Hazard Alert No 112 Blade failure of a wood chipper - SafeWork SA ...

Hazard Alert No 112 Blade failure of a wood chipper - SafeWork SA ...

Hazard Alert No 112 Blade failure of a wood chipper - SafeWork SA ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HAZARD ALERT<br />

<strong>No</strong>. <strong>112</strong> ISSUED: OCTOBER 2012<br />

BLADE FAILURE OF A WOOD CHIPPER<br />

SUMMARY OF INCIDENT<br />

A <strong>wood</strong> <strong>chipper</strong> machine was in use when a sudden<br />

<strong>failure</strong> resulted in a cutting blade shattering and<br />

large fragments were ejected through the solid metal<br />

guard.<br />

The <strong>failure</strong> had the potential to cause serious injury<br />

to the <strong>wood</strong> <strong>chipper</strong> operator or other workers in the<br />

vicinity.<br />

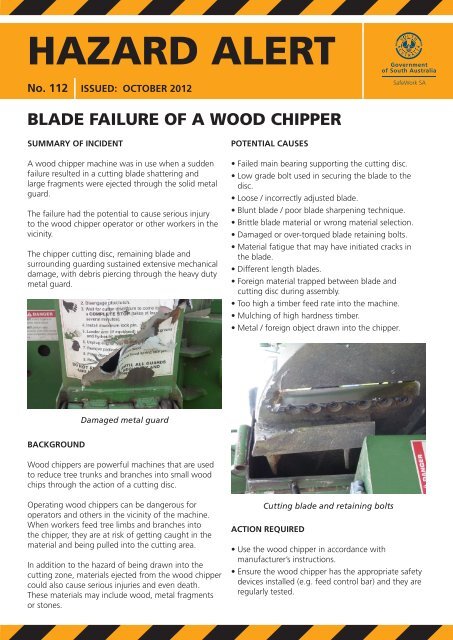

The <strong>chipper</strong> cutting disc, remaining blade and<br />

surrounding guarding sustained extensive mechanical<br />

damage, with debris piercing through the heavy duty<br />

metal guard.<br />

BACKGROUND<br />

Damaged metal guard<br />

Wood <strong>chipper</strong>s are powerful machines that are used<br />

to reduce tree trunks and branches into small <strong>wood</strong><br />

chips through the action <strong>of</strong> a cutting disc.<br />

Operating <strong>wood</strong> <strong>chipper</strong>s can be dangerous for<br />

operators and others in the vicinity <strong>of</strong> the machine.<br />

When workers feed tree limbs and branches into<br />

the <strong>chipper</strong>, they are at risk <strong>of</strong> getting caught in the<br />

material and being pulled into the cutting area.<br />

In addition to the hazard <strong>of</strong> being drawn into the<br />

cutting zone, materials ejected from the <strong>wood</strong> <strong>chipper</strong><br />

could also cause serious injuries and even death.<br />

These materials may include <strong>wood</strong>, metal fragments<br />

or stones.<br />

POTENTIAL CAUSES<br />

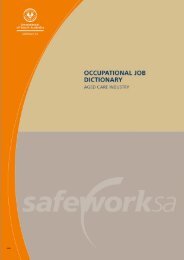

• Failed main bearing supporting the cutting disc.<br />

• Low grade bolt used in securing the blade to the<br />

disc.<br />

• Loose / incorrectly adjusted blade.<br />

• Blunt blade / poor blade sharpening technique.<br />

• Brittle blade material or wrong material selection.<br />

• Damaged or over-torqued blade retaining bolts.<br />

• Material fatigue that may have initiated cracks in<br />

the blade.<br />

• Different length blades.<br />

• Foreign material trapped between blade and<br />

cutting disc during assembly.<br />

• Too high a timber feed rate into the machine.<br />

• Mulching <strong>of</strong> high hardness timber.<br />

• Metal / foreign object drawn into the <strong>chipper</strong>.<br />

Cutting blade and retaining bolts<br />

ACTION REQUIRED<br />

• Use the <strong>wood</strong> <strong>chipper</strong> in accordance with<br />

manufacturer’s instructions.<br />

• Ensure the <strong>wood</strong> <strong>chipper</strong> has the appropriate safety<br />

devices installed (e.g. feed control bar) and they are<br />

regularly tested.

- 2 -<br />

The manufacturer <strong>of</strong> the “Super Axe” has developed a that any axe blade control systems are properly labelled and<br />

modification • Check the that condition includes <strong>of</strong> a double blades action prior to to startup, interlock the cannot be inadvertently activated.<br />

blade including control, minimising the securing unintended bolts. operation.<br />

• Ensure workers wear the appropriate Personal All operators should be trained in the operation <strong>of</strong> log<br />

Install Protective the modification Equipment provided (PPE). by the manufacturer. splitting machines.<br />

• All repairs/servicing must be done by competent Safety Procedures should include a system <strong>of</strong> work<br />

Owners persons. and operators <strong>of</strong> machines with a similar operating to shutdown or isolate the axe control system before<br />

mechanism<br />

• Establish<br />

should<br />

a regular<br />

check<br />

servicing,<br />

their machines<br />

maintenance<br />

to see if<br />

and<br />

similar attempting to free a log stuck on the axe blade.<br />

modifications<br />

inspection<br />

are<br />

program.<br />

required.<br />

Repair or replace faulty parts<br />

as identified from inspection.<br />

Safety procedures should be regularly monitored and<br />

Owners and operators <strong>of</strong> log splitters should make sure reinforced<br />

• Ensure that a hazardous work zone is appropriately<br />

that any axe blade control systems are properly labelled and<br />

identified to exclude members <strong>of</strong> the public and<br />

cannot be inadvertently activated.<br />

FURTHER INFORMATION<br />

non-essential workers.<br />

For further information please contact:<br />

All operators should be trained in the operation <strong>of</strong> log<br />

splitting machines.<br />

<strong>SafeWork</strong> <strong>SA</strong><br />

GPO Box 465<br />

ADELAIDE <strong>SA</strong> 5001<br />

Safety Procedures should include a system <strong>of</strong> work<br />

to shutdown or isolate the axe control system before<br />

attempting to free a log stuck on the axe blade.<br />

Safety procedures should be regularly monitored and<br />

reinforced<br />

This incident may be unique to the leg operated axe control<br />

<strong>of</strong> the Whitlands Engineering “Super Axe”<br />

A stirrup fits around the operator’s upper right leg, with<br />

movement <strong>of</strong> the leg causing the axe blade to either raise<br />

or lower.<br />

When a log stuck on the axe blade, the operator used<br />

both hands try and lever the log <strong>of</strong>f the axe blade, as<br />

the operator moved, the machine accidentally operated,<br />

crushing three fingers <strong>of</strong> the worker’s left hand between<br />

the log and the machine table.<br />

ACTION REQUIRED<br />

The manufacturer <strong>of</strong> the “Super Axe” has developed a<br />

modification that includes a double action to interlock the<br />

blade control, minimising unintended operation.<br />

Install the modification provided by the manufacturer.<br />

Owners and operators <strong>of</strong> machines with a similar operating<br />

mechanism should check their machines to see if similar<br />

modifications are required.<br />

Issued: October 2012<br />

Owners Review: and operators October 2014<br />

<strong>of</strong> log splitters should make sure<br />

CONTACT DETAILS<br />

Country Offices<br />

Berri, Mount Gambier, Port Lincoln, Port Pirie and Whyalla<br />

Help Centre<br />

Library and Bookshop<br />

100 Waymouth Street, Adelaide<br />

Telephone: 1300 365 255<br />

Website: www.safework.sa.gov.au<br />

Issued: July 2011<br />

Review: July 2013<br />

<strong>SafeWork</strong> <strong>SA</strong>: GPO Box 465, ADELAIDE <strong>SA</strong> 5001<br />

Country <strong>of</strong>fices: Berri, Mount Gambier, Port Lincoln, Port Pirie and Whyalla<br />

Library and Bookshop: Ground floor, State Administration Centre<br />

200 Victoria Square, Adelaide<br />

Help Centre: 1300 365 255<br />

www.safework.sa.gov.au<br />

This information is provided to <strong>of</strong>fer<br />

guidance on a particular aspect <strong>of</strong><br />

legislation. It is not to be taken as a<br />

statement <strong>of</strong> law and must not be<br />

construed to waive or modify any<br />

legal obligation.