SLUDGE DEWATERING - SNF Group

SLUDGE DEWATERING - SNF Group

SLUDGE DEWATERING - SNF Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

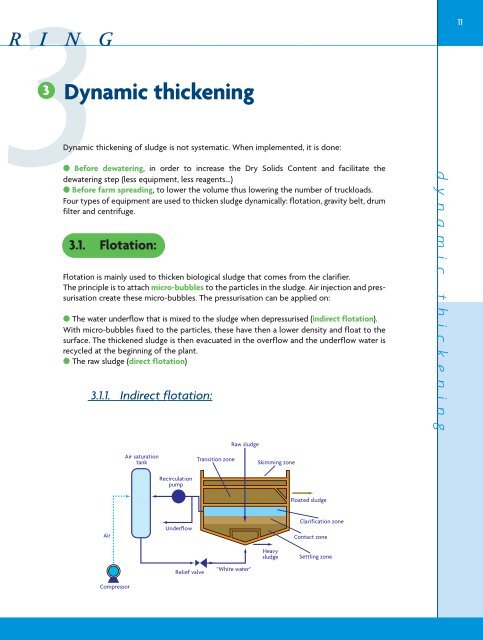

3Dynamic thickening of sludge is not systematic. When implemented, it is done:<br />

R I N G<br />

3<br />

Dynamic thickening<br />

● Before dewatering, in order to increase the Dry Solids Content and facilitate the<br />

dewatering step (less equipment, less reagents…)<br />

● Before farm spreading, to lower the volume thus lowering the number of truckloads.<br />

Four types of equipment are used to thicken sludge dynamically: flotation, gravity belt, drum<br />

filter and centrifuge.<br />

3.1. Flotation:<br />

Flotation is mainly used to thicken biological sludge that comes from the clarifier.<br />

The principle is to attach micro-bubbles to the particles in the sludge. Air injection and pressurisation<br />

create these micro-bubbles. The pressurisation can be applied on:<br />

● The water underflow that is mixed to the sludge when depressurised (indirect flotation).<br />

With micro-bubbles fixed to the particles, these have then a lower density and float to the<br />

surface. The thickened sludge is then evacuated in the overflow and the underflow water is<br />

recycled at the beginning of the plant.<br />

● The raw sludge (direct flotation)<br />

3.1.1. Indirect flotation:<br />

Air<br />

Compressor<br />

Air saturation<br />

tank<br />

Recirculation<br />

pump<br />

Underflow<br />

Relief valve<br />

Transition zone<br />

Raw sludge<br />

"White water"<br />

Skimming zone<br />

Heavy<br />

sludge<br />

Floated sludge<br />

Clarification zone<br />

Contact zone<br />

Settling zone<br />

d y n a m i c t h i c k e n i n g<br />

11