Advanced Granulation Technology™ (AGT™) Media for ... - Invitrogen

Advanced Granulation Technology™ (AGT™) Media for ... - Invitrogen

Advanced Granulation Technology™ (AGT™) Media for ... - Invitrogen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Advanced</strong> <strong>Granulation</strong> Technology <br />

(AGT ) <strong>Media</strong> <strong>for</strong> Bioproduction

<strong>Advanced</strong> <strong>Granulation</strong><br />

Technology <br />

<strong>Media</strong><br />

Patented technology enables<br />

complex, chemically-defined media<br />

to be supplied in an innovative,<br />

complete, dry granular <strong>for</strong>mat.<br />

• Simplify media preparation by eliminating<br />

the need to add multiple ingredients and adjust<br />

pH and osmolality<br />

• Reduce multiple vendor audits<br />

and qualifications<br />

• Reduce raw material QC testing<br />

and documentation<br />

• Improve inventory management and<br />

warehouse storage efficiency<br />

• Decrease overall process-associated<br />

documentation and training requirements<br />

• Minimize dust generation, reducing clean-up<br />

and possibilities <strong>for</strong> contamination<br />

• Dissolve instantly <strong>for</strong> faster mixing time<br />

<strong>Media</strong> Preparation<br />

Prep with <strong>Advanced</strong> <strong>Granulation</strong> Technology <strong>Media</strong><br />

AGT Complete Medium<br />

Unit Dose Package<br />

Basal Powder<br />

Medium<br />

Salts II<br />

WFI Quality<br />

Water<br />

NaHCO3<br />

WFI<br />

Water<br />

NaCl <strong>for</strong> Final<br />

Osmolality Adjustment<br />

COMPLETE CCOMPLETE O M P L E T E M MEDIUM E D I U M<br />

READY-TO-FILTER<br />

RREADY-TO-FILTER E A D Y - T O - F I L T E R<br />

Prep with Dry Powder <strong>Media</strong><br />

Growth Factors<br />

e.g. EGF<br />

HCI or NaOH <strong>for</strong><br />

pH Adjustment<br />

COMPLETE CCOMPLETE O M P L E T E M MEDIUM E D I U M<br />

READY-TO-FILTER<br />

RREADY-TO-FILTER E A D Y - T O - F I L T E R<br />

In-process<br />

pH Adjustment<br />

Acid<br />

Soluble I<br />

Lipid Supplement<br />

Stock Solution<br />

COMPLETE CCOMPLETE O M P L E T E MEDIUM MMEDIUM E D I U M<br />

READY-TO-FILTER<br />

RREADY-TO-FILTER E A D Y - T O - F I L T E R<br />

NaHCO 3<br />

WFI Quality Water<br />

Addition of NaCl <strong>for</strong><br />

Final Osmolality<br />

Adjustment<br />

Protein Supplement<br />

Stock Solution<br />

Insulin and Transferrin<br />

Stock Solutions<br />

Prep with Liquid <strong>Media</strong> Concentrates<br />

Acid<br />

Soluble II<br />

HCI or NaOH <strong>for</strong><br />

final pH Adjustment<br />

Salts I

Sometimes simplification<br />

is the best innovation.<br />

Since the early 1960s, the GIBCO brand has been associated<br />

with breakthrough technologies <strong>for</strong> cell culture. Several of these<br />

include novel media <strong>for</strong>mats that have been critical to the<br />

evolution of the process: Dry Powder <strong>Media</strong> (DPM) in 1963,<br />

Liquid <strong>Media</strong> Concentrates (LMCs) in 1992, and now—in our<br />

40th anniversary year—innovative <strong>Advanced</strong> <strong>Granulation</strong><br />

Technology (AGT) <strong>Media</strong>.<br />

<strong>Invitrogen</strong>’s patented AGT process produces a new <strong>for</strong>mat of<br />

dry media that can streamline your process from R&D and<br />

Process Development through Production.<br />

AGT media help speed your process<br />

and reduce total cycle cost.<br />

<strong>Advanced</strong> <strong>Granulation</strong> Technology produces media in a new,<br />

easy-to-use granular <strong>for</strong>mat. The technology enables the<br />

production of dry media <strong>for</strong> many complex <strong>for</strong>mulations,<br />

providing a complete single-component configuration that is<br />

easy to use and scale up from research through production.<br />

Optimally, <strong>for</strong> large-scale production, process development<br />

engineers prefer a scalable, serum-free medium in a dry <strong>for</strong>mat<br />

requiring minimum supplementation. AGT media can meet<br />

these requirements.<br />

In addition to offering AGT media in a growing variety of<br />

GIBCO catalog <strong>for</strong>mulations, we can also apply our AGT process to your complex custom <strong>for</strong>mulation.<br />

An alternative to liquid and powder.<br />

Compared to other cell culture media <strong>for</strong>mats, the AGT <strong>for</strong>mat<br />

offers those involved in process development and manufacturing<br />

many advantages.<br />

AGT media are complete and require no supplementation<br />

or pH adjustment. They eliminate additional procurement,<br />

dispensing, and process steps, and improve set-up in large-scale<br />

media operations.<br />

These media can help reduce total cycle cost. The essential<br />

benefit of a complete AGT medium is that it provides one raw<br />

material <strong>for</strong> the user, which can decrease costs and time involved<br />

in raw material planning, procurement, and testing. Medium<br />

preparation time is also lessened, because an AGT medium<br />

requires no supplementation and is pH pre-adjusted. Additionally,<br />

because the granules dissolve instantly <strong>for</strong> faster mixing and<br />

produce less dust, overall medium preparation and clean up<br />

time is reduced.<br />

AGT media offer significant advantages, both technical and<br />

operational, over other cell culture media <strong>for</strong>mats to meet the<br />

needs and requirements of the large-scale production user.<br />

1

Per<strong>for</strong>mance-Tested <strong>for</strong> Growth and Yield<br />

I<br />

2<br />

In cell culture growth and biological production studies of<br />

Hybridomas, CHO, VERO, and HEK 293 cells, GIBCO specialty media derived from the AGT process supported<br />

equivalent per<strong>for</strong>mance to identical <strong>for</strong>mulations produced by<br />

traditional liquid and powder processes. (See figures 1 and 2.)<br />

β-Gal Production (units/mL)<br />

IgG Production (ug/mL)<br />

0.4<br />

3.5<br />

0.35<br />

3<br />

0.3<br />

2.5<br />

0.25<br />

0.2<br />

0.15<br />

2<br />

1.5<br />

0.1<br />

1<br />

0.05<br />

0.5<br />

0<br />

0<br />

Day 3 Day 4 Day 5 Day 6 Day 7 Day 8 Day 9 Day 10<br />

Days in Culture<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

CD CHO 1X Liquid – β-Gal Production<br />

CD CHO AGT Lot #1 – β-Gal Production<br />

CD CHO AGT Lot #4 – β-Gal Production<br />

CD CHO 1X Liquid – cell growth<br />

CD CHO AGT Lot #1 – cell growth<br />

CD CHO AGT Lot #4 – cell growth<br />

Day 3 Day 4 Day 5 Day 6 Day 7 Day 8<br />

Days in Culture<br />

CD Hybridoma 1X Liquid – IgG Production<br />

CD Hybridoma AGT Lot #1 – IgG Production<br />

CD Hybridoma AGT Lot #2 – IgG Production<br />

Evaluated <strong>for</strong> Scalability<br />

AGT media are optimally suited to industrial-scale applications.<br />

They demonstrate scalability in characterization studies that<br />

include pH, osmolality, and homogeneity (through HPLC<br />

analysis of amino acids, vitamins, and other components).<br />

(See figures 3 through 9.)<br />

Additionally, data from ongoing real-time stability studies<br />

demonstrate stability of serum-free media made by AGT to<br />

be equivalent to conventional preparation <strong>for</strong>mats.<br />

Per<strong>for</strong>mance Scale-up Consistency<br />

CD CHO AGT: Growth and Productivity<br />

Figure 1: Comparable growth and ββ -Gal production<br />

per<strong>for</strong>mance is demonstrated with multiple lots of<br />

CD CHO AGT when tested versus 1X Liquid<br />

CD Hybridoma AGT: Growth and Productivity<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

Cell growth (viable cells x 10e6/mL)<br />

Cell growth (viable cells x 10e6/mL)<br />

CD Hybridoma 1X Liquid – cell growth<br />

CD Hybridoma AGT Lot #1 – cell growth<br />

CD Hybridoma AGT Lot #2 – cell growth<br />

Figure 2: Comparable growth and IgG production<br />

per<strong>for</strong>mance is demonstrated with multiple lots of<br />

CD Hybridoma AGT when tested versus 1X Liquid<br />

0<br />

pH Units<br />

mOsmo<br />

7.6<br />

7.5<br />

7.4<br />

7.3<br />

7.2<br />

7.1<br />

7<br />

6.9<br />

6.8<br />

6.7<br />

6.6<br />

330<br />

325<br />

320<br />

315<br />

310<br />

305<br />

300<br />

9Kg<br />

(n=1)<br />

9Kg<br />

(n=1)<br />

CD CHO AGT: pH<br />

9Kg<br />

(n=1)<br />

9Kg<br />

(n=1)<br />

9Kg<br />

(n=1)<br />

90Kg<br />

(n=6)<br />

90Kg<br />

(n=6)<br />

Lot Size<br />

(n = Number of samples tested)<br />

9Kg<br />

(n=1)<br />

90Kg<br />

(n=6)<br />

90Kg<br />

(n=6)<br />

500Kg<br />

(n=18)<br />

500Kg<br />

(n=18)<br />

500Kg<br />

(n=18)<br />

500Kg<br />

(n=18)<br />

Lot Size<br />

(n = Number of samples tested)<br />

Figure 4: Osmolality within 5 m0smo of target (325)<br />

throughout manufacturing scale-up<br />

330<br />

325<br />

320<br />

315<br />

310<br />

305<br />

300<br />

Figure 3: pH within ±0.1 pH units of target (7.4) throughout<br />

manufacturing scale-up<br />

CD CHO AGT: Osmolality<br />

mOsmo

Percentage of Direct Weigh Control<br />

120<br />

100<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Percentages of Direct Weigh Control 140<br />

0<br />

Units/mL<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0.2<br />

0.15<br />

0.1<br />

0.05<br />

0<br />

CD CHO AGT: Vitamins<br />

Folic Acid Niacinamide Riboflavin<br />

Mean +/- SEM (n=18)<br />

Thiamine B12<br />

Figure 5: Vitamin concentrations were found to be<br />

within 10% of direct weigh control<br />

Scale-up of CD CHO AGT<br />

Sample #1<br />

Sample #2<br />

Sample #3<br />

Sample #4<br />

Sample #5<br />

Sample #6<br />

Sample #7<br />

Sample #8<br />

Folic Acid<br />

Niacinamide<br />

Riboflavin<br />

Thiamine HCI<br />

L-Histidine<br />

Hydrox-L-Proline<br />

L-Isoleucine<br />

L-Leucine<br />

L-Lysine<br />

L-Methionine<br />

Mean ± SD x 2<br />

(n = Number of samples tested)<br />

3 4 5 6 7 8 9<br />

Days in Culture<br />

9Kg (n=3)<br />

90Kg (n=12)<br />

500Kg (n=36)<br />

Figure 7: Vitamin and amino acid concentrations<br />

were found to be within 10% of direct weigh control<br />

throughout batch scale-up<br />

CD CHO AGT: Productivity<br />

Figure 9: Multiple intra-lot samples demonstrated identical<br />

ββ-Gal productivity<br />

Homogeneity<br />

Percentages of Direct Weigh Control<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Cells/mL (x10e6)<br />

0<br />

ARG ASP GLM HIS ISO LYS PHE SER TYR TRP<br />

Mean +/- SEM (n=18)<br />

4.5<br />

4<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

CD CHO AGT: Amino Acids<br />

Figure 6: Amino acid concentrations from multiple<br />

intra-lot samples were found to be within 10% of<br />

direct weigh control<br />

CD CHO AGT: Growth<br />

Sample #1<br />

Sample #2<br />

Sample #3<br />

Sample #4<br />

Sample #5<br />

Sample #6<br />

Sample #7<br />

Sample #8<br />

3 4 5 6<br />

Days in Culture<br />

7 8 9<br />

Figure 8: Multiple intra-lot samples demonstrated<br />

identical growth characteristics<br />

3

A New Application <strong>for</strong><br />

Fluid Bed <strong>Granulation</strong><br />

W<br />

4<br />

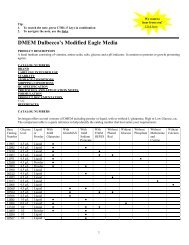

We use the pharmaceutical manufacturing technology of fluid<br />

bed granulation to manufacture AGT media. The gentle nature<br />

of fluid bed processing does not affect delicate, biologically<br />

active ingredients. This allows us to do what has never been<br />

done be<strong>for</strong>e: manufacture complex, serum-free, protein-free,<br />

and chemically-defined media in a dry <strong>for</strong>mat.<br />

In cGMP manufacturing facilities, dry biochemicals are<br />

transferred to a fluid bed processor that suspends the powder<br />

on a column of conditioned air. The suspended powder is<br />

sprayed with a fine mist of aqueous solutions, distributing trace<br />

components homogeneously. As water is evaporated from the<br />

moistened particles, they fuse together into porous granules—a<br />

new <strong>for</strong>m of free-flowing dry media, ready <strong>for</strong> hydration and<br />

immediate use.<br />

A Novel Granular Format with Unique Properties<br />

Scanning electron micrograph of GIBCO CD CHO AGT granules<br />

The granules produced by the AGT process dissolve instantly and generate<br />

minimal dust. They comprise a free flowing dry medium that is complete and<br />

pH pre-adjusted. Reconstitution with water produces ready to use media,<br />

at target pH and osmolality.<br />

GIBCO <strong>Media</strong> Available in AGT Format<br />

Chemically-Defined (CD) <strong>Media</strong> contain no proteins,<br />

hydrolysates, or components of unknown composition. All<br />

components have a known chemical structure, resulting in<br />

consistent product per<strong>for</strong>mance and the elimination of<br />

lot-to-lot per<strong>for</strong>mance variability.<br />

Protein-Free <strong>Media</strong> (PFM) are a step closer to defined<br />

<strong>for</strong>mulation as compared to serum-free. A protein-free medium<br />

may still contain undefined components of animal or plant<br />

origin (e.g., various hydrolysates that contribute low molecular<br />

weight peptides).<br />

Serum-Free <strong>Media</strong> (SFM) do not require supplementation<br />

with serum, but may contain discrete proteins or bulk protein<br />

fractions. In most cases, the protein has been kept to a minimum<br />

and the medium has been optimized <strong>for</strong> a specific cell type.<br />

To learn how innovative AGT <strong>Media</strong><br />

will improve your process, contact your<br />

<strong>Invitrogen</strong> representative <strong>for</strong> a detailed<br />

process consultation.<br />

Several GIBCO media <strong>for</strong>mulations, including those listed below,<br />

are available in the AGT <strong>for</strong>mat as standard catalog items.<br />

Others are available on a make-to-order basis.<br />

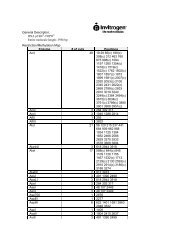

Ordering In<strong>for</strong>mation<br />

Description Cat. No. Size<br />

CD CHO AGT 12490-017 1 ✕ 1.L<br />

(Add L-glutamine if required) 12490-025 1 ✕ 10.L<br />

CD Hybridoma AGT 12372-025 1 ✕ 1.L<br />

(Add L-glutamine if required) 12372-017 1 ✕ 10.L<br />

VP-SFM AGT 12559-027 1.✕.1 L<br />

(Add L-glutamine if required) 12559-019 1.✕.10 L<br />

CD 293 AGT 12529-020 1.✕.1 L<br />

(Add L-glutamine if required) 12529-012 1.✕.10 L

United States Headquarters<br />

<strong>Invitrogen</strong> Corporation<br />

1600 Faraday Avenue<br />

Carlsbad, Cali<strong>for</strong>nia 92008<br />

Phone: 1 760 603 7200<br />

Toll Free: 1 800 955 6288<br />

Toll Free Fax: 1 800 331 2286<br />

Email: tech_service@invitrogen.com<br />

European Headquarters<br />

<strong>Invitrogen</strong> Ltd<br />

3 Fountain Drive<br />

Inchinnan Business Park<br />

Paisley PA4 9RF, UK<br />

Tel: +44 (0) 141 814 6100<br />

Fax: +44 (0) 141 814 6260<br />

Email: eurotech@invitrogen.com<br />

International Offices<br />

Argentina 5411 4556 0844<br />

Australia 1 800 331 627<br />

Austria 0800 20 1087<br />

Belgium 0800 14894<br />

Brazil 0800 11 0575<br />

Canada 800 263 6236<br />

China 10 6849 2578<br />

Denmark 80 30 17 40<br />

France 0800 23 20 79<br />

Germany 0800 083 0902<br />

Hong Kong 2407 8450<br />

India 11 577 3282<br />

Italy 02 98 22 201<br />

Japan 03 3663 7974<br />

The Netherlands 0800 099 3310<br />

New Zealand 0800 600 200<br />

Norway 22 83 16 00<br />

Spain & Portugal 900 181 461<br />

Sweden 020 26 34 52<br />

Switzerland 0800 848 800<br />

Taiwan 2 2651 6156<br />

For other countries see our website<br />

www.invitrogen.com<br />

www.invitrogen.com/gibco<br />

For 40 years, one name has been synonymous<br />

with quality and reliability in cell culture<br />

media, sera, and reagents worldwide.<br />

Printed on recycled paper<br />

These products are <strong>for</strong> research use, and where appropriate, as raw material<br />

components in further cell culture manufacturing applications. They are not<br />

intended <strong>for</strong> human or animal diagnostic, therapeutic, or other clinical uses,<br />

unless otherwise stated.<br />

Photograph of fluid bed processor courtesy of Glatt Air Technologies, Inc.,<br />

Ramsey, N.J.; electron micrograph of AGT granules courtesy of McGill<br />

University, Montreal, Quebec.<br />

© 2002 <strong>Invitrogen</strong> Corporation PAS02-041MS Part No. 332-021646