MEGA MC Cable Installation & Application Guide - Southwire

MEGA MC Cable Installation & Application Guide - Southwire

MEGA MC Cable Installation & Application Guide - Southwire

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>MC</strong> <strong>Cable</strong> advantage<br />

Using Type <strong>MC</strong> cable, contractors can install multiple conductors with professional-looking, owner-<br />

satisfying appearance in less time than it takes to hang empty conduit.<br />

<strong>MC</strong> cable delivers up to four conductors up to 1000 kcmil plus a ground wire in a tough, flexible<br />

aluminum armor. <strong>MC</strong> cable puts an entire 600V feeder circuit into a single, rapid-installation assembly,<br />

and it’s National Electrical Code ® (NEC)-compliant for high-rise buildings, assembly halls and many<br />

hazardous locations.<br />

ReduCed installation steps<br />

The biggest advantage of <strong>MC</strong> cable over conduit-and-wire installations is the reduction in time and labor<br />

to achieve neat, workmanlike appearance, code compliance and owner satisfaction. A typical <strong>MC</strong> cable<br />

installation requires only five steps, where comparable conduit applications require 14. <strong>MC</strong> reduces<br />

overall installed costs by roughly 30-50% when compared to pipe-and-wire systems.<br />

unliMited 90-degRee bends<br />

Pipe and wire installations require a pull box or junction box after every fourth 90° bend (total of 360<br />

degrees of bends). <strong>MC</strong> cables aren’t limited by that restriction. <strong>MC</strong> eliminates the need for junction<br />

boxes between pull points, and also the need for large pipe benders on the job.<br />

FaCtoRy Ry R tested asse asseMblies<br />

With conduit installations, the vast majority of insulation damage happens during installation. <strong>MC</strong> cable<br />

assemblies are factory tested before leaving the plant, and conductors are fully protected inside the<br />

armor during shipping and installation. That greatly reduces the potential for damaged conductors in the<br />

finished job.<br />

ReduCed waste<br />

<strong>Southwire</strong> can provide custom-cut lengths of <strong>MC</strong> cable including very long runs. Using custom-cut<br />

lengths can significantly reduce waste on the jobsite. (With longer runs, contractors must have the<br />

equipment necessary to move and install the cable.)<br />

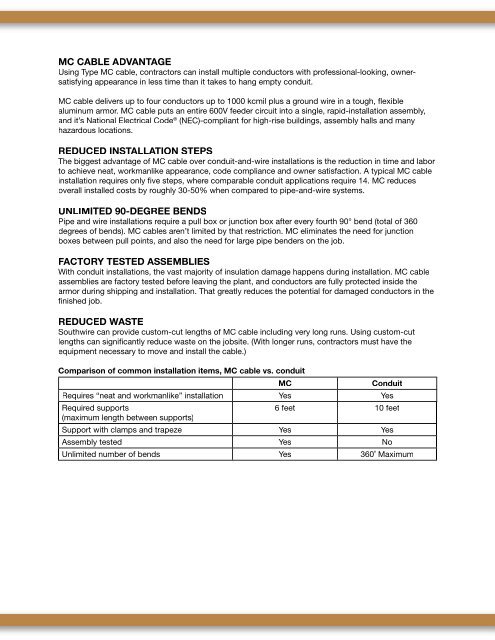

Comparison of common installation items, <strong>MC</strong> cable vs. conduit<br />

<strong>MC</strong> Conduit<br />

Requires “neat and workmanlike” installation Yes Yes<br />

Required supports<br />

(maximum length between supports)<br />

6 feet 10 feet<br />

Support with clamps and trapeze Yes Yes<br />

Assembly tested Yes No<br />

Unlimited number of bends Yes 360˚ Maximum