MEGA MC Cable Installation & Application Guide - Southwire

MEGA MC Cable Installation & Application Guide - Southwire

MEGA MC Cable Installation & Application Guide - Southwire

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

page 11<br />

bending radius for cable under tension—When pulling <strong>MC</strong> feeder cable, the factor<br />

that limits pulling tension is usually the pressure exerted on the cable sidewall when<br />

pulling around bends.<br />

When <strong>MC</strong> cable is pulled around a bend, the pulling tension causes pressure on the sidewall<br />

of the cable. Sharp bends concentrate the sidewall pressure in a small area, so larger radiuses<br />

allow higher pulling tensions.<br />

When pulling <strong>MC</strong> cable through a series of bends, pulling tension is cumulative. If the radiuses are<br />

all equal, the first bend will see the least tension and create the least sidewall pressure. As the cable<br />

goes through the last bend of a series, it is subjected to all the tension required to pull it through the<br />

earlier bends. The result is that the last bend typically will have the most tension and the most sidewall<br />

pressure.<br />

To avoid cable damage, it’s important to make sure that the radiuses around all bends are large<br />

enough to keep the pressure on the cable sidewall within recommended limits. A typical sidewall<br />

bearing pressure limit for Type <strong>MC</strong> cable is 300 pounds of pulling tension per foot of bend radius.<br />

By this rule of thumb, a 36-inch bend radius would limit the pulling tension to 900 pounds.<br />

NOTE: Be careful about relying on pulling-tension experience with pulling singleconductor<br />

or non-armored PVC jacketed cables. In general, because of the<br />

sidewall pressure created during the pull, interlocked armored cable under<br />

pulling tension must use larger bending radiuses than those allowed for nonarmored,<br />

non-shielded cables with the same number of conductors and the<br />

same conductor size.<br />

If there is any question about the sidewall pressure and pulling tension with <strong>MC</strong> feeder cables,<br />

please refer to Annex A, “Calculating Roller Spacing and <strong>Cable</strong> Pulling Tensions.” These calculations<br />

will help to determine whether your pull will be easy, difficult or impossible. If you have further<br />

questions, or need additional help concerning your particular installation, please contact your<br />

<strong>Southwire</strong> Project Engineer.<br />

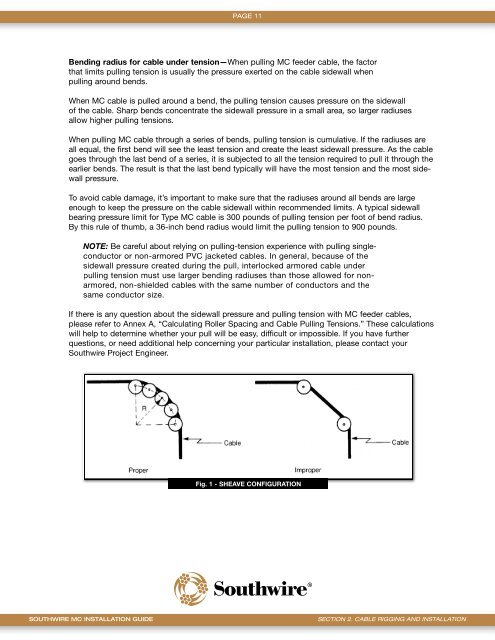

Fig. 1 - sheave ConFiguRation<br />

<strong>Southwire</strong> <strong>MC</strong> inStallation <strong>Guide</strong> section 2. cAble riGGinG And instAllAtion