Bioethanol – status report on bioethanol production from wood and ...

Bioethanol – status report on bioethanol production from wood and ...

Bioethanol – status report on bioethanol production from wood and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Lignin is a byproduct of this process, <strong>and</strong> can be used<br />

as a boiler fuel or processed into specialty chemicals.<br />

Hydrolysis <strong>and</strong> fermentati<strong>on</strong> can be c<strong>on</strong>ducted<br />

simultaneously in <strong>on</strong>e stage but simultaneous<br />

saccharificati<strong>on</strong> <strong>and</strong> fermentati<strong>on</strong> (SSF) is yet to be<br />

implemented commercially, significant advances are<br />

being made in this area.<br />

Thermochemical c<strong>on</strong>versi<strong>on</strong><br />

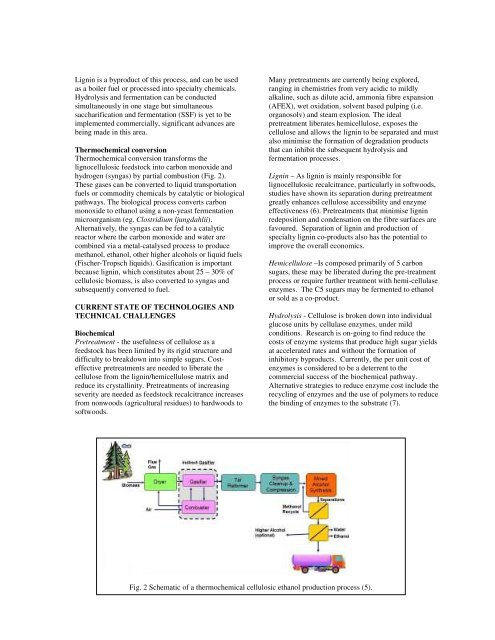

Thermochemical c<strong>on</strong>versi<strong>on</strong> transforms the<br />

lignocellulosic feedstock into carb<strong>on</strong> m<strong>on</strong>oxide <strong>and</strong><br />

hydrogen (syngas) by partial combusti<strong>on</strong> (Fig. 2).<br />

These gases can be c<strong>on</strong>verted to liquid transportati<strong>on</strong><br />

fuels or commodity chemicals by catalytic or biological<br />

pathways. The biological process c<strong>on</strong>verts carb<strong>on</strong><br />

m<strong>on</strong>oxide to ethanol using a n<strong>on</strong>-yeast fermentati<strong>on</strong><br />

microorganism (eg. Clostridium ljungdahlii).<br />

Alternatively, the syngas can be fed to a catalytic<br />

reactor where the carb<strong>on</strong> m<strong>on</strong>oxide <strong>and</strong> water are<br />

combined via a metal-catalysed process to produce<br />

methanol, ethanol, other higher alcohols or liquid fuels<br />

(Fischer-Tropsch liquids). Gasificati<strong>on</strong> is important<br />

because lignin, which c<strong>on</strong>stitutes about 25 <str<strong>on</strong>g>–</str<strong>on</strong>g> 30% of<br />

cellulosic biomass, is also c<strong>on</strong>verted to syngas <strong>and</strong><br />

subsequently c<strong>on</strong>verted to fuel.<br />

CURRENT STATE OF TECHNOLOGIES AND<br />

TECHNICAL CHALLENGES<br />

Biochemical<br />

Pretreatment - the usefulness of cellulose as a<br />

feedstock has been limited by its rigid structure <strong>and</strong><br />

difficulty to breakdown into simple sugars. Costeffective<br />

pretreatments are needed to liberate the<br />

cellulose <strong>from</strong> the lignin/hemicellulose matrix <strong>and</strong><br />

reduce its crystallinity. Pretreatments of increasing<br />

severity are needed as feedstock recalcitrance increases<br />

<strong>from</strong> n<strong>on</strong><strong>wood</strong>s (agricultural residues) to hard<strong>wood</strong>s to<br />

soft<strong>wood</strong>s.<br />

Many pretreatments are currently being explored,<br />

ranging in chemistries <strong>from</strong> very acidic to mildly<br />

alkaline, such as dilute acid, amm<strong>on</strong>ia fibre expansi<strong>on</strong><br />

(AFEX), wet oxidati<strong>on</strong>, solvent based pulping (i.e.<br />

organosolv) <strong>and</strong> steam explosi<strong>on</strong>. The ideal<br />

pretreatment liberates hemicellulose, exposes the<br />

cellulose <strong>and</strong> allows the lignin to be separated <strong>and</strong> must<br />

also minimise the formati<strong>on</strong> of degradati<strong>on</strong> products<br />

that can inhibit the subsequent hydrolysis <strong>and</strong><br />

fermentati<strong>on</strong> processes.<br />

Lignin <str<strong>on</strong>g>–</str<strong>on</strong>g> As lignin is mainly resp<strong>on</strong>sible for<br />

lignocellulosic recalcitrance, particularly in soft<strong>wood</strong>s,<br />

studies have shown its separati<strong>on</strong> during pretreatment<br />

greatly enhances cellulose accessibility <strong>and</strong> enzyme<br />

effectiveness (6). Pretreatments that minimise lignin<br />

redepositi<strong>on</strong> <strong>and</strong> c<strong>on</strong>densati<strong>on</strong> <strong>on</strong> the fibre surfaces are<br />

favoured. Separati<strong>on</strong> of lignin <strong>and</strong> producti<strong>on</strong> of<br />

specialty lignin co-products also has the potential to<br />

improve the overall ec<strong>on</strong>omics.<br />

Hemicellulose <str<strong>on</strong>g>–</str<strong>on</strong>g>Is composed primarily of 5 carb<strong>on</strong><br />

sugars, these may be liberated during the pre-treatment<br />

process or require further treatment with hemi-cellulase<br />

enzymes. The C5 sugars may be fermented to ethanol<br />

or sold as a co-product.<br />

Hydrolysis - Cellulose is broken down into individual<br />

glucose units by cellulase enzymes, under mild<br />

c<strong>on</strong>diti<strong>on</strong>s. Research is <strong>on</strong>-going to find reduce the<br />

costs of enzyme systems that produce high sugar yields<br />

at accelerated rates <strong>and</strong> without the formati<strong>on</strong> of<br />

inhibitory byproducts. Currently, the per unit cost of<br />

enzymes is c<strong>on</strong>sidered to be a deterrent to the<br />

commercial success of the biochemical pathway.<br />

Alternative strategies to reduce enzyme cost include the<br />

recycling of enzymes <strong>and</strong> the use of polymers to reduce<br />

the binding of enzymes to the substrate (7).<br />

Fig. 2 Schematic of a thermochemical cellulosic ethanol producti<strong>on</strong> process (5).