strong>m from note to note,<br />

the line <strong>for</strong>med through the inner pilot holes will not <strong>for</strong>m a perfectly straight<br />

line. For this reason, as you apply the inner strips, it is preferable to let the<br />

strip waiver a bit, with the objective being to keep each piece as close to the<br />

inner pilot hole line. This will keep the pilot holes visible when you screw the<br />

bars on, yet keep them well supported.<br />

c) Using the same material, apply a 3/8” square piece on the underside at<br />

each corner, to act as non-marring feet, as well as improve sound quality.<br />

9) With the bars placed over the plank in order of length, secure each with one<br />

#10 x ¾” long screw at each end . Inst<strong>all</strong> each screw only so far as the bars are<br />

still loose and free to vibrate.<br />

Optional : To prevent a metal-to-metal clanking sound should any bars shift and<br />

make contact with the screws, plastic insulators may be made by cutting ¼” to<br />

5/16” long pieces from a plastic drinking straw. Be<strong>for</strong>e inst<strong>all</strong>ing the screws, push<br />

one of the insulators onto each screw, then tighten each until the insulator fully<br />

takes up any space between the wood and the underside of the screw head. Do<br />

not over tighten and crush the insulators.<br />

Figure 1<br />

M<strong>all</strong>et:<br />

(37604)<br />

To make the m<strong>all</strong>et, drill a ¼” hole, halfway to two thirds into the center of a ¾”-1”<br />

wooden b<strong>all</strong>, or into a square block of the same size. Glue the dowel into the<br />

predrilled hole. Alternatively, you may use a 12” length of ½” dowel and simply<br />

round the ends.<br />

You will also need some soft foam or felt to support the bars so they<br />

are free to vibrate and produce a pleasant ringing tone. 3/16” thick<br />

x 3/8” wide soft or open cell adhesive backed foam weather-<br />

stripping works best.<br />

The 25 Note <strong>Xylophone</strong> Kit should include the<br />

following bars: 3 notes of C and 2 of each: D, E, F,<br />

G, A, B, C#, D#, F#, G# and A#. These notes should<br />

be placed in descending order of length from left to<br />

right as shown below (image not to scale).<br />

C# D# F# G# A# C# D# F# G# A#<br />

C D E F G A B C D E F G A B C<br />

Slender Bar Construction:<br />

1) This design uses ¾” thick x 1” wide<br />

rectangular pieces of wood. Cut two<br />

pieces 22-3/8” long, two pieces 22” long,<br />

one piece 11-7/8” long, and one piece<br />

6-1/4”.<br />

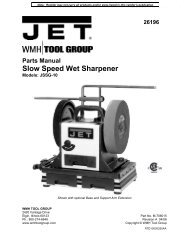

2) Glue and clamp the two 22-3/8” long pieces together to the<br />

two shortest pieces as shown in Figure 2 . Take care to<br />

ensure that the assembly is symmetric by checking <strong>for</strong><br />

equal diagonal measurements.<br />

3) Glue and clamp the inner (22” long) pieces as<br />

shown in Figure 2 , ensuring they are perpendicular to the<br />

short pieces, Once the glue has cured sand the ends of each<br />

piece flush with the sides of the adjoining piece. For added strength, drill<br />

hole and countersink and inst<strong>all</strong> one #6 to #8 x 1-1/4” flat-head screw at<br />

each joint, from the faces that contain the two shortest pieces.<br />

4) As shown in Figure 2 , lightly draw:<br />

a) The Outer Pilot Hole Lines (2) .<br />

b) 25 Vertical Centerlines as indicated.<br />

Using an awl or other sharp marking tool, mark the 25 intersections of the Outer<br />

Pilot Hole Lines and the Vertical Centerlines .<br />

5) Lay the longest C note bar over long bars as shown in Figure 2 . By eye,<br />

position the bar such that:<br />

a) The hole at one end so it is centered over the intersection of Outer Pilot<br />

Hole Line and the first Vertical Centerline , and ,<br />

b) The hole at the opposite end is centered about the same Vertical Centerline .<br />

Using an awl or other sharp marking tool, and being careful not to shift the bar,<br />

again by eye mark the center of the hole at the opposite end of the bar. Repeat<br />

this step <strong>for</strong> <strong>all</strong> 25 bars.<br />

6) With <strong>all</strong> bars removed, drill 1/8” pilot holes (50 in <strong>all</strong>), at <strong>all</strong> marked locations,<br />

which may be through holes.<br />

7) Sand and apply your desired finish.<br />

8) Once the finish has fully cured, apply four 3/16” thick x 3/8” wide strips of<br />

adhesive backed weather-stripping or felt:<br />

a) One strip just inside each Outer Pilot Hole Line .<br />

b) One strip just inside the two inner rows of pilot holes.<br />

Note: Because the bar length progression is not uni<strong>for</strong>m from note to note,<br />

the line <strong>for</strong>med through the inner pilot holes will not <strong>for</strong>m a perfectly straight<br />

line. For this reason, as you apply the inner strips, it is preferable to let the<br />

strip waiver a bit, with the objective being to keep each piece as close to the<br />

inner pilot hole line. This will keep the pilot holes visible when you screw the<br />

bars on, yet keep them well supported.<br />

c) Using the same material, apply a 3/8” square piece on the underside at<br />

each corner, to act as non-marring feet, as well as improve sound quality.<br />

9) With the bars placed over the plank in order of length, secure each with one<br />

#10 x ¾” long screw at each end . Inst<strong>all</strong> each screw only so far as the bars are<br />

still loose and free to vibrate.<br />

Optional : To prevent a metal-to-metal clanking sound should any bars shift and<br />

make contact with the screws, plastic insulators may be made by cutting ¼” to<br />

5/16” long pieces from a plastic drinking straw. Be<strong>for</strong>e inst<strong>all</strong>ing the screws, push<br />

one of the insulators onto each screw, then tighten each until the insulator fully<br />

takes up any space between the wood and the underside of the screw head. Do<br />

not over tighten and crush the insulators.<br />

Tripar Inc. 9750 Maurice Duplessis, Montréal, QC Canada, H1C 1G1, 1-800-361-0983<br />

Figure 2<br />

For an introductory selection of music that can be<br />

played on this kit, please visit:<br />

www.TriparInc.<strong>com</strong>/xylomusic<br />

PP220 ©03/2009<br />

RTD10000696AA

<strong>Additional</strong> <strong>In<strong>for</strong>mation</strong> <strong>for</strong> <strong>all</strong><br />

<strong>Xylophone</strong> <strong>Kits</strong><br />

To further simplify the building process <strong>for</strong> the xylophone kits, please<br />

refer to these additional instructions:<br />

The 8 Note <strong>Xylophone</strong> Kit includes the following bars: 2 notes of C and 1 of<br />

each: D, E, F, G, A and B. These notes should be placed in descending order of<br />

length from left to right as shown below (image not to scale).<br />

C D E F G A B C<br />

The 13 Note <strong>Xylophone</strong> Kit includes the following bars: 2 notes of C and 1 of<br />

each: D, E, F, G, A, B, C#, D#, F#, G# and A#. These notes should be placed in<br />

descending order of length from left to right as shown below (image not to<br />

scale).<br />

C# D# F# G# A#<br />

C D E F G A B C<br />

The 25 Note <strong>Xylophone</strong> Kit includes the following bars: 3 notes of C and 2 of<br />

each: D, E, F, G, A, B, C#, D#, F#, G# and A#. These notes should be placed in<br />

descending order of length from left to right as shown below (image not to<br />

scale).<br />

C# D# F# G# A# C# D# F# G# A#<br />

C D E F G A B C D E F G A B C