Xtra-Seal Chipping Compound - Icopal

Xtra-Seal Chipping Compound - Icopal

Xtra-Seal Chipping Compound - Icopal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

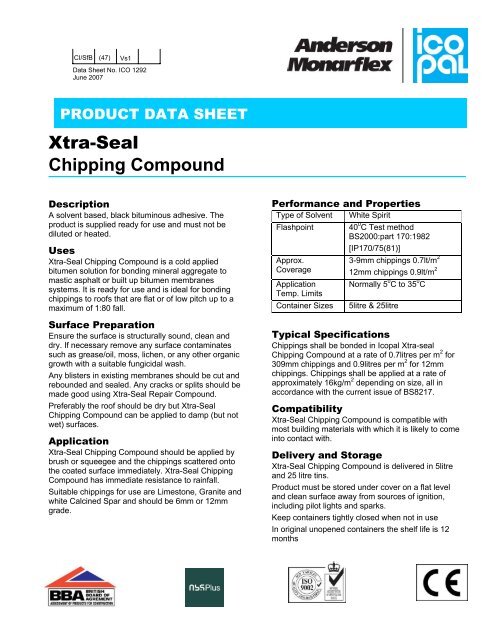

CI/SfB<br />

(47) Vs1<br />

Data Sheet No. ICO 1292<br />

June 2007<br />

PRODUCT DATA SHEET<br />

<strong>Xtra</strong>-<strong>Seal</strong><br />

<strong>Chipping</strong> <strong>Compound</strong><br />

Description<br />

A solvent based, black bituminous adhesive. The<br />

product is supplied ready for use and must not be<br />

diluted or heated.<br />

Uses<br />

<strong>Xtra</strong>-<strong>Seal</strong> <strong>Chipping</strong> <strong>Compound</strong> is a cold applied<br />

bitumen solution for bonding mineral aggregate to<br />

mastic asphalt or built up bitumen membranes<br />

systems. It is ready for use and is ideal for bonding<br />

chippings to roofs that are flat or of low pitch up to a<br />

maximum of 1:80 fall.<br />

Surface Preparation<br />

Ensure the surface is structurally sound, clean and<br />

dry. If necessary remove any surface contaminates<br />

such as grease/oil, moss, lichen, or any other organic<br />

growth with a suitable fungicidal wash.<br />

Any blisters in existing membranes should be cut and<br />

rebounded and sealed. Any cracks or splits should be<br />

made good using <strong>Xtra</strong>-<strong>Seal</strong> Repair <strong>Compound</strong>.<br />

Preferably the roof should be dry but <strong>Xtra</strong>-<strong>Seal</strong><br />

<strong>Chipping</strong> <strong>Compound</strong> can be applied to damp (but not<br />

wet) surfaces.<br />

Application<br />

<strong>Xtra</strong>-<strong>Seal</strong> <strong>Chipping</strong> <strong>Compound</strong> should be applied by<br />

brush or squeegee and the chippings scattered onto<br />

the coated surface immediately. <strong>Xtra</strong>-<strong>Seal</strong> <strong>Chipping</strong><br />

<strong>Compound</strong> has immediate resistance to rainfall.<br />

Suitable chippings for use are Limestone, Granite and<br />

white Calcined Spar and should be 6mm or 12mm<br />

grade.<br />

Performance and Properties<br />

Type of Solvent White Spirit<br />

Flashpoint 40 0 C Test method<br />

BS2000:part 170:1982<br />

[IP170/75(81)]<br />

Approx.<br />

3-9mm chippings 0.7lt/m<br />

Coverage<br />

2<br />

12mm chippings 0.9lt/m 2<br />

Application Normally 5<br />

Temp. Limits<br />

0 C to 35 0 C<br />

Container Sizes 5litre & 25litre<br />

Typical Specifications<br />

<strong>Chipping</strong>s shall be bonded in <strong>Icopal</strong> <strong>Xtra</strong>-seal<br />

<strong>Chipping</strong> <strong>Compound</strong> at a rate of 0.7litres per m 2 for<br />

309mm chippings and 0.9litres per m 2 for 12mm<br />

chippings. <strong>Chipping</strong>s shall be applied at a rate of<br />

approximately 16kg/m 2 depending on size, all in<br />

accordance with the current issue of BS8217.<br />

Compatibility<br />

<strong>Xtra</strong>-<strong>Seal</strong> <strong>Chipping</strong> <strong>Compound</strong> is compatible with<br />

most building materials with which it is likely to come<br />

into contact with.<br />

Delivery and Storage<br />

<strong>Xtra</strong>-<strong>Seal</strong> <strong>Chipping</strong> <strong>Compound</strong> is delivered in 5litre<br />

and 25 litre tins.<br />

Product must be stored under cover on a flat level<br />

and clean surface away from sources of ignition,<br />

including pilot lights and sparks.<br />

Keep containers tightly closed when not in use<br />

In original unopened containers the shelf life is 12<br />

months

PRODUCT DATA SHEET<br />

<strong>Xtra</strong>-<strong>Seal</strong> <strong>Chipping</strong> Solution<br />

Health and Safety<br />

Flammability: Flammable<br />

Keep away from sources of ignition including pilot<br />

lights and sparks.<br />

Take precautionary measures against static<br />

discharge.<br />

Keep containers tightly closed when not in use.<br />

DO NOT SMOKE<br />

If used in an enclosed space ensure thorough<br />

ventilation of the area (using flame proof mechanical<br />

blowers if necessary) to avoid any accumulation of<br />

vapour until the product has dried. In case of fire use<br />

dry powder, carbon dioxide (CO2), foam, sand or<br />

earth. Never use water as this may spread the fire.<br />

Note: Electric motors, light/power switches and steel<br />

tools may generate sparks sufficient to ignite the<br />

product or vapour, resulting in an explosion and/or<br />

fire.<br />

Skin Contact: Contains solvents that cause de-fatting<br />

of the skin and, in extreme circumstances dermatitis.<br />

Avoid contact by careful working and use of barrier<br />

creams or wear gloves. Remove skin contamination<br />

immediately with a proprietary cleaner and wash<br />

hands with soap and water.<br />

Eye Contact: Avoid contact. Could have an irritating<br />

effect. In the event of accidental contact, wash eyes<br />

with clean water for 15 minutes and obtain medical<br />

attention.<br />

Inhalation: Contains low volatility solvent. When used<br />

on roofs stand upwind of the work and avoid<br />

inhalation.<br />

Switch off all working ventilation inlets prior to the use<br />

of the material; leave covered until there is no odour<br />

of the solvent in the vicinity.<br />

Indoors, use only in well ventilated areas. In the event<br />

of discomfort as a result of inhalation move person to<br />

fresh air. If discomfort persists obtain medical<br />

attention.<br />

Oral ingestion: With proper handling this should not<br />

occur. The possibility can be minimized by not<br />

consuming food in the working area and by washing<br />

hands thoroughly before eating, drinking or smoking.<br />

Anderson Monarflex<br />

Barton Dock Road<br />

Stretford<br />

Manchester M32 0YL<br />

Tel: 0161 865 4444<br />

Fax: 0161 865 8433<br />

www.icopal.co.uk<br />

Spillage: Spilt material should be mopped up<br />

immediately with an inert absorbent material, such as<br />

sand, and disposed of in accordance with the<br />

regulations.<br />

Disposal of containers: Do not leave containers on<br />

site where residue could be a hazard to children,<br />

animals or the environment. Replace lids securely<br />

and remove any containers to a central disposal point.<br />

Cleaning of Tools: Clean tools with paraffin<br />

(kerosene) or white spirit.<br />

Technical Support<br />

Specialist design guidance and advice on all matters<br />

relating to this product including CAD detailing for all<br />

your waterproofing requirements is freely available<br />

from our technical department at the address below.<br />

NOTE: This information is given in good faith being based on the latest knowledge known to Anderson Monarflex.<br />

Whilst every effort has been made to ensure the contents of the publication are current while going to press,<br />

customers are advised that products, techniques and Codes of Practice are under constant review and liable to<br />

change without notice. Up to date information is available from our Technical Services Department on request.<br />

Responsibility cannot be accepted for the application of products, and no claims can be considered, where the<br />

manufacturer’s instructions have not been followed. The user should not assume; based on information provided<br />

in this sheet, that the product is suitable for any abnormal use.<br />

All products are sold subject to our standard conditions of sale, available on request.