Product brief Angl.recto Hydroclean - VAM Drilling

Product brief Angl.recto Hydroclean - VAM Drilling

Product brief Angl.recto Hydroclean - VAM Drilling

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>VAM</strong> <strong>Drilling</strong>’s patented <strong>Hydroclean</strong> is a Hydro-Mechanical Hole Cleaning Device (MCD) uniquely designed to<br />

increase hole cleaning efficiencies while drilling primarily large hole sections of in highly deviated wells. The tool<br />

features fit-for-purpose bladed scallops and grooves producing a number of hydro-mechanical effects resulting in<br />

drilling performance improvements. The <strong>Hydroclean</strong> has two separate design configurations, one in the form of a<br />

drill pipe joint (HDP) and the other in the form of a Heavy Weight Drill Pipe (HHW), both configured as an add-on to the<br />

drill string. When adequately spaced and properly used, measurable performance improvements can be expected.<br />

These are achieved by eroding or eliminating cutting beds buildup which naturally develop with the drilling process.<br />

Consequently wells clean faster and better with less time spent on cleanups.<br />

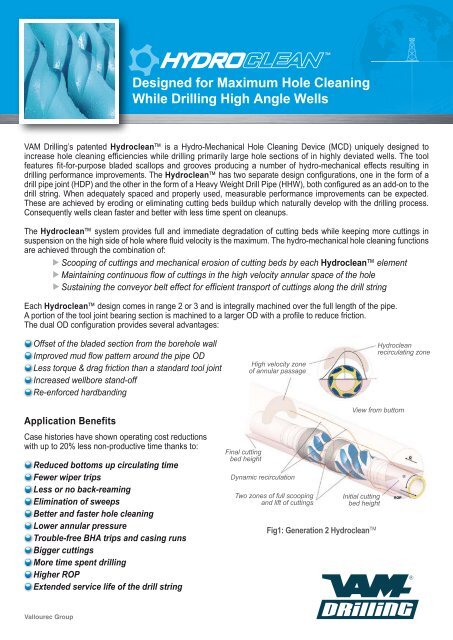

The <strong>Hydroclean</strong> system provides full and immediate degradation of cutting beds while keeping more cuttings in<br />

suspension on the high side of hole where fluid velocity is the maximum. The hydro-mechanical hole cleaning functions<br />

are achieved through the combination of:<br />

Scooping of cuttings and mechanical erosion of cutting beds by each <strong>Hydroclean</strong> element<br />

Maintaining continuous flow of cuttings in the high velocity annular space of the hole<br />

Sustaining the conveyor belt effect for efficient transport of cuttings along the drill string<br />

Each <strong>Hydroclean</strong> design comes in range 2 or 3 and is integrally machined over the full length of the pipe.<br />

A portion of the tool joint bearing section is machined to a larger OD with a profile to reduce friction.<br />

The dual OD configuration provides several advantages:<br />

Offset of the bladed section from the borehole wall<br />

Improved mud flow pattern around the pipe OD<br />

Less torque & drag friction than a standard tool joint<br />

Increased wellbore stand-off<br />

Re-enforced hardbanding<br />

Application Benefits<br />

Case histories have shown operating cost reductions<br />

with up to 20% less non-productive time thanks to:<br />

Reduced bottoms up circulating time<br />

Fewer wiper trips<br />

Less or no back-reaming<br />

Elimination of sweeps<br />

Better and faster hole cleaning<br />

Lower annular pressure<br />

Trouble-free BHA trips and casing runs<br />

Bigger cuttings<br />

More time spent drilling<br />

Higher ROP<br />

Extended service life of the drill string<br />

Designed for Maximum Hole Cleaning<br />

While <strong>Drilling</strong> High <strong>Angl</strong>e Wells<br />

Final cutting<br />

bed height<br />

High velocity zone<br />

of annular passage<br />

Dynamic recirculation<br />

Two zones of full scooping<br />

and lift of cuttings<br />

Initial cutting<br />

bed height<br />

Fig1: Generation 2 <strong>Hydroclean</strong> TM<br />

<strong>Hydroclean</strong><br />

recirculating zone<br />

View from buttom

For general information only ©<strong>VAM</strong> DRILLING FRANCE - September 2012 - All rights reserved.<br />

<strong>Hydroclean</strong> - HDP<br />

<strong>Hydroclean</strong> - HDP is manufactured with a welded construction design featuring a dual OD tool joint and three bladed upsets machined directly onto<br />

the pipe body. Standard casing friendly hardbanding is also applied. On average HDP is 20-25% heavier than standard drill pipe.<br />

HDP is operated with standard rig handling equipment and may require switching top drives in manual mode when operated in automatic.<br />

<strong>Hydroclean</strong> HDP - Construction Data<br />

<strong>Hydroclean</strong> Drill Pipe - Dimensional Data<br />

A Nominal OD<br />

2 7/8<br />

3 1/2<br />

4<br />

4 1/2<br />

5<br />

5 1/2<br />

B Tube ID<br />

2<br />

2 5/8<br />

3<br />

3 1/2<br />

4<br />

4 1/2<br />

C Tool Joint OD*<br />

4 1/8<br />

4 3/4<br />

5 1/2<br />

6 1/4<br />

6 5/8<br />

7<br />

D Tool Joint ID*<br />

2<br />

2 9/16 2 9/16<br />

3<br />

3 1/4<br />

3 3/4<br />

E Tool Joint length Box 23<br />

23<br />

23<br />

23<br />

23<br />

23<br />

F Tool Joint length Pin 29<br />

29<br />

29<br />

29<br />

29<br />

29<br />

G Connection type* NC 31 <strong>VAM</strong> EIS NC 38 <strong>VAM</strong> EIS NC 40 <strong>VAM</strong> EIS NC 46 <strong>VAM</strong> EIS NC 50 <strong>VAM</strong> EIS 5 1/2 FH <strong>VAM</strong> EIS<br />

H Dual OD<br />

4 3/4<br />

5 3/8<br />

5 7/8<br />

6 5/8<br />

7<br />

7 5/8<br />

I <strong>Hydroclean</strong> Diameter 4 5/16 4 15/16 5 7/16 6 3/16 6 5/8<br />

7 3/16<br />

J Upset length<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

K Central Upset Spacing 57<br />

57<br />

57<br />

57<br />

57<br />

57<br />

L Overall length*<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

M<br />

Hardbanding Length<br />

Tool Joint<br />

2 * 3" 2 * 3" 2 * 3" 2 * 3" 2 * 3"<br />

2 * 3"<br />

N Hardbanding Length<br />

Central Part<br />

*Can be modified on request<br />

2 * 3" 2 * 3" 2 * 3" 2 * 3" 2 * 3"<br />

2 * 3"<br />

Range 3 is available on request<br />

<strong>Hydroclean</strong> Heavy Weight - HHW<br />

<strong>Hydroclean</strong> Heavy Weight - HHW is manufactured in a mono-block construction with two bladed upsets machined directly onto the tube body.<br />

HHW is run with conventional heavy weight drill pipe. Experience has shown that placing HHW as near as possible to the large OD BHA components<br />

can significantly reduce the risk of pack-off in this critical area.<br />

<strong>Hydroclean</strong> HHW - Construction Data<br />

<strong>Hydroclean</strong> Heavy Weight Drill Pipe - Dimensional Data<br />

A Nominal OD<br />

2 7/8<br />

3 1/2<br />

4<br />

4 1/2<br />

5<br />

5 1/2<br />

B Tube ID<br />

1 1/2 2 1/16 2 1/2<br />

2 3/4<br />

3<br />

3 3/4<br />

C Tool Joint OD*<br />

4 1/8<br />

4 3/4<br />

5 1/2<br />

6 1/4<br />

6 5/8<br />

7<br />

D Tool Joint ID*<br />

2<br />

2 9/16 2 9/16<br />

3<br />

3 1/4<br />

3 3/4<br />

E Tool Joint length Box 26<br />

26<br />

26<br />

26<br />

26<br />

26<br />

F Tool Joint length Pin 30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

G Connection type* NC 31 <strong>VAM</strong> EIS NC 38 <strong>VAM</strong> EIS NC 40 <strong>VAM</strong> EIS NC 46 <strong>VAM</strong> EIS NC 50 <strong>VAM</strong> EIS 5 1/2 FH <strong>VAM</strong> EIS<br />

H Dual OD<br />

4 3/4<br />

5 3/8<br />

5 7/8<br />

6 5/8<br />

7<br />

7 5/8<br />

I <strong>Hydroclean</strong> Diameter 4 5/16 4 15/16 5 7/16 6 3/16 6 5/8<br />

7 3/16<br />

J Upset length<br />

48<br />

48<br />

48<br />

48<br />

48<br />

48<br />

K Central Upset Spacing 66 2/3 66 2/3 66 2/3 66 2/3 66 2/3 66 2/3<br />

L Overall length*<br />

31<br />

31<br />

31<br />

31<br />

31<br />

31<br />

M<br />

Hardbanding Length<br />

Tool Joint<br />

2 * 3" 2 * 3" 2 * 3" 2 * 3" 2 * 3"<br />

2 * 3"<br />

N<br />

Hardbanding Length<br />

Central Part<br />

*Can be modified on request<br />

2 * 4" 2 * 4" 2 * 4" 2 * 4" 2 * 4"<br />

2 * 4"<br />

Range 3 is available on request<br />

5 7/8<br />

4 7/8<br />

7<br />

4 1/4<br />

23<br />

29<br />

VX 57<br />

8 1/8<br />

7 11/16<br />

24<br />

57<br />

31<br />

2 * 3"<br />

2 * 3"<br />

5 7/8<br />

4<br />

7<br />

4 1/4<br />

26<br />

30<br />

VX 57<br />

8 1/8<br />

7 11/16<br />

48<br />

66 2/3<br />

31<br />

2 * 3"<br />

2 * 4"<br />

6 5/8<br />

5 1/2<br />

8<br />

5<br />

23<br />

29<br />

6 5/8 FH <strong>VAM</strong> EIS<br />

8 5/8<br />

8 3/16<br />

24<br />

57<br />

31<br />

2 * 3"<br />

2 * 3"<br />

6 5/8<br />

4 1/2<br />

8<br />

5<br />

26<br />

30<br />

6 5/8 FH <strong>VAM</strong> EIS<br />

8 5/8<br />

8 3/16<br />

48<br />

66 2/3<br />

31<br />

2 * 3"<br />

2 * 4"