Better Built Cage & Rack Washers - APEX Laboratory Equipment ...

Better Built Cage & Rack Washers - APEX Laboratory Equipment ...

Better Built Cage & Rack Washers - APEX Laboratory Equipment ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

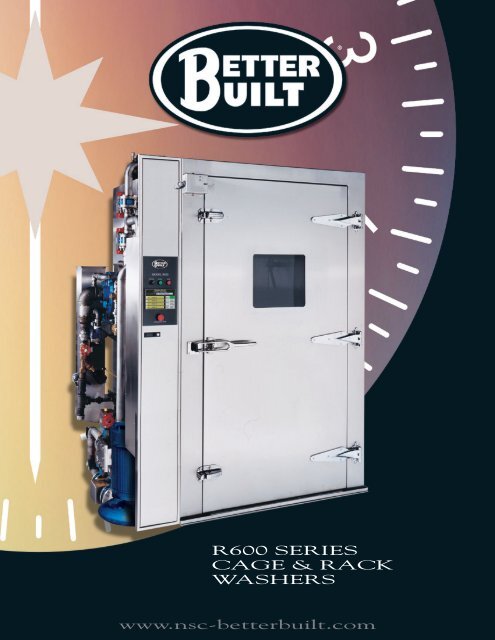

R600 SERIES<br />

CAGE & RACK<br />

WASHERS<br />

www.nsc-betterbuilt.com<br />

®

The <strong>Better</strong> <strong>Built</strong> R600 series cage and rack washer is the result of modern<br />

technology combined with a proven spray design. This approach delivers the<br />

cleaning performance, ease of use and long-term durability demands of today’s<br />

busy laboratories. Choose from four models to best suit your site conditions and<br />

washing requirements.<br />

R600 SERIES CAGE & RACK WASHERS<br />

High Pressure Spray with Total Coverage<br />

Wash and rinse solutions are distributed throughout<br />

the wash chamber by rotating spray arms positioned<br />

for complete coverage. Spray arms are driven by<br />

water pressure, no oscillating manifold is required.<br />

Choice of Sizes and Door Configurations<br />

The R600 series washers are available in single<br />

door and two door pass-thru models. The simplicity<br />

of our design allows us to fabricate custom<br />

sizes to match important length, width or height<br />

requirements.<br />

Turbo Wash System<br />

Two side tanks are positioned on the service side of<br />

the cabinet; one tank speeds up fill times, the other<br />

speeds up drain duration. The combination reduces<br />

alkaline wash to 15 minutes and acid wash to 20<br />

minutes.<br />

Guaranteed Temperatures<br />

Throughout the Cycle<br />

Chemical suppliers have specific temperature<br />

recommendations for best performance from their<br />

detergents. Our micro-processor control system<br />

allows the user to preset the correct solution<br />

temperature for each step of the wash cycle and for<br />

guaranteed bacteria kill during the final rinse.<br />

Touch Screen Controls<br />

The touch screen controls allow the user to easily<br />

select from 12 pre-programmed cleaning cycles. The<br />

easy to read information screen shows the current<br />

operating cycle and stage, actual temperature and<br />

time remaining.<br />

Micro-processor<br />

Cycles and communication features are controlled<br />

by micro-processor. Each cycle can be preset for<br />

time, temperature, multiple washes, multiple rinses,<br />

chemical additives, exhaust and water saving for<br />

maximum efficiency. Programmed wash cycle are<br />

protected via pin number access, ensuring up to 8<br />

* (Shown with optional stainless steel enclosure)

levels of security. Pre-set temperatures for wash<br />

and rinse cycles are guarantees and are verified<br />

with our alarm logging capabilities. Recording<br />

of wash cycle data is now available digitally<br />

with our optional compact flash card or with<br />

our Ethernet connectivity to PLC date retrieval<br />

option.<br />

Solid Construction for Durability<br />

All <strong>Better</strong> <strong>Built</strong> washers are built with durability<br />

in mind. Cabinets and doors are all stainless<br />

steel construction, fully welded and polished<br />

to a satin finish. The complete solution<br />

circulation system including pumps, flanges,<br />

pipe connections and loading equipment is<br />

constructed of type 304 stainless steel for<br />

compatibility with all types of detergents. Type<br />

316 stainless steel is available as an option. No<br />

plastic or rubber piping connections are used.<br />

Maintenance and Replacement Parts<br />

A preventative maintenance program is<br />

required for warranty purposes and is<br />

available from a local service agent. All <strong>Better</strong><br />

<strong>Built</strong> washers use the Omron PLC program<br />

controllers for long life and ease of service<br />

diagnostics. All other components are nonproprietary<br />

and are available from local<br />

suppliers or the factory.<br />

Noise Reduction<br />

Component selection and design engineering<br />

have ensured that sound levels around the<br />

washer are kept below 80dB which are in line<br />

with current worker safety recommendations.<br />

Acid Compatible<br />

All <strong>Better</strong> <strong>Built</strong> washers have a stainless steel<br />

cabinet and circulatory system, containing no<br />

plastic or rubber connections. This makes the<br />

washer compatible with all alkaline or acidic<br />

detergents.<br />

Safety Features<br />

Personnel safety features include an emergency<br />

stop (e-stop) button located at both the soiled<br />

and clean ends of the washer. Inside the wash<br />

chamber, a highly visible emergency stop<br />

cable is located on one side or as an option on<br />

both sides. The washer door latch is design to<br />

release easily when the door is pushed from the<br />

inside.<br />

Loading <strong>Equipment</strong><br />

A full line of washing racks and carts are<br />

available. Please refer to our cage and rack<br />

washer accessories brochure.

CHAMBER OVERALL<br />

MODEL W x H x L W x H x L<br />

R620 42 x 84 x 80” 80 1/2 x 103 x 86”<br />

1067 x 2134 x 2032mm 2045 x 2616 x 2184mm<br />

R630 48 x 88 x 90” 87 1/2 x 107 x 96”<br />

1219 x 2235 x 2286mm 2223 x 2718 x 2438mm<br />

R670 48 x 88 x 130” 87 1/2 x 107 x 136”<br />

1219 x 2235 x 3302mm 2223 x 2718 x 3454mm<br />

R690 48 x 88 x 180” 87 1/2 x 107 x 186”<br />

1219 x 2235 x 4572mm 2223 x 2718 x 4724mm<br />

Note: Custom sized cabinets are available, contact NORTHWESTERN SYSTEMS CORP. or our local representative for further details. Double wide<br />

cabinets are available on request. Due to continued engineering improvements, specifications are subject to change without notice.<br />

• Single Door Cabinet, Pit Mounted<br />

• All Stainless Steel Construction<br />

• Insulated Chamber Construction<br />

• Smooth Sided Chamber Interior<br />

• Interior Bumper Rails<br />

• Stainless Steel Floor Grating<br />

• Illuminated Chamber Interior<br />

• Left or Right Side Service Access<br />

• Manual Swing-out, Hinged Doors<br />

• Double Level Debris Screens in Wash Chamber<br />

• External Self Cleaning Debris Filter<br />

• Overlapping Rotary Spray System<br />

• Adjustable Spray Patterns<br />

• Chemical Injection Ports, Contacts and Fittings<br />

• Double Door Pass Thru Cabinet<br />

• Low Profile 6” Base for Mounting<br />

• on Finished Floor or in Shallow Pit<br />

• Barrier Wall Trim to Close Wall Openings<br />

• Seismic Anchoring<br />

• Knocked Down Shipment<br />

• Impact or Thermal Cycle Data Printer<br />

• RS485 Port for Data Download<br />

• Water Supply Temperature Booster<br />

• Ethernet Connectivity to PLC<br />

• Automatic Chemical Injection Pumps, Time Based<br />

BWC-6 Bottle Washing Cart<br />

UBC-6 Universal Basket Cart<br />

UC-6 Universal Cart<br />

R600 SERIES CAGE & RACK WASHERS<br />

Manufactured by:<br />

STANDARD FEATURES<br />

• Stainless Steel Steam Coil Heating<br />

• Multi-cycle Microprocessor Control System<br />

• 12 Fully Adjustable Programmed Cycles<br />

• 5” Touch Screen Control Panel<br />

• Automatic Multi Phase Treatment Cycles<br />

• Program Security via Pin Number Access<br />

• Temperature Guarantee During All Cycle Phases<br />

• <strong>Built</strong>-in Diagnostics<br />

• Personnel Safety System, Door Safety Release<br />

• Fully Drained & Flushed Solution Sump<br />

Between Cycle Phases; No Carry Over<br />

• Automatic Sump Level Control<br />

• Drain Discharge Cool Down System<br />

• Water Conservation System<br />

OPTIONAL FEATURES<br />

• Stainless Steel Automatic Damper<br />

• Power Exhaust Stainless Steel Fan<br />

• Convection Air Dryer System<br />

• Vapour Removal Condenser<br />

• pH Neutralization for Effluent<br />

• Automatic Manifold Connection to Accessories<br />

• Automatic Water <strong>Rack</strong> Flushing System<br />

• Turbo Wash System<br />

• Compact Flash Card (etc)<br />

• Modem<br />

ACCESSORIES<br />

VHS-6 Vertical Header System<br />

VHS-6-R <strong>Cage</strong> <strong>Rack</strong><br />

ITR-6 Interior Tilt Ramp<br />

NORTHWESTERN SYSTEMS CORP<br />

1 3 8 8 D E RW E N T WAY, D E LTA<br />

BRITISH COLUMBIA, CANADA V3M 6C4<br />

TEL 604-777-9988 • FAX 604-777-9910<br />

T O L L F R E E : 8 8 8 - 5 5 3 - 0 8 5 5<br />

EMAIL: sales@nsc-betterbuilt.com<br />

W E B : w w w. n s c - b e t t e r b u i l t . c o m<br />

R600C&R.06.07