SLUDGE DEWATERING - SNF Group

SLUDGE DEWATERING - SNF Group

SLUDGE DEWATERING - SNF Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

R I N G<br />

3.4. Centrifuge:<br />

The centrifuge principle is completely different (from previous methods). With centrifugation<br />

it is the centrifugal force instead of gravity that is used to force the solid/liquid separation.<br />

This force is created in a conical-cylinder bowl that rotates at high speed (2500-3500 rpm).<br />

The sludge particles are pressed against the bowl and conveyed out of the centrifuge by a<br />

screw that rotates at a slightly different speed than the bowl (a few rpms).<br />

KEY<br />

PARAMETERS<br />

LAB PROCEDURE/<br />

SPREADSHEET<br />

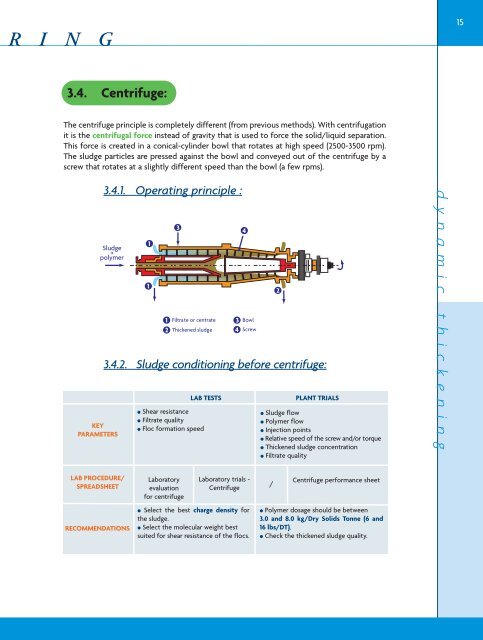

3.4.1. Operating principle :<br />

Sludge<br />

+<br />

polymer<br />

RECOMMENDATIONS<br />

1<br />

1<br />

3.4.2. Sludge conditioning before centrifuge:<br />

● Shear resistance<br />

● Filtrate quality<br />

● Floc formation speed<br />

3<br />

1 Filtrate or centrate<br />

2 Thickened sludge<br />

Laboratory<br />

evaluation<br />

for centrifuge<br />

LAB TESTS PLANT TRIALS<br />

Laboratory trials -<br />

Centrifuge<br />

● Select the best charge density for<br />

the sludge.<br />

● Select the molecular weight best<br />

suited for shear resistance of the flocs.<br />

4<br />

3 Bowl<br />

4 Screw<br />

● Sludge flow<br />

● Polymer flow<br />

● Injection points<br />

● Relative speed of the screw and/or torque<br />

● Thickened sludge concentration<br />

● Filtrate quality<br />

/<br />

2<br />

Centrifuge performance sheet<br />

● Polymer dosage should be between<br />

3.0 and 8.0 kg/Dry Solids Tonne (6 and<br />

16 lbs/DT).<br />

● Check the thickened sludge quality.<br />

d y n a m i c t h i c k e n i n g<br />

15