N17 ALMERA 17 DIGIT VIN LOCATIONS

N17 ALMERA 17 DIGIT VIN LOCATIONS

N17 ALMERA 17 DIGIT VIN LOCATIONS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

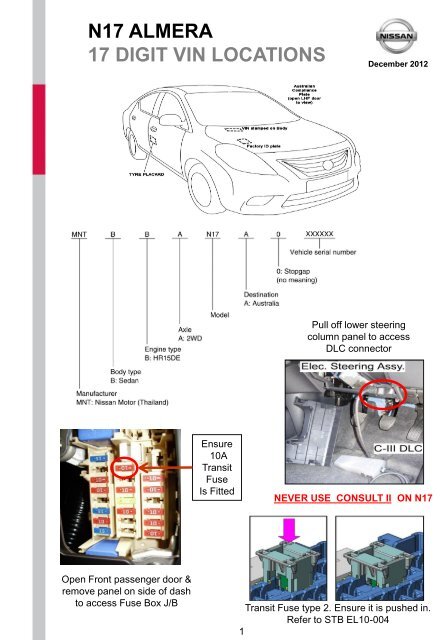

<strong>N<strong>17</strong></strong> <strong>ALMERA</strong><br />

<strong>17</strong> <strong>DIGIT</strong> <strong>VIN</strong> <strong>LOCATIONS</strong><br />

Open Front passenger door &<br />

remove panel on side of dash<br />

to access Fuse Box J/B<br />

Ensure<br />

10A<br />

Transit<br />

Fuse<br />

Is Fitted<br />

December 2012<br />

Pull off lower steering<br />

column panel to access<br />

DLC connector<br />

NEVER USE CONSULT II ON <strong>N<strong>17</strong></strong><br />

Transit Fuse type 2. Ensure it is pushed in.<br />

Refer to STB EL10-004<br />

1

PDI LOOSE PARTS<br />

2 keys tied together as per pictures below.<br />

• Wallet:<br />

o Owners Manual<br />

o Warranty and Maintenance guide<br />

o Dealer list and Misc. leaflets<br />

o Reverse Park Sensor Instruction Card (Ti only)<br />

• Spare tyre on steel rim for all models. Tyre matches those fitted to road wheels.<br />

• 4 x plastic wheel trims located in rear compartment (ST )<br />

• 4 x plastic centre caps for alloys wheels located in rear compartment (Ti)<br />

• Jack, tools & front tow hook located in spare wheel compartment.<br />

• Roof mounted aerial located in rear compartment.<br />

Ti<br />

Ignition Keys<br />

ST<br />

Cancellation of BCM Transit Mode.<br />

Ign. OFF / LH stalk DOWN / RH stalk DOWN<br />

Refer to STB EL10.004<br />

2<br />

Jack, tools & front tow hook<br />

Located in spare wheel compartment.<br />

Wheel Caps & Aerial Mast.<br />

(Ti Centre Caps not shown)

PDI LOOSE PARTS<br />

Tow Hook Cover (front only)<br />

Ensure the blanking cap in the front bumper for<br />

the Tow Hook is not missing.<br />

Ideally it should be placed in the Glove-box & only<br />

fitted when the vehicle is delivered to the<br />

customer.<br />

Aerial Mast<br />

Ensure the Aerial mast is not missing.<br />

Ideally it should be placed in the vehicle & only<br />

fitted when the vehicle is delivered to the<br />

customer.<br />

3

UNIQUE PRE–DELIVERY ACTIONS<br />

Clock Setting<br />

1. If the trip computer mode switch (*1) is pushed<br />

while the distance to empty or outside air<br />

temperature (if equipped) is displayed, the clock<br />

display will blink.<br />

2. Push & hold the clock settings switch (*1) for 3<br />

seconds. The hours display will start to flash.<br />

3. Push the clock settings switch (*1) to adjust the<br />

hour. To advance the time, hold down the switch<br />

(*1) & then release<br />

4. Wait at least 5 seconds for the minute display to<br />

flash.<br />

5. Push & hold the clock settings switch (*1) to<br />

adjust the minutes. To advance the time, hold<br />

down the switch (*1) & then release. Wait at least<br />

5 seconds for the second display “:” to flash.<br />

6. Push the clock settings switch (*1) to reset the<br />

second counter.<br />

Refer to Section 2 of the Owners Manual for more<br />

detail.<br />

Service Reminder Activation<br />

Ensure that the Service Reminder is set to remind<br />

the customer of the 1,000km service &/or the<br />

10,000km service.<br />

The service reminder function is set to OFF<br />

from the factory. This will need to be activated at<br />

Pre-Delivery.<br />

1. Switch Ignition ON.<br />

2. Press and hold switch (*1) for 3 seconds until<br />

the spanner symbol appears and then flashes at<br />

“0”.<br />

The service reminder function is now active.<br />

Service Reminder Setting<br />

1. Switch Ignition ON.<br />

2. Whilst the reminder is flashing, press switch (*1)<br />

to increment the setting to 1,000km for the first<br />

inspection and 10,000km after future services.<br />

NOTE: Wait for the reminder to stop flashing<br />

before switching the Ignition OFF, otherwise the<br />

setting won’t be saved.<br />

4<br />

(*1)<br />

Clock is located in LCD display below<br />

the odometer.

UNIQUE PRE–DELIVERY ACTIONS<br />

ST Ignition Keys<br />

Test the NATS operation of each key (start the<br />

engine).<br />

NOTE: Wait for the NATS security lamp to flash<br />

before testing each key.<br />

Remote Control Setting / Panic Alarm<br />

Keyless remote operation is separate to the NATS<br />

system. Therefore ensure the Keyless remote<br />

function works as well as being able to start the<br />

engine.<br />

Ti Ignition Keys (Intelligent Keys)<br />

Place the key in your pocket & from a lock<br />

vehicle condition, enter the vehicle & start the<br />

engine via the Intelligent Key process<br />

NOTE: Wait for the NATS security lamp to flash<br />

before testing each key.<br />

Also check that the key works via the Remote<br />

functionality (pressing the appropriate buttons<br />

should lock / unlock the doors)<br />

Remote Control / I-Key programming<br />

If the key starts the vehicle, the remote should<br />

also be working. Refer to the NATS Application<br />

chart and NATS OM in C-III to program<br />

additional keys.<br />

When I-KEY battery is flat<br />

If the battery in the I-KEY has failed, the only<br />

way the vehicle can be started is by holding the<br />

I-KEY unit against the Ignition button & pushing<br />

it.<br />

To open the doors mechanically, remove the<br />

mechanical key from the I-Key & insert it into the<br />

lock at the Exterior door handle.<br />

5

UNIQUE PRE–DELIVERY ACTIONS<br />

Engine Grounds - 1<br />

Ensure all engine ground connections are clean<br />

and tight.<br />

ECM / TCM Ground is located on the RHF strut<br />

tower in the engine bay.<br />

Engine Grounds - 2<br />

Ensure all engine ground connections are clean<br />

and tight.<br />

Engine Grounds - 3<br />

Ensure the Battery clamp connections are tight.<br />

Ensure the Ground from the Battery Neg > Body<br />

(LHF chassis rail) > Transmission housing is<br />

secure.<br />

NOTE: Battery MUST be tested and fully<br />

charged before delivery to Customer.<br />

Ensure ground cable link from Cylinder Head to<br />

Radiator support panel is secure.<br />

6

UNIQUE PRE–DELIVERY ACTIONS<br />

All DTC inspection;<br />

From the CONSULT III Plus Home screen, select<br />

DIAGNOSIS (All Systems).<br />

Ensure there are no DTC’s. There maybe cases<br />

where DTC’s are displayed, print them off as a<br />

record & then erase all the codes.<br />

Once again check for DTC’s after road test.<br />

CAN inspection;<br />

From the ALL DTC screen Select CAN Diag.<br />

CONSULT III PLUS OPERATIONS<br />

NOTE: The 18 character Model Code (SIS) must<br />

be typed into CONSULT III Plus – in capitals.<br />

This is found on the ID plate on the RH strut tower.<br />

Ensure the CAN is OK. All lines are to be GREEN.<br />

Steering Angle Sensor re-calibration after PDI<br />

Wheel Alignment;<br />

From the CONSULT III Plus Home screen, select<br />

MAINTENANCE.<br />

Select ST ANGLE SENSOR ADJUSTMENT.<br />

Follow the on screen prompts with the steering<br />

wheel in the exact straight ahead position.<br />

7

UNIQUE PRE–DELIVERY ACTIONS<br />

Reverse Parking Sensors (Ti only)<br />

Ensure the RP sensors functions as per the<br />

instruction card located in the Owners Manual<br />

wallet<br />

Instruction card should be located in the in the<br />

Glove Box with the Owners Manual<br />

Driver window Initialisation<br />

1. Switch ignition ON.<br />

2. Open window half way or more.<br />

3. Operate the power window switch to the UP<br />

direction and keep in this position for 3 seconds or<br />

longer once the window stops at the fully closed<br />

position.<br />

4. Test the AUTO window function to confirm correct<br />

operation.<br />

The drivers window on the ST variants does NOT have<br />

an ‘Auto-up / Anti pinch function. Therefore the<br />

above setting procedure is not possible.<br />

8

UNIQUE PRE–DELIVERY ACTIONS<br />

COOLING SYSTEM HOSE CLAMP PRE-CAUTION<br />

Always ensure that cooling system hose clamps have<br />

been properly secured as described in STB: LC10-001<br />

12V Battery Handling procedures<br />

Always ensure that the 12V Battery is properly maintained<br />

as outlined in STB: EL09-008<br />

Wheel Nut Tensions<br />

Ensure that the wheel nuts have been properly torqued as<br />

per the details in STB: MA12-001<br />

9

UNIQUE PRE–DELIVERY ACTIONS<br />

Audio System Repair / Exchange Process<br />

Clarion Audio – refer to Warranty Bulletin; AWB-<br />

011-07<br />

Contact TechLine for Bluetooth phone system<br />

related issues.<br />

Battery Saving Features<br />

Refer to STB EL10-004 for more details regarding<br />

the Battery Power Saving features.<br />

10