Bioethanol – status report on bioethanol production from wood and ...

Bioethanol – status report on bioethanol production from wood and ...

Bioethanol – status report on bioethanol production from wood and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

part of the integrated biorefinery. Ethanol is<br />

produced through enzymatic hydrolysis, while heat<br />

<strong>and</strong> power are generated using gasificati<strong>on</strong>.<br />

Currently the plant processes 70 tpd of biomass.<br />

The plant is being exp<strong>and</strong>ed to h<strong>and</strong>le up to 1500<br />

tpd. Steam explosi<strong>on</strong> pre-treatment will be used<br />

prior to enzymatic hydrolysis. Since mid-2007,<br />

Abengoa has operated a pilot plant in York, NE<br />

using corn stover. 0.08 ML/yr of ethanol can be<br />

produced using enzymatic hydrolysis <strong>and</strong><br />

fermentati<strong>on</strong> of C5 <strong>and</strong> C6 sugars. Abengoa also<br />

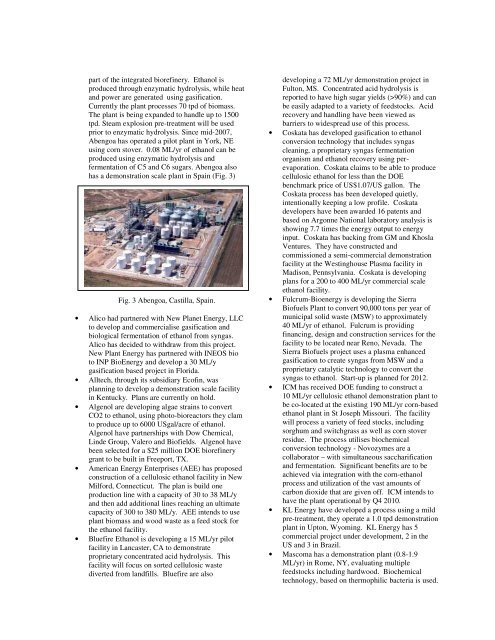

has a dem<strong>on</strong>strati<strong>on</strong> scale plant in Spain (Fig. 3)<br />

•<br />

•<br />

•<br />

•<br />

Fig. 3 Abengoa, Castilla, Spain.<br />

• Alico had partnered with New Planet Energy, LLC<br />

to develop <strong>and</strong> commercialise gasificati<strong>on</strong> <strong>and</strong><br />

biological fermentati<strong>on</strong> of ethanol <strong>from</strong> syngas.<br />

Alico has decided to withdraw <strong>from</strong> this project.<br />

New Plant Energy has partnered with INEOS bio<br />

to INP BioEnergy <strong>and</strong> develop a 30 ML/y<br />

gasificati<strong>on</strong> based project in Florida.<br />

• Alltech, through its subsidiary Ecofin, was<br />

planning to develop a dem<strong>on</strong>strati<strong>on</strong> scale facility<br />

in Kentucky. Plans are currently <strong>on</strong> hold.<br />

• Algenol are developing algae strains to c<strong>on</strong>vert<br />

CO2 to ethanol, using photo-bioreactors they clam<br />

to produce up to 6000 USgal/acre of ethanol.<br />

Algenol have partnerships with Dow Chemical,<br />

Linde Group, Valero <strong>and</strong> Biofields. Algenol have<br />

been selected for a $25 milli<strong>on</strong> DOE biorefinery<br />

grant to be built in Freeport, TX.<br />

• American Energy Enterprises (AEE) has proposed<br />

c<strong>on</strong>structi<strong>on</strong> of a cellulosic ethanol facility in New<br />

Milford, C<strong>on</strong>necticut. The plan is build <strong>on</strong>e<br />

producti<strong>on</strong> line with a capacity of 30 to 38 ML/y<br />

<strong>and</strong> then add additi<strong>on</strong>al lines reaching an ultimate<br />

capacity of 300 to 380 ML/y. AEE intends to use<br />

plant biomass <strong>and</strong> <strong>wood</strong> waste as a feed stock for<br />

the ethanol facility.<br />

• Bluefire Ethanol is developing a 15 ML/yr pilot<br />

facility in Lancaster, CA to dem<strong>on</strong>strate<br />

proprietary c<strong>on</strong>centrated acid hydrolysis. This<br />

facility will focus <strong>on</strong> sorted cellulosic waste<br />

diverted <strong>from</strong> l<strong>and</strong>fills. Bluefire are also<br />

developing a 72 ML/yr dem<strong>on</strong>strati<strong>on</strong> project in<br />

Fult<strong>on</strong>, MS. C<strong>on</strong>centrated acid hydrolysis is<br />

<str<strong>on</strong>g>report</str<strong>on</strong>g>ed to have high sugar yields (>90%) <strong>and</strong> can<br />

be easily adapted to a variety of feedstocks. Acid<br />

recovery <strong>and</strong> h<strong>and</strong>ling have been viewed as<br />

barriers to widespread use of this process.<br />

• Coskata has developed gasificati<strong>on</strong> to ethanol<br />

c<strong>on</strong>versi<strong>on</strong> technology that includes syngas<br />

cleaning, a proprietary syngas fermentati<strong>on</strong><br />

organism <strong>and</strong> ethanol recovery using perevaporati<strong>on</strong>.<br />

Coskata claims to be able to produce<br />

cellulosic ethanol for less than the DOE<br />

benchmark price of US$1.07/US gall<strong>on</strong>. The<br />

Coskata process has been developed quietly,<br />

intenti<strong>on</strong>ally keeping a low profile. Coskata<br />

developers have been awarded 16 patents <strong>and</strong><br />

based <strong>on</strong> Arg<strong>on</strong>ne Nati<strong>on</strong>al laboratory analysis is<br />

showing 7.7 times the energy output to energy<br />

input. Coskata has backing <strong>from</strong> GM <strong>and</strong> Khosla<br />

Ventures. They have c<strong>on</strong>structed <strong>and</strong><br />

commissi<strong>on</strong>ed a semi-commercial dem<strong>on</strong>strati<strong>on</strong><br />

facility at the Westinghouse Plasma facility in<br />

Madis<strong>on</strong>, Pennsylvania. Coskata is developing<br />

plans for a 200 to 400 ML/yr commercial scale<br />

ethanol facility.<br />

• Fulcrum-Bioenergy is developing the Sierra<br />

Biofuels Plant to c<strong>on</strong>vert 90,000 t<strong>on</strong>s per year of<br />

municipal solid waste (MSW) to approximately<br />

40 ML/yr of ethanol. Fulcrum is providing<br />

financing, design <strong>and</strong> c<strong>on</strong>structi<strong>on</strong> services for the<br />

facility to be located near Reno, Nevada. The<br />

Sierra Biofuels project uses a plasma enhanced<br />

gasificati<strong>on</strong> to create syngas <strong>from</strong> MSW <strong>and</strong> a<br />

proprietary catalytic technology to c<strong>on</strong>vert the<br />

syngas to ethanol. Start-up is planned for 2012.<br />

• ICM has received DOE funding to c<strong>on</strong>struct a<br />

10 ML/yr cellulosic ethanol dem<strong>on</strong>strati<strong>on</strong> plant to<br />

be co-located at the existing 190 ML/yr corn-based<br />

ethanol plant in St Joseph Missouri. The facility<br />

will process a variety of feed stocks, including<br />

sorghum <strong>and</strong> switchgrass as well as corn stover<br />

residue. The process utilises biochemical<br />

c<strong>on</strong>versi<strong>on</strong> technology - Novozymes are a<br />

collaborator <str<strong>on</strong>g>–</str<strong>on</strong>g> with simultaneous saccharificati<strong>on</strong><br />

<strong>and</strong> fermentati<strong>on</strong>. Significant benefits are to be<br />

achieved via integrati<strong>on</strong> with the corn-ethanol<br />

process <strong>and</strong> utilizati<strong>on</strong> of the vast amounts of<br />

carb<strong>on</strong> dioxide that are given off. ICM intends to<br />

have the plant operati<strong>on</strong>al by Q4 2010.<br />

• KL Energy have developed a process using a mild<br />

pre-treatment, they operate a 1.0 tpd dem<strong>on</strong>strati<strong>on</strong><br />

plant in Upt<strong>on</strong>, Wyoming. KL Energy has 5<br />

commercial project under development, 2 in the<br />

US <strong>and</strong> 3 in Brazil.<br />

• Mascoma has a dem<strong>on</strong>strati<strong>on</strong> plant (0.8-1.9<br />

ML/yr) in Rome, NY, evaluating multiple<br />

feedstocks including hard<strong>wood</strong>. Biochemical<br />

technology, based <strong>on</strong> thermophilic bacteria is used.